-

Posts

439 -

Joined

-

Last visited

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Hyperblade

-

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

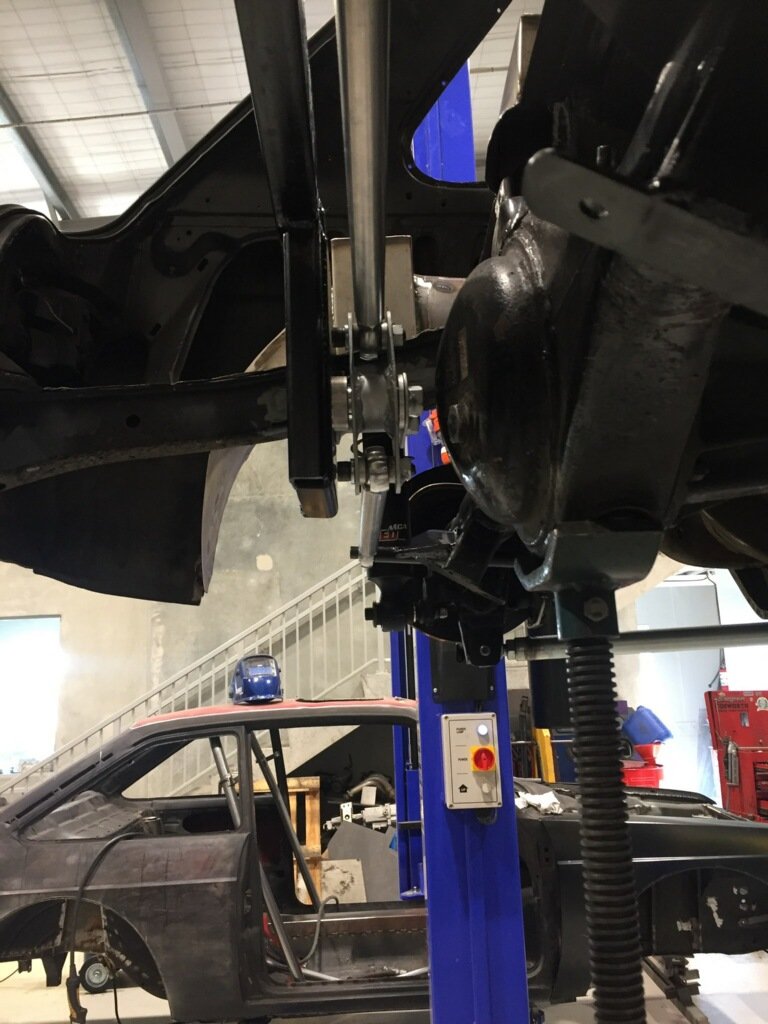

3 Link done. Required driveshaft length has turned out to be 898mm so any plans for a 2 piece are out the window as there's not enough space for it, it would be just all fittings. On the flip side does mean less weight slightly and no need to mount a center bearing.- 78 replies

-

- 20

-

-

Remote coil packs are a thing!

-

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

Good point on the counter balance shafts, your obviously paying to much attention, however the Civic and Integra don't run them and it's the same crank, block, head, camshafts as those engines etc so we can safely assume that was for the old man accords just to remove 4 cylinder vibration I would probably be ok to run an Ali pulley as on the track you are generally always accelerating/decelerating so less risk of staying at one frequency, but you just never know. -

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

Gear lever in position. Gear lever Moved 190mm forward on gearbox, mount was cut off and the selector shaft shortened then mount welded back on. Means no need for loose linkage system to move the lever forward which should keep the nice gear change feel the box is known for. Can see it's quite a long way forward compared to original position. Nice lightweight panel to cover access hole. Engine sitting back in with front tubs done. Heaps of room around intake to have fun later on. Rear tubs in, the coil over mounts have been raised as well as I was running out of adjustment on the shocks. They have come up awesome, so tidy, Brent is doing an amazing job.- 78 replies

