-

Posts

170 -

Joined

-

Last visited

Everything posted by MARTS-PL310

-

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

Building the 1961 Datsun 310 Bluebird - Glass and Trim. Bluebird is glazed! I finally installed the front and back glass. Other work happened as well. Here's a little photo preview with details to follow shortly.- 75 replies

-

- 14

-

-

-

J.e.d.'s 1963 Ford Galaxie Hardtop Discussion

MARTS-PL310 replied to The Bronze's topic in Project Discussion

@j.e.d. Here's a few recent exterior pics of my 63 from over the last four months or so in the Seattle, Washington area. My dad bought it in 1967 and passed it on to me in 1999. Stock except for dual exhaust and aftermarket radio. Rain or shine it gets driven. Cruises smoothly at 70mph on the interstate. Guzzles at 14 mpg. Paint is original Ming Green metallic except for spot repairs years ago to lower rear quarters, sills and hood. Interior, not shown, is a bit shoddy and needs new front bucket seat covers (currently t-shirts wrapped around the seat backs, that sort of thing). Most recent work was the replacement of the cam bore plug on the back of the 352 FE engine after it had come out, got tangled up between the block, adapter plate and flywheel and punched out a chunk of the bell housing... -

J.e.d.'s 1963 Ford Galaxie Hardtop Discussion

MARTS-PL310 replied to The Bronze's topic in Project Discussion

Love those 63 Galaxies! Keep em rolling. I have similar, a 352, 2dr boxtop, 500 XL, family heirloom, 335k miles and still running smooth and strong. Engine pic from last overhaul 18 years ago. Watch out for that darn secondary hood latch. I painted mine striped but it doesn't help much to prevent the occasional ding on the scalp! -

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

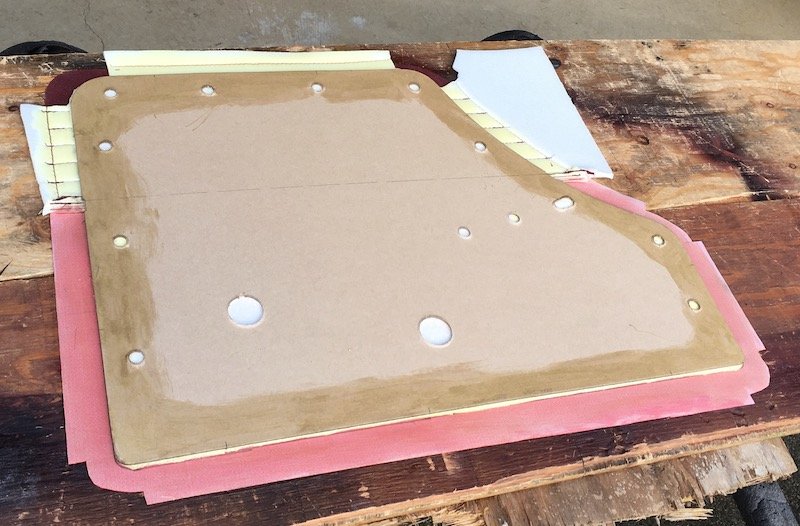

Building the 1961 Datsun 310 Bluebird - Prime and Fill. The Pacific Northwest weather dried out a bit this month thus allowing the spray of a couple of coats of epoxy primer. So now I’m doing light filler work to make invisible the imperfections that would otherwise show through the finished paint. These are mostly weld joints and some small rock dings on the doglegs. Not too exciting stuff but I'm aiming for a nice professional look. Initial body filler applied and sanded back. I'll knock down a few high spots and continue with a couple of more thin applications.- 75 replies

-

- 18

-

-

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

Building the 1961 Datsun 310 Bluebird - Exterior Paint Preparation- Limited. Minor progress today. Bent and beat the previously rolled wheel opening flanges on the doglegs back to original, plus scuffed, cleaned and prepared the outer metal work for painting. As shown, the Bluebird is partially masked up for paint. Plastic wrap will cover the rest from overspray. I'm limiting the scope of the paint work for now from the A-post to the aft end of the doglegs. The rear lower quarters and numerous other exterior body items will be repaired sometime later, perhaps next summer. Each of these other repairs ought to be a lot easier than the monumental project that the floor was. Now I'm waiting for drier weather so I can roll the project outside and start the limited paint process. Just hope I don't have to wait for six months as it gets more rainy here for the next several months. Btw, the orange things are foam ear plugs inserted into all the threaded holes to keep them clear of paint. Applied a bit of POR-15 on the rust scarred forward face of the left A-post. Here I've just bent the rolled flange on the right side dogleg back to original. This leaves a lot of stretched metal ripples that then take a lot of panel beating to smooth it out nice. The remainder of the flange rearward of the dogleg is left in the rolled condition for now. Trouble is, there are two layers of metal (outer skin plus outer wheel tub) rather than the one on the dogleg so it will be more stubborn to restore. Slightly rust scarred on the inside of the flanges but not enough to require cut off and replace. The insides will get POR-15 coated once the contour is made smooth and prepared. It takes only about 15 minutes to unroll one flange using a lever and crescent wrench but then several hours working the dents and ripples reasonably smooth again with these various instruments. Definitely not an ergonomic position for panel beating, very bad for the neck and shoulders.- 75 replies

-

- 14

-

-

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

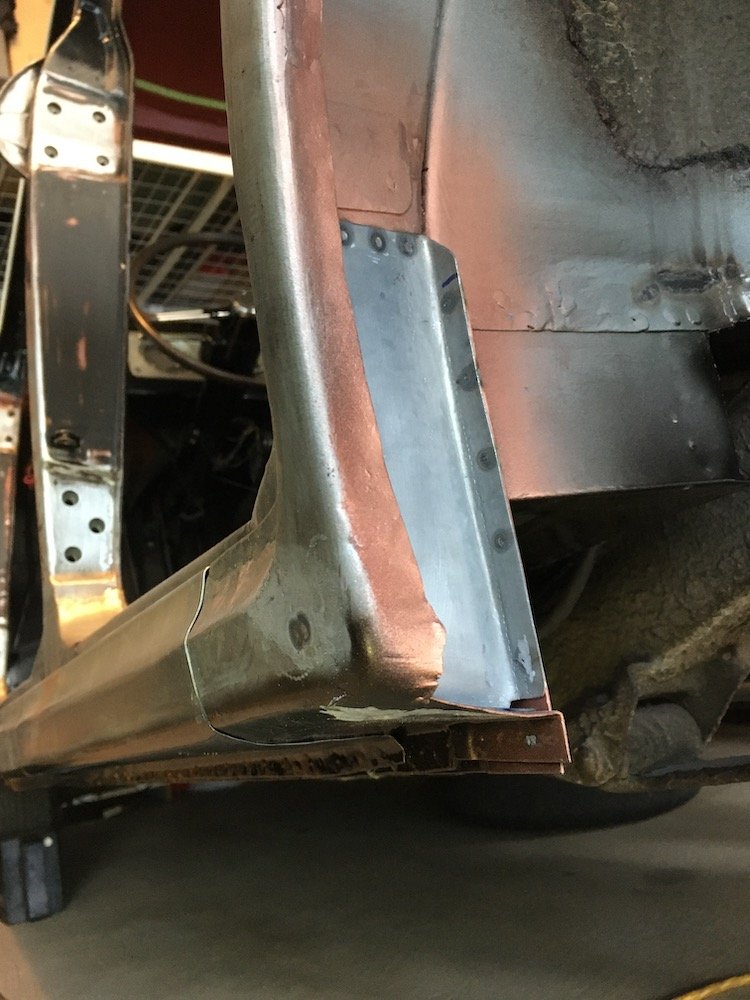

Building the 1961 Datsun 310 Bluebird - Sill Box Close Out Panels - Installation. Welded in the sill box close out panels using an electric spot welder, just like original. Cleaned, etched and weld through primered panels on forward faces. Last views of the prepped sill box insides. Right hand side sill box closure before any repairs were made. Photo taken several years ago. Somewhat rusty. Note PO rolled wheel well flanges on dogleg. Right hand side after lots of new metal welded in. Another old right hand side before for comparison purposes. Quite a rusty mess it was. And after. A couple more from the right side. And a couple of photos from the completed left hand side. Welds are all made by a very heavy and awkward electric spot welder from an ergonomically uncomfortable body position due to the rear axle and brake drum being in the way. I'll probably coat a lot of these inner wheelwell exposed surfaces with some kind of stone guard or lumpy underseal after its all edge sealed, epoxy primered and painted. Way better than original which was asphalt underseal on bare metal only.- 75 replies

