-

Posts

1010 -

Joined

-

Last visited

-

Days Won

3

Everything posted by dmulally

-

Bump! Anybody have any recommendations on who can do this in the north island? Cheers

-

Ok managed to source an engine. Looks to be in pretty good condition. Next on the agenda is to rip out the old one!

- 90 replies

-

- 26

-

-

-

TROUBLE IN PARADISE! Whilst bogan tetris-ing my cars round the shed I found the Imp even harder to start than usual (still havent connected the choke yet). I checked the engine and noticed it was low on coolant. I could have sworn I always kept it topped up so checked the dipstick. It was a caramel milkshake in there. Ironically I decided on the weekend that I was going to sell it. I guess I'll have to spend a shit load of cash first unless somebody wants to low ball me an offer I can't refuse on it. Time for Phase 2 of the Imp project to begin.

-

Jeez that is in far better shape than mine.

-

Lovely looking truck and thanks for posting. Just wondering if you know the GVM of the 550fg? I'm still not sure what it falls under but I'd be keen to put it through a wof if possible so was going to swap to a single wheel diff.

-

The way steel prices are at the moment it's almost worth the trip

-

$10 and 25 mins away.

-

I couldnt get through to them so put it on the backburner to attend to some dramas with my s-type. I'll just have to keep an eye open whilst doing the rest of the truck as it is holding water for now anyway. Next thing to sort will be the rust. I have bought a door from a 1930's pommy something and pick it up this weekend. Only $10 and cheaper than buying fresh steel from Steel and Tube.

-

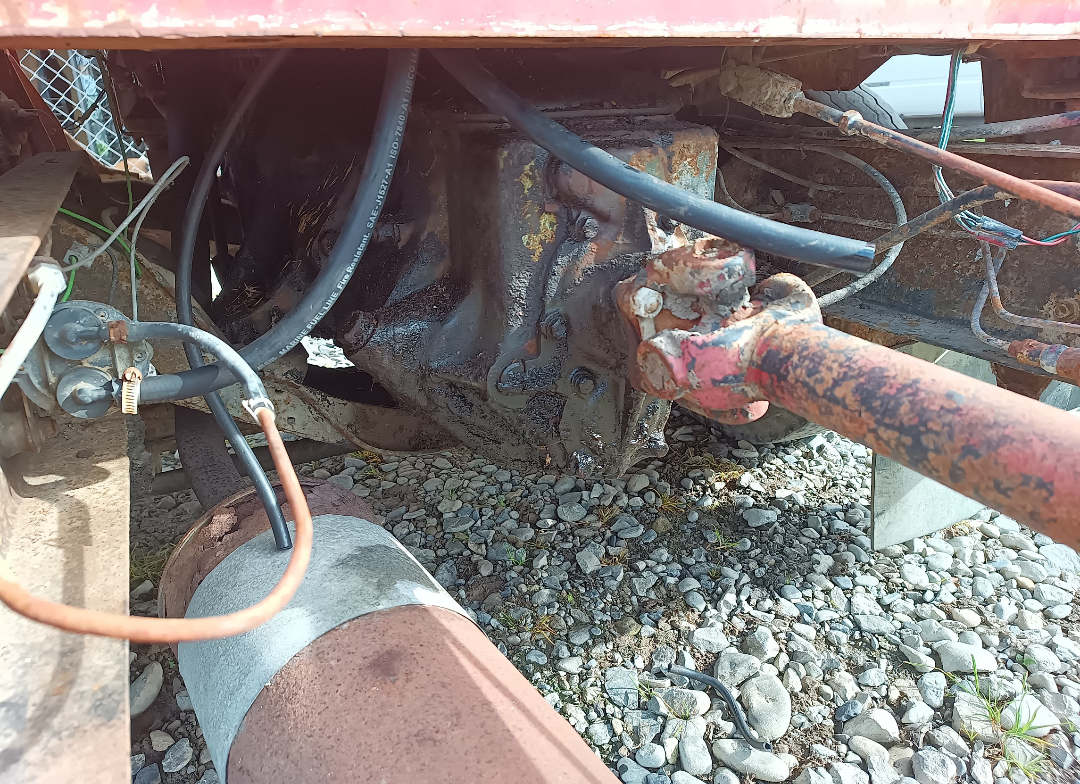

Also the diff has to be swapped. After the power wash and the engine dried off I took it for a drive down the road. First gear is unusable like most light trucks but 4th feels like 2nd. I thought the diff was 4.5:1 but It's in the 6 or 7's. It's able to easily take off in 4th! I might look into a GMC or 9" swap as loads of ratios and easily enough to convert to dual wheels with off the shelf bits. I couldn't be bothered to stuff around with an overdrive conversion. Although the gearbox is green which was news to me. Another thing I have to do is move the shifter. Quite impressive that you scrape your knucks going to second as well as up to third. Not to mention it's behind you so have to find it.

- 11 replies

-

- 15

-

-

Pretty crappy weather on Sat so decided to make the most of and get the power washer out. Interesting to see what I'm working with.