-

- 22

-

-

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

I won't be running a knock sensor, so someone else will have to do that testing. Interesting, not sure about the argument that Honda didn't use it on X so we don't need to use it on Y. Why did Honda use it on Y then... They spent mega dollars developing the K20/24 trying to get weight out of them, even going so far as to make hollow cam shafts, yet they still added the heavy dampener. The argument that it's for the accessories has some merit, but you can clearly see it's just an opinion and they have done absolutely no testing on it, no complaints is a poor excuse for lack of actual real world testing, and it didn't break after x years is not testing. Machining a aluminium pulley is easy stuff, easy sell too with "get more hp, faster revving" it's quite attractive to a customer. That's the thing with dampeners you can get away with not using them if you avoiding the frequency so will be fine for years, but if your engine happens to run at that frequency then you get the damage. Not a risk I think is worth taking personally. Thanks for sharing though, always good to have debates on this stuff. -

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

Brent is working away at a great pace. Here's a good shot of how far over the engine is to the left. Struts swapped left to right, bottom arms modified and tied back to the chassis, instead of the stock starlet swaybar which goes forward. Driveshaft tunnel tided up. We are going to have to move the gear lever 190mm forward to get it into the right position (more info on that later). Beginnings of rear changes, 3 link going in. The whole axle is being moved back 50mm and tubs going in the rear, so quite a bit more cutting to go...- 78 replies

-

- 16

-

-

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

You don't want to go anywhere near alloy crank pulleys, you need the harmonic dampening in the crank pulley, putting one of those ali ones on means it's only a matter of time until you destroy your crank. Good video on it: You can get legit aftermarket harmonic dampeners like the ati super damper, but they aren't cheap. http://www.atiracing.com/links/pr/honda-k20-damper/index.htm -

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

Right, now we are up to speed on where I am at. Now for the fun stuff. First strip the engine bay. Second turn the cross member around and bolt back on, so we get more room behind it, this also moves the front suspension forward so less angle on the bottom arms (as i was running quite a bit of castor), so benefits all round. We will swap the suspension over from left to right to suit, and then the questions is how to do the steering rack. At this stage I have a lead on what must be the only LHD starlet rack in NZ, so that is plan A, plan B is to use a LHD escort rack which is the same length so bump steer etc is kept consistent with current rack. Both require making new mounds for them. The engine is sitting behind the cross member, so no need to make any modifications to the sump which makes life easier! Obviously a heck of a lot of metal cut out to fit... Engine is deliberately offset to the left hand side of the car to help with clearance on exhaust port 4 and for weight distribution. #1 spark plug is inline with center of strut towers. #4 spark plug is under cowling, so we are going to make a panel removable to get at it. Clearance to the pedals/pedal box was the biggest worry, but we have ended up being no closer then the BEAMS motor. Exhaust ports 1-3 are all in free air, only the 4th is tight, we moved the engine forward from this position 20mm and up righted it a little bit to get more space. Heaps of clearance on intake side. And strut bar even fits across, Fab work going in, corner by pedal box has been rounded off to give event more space, bit area next to intake to give lots of options. Bell housing on gearbox is fairly large and also want to be able to remove it from engine in place. Goes back a long way. Bit rough under the car, passenger side will be cut out and redone to give more room for muffler. Engine mounted to cross member, can see how far back it's sitting. Boxing it all up, the big hole is for access to back of engine from inside the cabin, will have ali sheet covering it, nothing worse then trying to fix a water leak in an awkward location. Pedal box also gets an access panel to the top of it as it's impossible to access now. Steel used where the bolts go to the pedal box uses thicker gauge and rolled top edge for extra strength in handling the pedal forces when braking. Been told I could fit a TV in there, I was thinking some glass so i could admire the engine. Tubbing the front to support 10" wide rims so later on I can use the new TRS slick tyres. That's just the front... The rear is going to get a few changes too- 78 replies

-

- 24

-

-

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

Next challenge was the intake manifold. With the engine rotated around into RWD config the throttle body points directly at the firewall. This is where you have so many options off the shelf as it's all been done before. You can buy an adapter plate to fit an F20c (S2000) intake manifold to the K motors, but they look terrible so I didn't want to go down that track. You could go Quad Throttle Bodies (with multiple options from different manufacturers, swoon...) Straight: Curved: Kinsler mega dollar ones... But this conversion is already going to cost a fair bit, so that can be an option for a later day... So I ended up with the Skunk 2 Ultra Street Intake Manifold https://skunk2.com/induction/intake-manifolds/ultra-street-intake-manifolds/307-05-0600.html It has a rotatable plenum cover, which can be removed if you want to go crazy and port the runners and you can also buy spacers for it to increase the chamber size. Supposedly it also gives 20hp over stock manifolds. It also matches up perfectly to a 74mm throttle body (standard for the engine is 65mm) so I didn't need to port anything and it saved a lot of time. The downside is the quality of the casting is not super great with some imperfections and I had to port match the thermal gasket to the head, which was disappointing as it should just be cut correctly from factory. The other thing to note is the Idle Air Control Valve (IACV)on a Euro R is NOT the same as other K20'a Type R engines, i.e it won't bolt up, so I got an Integra R which fits.. -