-

- 14

-

-

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

Building the 1961 Datsun 310 Bluebird - Refitting the interior- Headliner. Switching gears a bit as the floor is now more or less complete. This is the plan prior to installing the front and back glass. An installation sequence is required. Hope I'm not missing something. Required events preceding the glass install are: Restore the rolled rear wheel well opening flanges on the doglegs back to stock. DONE. Luckily these were not rusted away so I just had to carefully bend them back and do some hammer on dolly work. I have no idea why a PO rolled the flanges, ultra wide drag slicks maybe? ;- ) Install the sill box aft end close out plates. DONE. Sand and prepare the outer surfaces of the sills, A and B posts, doglegs and door jambs. IN WORK. May also have to use a little plastic filler at visible butt weld joints. Epoxy prime and paint all the surfaces noted above. Install new door opening seals onto the pinch welds. Glue in the under roof insulation pad. Test fit the headliner. DONE. Couldn't wait as I wanted to know well in advance that the reproduction headliner would fit. I bought the vinyl headliner in 2017 and was concerned it might have shrunk or otherwise distorted to an unusable shape. Install the headliner. Install the back and front glass into the custom one off seals I had manufactured years ago (around year 2004). These new custom seals should take the original chrome, maybe. Install the chrome trim into the seals. Finally, install the front and back glass. A quick test fit of the reproduction vinyl headliner shown. No problems noted. It appears to be well made using correct patterns. I'm not able to tuck it in at the sides until all the other work leading up to the door seal install is done since it is to be pinched between the gripper teeth panels and the door seals for a semi-permanent installation. It would probably be damaged if I pinch it in on the sides and take it out again. Satisfied with the headliner test fit. It matches the original very well, I just need to apply light tension at the sides. The old sponge rubber, metal and cloth door seals. These are badly rotted and will not be reused. Modern door seals that are functionally equivalent will be used but these will not match the appearance of the old cloth covered portion (rubber surfaces only on the new seals). The sill box aft end close out panels. Slightly crudely made early on several years ago but will do the job. Installation of the panels is next. -

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

Building the 1961 Datsun 310 Bluebird - Painting Floor Top Coats- Black Basecoat and Clearcoat. Paint application photos. Floor is finished! This brings the latest intense flurry of completed work up to date. I've now got most of the parts and materials required to get started installing the roof insulation, headliner, and glass, but it's going to be another slow learning process each step of the way. I definitely don't want to break the difficult to find glass! Thanks for checking out this latest series of posts on the PL310 1961 Datsun Bluebird!- 75 replies

-

- 18

-

-

-

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

Building the 1961 Datsun 310 Bluebird - Floor Painting- Mask and Prime. Not too much to describe when it comes to masking and priming, except that it takes a lot of time. Taking the doors off did not take much time, so simple they are, a couple minutes each and off it goes. I'll let the photos do the rest of the tale here. Rolled the car outdoors into the fresh air before doing the primer spray work. I also did a little detail work with the small spray gun to get into the difficult to reach areas with primer followed by a bit of black base coat. And I had to cut open some door opening masking to gain better access. Then onwards to the full paint next.- 75 replies

-

- 11

-

-

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

Building the 1961 Datsun 310 Bluebird - Floor Painting- Prep. Preparation for paint. Metal cleaning, etching, brush priming and sealant application. A lot of labor and overkill I admit, but then again the old floor did demonstrate how susceptible it was moisture. This should be good for at least a hundred years or so! My favorite metal chemicals, I've shown these before and here they are again. First a rough cleanup by vacuuming, wet rag wipe down and wax and grease remover solvent. I then apply the PPG metal cleaner with a scuff pad, sponge off with water, and finish with compressed air dry. Repeating the process for the PPG metal conditioner. After the metal cleaner pics. Basically the metal cleaner contains plain phosphoric acid and mild cleaning agents which takes care of flash rust and residual contamination at the welds. After the metal conditioner pic. This etches the metal for a good mechanical bond with the primer and leaves a thin chalky zinc phosphate coating for resisting rust. Continued the prep with brush epoxy prime at all the lap joints and butt weld joints and any rough spots that could use it. Finished with sealant at all the lap joints. Then pull the doors off, mask and prime next.- 75 replies

-

- 13

-

-

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

Building the 1961 Datsun 310 Bluebird - Paint - Steering Wheel Hub Restoration. Painted the steering wheel hub since I might as well with plenty of paint to do the floor and it needed it. Before After Hmm, now the faded plastic around the column looks lousy. Glimpse of the finished floor bonus. It's late. Posting more tomorrow on the actual floor paint.- 75 replies

-

- 11

-

-

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

Building the 1961 Datsun 310 Bluebird - Fixing the Trans to Tunnel Interference. Not sure how I messed this up but the upper aft bolt head on the side of trans cover was touching and rattling quite a bit on the first test drive. I did a lot of preparation work when forming the patch piece for the previously modified tunnel to fit the larger "full-synchro" P311 trans. I padded up spots for a bit of clearance where there appeared to be contact when doing prototyping of the patch panel yet must have missed this bolt head. Maybe too much attention was paid to bumping out the nearby spot where the tailshaft housing to trans body ear sticks way out. Don't know. Original very rough mod was done way back in the early 80s when the P310 trans broke a shift input shaft and was swapped out for the big trans. Modification of the tunnel then was by cutting torch, and very expedient, just left huge openings. In this case, the fix was to take a piece of bar stock and carve the end into a convex shape. Then the convex end of the bar was hammered upwards into the bolt head interference spot to form a bit of a pimple sufficient for clearance. Paint was touched up and that was it. Pics: In the beginning. Started with this old rough torch cut left over from rapid repair back in the early 80s. A good illustration as to how much wider the later trans is. The cut metal was covered up by the vinyl floor mat. Out of sight out of mind for years. A couple of other views after the original damaged metal was removed. The future interference is the side cover bolt on upper right, above and to the left of the tailshaft housing ear. The formed patch a few years back. Bumped it out as necessary with plastic mallet on sand bag then smoothed out on english wheel. It was beginning to resemble medieval breastplate armor. Just didn't bump it out enough on that one spot apparently. Fixed. You can't really see much here because it is so tight. Look deep into the photo middle, upper, then above and behind the bolt that is visible, where you might see the paint scratched off by the bumping tool used to beat the sheet metal out a bit from the bolt head. I also tried to pry it out overall in the area by leveraging against the ear, but it didn't help much, the initial forming process work hardened the metal and it just bounced back. Brushed in some touch up paint later on and now I'm done with it. Posting about the floor painting later -

