-

Posts

1,399 -

Joined

-

Last visited

Content Type

Forums

Downloads

Events

Gallery

Posts posted by shrike

-

-

2 hours ago, Roman said:

If you get canbus based wideband controllers, you can run one in each bank and read from them both.

Then this way you also dont use up any of your precious analog inputs, annnndddd its way more accurate.

G4+ is pretty good but honestly wouldn't recommend going older than that.

As the software is a bit more janky and you'll grow into some of the features that are in G4+ but not earlier models.

Idle speed correction isnt a huge deal really, but yeah get rid of the stepper based one.

You can calibrate any sort of IAT to work, same goes for MAP etc.

However I've got a favorite that has good fast response and they cost nearly nothing. Dont go paying $100 for an IAT sensor, they are literally just a 0.005c thermistor with some plastic bits to hold it in the air stream.

What kind of plug do those sensors use? are they a deutsch plug?

-

15 minutes ago, Roman said:

I quite like the Sumitomo plugs, just google "Sumitomo 12 way connector" or whatever and heaps of things come up.

Have used these to make sub looms on mine.

Do you have a known good supplier or are the aliexpress connectors ok?

-

Thread revival, have decided based on other reading milspec bulkhead connectors aren't worth the effort/cost and to just have a grommet I can pull loom plugs through etc

However been thinking about injector/coil looms that can be detached from the main engine loom

Does anyone have a recommendation on a male/female plug kit with pins?

Injectors

- 9 or 10 pin plug (1x12awg power split to 8x22awg, 8x22awg switched ground) allows for staged injectors

- 5 pin plug (1x12awg power split to 4x22awg, 4x22awg switched ground) and id wire two up and have two 4x injector looms so it doesn't need to be plugged in to start

Coilpacks

- 6pin (12awg power split into 4 x 20awg, 1x12awg gnd wired to head split to 4x 20awg, 4x20awg signals from ecu)

-

34 minutes ago, RUNAMUCK said:

Richard holdener recently ran a heap of tests with a GTX3584rs with I think a .85 housing?

They seem to ghfwii.

I'm sorely tempted to buy one off his website. (Even with the pacific paeso, and shipping they're still cheaper than buying one locally)

https://www.pulsarturbo.com.au/collections

Some alright pricing here as well

-

1

1

-

-

45 minutes ago, Doug Hill said:

My $5 is the valve/seat is all garbage from eating intake schmooze.

41 minutes ago, chris r said:Yeah it most likely is the issue. Upgraded valve springs were always going to be part of plan but just not this early O̶r̶ i̶n̶ t̶h̶i̶s̶ v̶e̶h̶i̶c̶l̶e̶

Is there anything you can put down the valve to try and dissolve any potential build up that could be causing it to have seating issues?

-

26 minutes ago, Roman said:

Might not be any point with my motor.

Since it's got a longer rod ratio than the 2GR, the piston dwells at TDC for longer.

So it would likely hit pistons sooner than a 2GR.

Maybe cant make use of the extra range anyway.

Will see.

Ordered big cams! ExcitingAll good, im assuming the Camgears are the same between motors? unlike the K20 and K24

Just thought it might give you inspiration :p he did have to clearance the piston valve pockets to use the extra range as well

-

3 minutes ago, Roman said:

The 2GR is normally 10:1 compression or something, and the FXE pistons bump it up to 12.5:1

The 4GR is 12:1 by default, and there's no FXE version.

