-

Posts

2,354 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Kimjon

-

For whatever reason these brakes were a cunt to get working. This tool helped, but it seemed to suck fluid through, yet brakes still soft as. I put it down to an air leak around nipple thread? But after an hour of fucking around, I got the results I wanted. Everything is working fine now. Got a handy tip from @Raizer on using ptfe tape to seal the nipple. I'll definitely try this next time.

-

I'm trying to make one working Vespa out of 4 parts bikes. Pretty much there now, just things like the brakes and complicated internal cable system are fighting me. Tried bleeding the brakes the conventional way, but its still not getting a firm pressure on the hand controls. So I've ordered a sucky sucky brake bleeder to pull the fluid from top to bottom and hope that works? Fingers crossed the sucky sucky pulls whatever is stuck out of the lines... Aside from that, it's turning out to be a very sexy looking scooter, in its tuxedo colours.

-

- 543 replies

-

- 11

-

-

I love my cabinet. I guess my expectations were low, so it's done better than I thought it would. Sure, if I did it for a living - this would not be the right tool for the job, but for my needs it's fine. I've got it mounted on a tool trolley, so its a comfortable working height. Vacuum cleaner is hooked into the rear, behind a baffle. I tried the side port and this was less effective. No dust filter, but not having issues there. Light is shit, but I wheel it outside and use free light of the sun. Keeps dust out of shed too. May look at adjusting the feed situation, but my compressor is small, so maybe the constant breaks waiting for air allows the media to keep up? I did load it up nearly to the grill, so it's chocka with media...so this can't be hurting available supply.