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

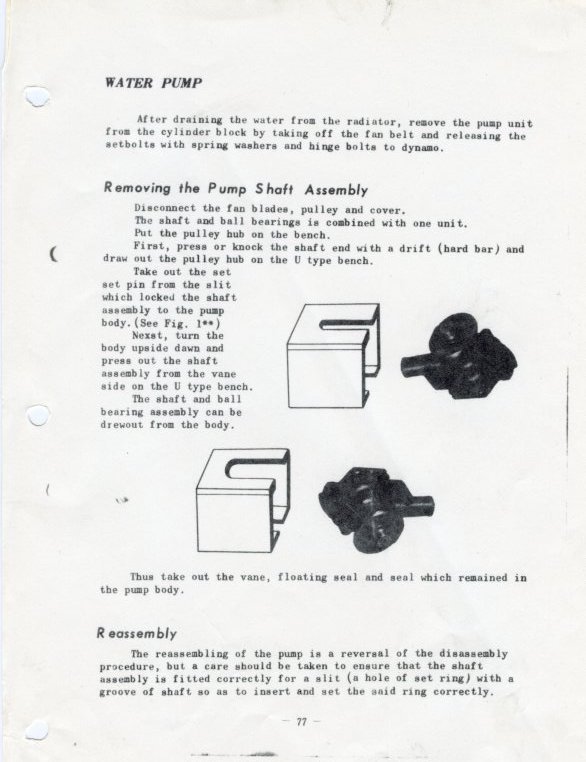

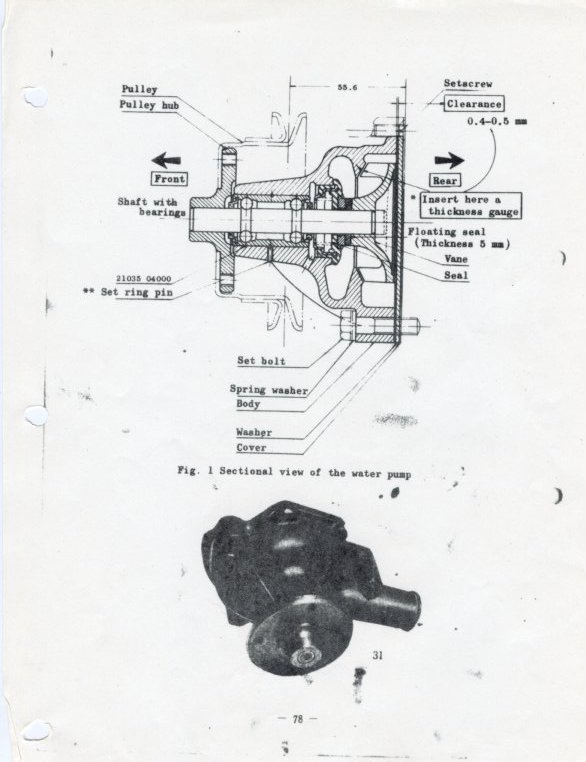

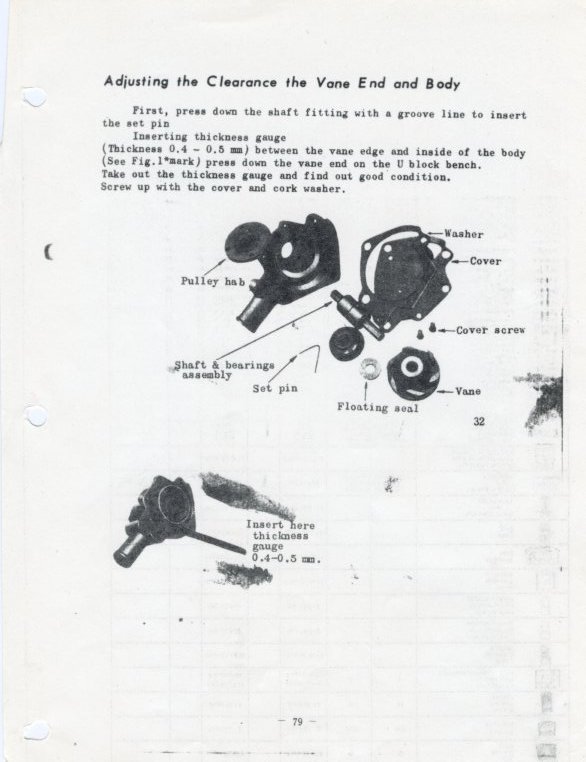

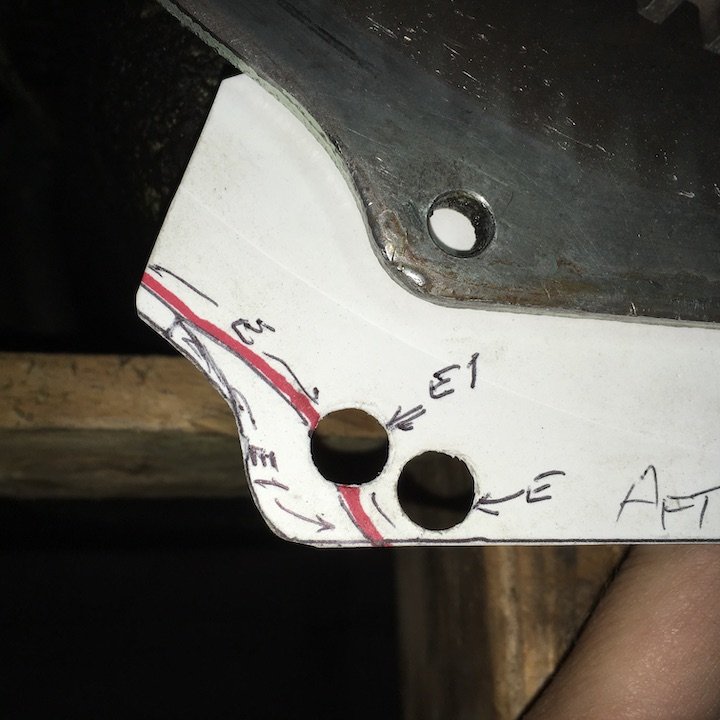

Building the 1961 Datsun 310 Bluebird - Fixing the Noisy Water Pump. So once the engine exhaust was quieted down, it was obvious that the water pump bearings were worn out. Fortunately I had picked up a genuine new Nissan shaft/bearing assembly several years ago from eBay. The water pump as a new assembly is NLA. The water pump was rebuilt with the new bearings and it was successful in quieting the water pump. My first time rebuild of a water pump which, in this case, was fairly simple if you have the parts and are good at making new gaskets. I also had the assistance of the PL310 Nissan FSM, several DIY videos on youtube and a hydraulic press. Unfortunately I took no photos during the rebuild process, only the completed installation and my build of the tool as described by the FSM. One note on the FSM pages, included here for anyone's reference doing similar work, there is no cautionary note on the assembly process saying to avoid applying a press force between the inner and outer bearing race. But I guess that's just common sense practice so as not to damage the bearing. The FSM merely says to reverse the disassembly steps where it doesn't really matter if you damage the old bearing since it is to be trashed. While I was at it, I refurbished a pair of E1 engine fan blades that were previously obtained some time ago from "wayno" on the local Ratsun forum. These stacked together fan blades replaced the single old style E engine fan blade that was on the engine where there should have been two. No idea why someone had deleted the other blade. Noisy design at 4500 rpm freeway cruising speed perhaps. Some self explanatory photos below of the installation, tool, old shaft/bearing assembly, fan blades and FSM. Engine is a little dirty but it runs very well. I probably out to replace that giant '59 Chevy pickup truck generator for a modern lightweight alternator one of these days. Old well used "E" engine fan blade Wooden tool as constructed per FSM graphic Worn out old bearing/shaft assembly Ancient Datsun PL310 Bluebird FSM (plus the PL311 service bulletin supplement). I obtained this Zerox copy of helpful info decades ago from Nissan Corporation in USA when they were located in Gardena, Calif. Free of charge. And can you image getting such service today to support repairs on a 63 year old car? ... More soon -

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

Building the 1961 Datsun 310 Bluebird - Exhaust Pipe and Muffler. Making exhaust pipes and muffler installation. I've never done this fabrication work before but there is no other economical alternative. There does not exist a made to order system that I can just bolt up and hauling costs for transporting the car back and forth to a shop would be close to $350 plus maybe another $500 to $700 labor costs for a true custom quality professional quality job as opposed to a quick in and out one hour job. So I went forward to make my own exhaust system. Nothing fancy in materials, carbon steel, or design, two pipes connected to one $25 muffler from O"Reilly auto parts. The drop or header pipe from the engine is a very old stock aftermarket piece about three feet long that I was lucky to find on eBay many years ago. The small muffler is being test fitted and adjusted at what should be close to the original stock location. Adjoining pipes are only tack welded together at this time. There was a lot of back and forth fitting and adjusting while laying on the floor. Wish I had a fancy lift to save my back. Anyway, it doesn't look too bad in this view but hiding in the shadows is the crude routing above the rear axle housing. Going a bit further forward..., Ugly happens. I regret making way too many pie cuts and welds to get the curvature over the axle housing. Maybe next time I'll use just a few curved pieces with short straight lengths in between. Backing up to the tail pipe, I had become more proficient by this end point and chopped and fitted the elbow and straight bits more to my liking, dodging nearby body, frame and bumper structure, and with a nice angle cut across the outlet. Btw, shown is the only factory original clamping left, all others are left over from long ago quick cheap jobs done by muffler shops. One clamp was definitely not safe. A shop had drilled a hole under the rear seat cushion straight through the body sheet pan and hung a support and clamp without any sealing added to prevent exhaust gasses from getting inside and causing CO poisoning. I have welded that hole shut. Same tail section fabrication off car. And then the long straight section looking forward to the pass through hole. The fit to the curved piece wasn't perfect but it works. There are the diamond traces of the original somewhat complicated support clamp assemblies at the forward frame x-member. It will be another mini project just to try and reproduce those clamps since they are not available anywhere. I just have some photos of what the OG clamps look like. I clamped instead horizontally with a couple of generic tire rubber strap types that I can't even photograph because they look so bad and result in some rattle contact at the through hole. The not shown pipe connection forward of the straight pipe, and on the other side of the x-member, is the old stock header pipe mentioned earlier. No problem with that pipe, it fit very good. A video screenshot copy of the OG clamping design at the x-member. Because of such a close clearance, good support is critical here to keep the pipe centered yet flexible as the engine and header pipe move about slightly on the rubber engine mounts under load and deceleration. The cylindrical section is backed up by a diamond shaped flat piece which bolts to the x-member. I'm guessing there is a rubber isolator inside the cylinder. These clamp assemblies are not available, at least not new, and I'll figure out a way to reproduce a pair eventually. Only guidance I have is this photo and the diamond imprint on my x-member. Workbench view of my finalized pipe creations. Ugly unground welds left as is for integrity and containment of exhaust. Functional. The header kit bits used for the elbows were made of slightly thicker steel compared to the straight pipe and thus much easier to weld without the risk of blowing holes through. So after installing the exhaust, I installed lights, blinkers, front bumper, number plate, then waited until about midnight and went for a stealthy and much quieter drive around the local roads to flesh out additional issues. The speed was kept under 35 mph because there is no front glass installed yet, thus also the stealth approach so as not to attract any unwanted attention. Only a few issues of significance showed up after about five miles of driving. One, the exhaust rattles badly at the x-member pass through. Two, the water pump bearings are worn out and making lots of noise. Three, there is just slight contact between the tunnel and transmission at one of the side cover plate uppermost bolt heads. All issues have since been addressed with appropriate corrections. Midnight test cruising in a Bluebird. More later on the "fixes."- 75 replies