As the 4GR is already a race ready engine (conditions apply)

Conditions:

Absolutely garbage valvetrain, pulleys, rockers, valve springs etcHe also goes through machining the cam phasers for more movement and timing shift, think they get it up from 40degree to 55degree of movement

-

1

1

-

-

For when you get FXE pistons :p

-

1

1

-

-

27 minutes ago, xsspeed said:

Trying to bend my head around what's happening to the gas, is it that with lower duration cams you're getting fast squirts of gas and that has more momentum than longer lower velocity durations

Cam overlap is also a rabbit hole to look at :p

-

1

1

-

-

11 minutes ago, sheepers said:

the fuck you did

Need to add the links to your sig :p

-

8 minutes ago, xsspeed said:

Thanks guys

@shrike I'm still putting together parts from the nissan bin and and need to decide where im going with things

I could just do a r32 20det

As an option I have a couple of rb20 neos I could swap the vct head onto a det bottom end but this is a lot of work

I could stroke and bore one of the 20s to rb22

They way I'm leaning which is all just for fun not for logic (and have most of the core bits for) is to destroke a rb25, with rb20 crank, use hks rb28 low height pistons and buy some long rods (hence maxpeedingrods thread) which gives a 2.4 with 69.7mm stroke and rod ratio of 1.8. This is just a s1 head atm so not neo and I think it's just on/off vct (I thought the neo vct is just on/off anyway?)

Cams I don't have in hand yet but would be buying regardless, I haven't looked too hard at the options, many seem to run tomei or kelford cams seeing there's lots of support there

If your doing wiring anyway, a rb20de neo plus turbo isn't a bad option

I have more exposure to the neo then the normal VCT heads but I think your right its on off and not variable however from memory the Neo heads flow better

I wouldn't bother stroking the 20 to 22, I like your long rod idea tbh on the 25

I wonder if you could retrofit the CVVTCS off something like the 350/370Z onto the RB similar to what KPR has done from the VVTI 2J onto the 4age

A little more compression will help with spool and off boost (9.5-10:1)

Cam wise id be starting at 272's with as much lift as you can get, and the VCT will help with lower down, if you can get CVVTCS working as an option you could possibly go bigger or have better under the curve power

-

Rather then double post, to add some context the K24 build I'm slowly putting together for my AE111 is going to be using a Pulsar 6262 (equivalent of a G35-900) as the K24 flow really well, run higher comp (11:1) and with Vtec you can get good response etc

Really need more info around how your setting up the motor and what sizing etc

Last time I looked at High revving RB, I was looking at a 25de/t neo with a 20de crank and all the usual oil pump mods etc

-

I'd be looking at the G30 frame rather then the G25 for an RB as a starting point, the cheaper Pulsar turbos are fine and have good results

G30-770 T4 twin scroll 1.06a/r is good for about 500hp on an rb25/26

The G30-660 with an 0.83 AR and T3 should do the kind of power your looking at, which is a PULSAR 5455G Id go bigger A/R as your revving it out and have cams

"A GTX3076r is the direct equivalent of a G30-770 (58/55). The G30-660 is the direct replacement of a GTX3071r (54/55)." if that gives you idea on sizing

A Gtx3071r will do circa 411whp on 22psi (E85) with a 0.73AR

Positive boost at 2500 and full boost around 4k note the G30 series and its clones are more efficient and should spool better

Hope that helps

Edit adding to this most of the kits for RB20/25 over here have the G30-660 as the smallest turbo option

@xsspeed are you using a neo head and variable valve timing at all?

-

1

1

-

-

Just add more boost?

That sucks any idea what could be causing it to not seal?

Anything you can check before ripping the head off?

-

1 hour ago, xsspeed said:

yeah, not exhausted all options there but been through a bit and still looking

What sizing are you after encase anyone just happens to know of something that will work

Any yeah Maxspeeding gear I have heard manufacture a lot of brands rods etc

-

2 hours ago, xsspeed said:

Anyone got experience on who to contact/the process/costs involved of getting made to order (one off spec) conrods?

I've started firing off some emails to carillo, spool. Spool came back and said they can order via carillo so will see about cutting out a middle man unless need their buying power

I am assuming youve had a look at what existing rods are around that could be close?

-

2

2

-

-

Just now, Roman said:

Thread bump for good option found.

Has a 5 pin plug that is + - DC motor and a 3 pin TPS.

Has been successfully used for ITB ethrottle.

https://www.aliexpress.com/item/1005007187820465.htmlGot one on order?