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

The B16 and B18 have stronger internals and can take those revs, the K20's have weak rods (well designed right to the required limit), so if you miss a gear your stuffed, one guy here did it and the rod let go and block + head were destroyed on a stock K20 he is now going forged internals just to stop it being an engine destroying event. Yep I run a shift light, frequency of flashes changes as it gets closer to rev limit. I also set it differently for each gear i.e 1,2 comes in 500rpm before limit, while 5,6 are 200 rpm, the link makes it easy. Trying to stay away from sequential, it's just the start of your problems if you go that way. The pulley came with the water block kit, I think it was slightly bigger but not by much, thanks for the heads up, will see how it goes, if i keep blowing them then will have to look at options, maybe putting the K20 one back on. -

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

Up above I mentioned the stock water pump housing was 4.8kgs It's also a huge chunk of metal, and has a idler pulley down low in an awkward place. You can find AC/PS eliminator kits like this one. http://k-tuned.3dcartstores.com/Universal-AC-PS-Eliminator-Kit_p_248.html The issue is it puts the alternator even lower and I'm going to have a cross member there. So looking at the options I decided to go with a water plate kit This allows me to get rid of a lot of weight, run a lighter alternator, and keep it all away from the cross member. I chose the older k-tuned kit which doesn't support the K series alternator, only because it was slightly cheaper. I chose to only get the plate and the alternator bracket and pully. (not the water pump) as when I contacted K-Tuned they commented they had only used it in drag applications, and hadn't tested it in a road race application. http://k-tuned.3dcartstores.com/Water-Plate-w-Alternator-Brackets_p_600.html So why use an older alternator? Alternator Weights: K20a - 5.68kg B18 - 4.64kg D15 - 4.9kg Cause they are slightly lighter! Now ideally I would have gone with a B18 alternator but the shaft on it was too small for the pulley. So D15 it was, however it wasn't a straight fit, I had to clearance the top of the alternator slightly to fit. But the other advantage was the plug is the same as the K20 alternator. Sticks out a fair way, would have been nice to have it closer, but can't have everything. Chose a Davies Craig EWP 115 (alloy 8140) https://daviescraig.com.au/product/ewp115-alloy-12v-115lpm30gpm-remote-electric-water-pump-8140/ewp115-alloy-electric-water-pump-12v-8140 Australian made and with the Aussie dollar pretty good to NZ and shipping prices makes sense to go localish. Only annoying thing is they don't have mounting points, they can just be held up by the hosing, however will have to see how that looks when I go to mount it. Otherwise you can buy this bracket: https://daviescraig.com.au/product/ewp-mounting-bracket-kit-ewp115-130-150-8700/ewp-mounting-bracket-kit-ewp115-130-150-8700 The pump can be PWM controlled, so i will do this via the LinkECU through a PWM relay, so it will be pulsed on an off to control the flow depending on the temperature. So with this change I've cleared up some space, dropped 5kg and freed up some HP from the engine. -

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

It begins...- 78 replies

-

- 14

-

-

Holden/Ford 2 Piece CV Driveshafts which models?

