-

Posts

1583 -

Joined

-

Last visited

-

Days Won

1

Posts posted by fletch

-

-

7 hours ago, SOHC said:

not in a major hurry,

if anyone was scraping some heat exchanger from some factory or some big refrigeration thing might have it

We just pulled out some heat exchangers out of a large compressor that have a bundle of tubes like the ones pictured.

What pressure rating do you need?

How long?

They are steel tubes. Slightly corroded hence the replacement.

I'll see if I can chop some out for you. Our company has one of those policies that it all has to go to scrap, but I'm pretty sure some of the tubes had to be 'cut' out to get the coolers out...

-

2

2

-

-

On 20/11/2014 at 21:29, fletch said:

heres my brake and combined ankle guard

i put it on roughly to see if it was sweet and it was so i have not touched it. the nuts on the stud are supposed to hold it over the clutch but they vibrate loose. it seems to stay in the perfect spot somehow even when the nuts fall off. can lock the tyre at 60ks with minor effort!

around 35 nz pesos shipped

Can lock the wheel with 1 finger on the brake lever at 75k.

An improvement on the photo above is a spring below the band to pull it open to stop it dragging on the clutch. It was not too bad as pictured, but the spring helped generate a bit less heat.

https://m.ebay.com/sch/i.html?_from=R40&_trksid=m4084.l1313&_nkw=4+inch+band+brake

-

4

4

-

-

Yea will do tomorrow. Its buried under some other important stuff..

It was $8 from ebay. 4 inch band brake i think. I'll find a link

-

6 hours ago, Yowzer said:

GX200 with a GX160 head, bigger carb, aluminium flywheel, cam, and exhaust and you'll be rocking like a boss

Gx200 titan. 160 head with 2mm shaved off it. Higher ratio rockers. Aluminum flywheel with a field key for more timing. Straight pipe exhaust. Governor removed and a few jet swaps and I can do 75kmh on mine. 10t front sprocket 44 rear.

And I'm no lightweight so it's making plenty of power.

-

3

3

-

-

Lol China factor.

Might as well chuck some higher ratio rockers in for a bit more grunt while your at it

-

1

1

-

-

Think I saw you heading south last Saturday. Can't remember where. Just remember the car.

Looks good!

-

Old balancer no longer true/slipped around a bit on the rubber?

I have seen it a few times on various old cars. Need to take out front spark plug and stick a bolt in and find true tdc.

/saw a cool video of some diesel bogans and they had a magnetic degree wheel that they just slapped on the balancer.

Also have my own problems sneezing out the carb. Think its air leaks from worn throttle shaft or the flogged out hole

-

1

1

-

-

Are you just replacing the rod and piston? I have a 4.5 crank, rods, and pistons you can have. I believe it's a bolt in into the 4.1 block.

-

1

1

-

-

yea, start at the highest nipple and work ya way down so your not pushing air down.

-

1

1

-

-

needs a bleed now

-

1

1

-

-

Can you shorten the rod from the pedal to the master a bit. Sounds like it needs to go back a bit to let the pressure out.

-

2

2

-

-

22 minutes ago, niswhale said:

Been looking at one of these, https://www.arcweld.co.nz/itemdetails/Hugong-Carimig-200Wd-Welder---Euro-Connect/3419.aspx

Duty cycle looks good, also 3 year warranty.

Anyone had any experience with this brand?

One of our guys in the heavy fab shop has a hugong something like that ad. He uses it for tig and stick. Usually wound right up. For hours at a time.

Has had a few minor issues. He purchased through duroweld in new plymouth.

The 3 years commercial warranty was the main selling point. Any issues he just takes it back and they have sorted it.

-

2

2

-

-

3rz 3rz 3rz!

I helped a mate turbo one in oz. It was silly at 7psi.

There is a motor in a shed up here that would be cheap for a spare if you needed it

-

Check with robinson instruments in auckland. An inline gearbox from them might not be that expensive.

As for the meshing, most of the nissan boxes can have a bunch of different plastic speedo gears all running off the same gearbox gear.

-

3

3

-

-

123 slightly(like 1 tooth) lower than the petrol. 4/5 the same.

The diff is the difference.

Edit- i converted one to a rb25 bellhousing for a drifter mate and told him the ratios would be slightly different and he said he could not tell.

I suppose 400kw is going to turn the wheels no matter what. Haha

-

21 hours ago, fuel said:

if staying N/A then the gearbox option should be much easier.

The Triton R5M31 would probably be the easiest to do, otherwise you could just source the bellhousing from one and fit to a Toyota box.