-

5 minutes ago, kpr said:

Has a hilux diff with trd lsd. Had a w57 in it when was turbo, last thing i done on the car was rebuild that box and still have it. but yeah have a j160 lined up for it.

Likely run a link extreme, since the lower models need an external box to run e throttle. by the time mess around with that better off just to get the extreme

I do like the built in pdm of the haltech r series. but otherwise rather a link. You can keep your speeduinos haha. I just spent awhile on one, fighting trigger issues ended up swapping to a link. everything just works, tune and doneOk so probably too much diff for an N/A build

at least no worries about breaking it

at least no worries about breaking it

Yeah Link extreme makes sense

The Speeduinos I got over covid as a bit of something to keep me busy/have a play, agree Link/Haltech just work

PDM is the big drive for me with the Haltech R3

-

12 hours ago, kpr said:

Yeah. I probably could just build another manifold for the cable itbs and test this setup in the starlet. it would be a good test, to throw the high port head on the bottom in starlet, with all the bolt ons and same cams. the only difference being the high port and smaller valves. may happen yet. kinda depends how long getting the trueno operational takes. It doesn't have a gearbox, driveshaft or ecu. plus lots of small things

Going to stick with a T50? Or is it an opportunity to go to the J160 (is200/Altezza) box and give 6speed a go?

I mean if you need a drive shaft anyway.

Whats the diff in the ae85?

Going for another link for the ecu? I quite like haltech as an option these days (been looking at the nexus R3 but they aren't cheap) need to pull the pin and just get one for my ae111 project.

Ive got 2 speeduinos kicking around in a box over here but they dont have dbw support.

Also been looking at Rusefi just out of curiosity and they have a few interesting options

Im assuming its still alot of Link in NZ though

-

22 hours ago, kpr said:

primary's are 38.1mm tube. so 35mm id. out of the port its 32mm and actually tapers down to 31mm before the cone out to 35mm. sounds small, but have made 160kw on same sizes.

They are actually going to be 4-2-1 . once get the 4-2 section merged together. will design a flange that will go just after the merge. Then can test a bunch of different length 2-1 sections.Im kinda going against proper science and trying a few things at once. Ideally i should test the high port head with the starlet exhaust side. but that wont fit the trueno. and the starlet ecu wont run the e -throttles.

Have tested couple of very different merge collectors on my big headers, with zero change in power. How small they merge down to and whats directly after, can make a big difference though. especially in the bottom end.

So long term plan if it works well is to update the KP motor to similar head specs but with better bottom end and cams etc? though ecu doesnt suit on the KP currently for DBW

-

@kpr whats the bottom end plan for your new head? Same as the KP? Long rod high comp with vvti?

-

On 24/02/2023 at 08:56, shrike said:

So I'm still tipping 200kw+ not sure what the factory rods are like, but not sure if they will do 10k rpm guess it depends how heavy they are and how well its balanced from factory

I am assuming you'll do valve springs as a minimum and be going for custom exhaust/headers might even crack 220kw atw (would love if it got more however :p)

Whats the harmonic balancer/engine dampener weigh? and are you going to run many auxiliaries on the motor?

I've been having a play with the Automation game and well some of the figures aren't super realistic it can be an ok guide/indication sometimes

Couldn't get down to 83mm bore (84.4mm smallest I could go) but with cast rods/pistons it was happy with 8400rpm, would say 9k with the smaller bore is reasonable

ITBs, exhaust etc (with springs) it did 270kw at 10k rpm lol which Im not sure about, might upload something later if you want a laugh?