Hyperblade replied to Hyperblade's topic in Tech Talk

Thanks! Thanks! Interesting they have CV and u joints, I thought U joints had to be at the same angles as they aren't constant velocity. I don't quite get how that works, unless they have the rear diff on an angle upwards? -

I have to get a custom driveshaft made for the new engine/gearbox combo that's going in my starlet. I need to go from a S2000 Gearbox to a AE86 Diff. But the max RPM on the shaft will be fairly high at 9500 rpm. So I've been advised by a few people to go to 2 piece, however unfortunately the S2000 gearbox has a flange at the rear which makes things a bit harder than normal. Ideally I want the joints able to be rebuilt if required, and as light as possible. Ideally i want to run CV's (due to the speed) and 2 piece, and I've been told both Holden and Ford ran a form of these driveshafts in some of their cars. But what models? I've seen mention of Crewcab. Does anyone know other common models worth looking into? The challenge: S2000 Gearbox Flange AE86 Rear Pinion Flange

-

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

That comparison to the BEAMS included the EWP in it. So K20 weight is as I'm going to put it in. I'm also in two minds, it's not as much as I thought, but than again we are talking about 2 very similar motors and one is 20kg lighter than the other, yes its aluminium but that doesn't account for all the weight loss, if you tried to take 20kg out of the beams you would struggle. They are also only a 4 cylinder not a 8 so a lot less to remove. Also need to be careful as the BEAMS weight included a light weight alternator setup, and I can't remember If I included the starter or not, so if not than it's another 5kg on top. So overall I'm happy with that gain, will try and make a lighter exhaust which will help the difference. Integra is 8400 red line, and 8600 rev limit. accord euro R is 8400 rev limit Since the Euro R is same cams/valves etc I will be safe to run up to 8600 at least. Stock oil pump can cause issues, but that won't be a problem for me, issues is normally rods from what I've seen, A lot of people mis shift (especially with 6 speed box) and overrev and than destroy the engine, where as the B16/B18 are a bit more forgiving. Won't be touching the internals so will be keeping the rev limit stock. I'm hoping it matches my expectations! -

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

So now for the Honda K20a Weights. 105 kg - K20a Euro R, no oil, no balance shafts, ktuned alternator bracket and water block off, D15 alternator, stock oil cooler removed, MRP oil cooler sandwich plate, no intake, no exhaust, no flywheel, no clutch and lots of bolts left in the block, no engine mounts. 34.8 kg - S2000 AP1 Gearbox, no oil, no slave cylinder, no gear stick. 11.69 kg - Stock 4 - 1 Headers with Heat shield. 5.72 kg - Skunk 2 Ultra Street Intake mainifold with 74mm Skunk2 Throttle body, stock injectors and stock fuel rail. Misc Info: 4.85 kg - Stock water pump housing with thermostat 5 kg - Stock Balance shafts and oil pump. 1.1 kg -Electric Davies Craig Water Pump 0.47 kg - Hybrid Racing Pod Filter 1.39 kg - K2F Adapter Plate 5.87 kg - K2F Flywheel 1.27 kg - Exedy S2000 Clutch Plate 4.64 kg - Exedy S2000 Pressure Plate. Alternator Weights: K20a - 5.68kg B18 - 4.64kg D15 - 4.9kg So if we compare like for like with the BEAMS 119.27 kg = Engine with clutch, no engine mounts. 34.8 kg = Gearbox 6.19 kg = Intake 11.69 = Stock Headers Honda K20a with S2000 Gearbox Weights: 137.15 kg Engine + Intake + headers 154.07 kg Engine + gearbox 160.26 kg Engine + Intake + gearbox 171.95 kg Engine + Intake + headers + gearbox Toyota 3SGE BEAMS with J160 Gearbox Weights: 161.39 kg Engine + Intake + headers 182.91 kg Engine + gearbox 189.91 kg Engine + Intake + gearbox 199.39 kg Engine + Intake + headers + gearbox Difference: -24.24 kg Engine + Intake + headers -28.84 kg Engine + gearbox -29.65 kg Engine + Intake + gearbox -27.44 kg Engine + Intake + headers + gearbox- 78 replies

-

- 13

-

-

-

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

So old engine is now out of the car, so time to work out what it weighed. 144.91 kg - 3SGE Beams Gen 5 with lightweight flywheel (6kg), Exedy HD clutch, sq engineer Alternator bracket, echo/yaris alternator, sq engineering slim line water housing, water lines at back of head chopped, top cover chopped, altezza engine mounts, no oil, no intake, no exhaust. 38 kg - J160 with cross member, gear lever + knob, slave cylinder, no oil 9.48 kg - Stainless 4-2-1 Headers went back just past firewall 7 kg - Blacktop throttles, SQ Engineering Adapter plate, Toda 75mm trumpets, Standard Altezza rubber spacer, and standard Altezza engine to rubber spacer plate, steel bracket for quad vacuum manifold, vacuum manifold and idle up valve and piper cross filter and fibreglass backing plate. So in Total: 161.39 kg Engine + Intake + headers 182.91 kg Engine + gearbox 189.91 kg Engine + Intake + gearbox 199.39 kg Engine + Intake + headers + gearbox I honestly wasn't expecting it to be that high. -

