-

Posts

789 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Downloads

Events

Gallery

Everything posted by sr2

-

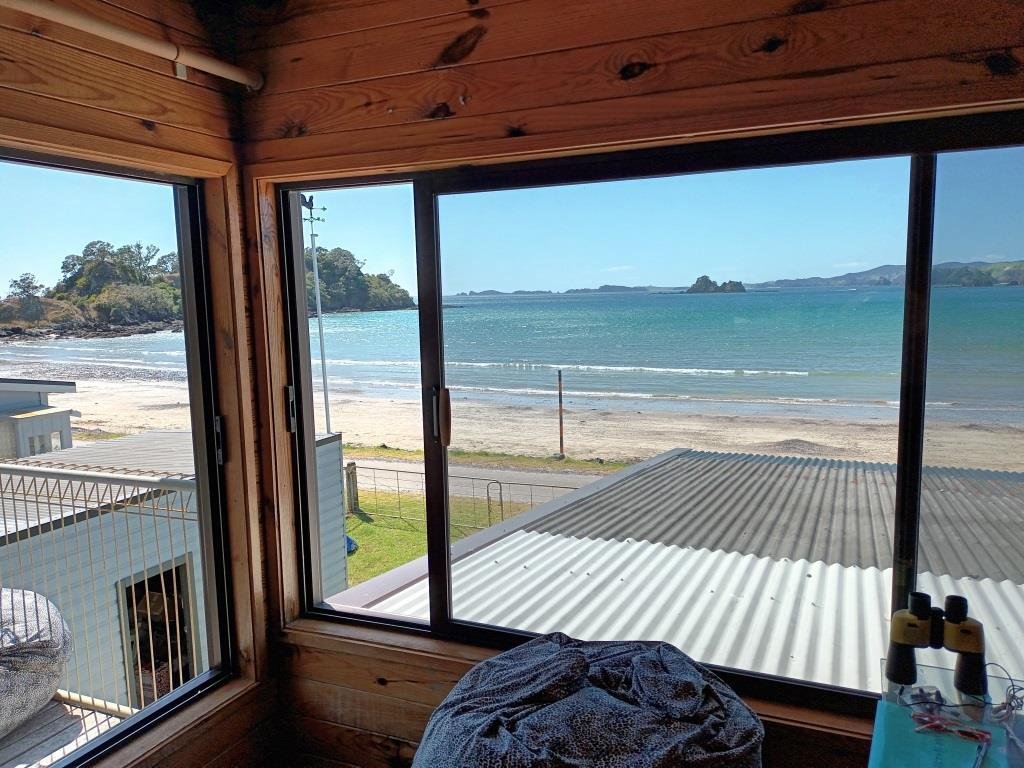

New Year came around real quick, the view from the batch is still as good as it gets. The fishing however was not all that was promised…….. 1st & only fish on New Years day went back for a 2nd chance! (The trusty crew named this one Cyclops).

- 185 replies

-

- 12

-

-

-

Guys, I'm just loving this thread. Totally impractical solutions for problems that never existed in the first place tick all my boxes. Go the mighty 4AEG! (Merry Xmas everyone).

-

Great work on a great project, well done. My system with rust repair is go deeper than you think you need to while never cutting out a panel you haven't already duplicated. CRC cold galv. makes a great budget weld through primer and Penitrol (as many on here will attest) is as good as it gets.

-

And now for some handy tips from the world famous sr2 man cave; que the cheezy music……..!. What could possibly go wrong! “WELDING 101 FOR OLD BLIND BASTARDS” Step 1: Spend 20 bucks one of these bad boys from your local safety shop or welding supplier. ( An “Omnimag” welding magnifying lens) Step 2: Barry it up inside your helmet. Step 3: If like me you still struggle to see where to start the weld with your self-darkening helmet down, fit LED lights. Step 4: Most importantly a steady, steadfast hand is required for welding at all times. This is best achieved through a simple process of self-medication. Yes you do look a little stupid and yes it does scare horses and small children but it works for me!