-

- 12

-

-

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

Building the 1961 Datsun 310 Bluebird - Drive Time - It Moves! Lowered the Bluebird and drove it around only in front of the house for a few photos and repositioning back into the garage. First time back on its wheels in six years! Btw, I could use a couple more OG wheels (4J by 13 with stick out mounting clips for the hubcaps) as one is very bent and another is badly rust pitted. Still looking locally but so far no luck finding any in serviceable condition. A couple of issues happened but were expected. One, it was very loud without any exhaust pipes/muffler. My neighbors did take note of the emergence of the Bluebird, especially after giving it a few healthy revs. Two, one of the hydraulic brake cylinders locked up in the full on mode. This was semi expected since it had been a while since I'd serviced the cylinders, My experience has been that wheel cylinders tend to build up rust every few years of inactivity on the dry side of the piston cup seal. And this happens regardless of how clean I keep the brake fluid free of moisture contamination. Getting ready to launch. Temporarily bolted in the front seat. Only took a couple of minutes by threading on four nuts to the mounting studs. Lowering. Rolled out the floor jack and began an iterative front to back lowering of the Bluebird off the fully raised six ton jack stands that had been raised even higher with concrete blocks underneath. The lowering sequence begins... Time to hop in! The mighty loud 1.2L engine starts up just fine and the Bluebird finally drives out of the garage and into the warm summer sunshine And then, after maneuvering the Bluebird back and forth a few times in front of my neighbors houses, the brake lock occurs. This was temporarily remedied just to get it back into the garage by tapping the back of the stuck right rear wheel cylinder a few times with a brass drift. The bird heads back into the roost. One of the rusty brake cylinders. Easily cleaned up the bore and piston with some 600 grit wet or dry paper. Followed with acid clean, etch and zinc phosphate treatment on the steel piston. Repeated process on the other three wheel cylinders. The aluminum cylinders will not be honed since the soft bore ID would become too large and not make a good seal. Brakes now function and seal fine. So the next thing I addressed was the exhaust system. In the next post I'll cover the build of a simple home built design from straight 1 1/2 inch pipe plus a kit of pre-bent header piping bits cut and MIG welded to an economy muffler. First time making an exhaust system from scratch for me and it was another learning experience.- 75 replies

-

- 11

-

-

-

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

Building the 1961 Datsun 310 Bluebird - Fuel Pump and Supply Line. A fuel pump rebuild kit was found on eBay about 15 years ago, sourced from OZ. This kit was then assembled into the old mechanical fuel pump about three years ago and now it was ready to be used again. It was finally time to get rid of the cheap electric pump installed on the frame rail as a result of the mechanical pump diaphragm having been destroyed by ethanol blended fuel. It's not good when the old diaphragm ruptures and dumps a gallon or more fuel into the engine crankcase as it happened way back about 25 years ago. Now that the rebuilt pump is installed, I'm using only non-ethanol fuel in the Bluebird, sourced from a local farm and feed supply store in order to preserve the rebuilt pump. So far the mechanical pump is working good. The glass filter bowl (lower left of photo) is devoid of a filter element and it would be wise to correct this and maintain the original configuration without adding one of those cheap in-line plastic filters. Anybody know of a verified source for a Bluebird fuel filter that fits the original glass bowl? Showing the left front inner fender wheelwell and newly fabricated fuel line routing. The 1/4 inch steel line has been sleeved with plastic heat shrink along the entire length before bending. This matches the original factory steel line design that was protected against abrasion or other damage with a hard plastic sleeving. To the far left is the penetration into the engine bay and where the glass filter bowl is located on the other side. More of the same located under the left/rear floor pan between the inner sill and frame rail. One continuous line, along the original routing and clips, between the glass filter bowl and fuel tank. The new line at the fuel tank outlet connection. The thing next to the connection is the tank drain outlet spigot where I had previously drained out about four gallons of the old fuel. It was a bit challenging to bend the end here just right for a decent match and alignment to the tank connection. Also difficult to use a pipe double flaring tool in the tight area where I could barely fit my hands to do the job with one of those cheap tools meant to be clamped into a bench vise. At first, I was lying flat on my back having dirt fall on me and failing, then went at it from the side through the wheelwell opening where it was slightly easier. Ok, no more for this post. Now just to pop the seat in, lower the car and take a little test drive in front of our house. Some issues do arise, see next post soon.- 75 replies