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

No plans at this stage, will see how we go when we get to it, the steering arms are T3 so have a bigger center, so i'm sure we will work something out. Ouch, that's an expensive mistake! Yeah it's not just the pans, but the pump, container and fittings. And because it's all over $1000 you get stung with GST + Duty importing it, so your looking at upwards of $5000nz to do. -

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

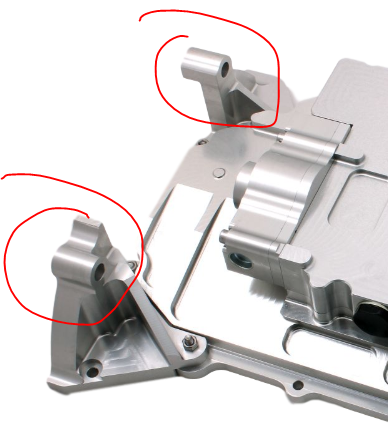

I was running the front sway bar (which does the castor on the lower arms) 25mm lower, this is the easiest way to reduce the diving as it reduces the leverage, it's relatively easy to do as you can see below, so doesn't have to be a massive amount, any little bit will help. For me as I'm moving to a front rack it makes sense to move to the escort style anti dive, but otherwise the above worked well. Yep, dry sump was considered but just too pricey, a single stage wet sump is also an option, but the pulley is really expensive for it. However the only dry sump i saw with the correct mounting was the AT Power one, all the others appeared to having the same problems as the other pans. vs Daily Engineering one. -

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

Now that's what I'm doing, however if you wanted to run it over the cross member you might consider the following kit from K Miata. https://kmiata.com/collections/kmiata-swap-parts/products/k-series-miata-oiling-solution Or a Ktuned Steel Oil Pan and chop it up. https://www.speedscience.co.nz/products/k-tuned-steel-oil-pan-k-series Or a Moroso Pan https://www.speedscience.co.nz/products/moroso-baffle-sump-w-trap-doors-k-series-incl-k-swap However be very careful as the standard cast aluminium oil pan has the bottom 2 bolts for the gearbox. And also this massive brace back to the bottom of the very solid pan. Replacing the pan with one of the above means you can't bolt the gearbox at one of it's highest stress points, i.e it want's to separate right at that point. Basically your going to fuck your main bearings with the forces on it. So that's out for me, if I need to I will cut up the existing pan. In terms of baffling, I have some pics of a Spoon K20 sump baffle, and @Roman did a great write up on improving the BEAMS sump to match the TRD version which I saved, so a combination of both should work out well. Main thing is stopping the oil freely going up the oil chain under braking. Here's a standard sump, which is just a dumb design: -

