-

Posts

314 -

Joined

-

Last visited

-

Days Won

1

Posts posted by Hurmeez

-

-

2 minutes ago, d.p.n.s said:

very good point...and highly doable at this point.

cheers mate

No worries, only too glad to get my fix helping others while I'm stuck with my withdrawals.

-

1

1

-

-

That's a good point. Personally I'd use your current setup as a jig (so to speak) to make two new standalone mounts and a new cross member. That way you don't need to put the motor and box back in and you can do away with the extra mounts at the same time.

-

2

2

-

-

I'd say while you have it at this stage with it on the spit it should be easy enough to drill the original mount spot welds out and shift them back a bit to better match up with the box. Then you can make a straight across cross member and make everything nice and strong.

-

1

1

-

-

I might have to grab a burger after school then and see what's shakin...

-

1

1

-

-

3 hours ago, DewaldSport said:

Well done thus far, I really enjoyed reading your thread. Hopefully, you can get a place with a garage soon!

Thanks very much mate, I appreciate your support. Just for future reference, we don't post on each other's build threads here to help keep down the clutter and make each thread easier to follow. By all means, head over to my discussion thread and have a yarn though. There's a link in my signature.

-

2

2

-

-

3 hours ago, Ghostchips said:

Back in my day people welded diff's. I would rather pour lead in them. The axle shafts will thank you.

1As in body fill lead? Does it help take some of the harshness out of it?

-

Which brings me to something of a bittersweet post. With the handbrake all sorted, I shifted my attention to sorting out some last few half-finished things. For example, I made final confirmation of my driveshaft angles at ride height and fully welded the rear spring pads to the diff.

The welder sure does sing at full noise like that but it was super satisfying to get it sorted.

With that back in and bolted up, I put the front end and doors back on.

The guards and doors are bolted on as normal but the front panel, slam panel, rad supports, etc are all tek screwed on.

Also, the bonnet went back on, radiator in, and the latch mechanism made to work.

Moving inside, I threw my dash topper pad and heater box in,

As well as front and rear seats.

Next, I pulled the front wheels and bolted up my princess calipers.

They're just the bare housing at the moment because I haven't got round to putting my rebuild kit to use.

Finally, I pulled all my spare parts out of storage and stacked them in the back. Everything from my spare V6, to spare wheel covers, to the cover for the torsion bars that hold the rear door up. Pretty much everything I'll need to finish the interior.

After all that, I was finally able to stand back.

As I said at the beginning of this post, this is a bittersweet moment. It was awesome to bolt everything to the car and see it down on its wheels again, but the reason behind it is less awesome. Having finished school at the end of 2017, I've spent most of last year bouncing between seasonal work to make a bit of money, but not doing anything about really starting a proper job. That's been great for working on the car since I've been living at home, but not so great for starting a career. So this year I've enrolled in a Certificate in Aeronautical Engineering in Auckland. Living in an 8mx8m flat leaves little room to store the car (or even an engine stand for that matter. That much has been made very clear by my better half) so I'm forced to leave it all behind.

The complicating factor in that too is that my parents are selling up while I'm gone, so I need to have all my car parts packaged up ready to be transported down the road to our dry storage. Hence bolting everything on. I figured everything takes up the least space if it's bolted up where it's supposed to live, and it makes it far more difficult to lose parts that way too.

So, nothing else to do but push it into a corner, throw a cover over it and wait until we can afford somewhere with a closed in garage.

My old man has said he's happy to look after it until then so hopefully sometime next year we'll be reunited.

Thanks to everyone for their advice and support.

Cheers.

-

7

7

-

7

7

-

-

I went ahead with the hand brake system and got it all assembled.

Next job was to make something for the cables to pull against. So I folded up some 2mm steel to emulate the original Mondeo bracket. Then I plug welded it to the underside of the transmission tunnel to keep the cables as sucked up out of the way as possible.

The bracket is the same thickness as the original Mondeo setup so the standard retaining clips will work well.

Finally, I needed to shorten the cables. Since these are just mock up units that were already damaged when I pulled them off the car, I had no qualms about cutting and welding them myself. Obviously, when I come to final fit up, I'll get some brand new cables professionally shortened to match.

With that done, it was time to throw it all together and give it a quick adjust to test it out.