-

- 13

-

-

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

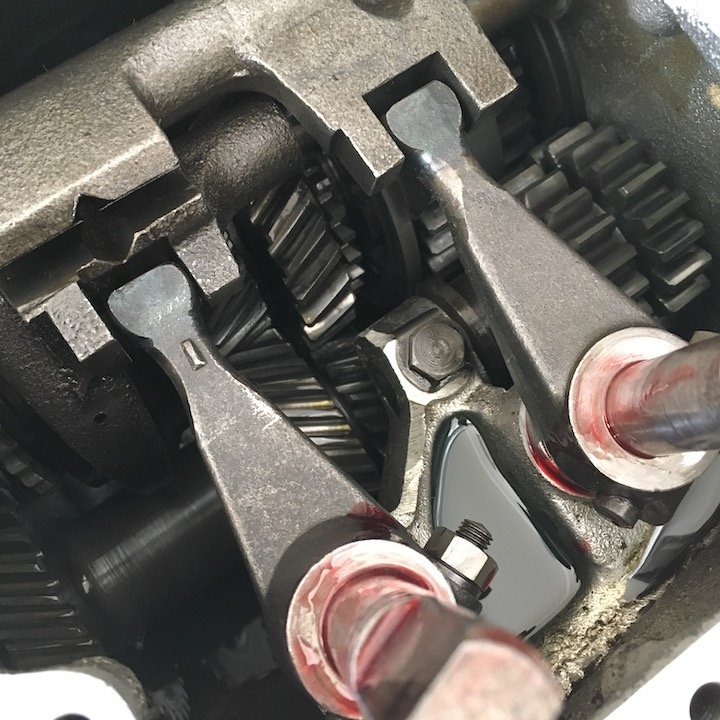

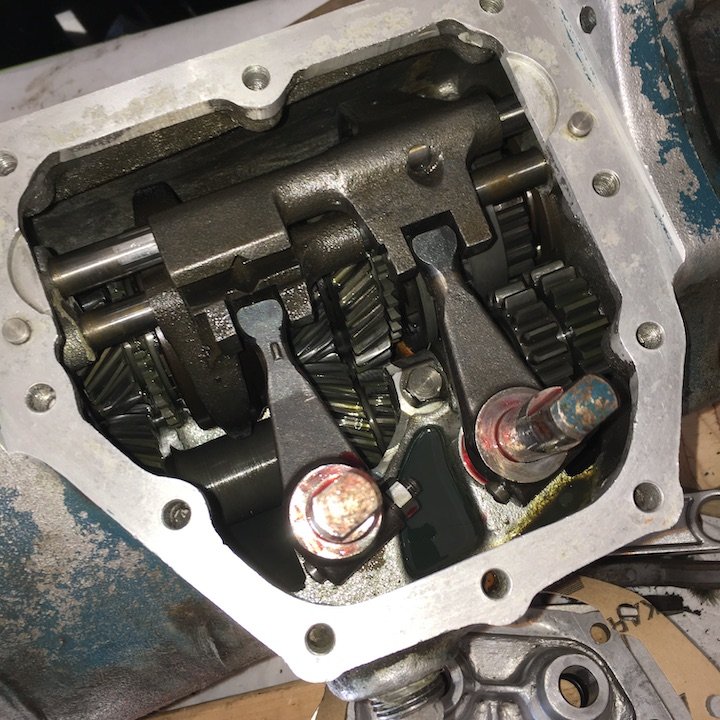

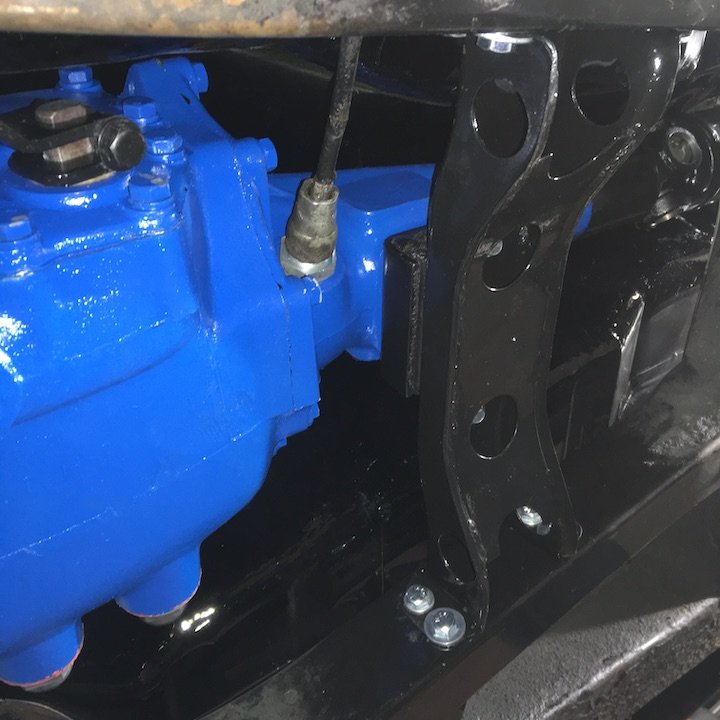

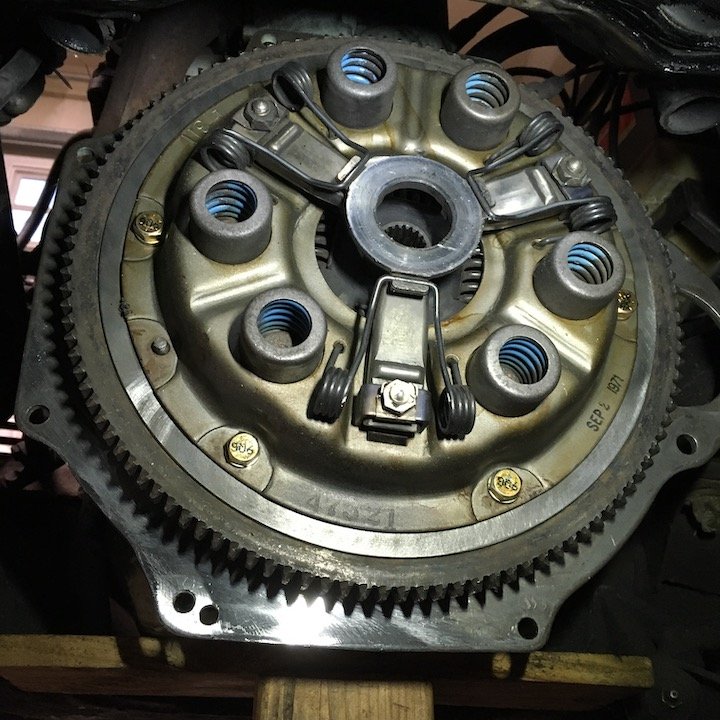

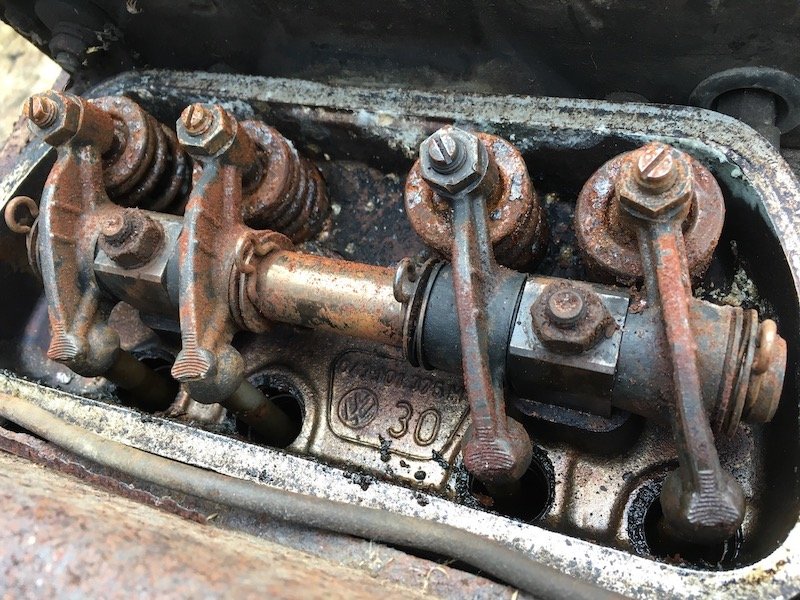

Building the 1961 Datsun 310 Bluebird - Drivetrain - Trans, Clutch, Flywheel and Driveshaft. Reinstalling the drivetrain included cleaning up, re-gasketing and sealing the three speed "full-SYNCHRO" transmission plus tuning up the driveshaft a bit. After cleaning the trans, I did a light disassembly plus inspection of the internals, sealed it up and painted. I did not fully tear the unit down as it had no obvious visual defects and worked well the last time the car was driven. If the trans ever does need any new hard internals such as bearings, synchros, etc., that will be a problem locating the parts. New gaskets were made for the front bearing cover plate, side shift input cover and tailshaft. Permatex Aviation sealer was used to dress the gaskets. The output shaft oil seal was replaced with new. The front input shaft does not use a conventional oil seal, instead it utilizes a labyrinth style or spiral grooved bushing ID to direct the lube oil back in, provided the outlet vent on the tailshaft is not clogged with dirt. The shift fork shafts were each previously sealed with a single double lipped oil seal. The double lip seals were hard to find in this size combination. Single lip seals were obtained from a hydraulics repair shop, and these were installed back-to-back (the open sides) at each shaft, to replace the original double lip seals. Finally, the speedometer drive o-ring was replaced and everything painted. Some transmission photos: The red stuff is engine assembly lube The red washers below on the small covers for the right hand drive provisions were reused, cleaned, sanded flat and coated with a thin layer of red high temp silicone. The P311/P312 trans x-member used here must mount approximately 4 inches further aft than the original P310 mount. Repairs to the two lower frame mounting holes, that had previously been hastily blow torched to match the "full-SYNCHRO" x-member, were made by tack welding washers over the lower rough holes and adding a pair of holes, with same washers, above to complete the full hole pattern as there were only half the bolts holding it together before. The clutch slave cylinder and hose were replaced with new parts. Still missing is the return spring The clutch cover, friction disk, flywheel and pilot bushing were all cleaned, inspected and are reused, except for new bolts. The old clutch cover bolts began breaking when torquing to the required 35 Lb-Ft. I do have a new clutch cover and disk but will keep those in reserve if ever needed. Note date on cover, SEP 1971. Mods to the engine-to-trans adapter plate: The engine-to-transmission adapter plate was modified slightly. The current installed plate was designed for the old non-first gear synchronized transmission as was supplied with the "E" 48 Hp engine. This plate has a different hole pattern and one lower left hole does not match up. So I made a modification that allows either transmission to fully bolt up by adding some metal and the necessary hole for the "full-SYNCHRO" trans. Before profile comparison After rough MIG welding new metal plate using a wide v-groove and a generous build-up Finished. Now it is a multi-trans adapter plate for either the non-synchro (first gear) or full synchromesh trans. Driveshaft saga The driveshaft u-joints were removed and the shaft and yokes were stripped back to bare metal, painted and one new u-joint installed at the front because I lost one of the needles during disassembly and cleaning. Now, the other joint on the aft end will be replaced because it was mis-assembled by me. I clocked the yoke 90 degrees out of phase with respect to the grease fitting threaded hole. I didn't realize the yoke had a clearance scallop specifically to permit install and removal of the grease fitting. Since I have to remove it to correct this mistake, then I might as well match it up with the same replacement u-joint installed on the front. It's packed with new grease for now so no rush. New bolts used of course. Old driveshaft installation long before floor repair and exhaust removal. A "temporary" electric fuel pump had been mounted to the right where you see the two bolts on the cleaned frame rail. Might have been a disaster if fuel began squirting out at that exhaust pipe! This was NOT the correct factory exhaust design for the P310 btw, especially the horrible support at the frame x-member pass through hole I'll post photos about the installation of my rebuilt mechanical fuel pump and new fuel line next. After that, the car is lowered to the ground for the first time in six years to do a little very rough and loud first test run.- 75 replies