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

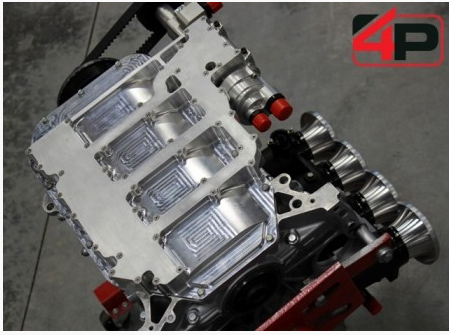

Next up was the oiling. The K20a from the Accord Euro R runs balance shafts off the oil pump in the sump. These are to reduce vibration at lower revs, the Integra and Civic versions don't have these so it's safe to remove them (or just buy an Integra/Civic engine to begin with...). The downside is they take up a huge amount of space in the sump, they sap power(supposedly about 9whp) and they weigh 5.3kg alone! So it's a win to remove them all round. Luckily you can raid the Honda parts bin, so the standard thing to do is to buy an Civic FD2 kit to replace them, it comes with a new oil pump, oil chain, oil chain guide and windage plate. So many stores sell these kits as the K24 engines also have them, so it's a pretty easy change. One thing is that the K20a oil pumps are known to not be great over 9000rpm, so a lot of stores are now porting the oil pumps which frees up a little bit of power and makes them safe to 10,000 rpm. I ended up going with one of these kits as it ended up cheaper than a stock kit, one thing to note is the K24 engines and the Euro R version of the K20a need the housing of the oil pump modified for clearancing, it's nothing major and the kit i brought already had it done. I brought the kit from kmodperformance with it being the K24a2 version which bolted straight up. https://www.kmodperformance.com/collections/bottom-end-engine-parts/products/kmod-oil-pump-kit?variant=9987006988324 Now that frees up a lot of space! Now a few might be wondering how i'm going to fit it in the car even with that sump. The plan is to put the steering rack on the front of the engine cross member (escort like) narrow the cross member and position the engine entirely behind the cross member or as far back as we can get it. There are a few challenges with this as I have a roll cage bar going through the dash, so would like to not have to alter that and it may put the gear lever quite a wee way back, but will deal with that later. It has some big advantages however, obviously the position is great from a weight balance point of view, but it also allows me to run escort style anti dive bars (tied from bottom arms BACK to chassis), which make a huge difference in braking. Yes there is going to be a lot of chopping. -

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

So having picked the engine/gearbox it was now a case of bolting them together. This is relatively easy, all you need is an adapter plate, and an off the shelf flywheel to suit. So what you are looking for is K2F as a search term as it's a pretty common conversion. I ended up going with a JSPFab adapter plate as they were half the price of everything else once landed, had all the hardware and had good instructions. https://jspfab.com/collections/f-and-k-series-engines/products/jsp-billet-k-series-to-f-series-transmission-adapter They were great to deal with. To fit I needed to clearance the adapter plate to the head (for k24's you don't need to do this as the block is taller), I chose to clearance the head vs the adapter as the top of the adapter is free floating on the engine so I wanted as much strength in the plate so the gearbox didn't move around. A little bit of chopping some unused bits of the head and it fits great. This keeps the engines 15 degree right hand lean. Next was the flywheel, the most common one found in many stores was the ClutchMasters FW-K2F-AL http://www.clutchmasters.com/aluminum-flywheel-fw-k2f-al/ It weighs about 4.5kg, and has a replaceable friction surface which is awesome (no need to resurface), it also came with all the clutch plate bolts. This allows any standard S2000 clutch to bolt up, which gives a lot of options, the downside is S2000 clutches are more expensive than say a K Series. -

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

Yep, had seen those, I will be doing custom sump baffles. -

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

So next question is what Gearbox to use? J160 + get adapter made to suit. MX5 6 Speed BMW S2000 AP1 S2000 AP2 There are pros and cons to each I ended up going for the S2000 AP1 gearbox. Here's why. J160 has no aftermarket internals support, basically you stuff one, you throw it out and replace it + cost to make adapter + flywheel. MX5 basically same as J160. BMW, I stay away from Euro so no thanks. That left the obvious choice of the S2000 AP1 or AP2 boxes. Pros: Lots of adapters from different companies to bolt them up to. Sold in the USA, means Honda OEM parts are easily available, I can buy bearings, gears, syncros from any number of stores. They were built for 9000 rpm, K20a will go to 8800rpm so a good match. Known as one of the best shifting boxes out there. Main difference between the AP1 and AP2 is the ratios and the AP2 run carbon sycros (AP1 got upgraded to these later on so can buy off the shelf from Honda for them now). Note the S2000 box is not another version of the J160, it runs a secondary shaft in the gearbox and runs another set of gears to alter the output ratio. Here's some comparisons I did of the ratios (I run 4.55 diff at present and have 4.3 spare) I'm currently hitting rev limiter before end of the straight, so something slightly higher will be good but not by much. I went with the AP1 as you can see it gives me a bit more room at the top end, and i can go to 4.3 which is a common AE86 ratio if required. All of this means a critical speed for the driveshaft of around 9354rpm, which is fairly high. Getting a S2000 box is a lot harder then getting the motor, but i managed to find one and have had it stripped down, and going to replace bearings etc.- 78 replies

-

- 13

-

-

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

Yep, oiling is a big issue on the K20a made even worse when you turn them around as under braking all the oil goes up the cam chain area, I have a plan for that though.

.jpg.385849fe7614f6febde6b51805bedebe.jpg)