- 185 replies

-

- 22

-

-

-

-

Welded a bent strip to the capping piece….. And trimmed it to fit. Happy with the result. A quick easy patch…. And we’re making slow but steady progress.

- 185 replies

-

- 22

-

-

The inside looked somewhat daunting… Started cutting until I found good metal and then gave it a good coat of CRC Rustkill followed by galv primer.…. With the aid of more high-tech CAD (cardboard aided design) I started cutting out the replacement panel. I have to say a metal cutting band saw is my choice for freehand cutting of sheet metal; you get none of the distortion you get when using shears. The panel fitted well so we stitched it in.

- 185 replies

-

- 17

-

-

SR2’s 1947 Vauxhall “Rigamortice” Discussion thread.

sr2 replied to sr2's topic in Project Discussion

Cheers mate much appreciated. Will let you know. -

SR2’s 1947 Vauxhall “Rigamortice” Discussion thread.

sr2 replied to sr2's topic in Project Discussion

Thanks mate. Some decades before I discovered more lucrative careers existed I was trained in stick & gas (gas was always my forte). I am an old guy with bad eyesight, but I know what a strong weld looks and feels like. (Youthful exuberance is still no match for old age and treachery!). -

Time to get started. I bought a quarter sheet of 16 gauge (1.6 mm for all you millennials) zintec mild steel sheet – great stuff to work with. I figure this part of the project will be covered up for at least another 70 years so the emphasis needs to be on strength and getting all the rot out. Thought I’d tackle the worst part first. I was going to have to repair the inside of the rail first so gave everything a good wire brush clean up and checked the chassis mounting threads we in good condition. My philosophy with complex shapes is to keep the component’s small and where possible never cut rusty bits out until you have made the replacement part. Good old fashioned “meatball surgery”. Having the chassis mounting bolts made things a lot easier. A tickle with the angle grinder…. And I’m left with the right shaped capping to weld in when I’ve finished repairing the inside of the rail.

- 185 replies

-

- 16

-

-

Closer inspection confirmed that getting the car on its side was well worth the effort. 70 plus years of being covered with a chassis rail has left me with a few rust repairs to do. Strangely enough similar to the chassis the starboard side is far more corroded than port, is there a dark chapter in Rigamortice’s chequered history that I’m unaware of? At least the years of “splash lubrication” from the diff has kept the rear underneath relatively rust free!

- 185 replies

-

- 11

-

-

Next problem was how to support each end? It was then I started eying up my engine stand with evil intent….. Raided the scrap pile to make a new vertical upright. And the old girls big arse end was suddenly sitting pretty. I settled for using my engine crane to hold up the front of the body – a little sketchy but hey it was all I had. Time to get the old diff out, love those lever action shocks. With the rear end out everything felt a little top heavy and I was a little worried that the engine stand at the rear could tip over. Found a piece of RHS that slid into the frame… Welded it to a piece of heavy angle from the now rapidly depleting scrap heap…. Found a castor to attach to the end and … Voilà…. The old girl’s safely on her side. I knew there was a reason I’d kept those old fenders… Time to go fishing……..

- 185 replies

-

- 17

-

-

Each to their own, I guess I will always be an automotive anarchist. On a different subject I heard there's a new policy on stainless steel brake lines? I have someone with an imported car that has stainless brakelines that they are looking at getting complied/certed; I've never seen the point of using it, it's a royal pain in the butt to bend and even worse to flare.

-

Mate, reality is that all we both bring to the debating table is only our opinions. We may just have to agree to disagree (I suspect we may be kindred spirits).

-

No offence intended mate (I'm in awe of the contribution you make to this MB) but isn't that kind of a "I'm right because everybody is wrong" argument? You probably need to substantiate it with at least your own qualifications.

-

Having dealt with many engineers over the last 3 decades it's not rocket science compared to what the average mechanical engineer deals with on a daily basis?