After a bit of fiddling, I managed to get it so that with five clicks on the lever, I can't move the car by hand. That's not too shabby for rusty disks and pads. It still needs a couple more tabs to keep the middle of the cables tucked away neatly but I've just left them cabled tied up for now.

With it all assembled and installed like this, I'm far happier with the slot in the bolt. With the whole system under a bit of tension all the time, there should be no way the cable can come loose and slip out.

-

That is an interesting idea. My thought though is that it is essentially the same as what I've already got, though a little more simplistic. I've done a bit more work on the cable today and I'm far more confident in the slotted bolt now I've seen it under tension; there's no way the cable would slip out. I think the added complication of the system I have is worth it, over making a whole system like you suggest, for the fact that it uses almost entirely factory consumable parts and can therefore be easily replaced when the time comes. The sheathed cables out of the Mondeo make it easier to route the cables round curved paths too without them binding up. Something for me to think about though so thanks.

-

1

1

-

-

With the benefit of hindsight, of course, the front rotors would be totally different with a larger braking area so they would have been completely useless to use on the rear. In any case, I didn't bother with them and moved ahead with making up some wheel spacers. I started with some alloy plate and roughly cut it to shape before chucking it up and beginning the turning process.

With the spigot sorted on the front, I bored a recess in the back to receive the spigot on the axle.

Then it was as simple as drilling the holes for the wheel studs and countersunk holes for the mounting screws.

Finally, I put a couple of tapped holes in the back side of two of the wheels and mounted them up.

I ended up with a little over 9mm of spacing and still 12 or 13 turns on the wheel nuts, so plenty of thread engagement. I'm still a bit annoyed about the fact that I had to drill and tap the wheel for a wheel spacer but such is life. I mean, there's nothing holding the brake rotor itself on other than the wheel nuts, so why does the wheel spacer need to be "mechanically fixed" while the brake rotor doesn't?

Moving on though, with the wheels fitting over the brakes properly, now I could continue with mounting the calipers in a more permanent fashion. I machined up eight bosses to replace the temporary wooden ones and slapped the whole lot together.

The thing I learned about the Mondeo handbrake system is that it has an auto(read: crap)adjustment system built into the lever itself. Which means the cables themselves are neutral in the system and have no adjustment mechanism built in. If I want to use them, or a shortened version of them, I need to design my own adjustment system. So I did. It's not particularly complex but I think it should get the job done.

On the bottom is the original Mondeo cable splitter that took the lever's action and turned it into a pull on both cables. I figured this would be the easiest place to make an adjuster since anything acting on this would affect each cable equally.

On the top left is a piece of steel tube I squished into shape to fit the standard Escort handbrake lever clevis pin. This has a keyhole shape cut into it to allow the cable end to slide in. Next in line is a threaded boss with a similar slot cut to allow the cable to slide in which will be welded into the end of the tube. Then is a locking nut, and finally, the adjuster bolt itself. This has a hole drilled up the center and a slot cut to allow the cable to slip in. When assembled, the lock nut just needs to be loosened and the bolt wound into the housing to tighten the cable.

The idea behind cutting slots in everything is to allow me to use a standard Mondeo part without modifying it, which should help keep the certifier happy. On the other hand, I'm not so sure about how easy it seems for the cable to slip out the side of the adjuster. I might cut the end off the cable and remake the adjuster bolt with a hole up the center only. Then I'd get a new end soldered on the end of the cable with the adjuster bolt made a permanent part of the cable. I'm not sure if this is legal or not though. Let me know your thoughts here:

-

6

6

-

-

And that wouldn't solve the hub centric problem either. I figure if I need to machine up a ring to match the hub spigot to the wheel, I might as well make a whole spacer up for that extra hella mad sick stance as well.

-

1

1

-

-

Interesting. I'll be down in Auckland for the first week of the new year so I might have to go to a wreckers and have a bit of a look. No Focuses in the one down the road unfortunately.

-

I got my axles back from the machinist for an unbelievably good price so I can start getting them set up to go back into the diff.

I made a start by pressing the brand new bearings on.

A handy thing about the skyline axles is they have identical bearing faces to the Falcon axles I got rid of out of my housing. So two brand new Falcon bearings later and I have a fully together diff and a rolling chassis once more.

Next, I threw my mockup brake setup on.

I quickly noticed a problem when I went to bolt the wheel on.