-

- 14

-

-

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

Building the 1961 Datsun 310 Bluebird - Underside Paint Preparation I'm back on the Bluebird project, beginning again in July, after spending eight months sorting issues on the 79 VW Bug convertible just to get it to a reliable driving state. About a dozen or so NZ OS posts to follow covering the last two months of intense effort. Main goal was to get the car moving again under its own power. Second goal was to paint the top side of the completed floor pan and adjoining interior areas. Lots of detail work was completed to accomplish both goals. There's tons more work to do including installing headliner and the front and back glass. Backing up a bit from the last post in October 2022 showing the completed underside paint, shown below is some of the preparation that went into that final coating to minimize future rust. The remaining bare metal was chemically cleaned, etched and zinc phosphate coated. Then brush epoxy primed on seams and significant weld joints, followed by seam sealer application and full epoxy prime spray. Aft end of floor pan and tunnel looking forward Tunnel looking aft Right side inner sill looking aft Left side inner sill looking aft Done with the direct underside finish as shown last October. Other adjacent areas may be addressed with a future exterior repaint. Next post will be photos of the trans refurbishment and install to finally get the car off the jack stands and moving again.- 75 replies

-

- 13

-

-

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

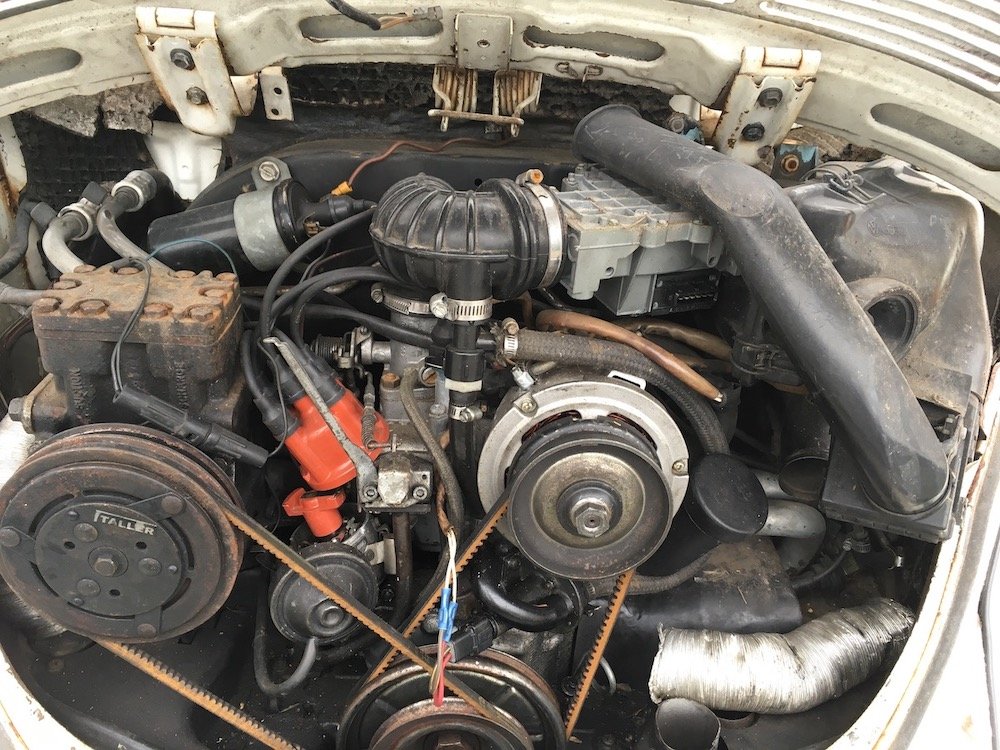

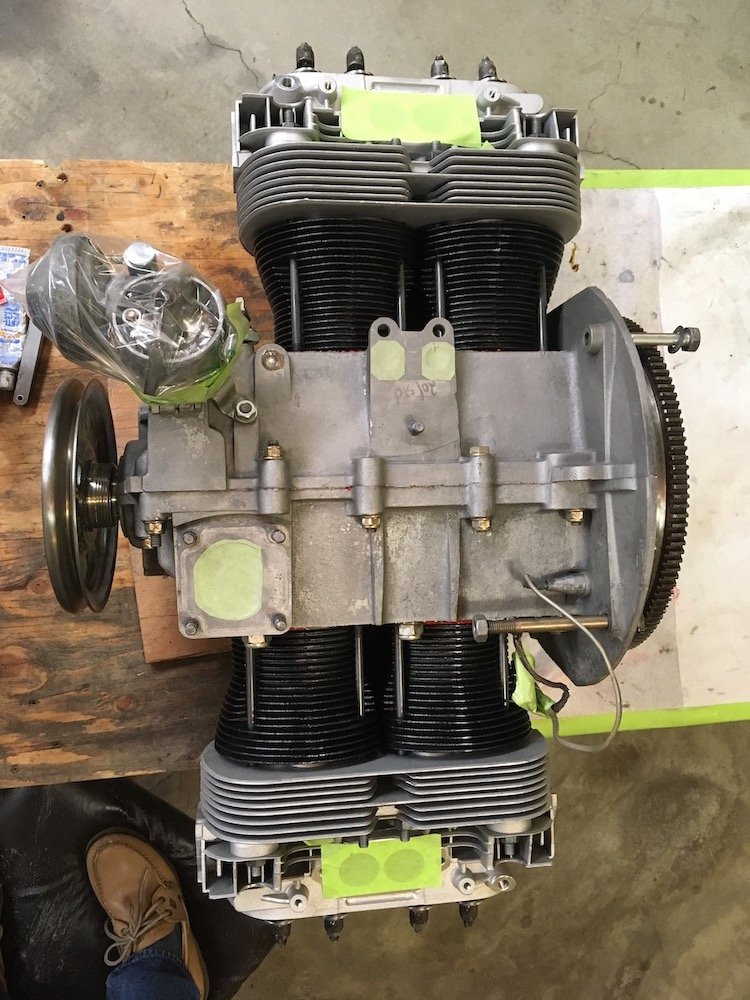

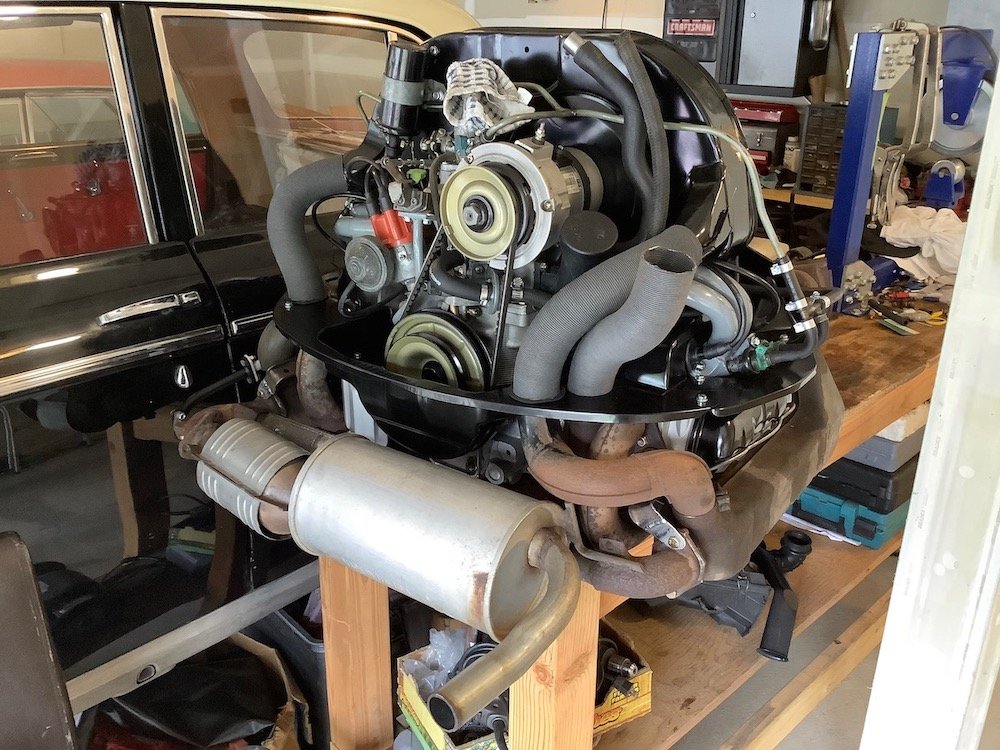

Building the 1961 Datsun 310 Bluebird - VW Distractions and painting the underside of the floors, tunnel and sills. I've been distracted by my other project for several months - getting the VW Beetle project that I inherited from my sister up and running. Now, over the last week or. so I've jumped back on the Bluebird project in order to complete painting the underside of the metalwork before the wet and cold weather sets in. Our Pacific Northwest "Endless Summer" that we have enjoyed since June flips over to the normal cool and wet fall in just a few more days. Yes, the frame rails are still filthy. Just thankful they aren't rusted out. Some day they will be cleaned up. Finished on the last warm day this week. I didn't want to be painting the underside of anything in the cold and have the paint drip down on me while laying on my back on the low boy creeper. Showing some photos below of the VW project distraction before moving on to more detailed posts of the painting job preparation and completion. Mainly it's a seized engine teardown and reassembly with new pistons, cylinders and heads. Engine bottom end was good except I elected to have the mains align bored. Plus, I'm still fixing numerous other problems due to corroded electrical connections throughout the VW chassis, especially the grounds. Hope nobody minds the momentary VW diversion. As the '79 VW was found, it included a huge AC compressor which will be discarded due to broken casting and excessive weight! Car had been sitting outside for years, fully exposed to the rain falling through the