I'm considering using a Nissan 350Z/370Z CD009 6-speed box as they are cheaper to find than a T56 that I was originally going to use, plus they shift much better and are the same size.Was going to suggest the 6 speed nissan box. As it seems like your going to make a bix fit, you could go a nissan navara diesel 5 speed. They are same as rb25 turbo skyline, so strong, but also 80mm shorter. Most of them had better synchros than the skylines too.

Can be had for 350-400 if you look around

-

1

1

-

-

We buy a lot of pipe/steel/ss from azmuss in new plymouth. They have been dominating all the other suppliers for price.

Pretty sure they are in h-town

-

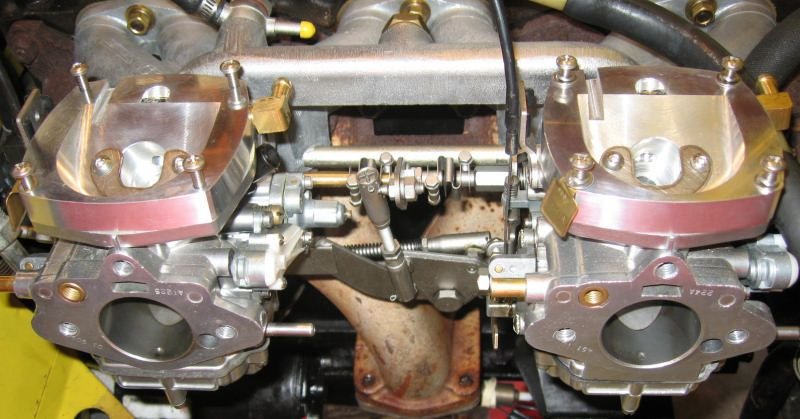

On 01/09/2018 at 11:07, mjrstar said:

Anywhere that has potential to pool fuel is total poison to tune. I had an encounter with a supercharged pinto which was injected pre supercharger.

Could tune it fine on song and at idle but the transition off idle when it gulped the pooling fuel was a disaster and the idea eventually was scrapped.

Get those injectors as close to the head as possible...

the runners are pretty short. -6cyl datsun

On 01/09/2018 at 11:13, scooters said:@fletch Best bet is after that throttle blade bud.

The fuel is just going to hit that blade at idle and cause you endless drama.

although I can see what your trying to do (hide the injector) Most other set ups are after the throttle for good reason.

its got to be better than a SU carb right? at idle the fuel already dribbles past the throttle plate

On 02/09/2018 at 08:45, yoeddynz said:@fletch You could point the injectors up from underneath after TB so then hidden? (but if this is going into a trumpet? then its a no go unless one wanted a melted mess of injector all over exhaust manifold..)

i hope to turbo it so much heat, there is a ton of room in the top of the hat to put the injectors. putting them up from below would work too, but would lose the carb heat circuit

On 02/09/2018 at 11:30, BobbyBreeze said:Will be fine pre throttle I think but I would run sequential with a big enough injector you can get all your fuel in within the intake valve event. Transient fueling with wall wetting/pooling issues might be a bit more varied when cold. Still gonna be a ton better than a SU carb haha.

i am fitting 2x 550cc ev14 short injectors into each carb. there is a good heat circuit through the carb floor, and intake floor.

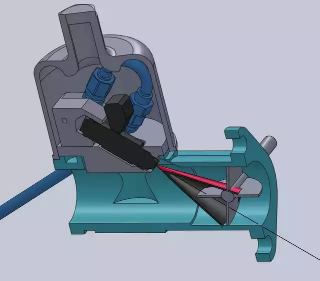

here is a diagram of some filthy U.S TBI carb, im doing the same thing but sideways.

heres a kit for a similar carb

-

Something like this.

-

4

4

-

-

I dont want to put them in the manifold.

I figured tbi would be at least a bit better than carb due to the ecu part.