The caliper actually sticks out further than the wheel mounting face. I'm not exactly sure how the Mondeo wheel looks, but I'm getting the idea that it must have a bit of offset with a mounting face the same diameter as the brake disk. The Cheviot Turbos that I have have a mounting face that is bigger than the brake disk face, so it doesn't sit down properly.

My best solution for this is a 10mm wheel spacer. I made a mockup out of MDF to test my hypothesis.

According to the Hobby Car bible, this would meet almost all the requirements of a wheel spacer. It also has the bonus effect of making the wheel hub-centric, because the turbos have a larger center hole than the standard Escort sized hub spigot and are do not transfer the load to it on a normal English diff.

The only thing I'm not sure of is the requirement for the spacer to "be set-screwed or attached by another secure mechanical method to either the wheel or hub face." Does the fact that it is clamped by the wheel nuts not cover this? Or would I have to drill and tap countersunk screws into the mounting face of the wheel to ensure they are compliant?

In any case, I threw the mockup spacer on to check fitments.

Here you can see that it provides a mounting face with sufficient clearance to the caliper.

And the hub centric support:

In the final version, I would probably make the center a blind hole that sits snugly over the axle spigot for extra support.

And finally, the wheels fill out the arch much better in my opinion with just that 10mm extra track width per side.

And with the center caps on, you'd never know the difference.

While typing all this, I had the thought that Mondeo front disks may have a different offset between the braking face and wheel mounting face which may solve this whole thing. It wouldn't solve the hub concentricity issues though. I think I'll still go to the wreckers and have a look but I'm open to suggestions.

Cheers.

-

9

9

-

-

- Popular Post

- Popular Post

I wasn't completely happy with using bolts with each mounting flange being tapped to hold each throttle body on. Not least because all my untamed strength acting on the quarter inch ratchet managed to strip one of the alloy tapped holes on the first try. So I decided to swap the whole lot for steel studs pressed in from the back side of the flanges.

So, two minutes of turning later...

You get these delightful little fellows:

And then pressed into place.

Which gives me a much more professional looking nut rather than bolt with a neat little button head on the back.

While I was in there I also added an extra throttle return spring.

I'm much happier with the throttle now. I wasn't quite returning to its seat after lifting from light throttle but now it snaps shut far more satisfactorily.

Next job is at the other end of the car...

-

12

12

-

- Popular Post

- Popular Post

So with the idle circuit sorted, I figured after working on getting a little bit of air into the engine, the next logical step is to figure out getting lots of air in as well.

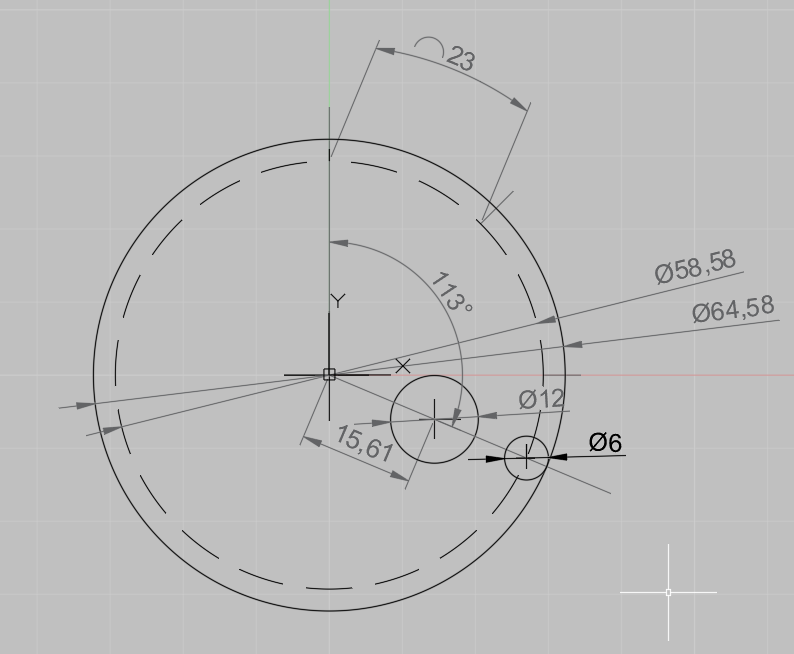

I'm not sure if I've mentioned it before but I plan to use the original BMW linkage rods to actuate each TB. They are stainless from factory and hard as a coffin nail, so I'd really like to avoid machining or drilling them as much as I possibly can. Because I basically can't. So I won't. I actually considered this way back when I designed the intake flanges, spacing them out the same as they would have been on the V10 in the first place. This meant that all the cross drilled holes in the link rods already line up with the throttle bodies and I can use the factory linkages and everything is peachy. Also, being originally off a V10, the rods were too long for the banks of three per side that I'm using. This left me with a handy little overhang on which to mount a custom eccentric throttle wheel. So with the help of @yoeddynz once again, and a little bit of maths, I designed this:

Using the standard Escort's pedal throw of ~46mm, it gives you a little over 1/3 (7/18ths) throttle opening at half total pedal throw and the remaining 2/3rds ish with the remaining travel. Hopefully this strikes a good balance between fine controllability and spongy pedal feel, like you get in so many modern fly by wire setups. Unfortunately I won't be able to know for sure for a very long time, but, such is life.

Using that neat little drawing, I spun this up in the lathe with the four jaw chuck.

Probably the most offset job I've ever done. Thought the bloody thing was gonna jump out at me any second when it hit its resonance.

Here it is mounted on the link rod:

With that done, the next thing was to make a bracket to hold the throttle cable. I'm using a standard Escort throttle cable shortened by about 150mm and with a late model style barrel end on it. This lets me use a standard pedal and clip and not have to worry about modifying anything on that end of the deal.

Here is what I came up with for the bracket:

It is made from 2mm sheet to match the original bracket. This means the clip system on the end of the throttle cable fits in snugly. As you can see it is mounted to the idle circuit tubing.

And here it is in place:

And full throttle:

Finally, I had to connect each bank together. I ordered some rose joint rod ends from china with a left-hand female thread, and repurposed a right-handed example from my original twin carb setup for the Pinto from way back. Then I modified a pair of the factory linkages to be parallel at half throttle but with one above the rod and one below, while still picking up the original holes in the link rods. This should mean that each rod should rotate at the same rate but in opposite directions for the entire arc.

Finally, each rose joint is connected by a stainless steel rod with opposite threads on each end to allow for fine adjustment of length and to balance each bank properly. I also made up a couple of lock nuts for each end.

So finally, this is how it all looks in action from the driver's seat:

With that all done, while I was in there, I installed the proper vacuum rated flexi hose for the idle circuit.

Looks flash as now.

Not sure what the next job will be but I'm sure it will end up on here at some point. Cheers.

-

15

15

-

Man I almost missed the engine jamming out too hard to those sick beats! I wonder if Kelford would be able to regrind the standard cams to an even more aggressive profile? I'm glad I bought the DE engine first now so I can swap in the reportedly superior valve train components.

-

1

1

-

-

Interesting how he was saying that it has a 7k redline. For some reason I had it in my head that it was more like 8 but I'm not sure where I got that from...

-

Also that video is awesome! Didn't think I'd watch the whole thing on data but next thing I know the whole things gone by. It sounds heavenly up in the revs!

-

You know, I knew all of that already but I never put the fact that you could wrap the throttle cable around the pulley as much as you like and it's still only going to pull it through 90 degrees if you've got the radius of the wheel right. The fact that yours was wrapped almost half way round was really messing with my head. Thanks for explaining it so well.

-

1

1

-

-

Each bit you do is one bit less at the end of the day. She'll be sweet when she's done!

-

Awesome! I'm gonna be off it for a year while I'm on a course in Auckland so progress will come to a screeching halt for me.

-

1

1

-

-

You'll definitely have yours done before me so it'll be interesting to see what you find.

-

1

1

-

-

It's a shame they didn't make them for the superior cylinder arrangement really!

Would have made my life a little easier. I'll have to send a strongly worded letter to Berlin next time the pony express comes through.

Would have made my life a little easier. I'll have to send a strongly worded letter to Berlin next time the pony express comes through.

-

1

1

-

-

- Popular Post

- Popular Post

Moving to the Throttle bodies, I decided I'd start with the idle air control circuit. Originally I planned to drill and tap some brass fittings into each intake runner and join them all with push on vacuum line to a central ICV somewhere hidden away. That would then require me to plug the BMW injector ports (I'm going to use the standard Mazda V6 injectors) since they are on the vacuum side of the butterflies and would pose a significant vacuum leak. Then I had an idea. Well @d.p.n.s had an idea and it was pretty smart so I thought I'd take the credit.