-

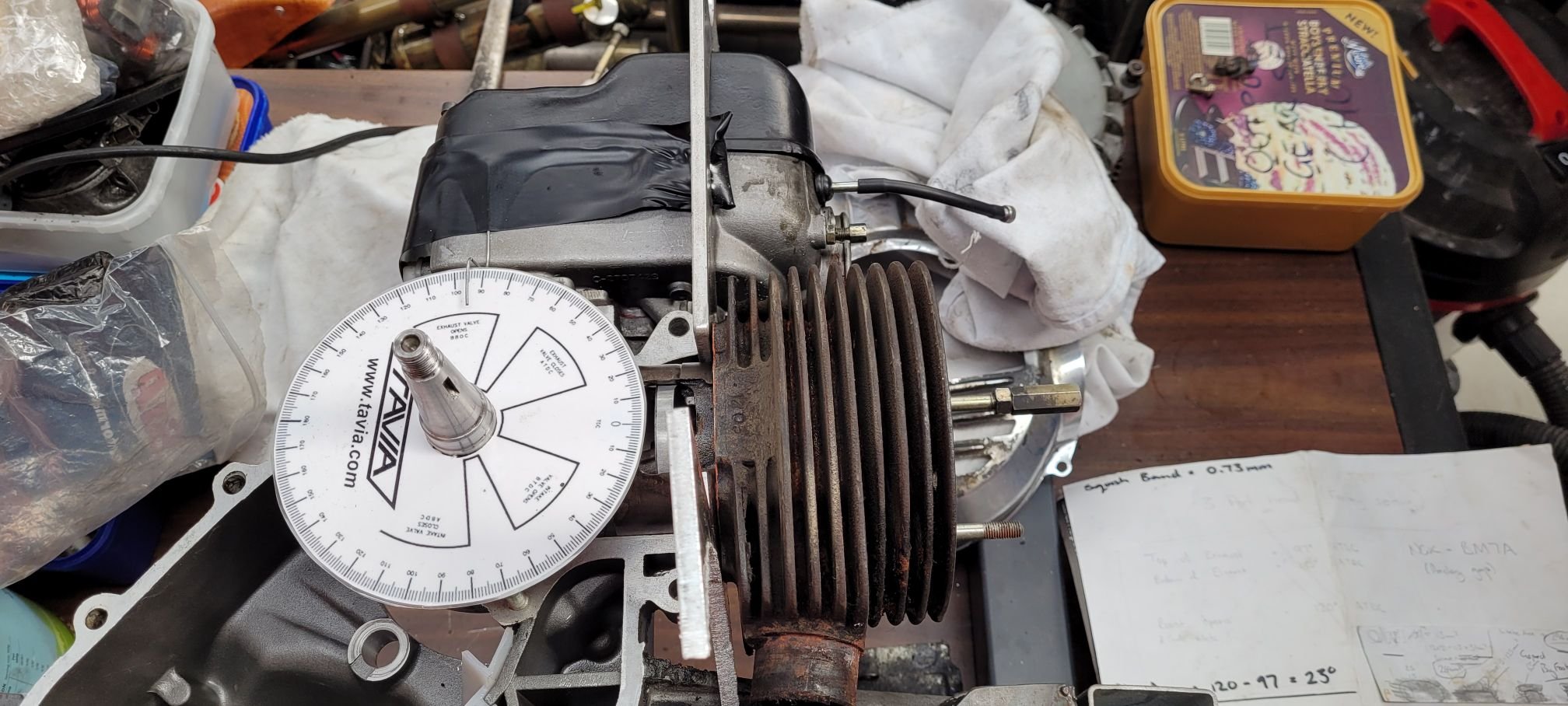

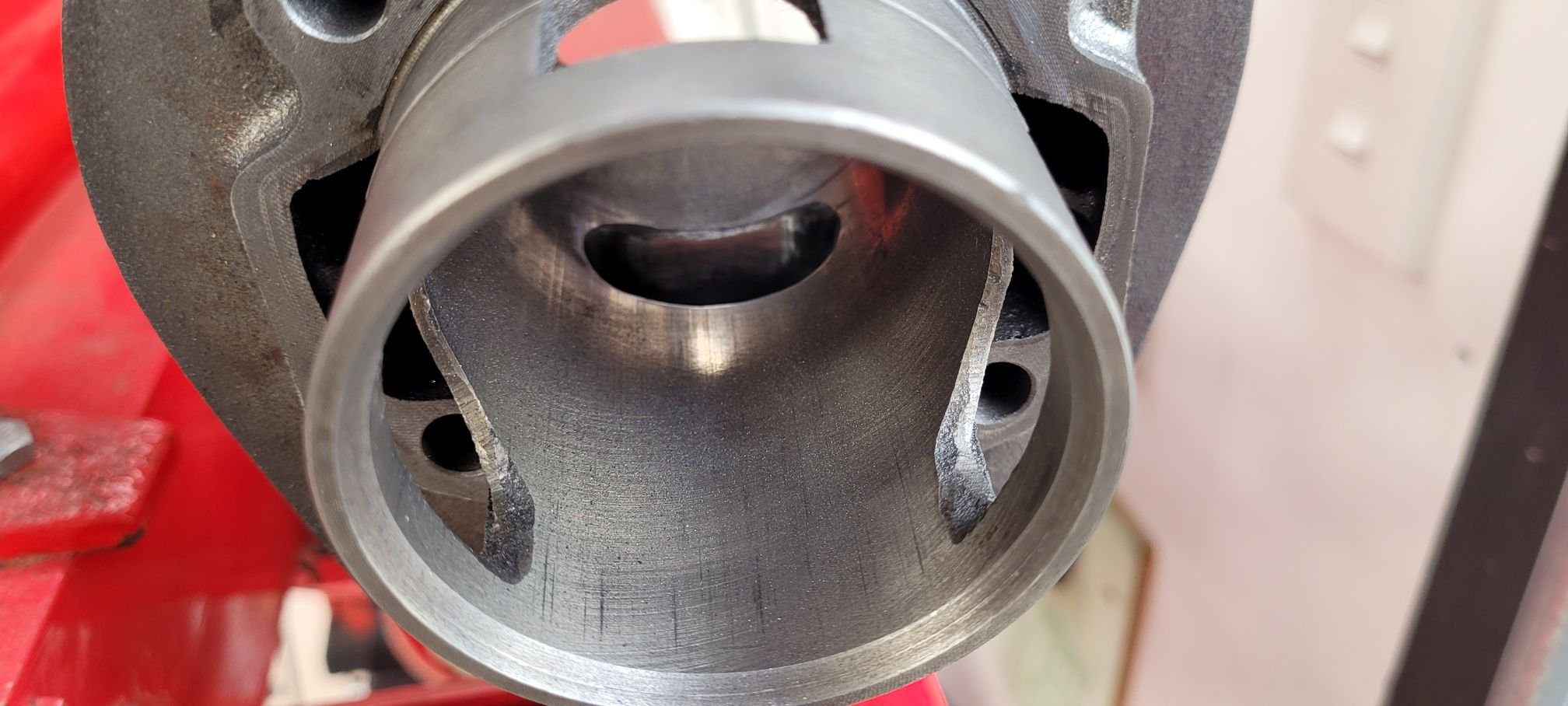

V2.0 3mm base spacer, 3.5mm milled off top of cylinder. Exhaust raised by about 3mm (6mm total if you add spacer height). Gives something like 130/180/30 timings. The blowdown of 30 was bigger than intended. Revs hard, like I'm scared of it turning into a grenade!! Pulls hard in 1st, 2nd, 3rd...but 4th gear sucks with 23T clutch sprocket as its a big jump and lands right in a flat spot in the power range. So after all that, yip...I put the other more mildly ported cylinder back on. Torque wins. The v2.0 probably made more power, but it had to rev high to get it and it just felt like I was thrashing it every gear. The v1.0 with more torque doesn't work as hard and goes faster being able to actually pull 4th gear.