-

You might find I'm more on your side than you think. I think any suitably qualified engineer should be able to judge if a vehicle is safe or not. The LVVTA has cornered the market on what is safe and what isn't. Most likely started with the best of intentions, after nearly 30 years it has morphed into a monopoly run by a group of private individuals who (if I was a cynical man ) one could claim that their primary objective is to justify their own existence.

-

Time to start pulling doors and boot lids off the old girl to lighten the shell for flipping her over. Love the way the doors use egg shaped brass balls for hinges. The boot floor made out or tongue and groove, can’t I.D. the timber but I’ll be using it again. Next problem was how to get the old tart over on her side. I didn’t have access to a rotisserie but I did have a pile of scrap that included some old, heavy scaffolding. Had a piece of pipe longer than the body & “guesstimated” the centre of gravity. Managed to hang the rear off the bumper mounts (they were real bumpers in those days). Tacked some tabs to the rear floor. (God I hate trying to weld galv!). Decided I could mount some temporary brackets to the front seat mounts so pulled out my much treasured collection of old imperial taps to clear out the threads. Have to point out how crazy it must have been with the shortage of fasteners after WW2. Look at the random collection of threads that holds the front seat down! Inside mounts finished. For the front of the body I used the bolt holes from where the chassis braces attached to the body and held things together with a scaffolding clamp.

- 185 replies

-

- 20

-

-

I'm not suggesting it be the hands of a government department (shudders at the thought!). What I am suggesting is that allowing the law maker and the law enforcer to be the same private entity is anything but democratic and has resulted in the current system which in the opinion of many of its clients has become user unfriendly self perpetuating law unto itself. We are up in arms about supermarkets in NZ being allowed to become a duopoly (at the expense of food prices) and yet we allow the certification of modified vehicles being controlled by one private group only, operating in a totally non competitive market. Bottom line is unless its the LVVTA you cannot have an engineer (no matter how qualified/experienced) cert your car. Surely that's one huge monopoly? Edited to say: enjoying the debate but it probably needs to be in it's own thread.

-

Either way my point is the control of it is in private hands.

-

Yes word had it they presented a very convincing pitch and appear to have been the obvious choice to manage the repair certificate process. Full credit to them, (although I've yet to hear the MTA or the CRA's position on this). I've had no issue with the cert guys I've dealt with, most were car mad good guys like the rest of us. What does concern me is having a privately owned company not only implementing the certification process but writing the rules and regulations we are legally obliged to adhere to. It's both unprecedented and unchartered territory, I can think of no other privately owned regulatory body in NZ that has this level of autonomy.

-

Yes I've had considerable experience with the "angry little certification men" over the years with race car builds. If this was a Cert build as opposed to the restoration of a still registered pre 92 exemption car it would be far more structured (and the build thread would be a lot less fun to read!). I do however have my local WOF guy watching every step of the restoration process; as well as his business being (IMOP) the best automotive shop on the shore - he also specialises in compliance for imported classic cars. He's vowed to show no mercy if I stray from the restoration process. All parties so far involved are of the opinion that my dear old Rigamortice will live again, resplendent with both registration and WOF. Not wishing to get political but I suspect it is simply a matter of time before NZ is aligned with Australian VSCCS Compliance Certificates, as we have with electrical compliance, H&S, Fire Regulations, etc., etc. Having a privately owned business writing and certifying it's own legally binding rules and regulations is not only unprecedented in NZ, consensus of opinion in the industry is that it is unsustainable.

-

LOL, watch this space. (I have an ace from 1992 up my sleeve).

-

I love it, I could see the LVVTA having a prophylactic fit if you attempted the same in over regulated NZ. Long live automotive anarchy!

-

SR2’s 1947 Vauxhall “Rigamortice” Discussion thread.

sr2 replied to sr2's topic in Project Discussion

Thanks for the feedback guys, neatsfoot oil sounds like the solution for me. -

The seats came our easily, plan is to keep them looking scruffy and original. The leather is cracked and dry - any suggestions on how we should be treat it will be much appreciated by both Rigamortice and yours truly. Love the old leather, the kapok stuffing, the springs and the wooden frame – not a modern staple in sight.

- 185 replies

-

- 10

-