air inlet vents directly onto cylinder no. 4 spark plug hole, unfortunately it had been stripped out and the plug was left out resulting in a cylinder filled with water. A bit rusty it was. Destructive teardown to separate rust welded no. 4 piston/cylinder. Cylinders and pistons were to be tossed out anyways. Reassembly of bottom end begins. Polished crank, main bearing align bore, new bearing shells and reused all the rest. Had the air cooling tins satin black powder coated. It lives! Yes, looking through the rear glass, that's a 2 by 4 board holding the rotted top structure up.- 75 replies

-

- 11

-

-

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

Building the 1961 Datsun 310 Bluebird - Upholstery Trimming - Door Cards and Armrests. Rebuilt the door cards, except maybe I should say made new ones minus a few salvaged clips and screws. Started with these black door cards which are not OEM covers, probably vintage 1971 or so. These didn't look too bad from far away but are. The old ivory armrests were salvaged from a parts car many years ago and painted black. Car was not equipped with rear armrests but there are mounting provisions in the door frame for them as optional parts. After removal photos. Then, lurking underneath are the factory original covers from 1961. Backsides showing water damage destruction and potato chip style warping. So I need new armrests to go with the new door cards I was about to make. Built some new ones out the old by disassembly and pattern making. Kept the original support base of solid wood and sponge rubber by filling some of the cavities with bits of glued in foam then glued a thin layer of poly foam on top of the repaired rubber. Covered them up with new vinyl and it's done. An easy sub job. Onward with the door cards then. Datsun Bluebird door card production central. I bought four new large door card sheets from Automotive Interiors and Accessories, INC, located in Belchertown, MA. These cards measured 32 by 48 inch each. I only needed two but four was the minimum order. Then I traced the best of the old cards onto the new and cut them out. All the holes were punched out with a gasket maker hole punch tool. Added some cotton batting as was found on the original construction. Weldwood contact cement was the glue of choice but have to use it outside because the fumes are really bad. Sewed up some cover designs similar to the original style except replaced the OEM vinyl lower half with pleated cloth on 1/8 inch foam to mimic the new seat style. Then glued all the new covers onto the new cards. Made a mistake here in that I should have trimmed out the spaces for the door clips and also should have trimmed back the 1/8 inch foam on the bottom edges. Messing with the aftermath of the mistake took several additional hours to trim once the material was glued. Finished products in trial fit installation. No problems and looks acceptable for fit. The light gray bezels should be dark gray for this model year as shown on the rear door above. All the light gray bezels shown (and plastic dash controls for choke, wiper and lights) are salvaged from a later model Bluebird PL311. Not too noticeable though. So I guess it looks kind of plush for a homemade trimming job but not too much.- 75 replies