-

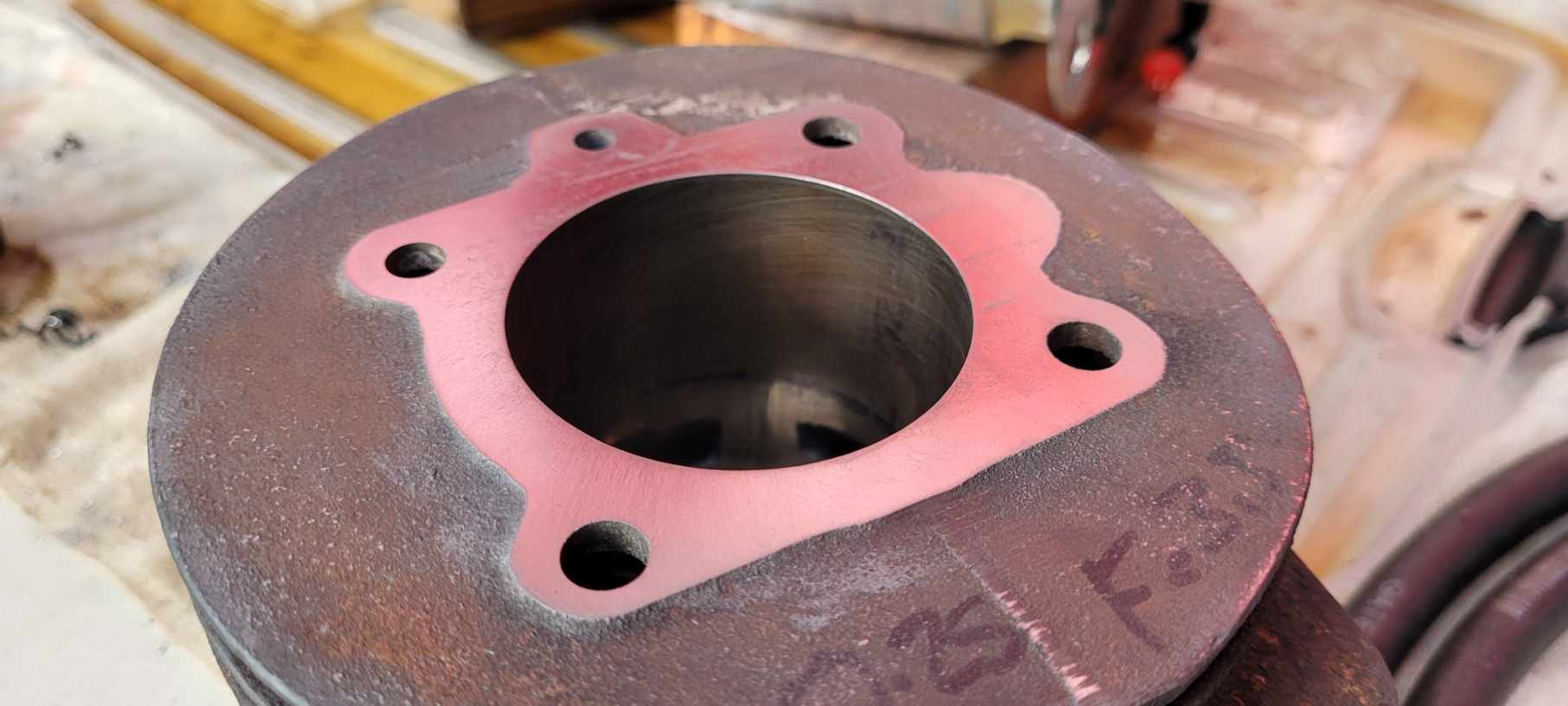

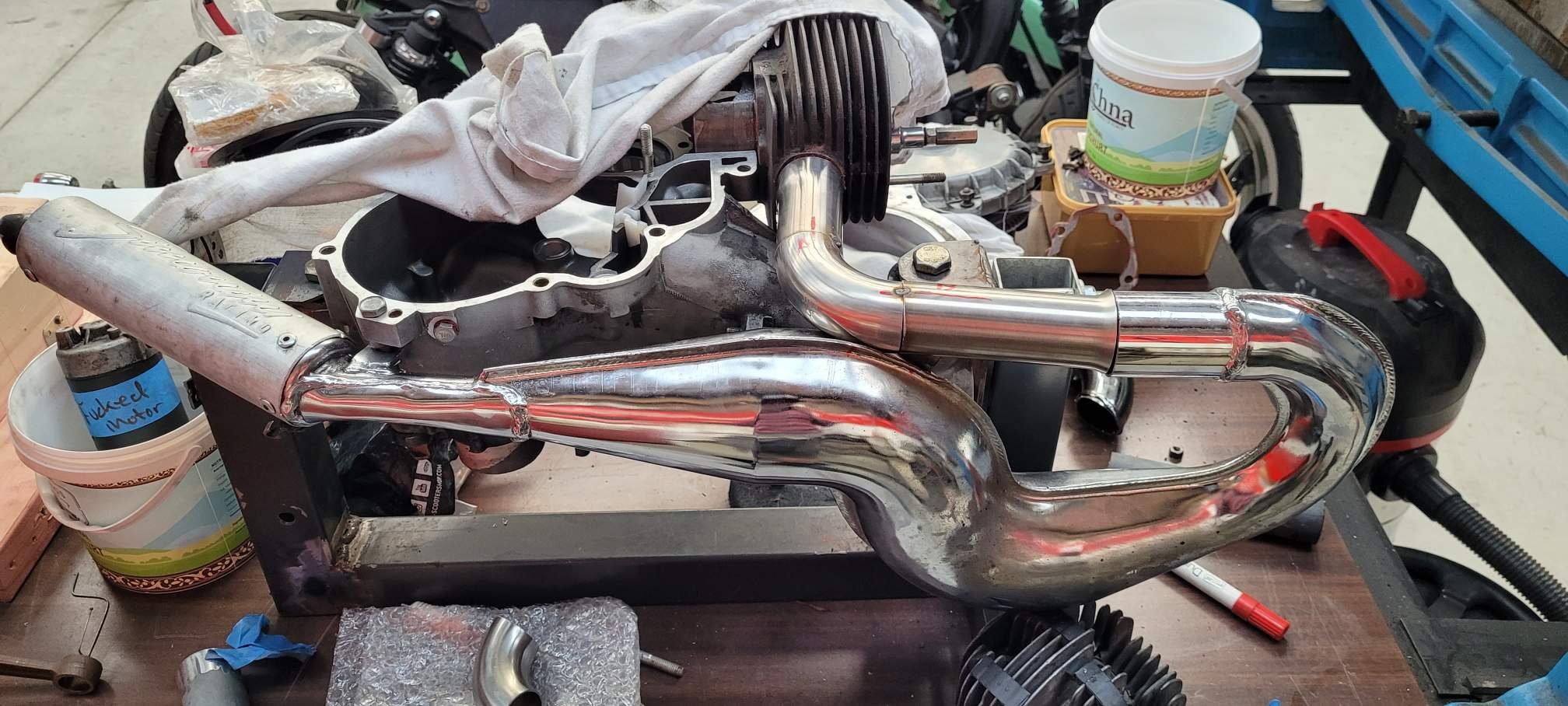

Milled cylinder down to get squish from an unreasonable amount (couldn't even measure it, as it was so large). Finished product. Ported the cylinder too...be rude not to while it was apart. All done with motor left on bike Bit smaller than I was hoping for (1.2mm was the goal)...but full send. Took it for a 70km trip. Performed flawlessly. Fuck yes!! Power is awesome thanks to new sito exhaust, porting, carb jets etc

-

- 299 replies

-

- 14

-

-

Only the train spotters will notice, but the PX series has a plastic foot mat on the tunnel. I've always had a hard-on for the early wide frames, which have a couple (aluminum with rubber) channels like the floor board has, but on the tunnel as well (no ugly mat). So I've kinda copied the early models, where I reckon they got it right all those years ago.

-

I managed to find the period correct guards, so pretty stoked about that. It's now with my sandblaster...so hopefully I'll get it back in a few weeks time, blasted back to bare metal and primed. The body is really good on this one and I've been over it with a hammer and dolly, so will only require a minimal amount of body work once I get it back.

.thumb.jpg.60b547d7ca35c3eb4d7232e6d4c77357.jpg)

.thumb.jpg.29bd66e4d321e969359fd03e2a13ae33.jpg)

.jpg.32b1822e3b5692d01509eecad89e9fa6.jpg)

.thumb.jpg.a422f13d61275286c9ce1d4cb061b010.jpg)

.thumb.jpg.32dcb5d9debf7ddbe32102282e2cd5ef.jpg)

.thumb.jpg.c9442026ee48d2194893bee6341f74cf.jpg)

.thumb.jpg.53f6dede94f73b9d126c237271ab2547.jpg)

.thumb.jpg.10b227a0bd89d103251d3d323c09f523.jpg)

.thumb.jpg.4ef696b526ea4870208992c0e0fc1937.jpg)

.thumb.jpg.e632aab52afc9ccc125761eab4b1c832.jpg)

.thumb.jpg.acd76f7ff3d0b34b01674fdd75e1367b.jpg)