-

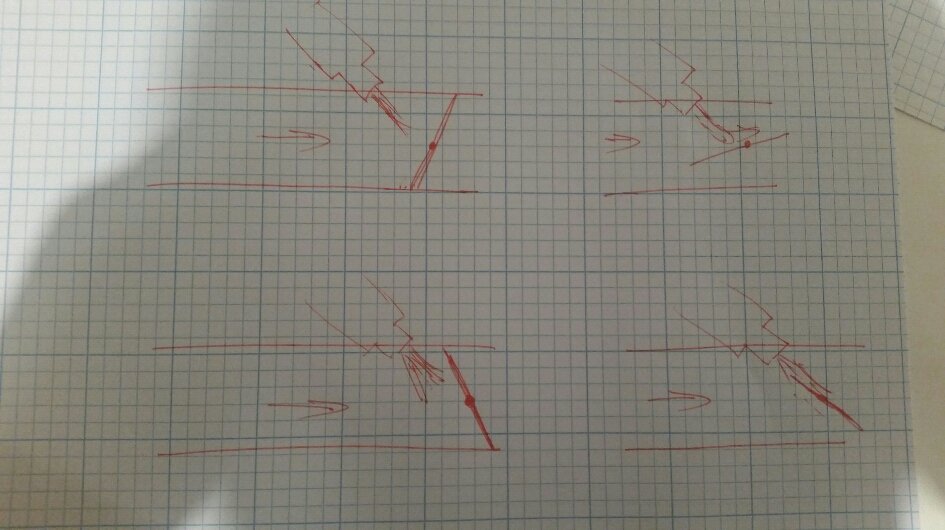

See the chicken scratchings below.

I am about to put some injectors into some carbs but have a query about placement.

Top drawing shows the fuel spraying on the throttle plate and as it opens it gets well smashed on the plate for good mixing, but ends up mostly going over the top above 50% throttle

Lower one is stock throttle plate.

I think at idle it will pool at the bottom of the plate?

The injector location is my only option unless i can find the injectors i saw once that have a lottle 45degree deflector thingy on the end of them to allow me to mount them vertical.

It appears to be easy to flip the plates so no issues with changing it.

Any ideas welcomed

-

- Popular Post

- Popular Post

So this made it to swapmeat and back, but i needed to change the hanger bearing as the driveshaft needed some more engagement in the back of the box, and the rubber was flying apart due to it not being designed to move with the suspension.

I made a new hanger bracket to fit the later bearing and a spacer to lengthen the driveshaft.

it took a few test fits on the hanger to get it right, but i got it fitted up Wednesday night and made it to chch today.

win.

except, somewhere north of amberley i smelt what i thought was rubber grease, and 10 minutes later i pushed the brake pedal and uh oh.

made it to the thieves at safe r brakes in chch 5 minutes before closing to get the required caliper kit and limped to the inlaws on the handbrake.

the front brakes are dunlop calipers as fitted to late 60s jags and aston martons. yes thats right, british. ughh

so thats my saturday sorted....

-

11

11

-

2

2

-

1

1

-

update

got a 330 diff, got a 3.9 head out of a r31, threw it together with some bearings and seals and thought i would just chuck it in bro.

well, it would appear that the 130 cedric, being the first if the nissan/datsun combo, has metric motor and box, imperial everything else.

so now i have a 330 diff, with 130 brake cylinders. and 12mm studs on the back wheels, 1/2 inch on the front.

I was going to run the 330 slave cylinders, with an imperial to metric hose, but they were only 3/4 cylinders vs the 1 inch of the 130 and since nobody has ever said, 'you know what?, i think i need less brakes on my datsun' so i had to swap the cylinders and lines. This was made harder by the fact that some old vice grip wielding barry has previously attempted to pull the fitting out of the cylinders and now they are round....

Next up, springs and blocks. easy. Except i fucked up bit and ordered the wrong rear shocks so i had to run these impressive specimens i found in a box of parts. they will do for now...

I then decided that i had 3 weeks until my chch/hanmer roadtrip, so i would chuck in a 4 speed column change box to go with the 3.9 diff. How hard could it be right?

Well the sneaky fuckers changed the style of gearboxes after the 130. the driveshaft was flanged at both ends.

and it was longer..

no problem, @- i5oogt - found me one that he had been aging in a paddock for a while.

except the rear half was too short so it wouldn't fit the hanger

and the hanger was way different.

no problem, i can fix that

The box being longer hit the roof of the tunnel so i made that fit too, but i didn't take any pics as you dont need to see that

The the fucking linkage didnt have enough travel as it was only for a 3 speed.

Lucky i have some spare parts

I had to mod one of the levers to make it have more throw. I found a welding rod in a puddle and dried it out a bit and it did the trick.

Photo taken in potato mode so you cant see the quality

bonus pic of custom racing shocks

-

6

6

-

-

Can you reach it with a welding rod?

Get your mate on the power switch of your arc welder and jam a 3.2mm rod onto thw end of the axle with plenty of juice.

1/2 a second after it strikes your mate turns off the power.

Then pull axle out.

Practice on a bit of steel to get the best time/current for good attachment.

Not great on the bearings, but it will get you going.

-

3

3

-

1

1

-

bonkas tired old Lancer EX - Engine Swap/Build Thread

in Project Discussion

Posted

You will need that water return to allow water to circulate while it warms up before the thermostat opens. Otherwise you will get hot spots where the water will boil