-

- 22

-

-

-

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

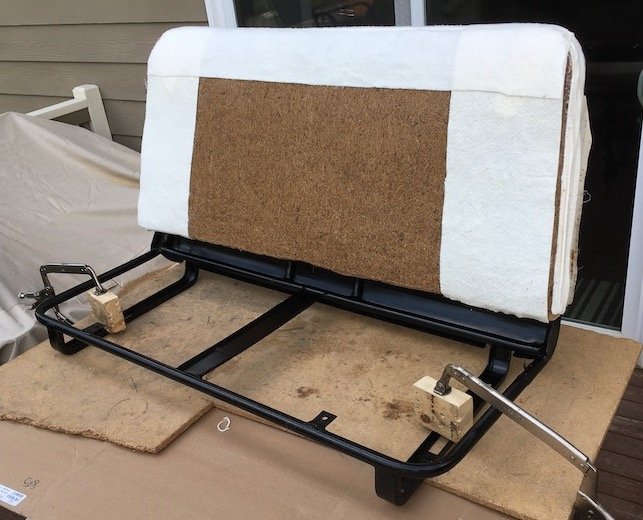

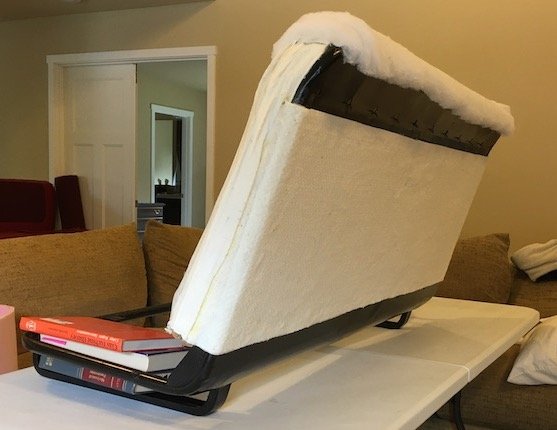

Building the 1961 Datsun 310 Bluebird - Upholstery Trimming Continued - Front Seat Backrest - Part 2. Picking up from Part 1, the backrest cushion of springs and layered coconut fibers was removed from the front bench seat frame. "Peeling back the onion." I began the research by deconstructing the 61 year old inner backrest assembly and peeled back the layers to see what's there. A very thin outer steel framework supports ten vertical rows of four coil springs each. For wrapping each row of coils, a layer of thin (now) coconut fibre cloth. Then on top of that delicate assembly is burlap cloth plus a flat layer of coconut fibre across the whole works. There were also strips of thin cotton batting and some foam rubber around the perimeter but that was removed before I took photos. On this the front side, it all has to go as disintegration has set in. The disintegrating mass is peeled back a bit further, with much of the material removed from the coils and thrown in the trash. I searched around and found some yard and garden shops that supply similar material called "coco liner." I purchased a tightly rolled bit and cut it up to layer each row of springs and attached it with hog rings at each end. Then new burlap cloth and coconut fibre liner of a flatter nature purchased from a local fabric store. Glued that down with Wildwood contact cement. Set that in the frame and progressed further by adding layers of cotton batting, and polyfoam to emulate what existed on the original. Initial layers of cotton batting. Attached the back hardboard. As far as it goes with respect to layering. I don't want it too thick, but just enough to fill out the seat cover with some tension and no voids. Glued the cotton batting to the hardboard same as original. Making the amateur Bluebird seat cover. Just a few detail construction photos as it was a little tough going to make it. Upholstery books and numerous internet videos demonstrate the process of reverse engineering the seat cover from the original as patterns. I just had a lot of difficulty with the upper corners that were rough on the original. In that case, I had to make some prototypes (masking tape version 01 then scrap vinyl version 02) and make adjustments to roll into the final patterns. Vinyl prototype version 2. Final production version going under the sewing machine. Some sewing challenges on those upper corners. A bit of a tight inside radius. The completed and ready to install seat cover. Beginning the install process from the seat cover inside out method and over the backrest top first. This is done rather than slide it over because of access required for a necessary listing rod to be clipped in places a few inches from the top and across the back to accommodate the concave shape. View from above as seat cover is slow massaged downward onto the backrest. Clipping the listing rod on the backside that is within a cotton sleeve of the cover. A bit awkward to perform but doable. Rolled about halfway down at this point. Then the adrenaline rose in me and I pushed a little too hard and fast resulting in a couple of small 10 mm long rips down near the bottom. Should be repairable though. It's on all the way now. Hog ring attachment of the front bottom edge to a rod on the frame. Contact cement applied to the backside and frame lower edges. All attached. Detail of corner attachment same as in photo of original with wrap around forward direction and then pinch into a metal frame clip. Another view of the rolled over fabric glued to lower frame sheetmetal edge. Some final views. Dropped in the previously completed lower seat cushion. Front seat assembly now resides in a bedroom serving as a potential lounger until the Bluebird floor is primed, sealed and painted. I'll post about the door cards next.- 75 replies

-

- 21

-

-

-

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

Building the 1961 Datsun 310 Bluebird - Upholstery Trimming Continued - Front Seat Backrest - Part 1. Though it has been several months since my last post, I actually have been hard at work on the project. A fair amount of progress has been made on the interior soft trim. The following is some of what has happened since then. Front Seat frame and backrest: Backrest separated from from frame Frame repaired and painted Insides of coconut fibre filled backrest reconstructed and padded Vinyl and pleated insert cloth seat cover patterns made Prototype and final seat cover assembled Seat cover installed All four door cards are built as new using the original materials as patterns. Armrests are rebuilt with new red vinyl. Miscellaneous trim over the inner rear wheel well arches made with new vinyl. Rear seat backrest coil spring frame assembly blasted and coated in black by Seattle Powder Coat. I’ll start with this post on the front seat backrest teardown and frame reconditioning/repairs. More posts to follow shortly once I downsize and edit a huge bunch of photos. A historical photo from several years ago (2017) showing the cheap orange-red and black top cover thrown over the original factory upholstery. Basically, an oversized sock roped down to the bottom of the frame with thick thread. It was probably installed when the car was about 10 years old (1971?) is my best guess. I tore it off several months ago and will trash it. Frontal view of original backrest cover that was hiding underneath Rear view Badly damaged corners All the material was sunlight faded except underneath the ash tray bezel. I pondered the wisdom and fire safety possibilities of the flammable coconut fibers directly in front of an ash tray. Some of the attachment details to the frame recorded so I can assemble it the same So then I undid these and other attachments and pulled the cover off. The outer layer of coconut fibers were somewhat unstable and messy as it would disintegrate simply by light touch I removed the cotton batting off the back Masonite hardboard and levered it away from the glue to the frame. This then revealed the burlap backing and supplier decal underneath. The hardboard was salvaged and reused. I salvaged the burlap and supplier decal as well. Then two small screws on either side of the ash tray pocket were removed to release the coil spring and coconut fibre assembly from the main frame. Cleaned the frame of dirt, rust and glue residue and repainted the bare steel areas. I failed to photograph the damage and repair where the sheet metal under curled bottom edge was broken due to seat travel extension modifications that pushed it hard against the driveshaft tunnel. Sorry, but it was a simple crack weld and grind back smooth fix. Cleaned Painted Hopefully, more posts soon, to show reverse engineered patterns and other such completed work as noted above Discussion & Build:https://oldschool.co.nz/index.php?/topic/60267-marts-pl310-61-datsun-bluebird-sedan/https://oldschool.co.nz/index.php?/topic/60264-marts-pl310-61-datsun-bluebird-sedan/- 75 replies

-

- 11

-

-

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

Building the 1961 Datsun 310 Bluebird - Front Seat Cushion Build. I completed the front seat cushion assembly and did a fit check today. The backrests for both seats still remains to be worked. Some photos of the front seat build follow. About all I had to go on when making vinyl patterns out of the existing front seat cover. Not good. Went ahead anyway and it turned out nice! The pleated cloth insert section was made identical in overall width (about 850 mm) to the rear seat but shorter in fore-aft direction. Seems the rear seat offers a bit more room than the front. So I salvaged what I could and trimmed out some patterns for direct use on the new vinyl. The discoloration from UV exposure is extreme! I had to iron the old bits to get them to lay flat. I prepared the seat frame with a clean up and touch of rattle can black. I bolstered the very soft coil springs by stuffing cotton batting into each one. Looks like a bunch of biscuit dough ready to bake! Added the burlap and one inch thick foam. This time, I added a thin layer of muslin over the seat foam and hog ringed it in few places to help bend the edges over. The muslin cloth reduced the friction when dragging the seat cover on. That helped a lot. Previously, it was a real struggle and fight to slide the rear seat cover on as the underlying half inch sewfoam of the cover dragged horribly against the seat foam. I still fought getting the front seat cover on, as the corners were quite tight by design, but not nearly as much as for the rear cover without the muslin layer. The finished front seat cushion. Not perfect, but serviceable and obviously much better than the tattered original. Just the outer corner welting turned out a bit wavy, otherwise ok. Hog ringed underside. There are two thick steel listing rods embedded in the vinyl loop that the hog ring rings grab onto and attach to the seat frame. One wraps around the front and sides while the other goes across the rear edge dipping in a bit at the seat center. Some installed views for fit check purposes. Fit check was near perfect, no real problems. Shows quite a contrast with the old scorched backrest upper! I sat on the seat and bounced around a bit. Firmness was just right with the cotton stuffed coil springs. Nice to sit behind the wheel again after several years! Front face view. Clearance with the seat adjuster lever is about 2 mm. Intersection view at the backrest bottom. Nests together nicely!- 75 replies

-

- 20

-

-

-

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Project Discussion

@bryck Thanks! Yeah, I went ahead with the stuffed spring concept and finished the front lower cushion. It worked out well and created firm support as confirmed with a trial fit and sit session in the car. I’m updating the build thread tonight. Next, the backrests. -

MARTS-PL310 61 Datsun Bluebird Sedan

MARTS-PL310 replied to MARTS-PL310's topic in Projects and Build Ups

Building the 1961 Datsun 310 Bluebird - Front Seat Springs. Soliciting some thoughts on seat springs. I'm working on the front seat and am now at the point of assembling my newly fashioned homemade front seat cover onto the lower seat frame and springs. The original 60 year old springs are very worn out and super soft, providing only enough support for maybe a small cat. Identical replacement springs are not available, all generic upholstery springs I've found are way too large in diameter and length. If any human sits on this after the burlap, foam topping and seat cover is installed, they will find their bottom bottomed out, so to speak. I expect the new seat cover and other materials to be quickly damaged as a result. So I'm stuffing the 36 front seat coils with cotton batting to bolster them a bit. The photos provide a glimpse of the stuffed coil plan. An idea snatched from a youtube video. Seems reasonable. Anybody else done this sort of odd seat spring repair? Does it work? Any better ideas? If so, please comment on the project discussion page.

.jpeg.2ebc77c414805ebe0aab9deba31453a9.jpeg)

.jpeg.bd4fb6cb86793ced4dcedd293fc68fd5.jpeg)

.jpeg.cb7f39a86d54bcd96f7e3972694e9b62.jpeg)

.jpeg.852e6a20efbcbbef2f63cdbb0195f764.jpeg)