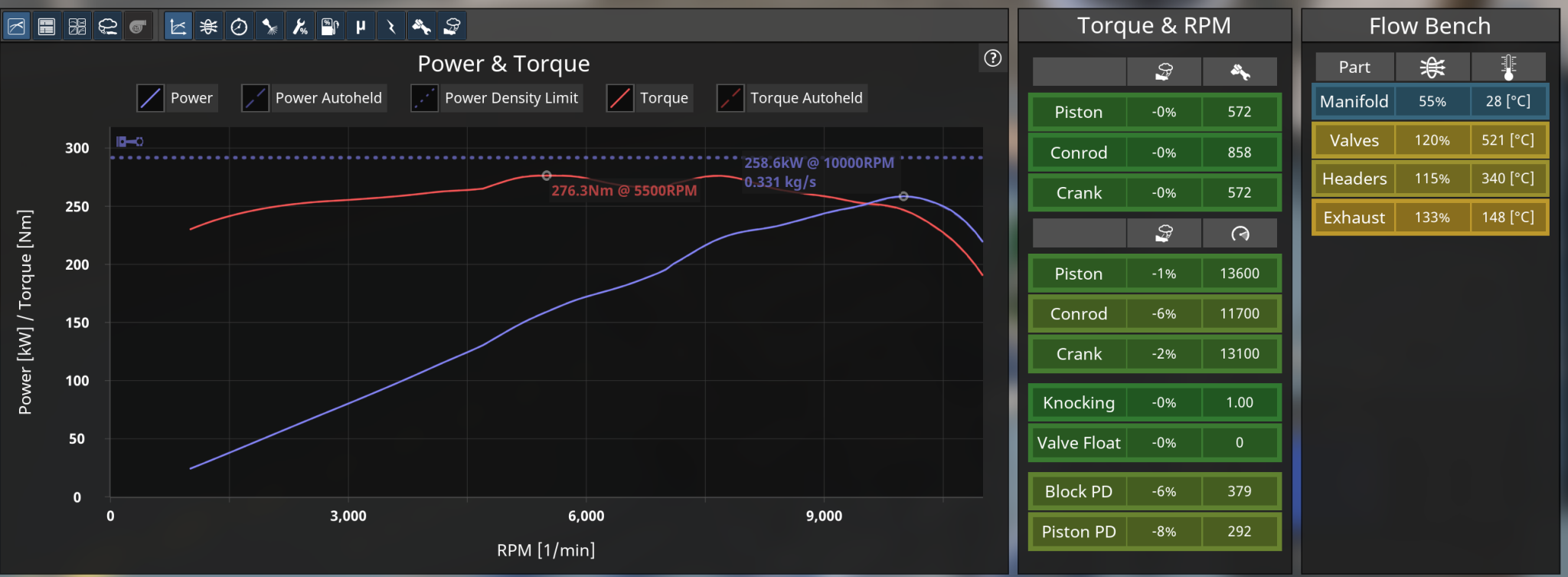

Update on this with the latest updates

Over 11000rpm it gets valve float (even with best valve springs etc)

Best variable timing shift is at 4700rpm

This is on 98octane and 3" exhaust and the intake as big as itll go, taking it down to 100% bring peak power to 9100 but is less power at that RPM vs the graph above

More timing does nothing, leaning it out moves the torque 2200rpm later

Bigger exhaust headers moves everything later without power gain, minimal benefit from going to a bigger exhaust (+/- 1kw and peak power is 100rpm later)

Cam is set at 50 out of 100, bigger cam does nothing but rob lower down torque

Forged rods/pistons

-

4

4

-

-

16 hours ago, chris r said:

It had some pressure when I initially put the gauges on so I think it's just never been re gassed. It did hold the pressure from the first can over a week so it's good enough for now

I was meaning for the intercooler piping but yeah, curious on why the a/c was down as its a closed system

any exhaust restriction?

-

21 minutes ago, chris r said:

Grabbed another couple of cans off marketplace and topped off the aircon, it's super cold now so I've managed to fix something which is nice.

Found a loose clamp on the intercooler. Tightened it but made no difference annoyingly.

Done a pressure test? What's the bet a hose has let go?

DIY Fuel injection thread.

in Tech Talk

Posted

Note you can add ethrottle to the Storm G4+ later if you need with an expansion module

https://dealers.linkecu.com/G4RET

Link do one but there are other DBW modules around that should also work