-

So managed to get it wired up enough to be able to run again. I have the thermostat housing bolted on as best I can and glued too. One thing I noted is that the corolla housing is pointing another direction to the original. So either I need a new radiator or to redirect the top outlet so it points the right way. Not a biggy. When I drive it inside for some rust work I might have a go at tig welding the broken housing up. Or at least melting the bolt in place. I ran the engine for a good 20 mins to see if the housing would leak and so far so good. I think until I can find a new lower housing to bolt on it will just have to do. All the valves are free and moving too although there is a slight miss occasionally. I think what it needs is a good long run at 2500rpms on the highway to clear the throat. The rebuilt carby hasn't even been dialed yet and starts on the smallest of choke. I'll still have to adjust the valves yet but am in no rush to do that yet.

- 11 replies

-

- 14

-

-

What's the best way to deal with them? Email, call, visit? It's about 4 hours away from me so I can't exactly pop in easily sadly.

-

Good shout. The bedford 6's especially are everywhere. I did have a Chev 250 full oil pressure one that I scrapped a year or two back. Bugger. A couple of hours in and the housing hasnt started leaking yet.

-

Ok slight change of plans. The truck cert guy said I should really really not bother with an engine repower without getting it registered first. I've spent the last day or so researching the TD42 and can only dream. So quick question: What is the neck called that the thermostat housing bolts to? I'll need to find a new one but don't know the name. I'll likely have to shop in England so have to find one. I could always fabricate one but would rather not. The other thing I could do is get a generic pommy 6 cylinder and just hope the VTNZ dude is under the age of 50 when first registering it. To try and scrape through in the meantime I have retapped the bolt holes with a more course thread and jammed some bolts on and glued the t-housing on with right stuff which I have had good luck with in the past. I didn't have the right length bolts so improvised. m presently having it sit cold full of water and I'll check throughout the day to see if it weeps. There is a chunk of cast iron in the water pump so if it stays water tight I'll pull it off and go fishing for it somehow.

-

Are you please able to chuck a tape measure over one by any chance? I can take some pics/measurements of the engine bay first if you like.

-

How hard is the wiring on a TD42? I know the isuzu is one wire for the fuel pump and starter each. Simple.

-

The TS3 is waaaay too wide. As is the daimler V8. What will fit so far that I have in stock: Isuzu 4b diesel (with some mods) Holden 202 Essex V6 Slight issue is that the truck cert guy wants to know the GVM as he thinks it is for a car cert person. I sent him the sales brochures I had and a guess. See what he says I guess.

-

Im sure with enough glue and brazing rods I could make anything happen. But I'm quite superstitious with my car projects and took this as a sign.

-

Cheers. I pinged Matt from here.

-

Technically too wide but there is a really nice space between cross members behind the cab it would be perfect for. Which leads me to the next question...who signs off truck mod certs?

-

I'd like whatever is easiest. Sadly I gave away the LD28 I had clogging up my shed for free. I'll chuck a tape measure over the 4be1 I have floating about. Even though it is a 4cyl it looks bloody wide.

-

I couldn't be bothered. All for a straight 6 petrol. Therefore I'm open to ideas of where to go with this project. I do have an isuzu diesel in the shed but I really wanted that for my C20 chev. A detroit diesel would be a LOT of fun but I don't even know where to find one. Might have to browse FB marketplace to see which diesel engines are floating about nearby.

-

Well that's a shame. I was just buttoning it all up for the 50 meter drive to my workshop to start on the rust and broke the thermostat housing. To add insult to injury when I lifted the top housing up the snapped off bit stuck to the bottom and dropped into the water pump which was pretty funny. I guess this means time to reflect. I might open it up in the chat thread for some ideas. I don't even know what this engine is even called let alone looking for a new housing.

-

Ticking along slowly with the FG. I rebuilt the carb and need to put that on. Naturally the linkage doesn't line up so I have put something together the wrong way round so I'll sort that. The thermostat housing was toast and I had no idea where to find a new one but apparently an old corolla one has the same bolt pattern. Unfortunately the outlet points a slightly different direction so I'll have to get a flexible hose and do some subtle bending. That there wasn't a thermostat inside the housing suggests it has had overheating problems in the past so I'll see how it runs but consider ditching the radiator for a better one. There is an acre of space to put a bigger one in although the flap at the front won't line up with the fill cap so I'd get a remote overflow tank to monitor the situation easier. I also had a trademark change of heart and decided to put in another more generic alternator. The special dragster one I had used an unusual pulley shaft size and a new pulley was 3/4 the price of a new cheapie alternator. Not really a big deal but I had to order a double row pulley to line it up with the water pump and crank pulley. That way I don't have to modify the housing of the alternator which I hate doing. For anybody thinking of doing similar I just use a threaded rod to use the original generator bracketry. Some washers are used as spacers for the adjuster and it's a 20 minute job. Next small job is to order a new pulley belt as the current one is old and get the old radiator back installed as soon as the alternator pulley is installed. Then I have to choose between doing the rewiring (not hard. Just boring) or tackling the numerous rust spots in the cab. Haven't decided if I'll take the cab off yet or not. Looks like a pain in the bum but would make life easier. See how I feel.

- 11 replies

-

- 18

-