If the BMW injector ports are going to create a significant vacuum leak, then why not use it to control the idle? Dan got lucky with a set of throttle bodies that already had a ICV setup on them and all he had to do was cut and shut it to fit. Unfortunately, for whatever reason, the V10 style of throttle bodies (Which I am using) don't have one built in. So I'd make my own using the unused ports.

I started by machining up some "false injectors" out of mild steel.

I considered stainless for the bling factor but the extra pain in the butt I'd have with the machining made me reject that idea. As you can see, they use the standard O-rings and are shaped essentially identically other than the long injector nozzle. Here they are in place:

I considered stainless for the bling factor but the extra pain in the butt I'd have with the machining made me reject that idea. As you can see, they use the standard O-rings and are shaped essentially identically other than the long injector nozzle. Here they are in place:

Then I cross

dresseddrilled each one and ground them out to shape to fit a common balance tube.

Which they were all then welded to.

I put a cheeky little cap on the front of each one at a jaunty angle to make them look a bit faster.

Next was a couple of little brackets to hold each new false fuel rail using two of the throttle body mounting bolts.

So now I have two separate balanced banks of throttle bodies. Next I need to connect each side together to balance the whole lot together and hook the whole lot up to an idle air control valve of some description.

Again, Dan's throttle bodies came with their original IACV but mine didn't. So I did a little research and found that there are an awful lot of BMW engines that use the same model of IACV, including a couple of six cylinders that were down at the local wreckers. So $30 later I was back with a nicely gummed up and seized valve. A bit of brake clean soon had it cleaned up and freed and I started looking at options for hooking it into the system. The first thing I did was try a random brand new filter I found in the empire of dirt.

What do you know? It fits over the intake perfectly! Magic! Then I wrapped it in a strip of sound insulating sticky backed foam which you can see above. This is a little too thick for the final fit but I carved it up to fit for now. Then I found a random ignition coil mounting strap and again, it fits perfectly!

A study in serendipity this is turning out to be!

With the mounting sorted, I continued by machining a few different fittings to assemble into this T-piece, among others.

I intentionally made all these custom pieces the same dimensions as the output side of the valve to keep all the hose runs easy and not have to worry about diameter changes along the way.

That then gets welded onto the passenger side false fuel rail. (I suppose balance tube is a better name actually)

With everything bolted up, you can see the short run for a piece of vacuum rated tube to connect the valve to the balance tube.

I also welded a fitting to the other balance tube to connect them up. I intentionally made this one the same length as the T-piece to give me the option of welding another tube on underneath for a brake booster vacuum source later on if I decide I want one.

Finally, I connected everything up with a piece of hose I had lying around.

I don't think it is vacuum rated at all, (it's pretty easy to squash by hand) but it looks good for now and I've got some proper silicone hose on order from the parts shop in town.

I'm going to start on my eccentric throttle wheel next but I'm struggling to figure out the maths behind the radius, versus center offset and so on and so forth. At the moment my thinking is that a throttle butterfly only opens by 90 degrees or a quarter turn, give or take, from closed to full throttle. Therefore, if I find the full travel distance of my cable and multiply by 4, that should give me the circumference of the wheel. Then I was going to decide on how far to offset the centers by looking at pictures online, but of the ones I've been able to find, none of them seem to have the cable pulling the wheel through 90 degrees. Most look more like 120 degrees and I mean, @yoeddynz's one on the old Viva looks like it wants to pull through almost 180 degrees and that doesn't make a lot of sense to me. If anyone can help me out with any advice in this case then I'm all ears.

Please share any ideas or advice here:

Also I just realised, I never properly showcased the finished intake runners with their flash professional welds. Hopefully these photos do enough to show off how pretty they are.

-

13

13

I considered stainless for the bling factor but the extra pain in the butt I'd have with the machining made me reject that idea. As you can see, they use the standard O-rings and are shaped essentially identically other than the long injector nozzle. Here they are in place:

I considered stainless for the bling factor but the extra pain in the butt I'd have with the machining made me reject that idea. As you can see, they use the standard O-rings and are shaped essentially identically other than the long injector nozzle. Here they are in place:

Aucklands Anon Burger meet!!

in Upper North Island Region

Posted

Who's coming this month? I'm keen to catch up again after my first meet last month!