-

Posts

504 -

Joined

-

Last visited

Everything posted by gazguy

-

Some more progress with the frame. I've always been a fan of the Jesse James Sturgis special with the drilled downtube so i've basically copied that concept. I marked out where I want my holes and drilled a pilot hole first then blasted through with a 32mm holesaw. Inserted the tube and fully welded it. At this rate I'm getting about 1 hole drilled each night as I'm trying not to fuck the neighbors off too much. There'll be a total of 5 holes spaced 75mm apart. I'm debating whether to call the bike Glory Hole from now on?.....

- 24 replies

-

- 10

-

-

So I picked up another project cos it was a great deal and came with all the right parts for the base of a new build. A mate of mine was selling as a bundle and threw in some more parts for extra $$. Its an mBike chonda deluxe frame thats already been cut by my mate. The style I'm going for is the Indonesian choppy cub I'll be hardtailing the rear and stretching the front by 150mm. Luckily for me the downtube is the same OD as some steam pipe i have, so I'll make some slugs and splice the frame and steam pipe together. But before that I thought I'd mock up some parts to get the overall look of the bike. I knew I wanted rabbit ear bars for the bike so I took a pair of really ugly bars with quite a tall rise and cut them just before the bend at the bottom where they clamp and then sleeved and braced them with some 1 inch stainless tube. the 7/8 part is left loose until I figure out the position I like. I then mounted the frame in my jig and cut the frame and inserted the 150mm extension and slugs. Its held in place with plug welds until I get it fully welded up. Having a frame jig that rotates makes life so much easier!

- 24 replies

-

- 21

-

-

Awesome, thanks mate

-

Does anyone know of a windscreen fitter that does cashies? It's bonded in, doesn't have a rubber seal. The rear screen is already out and the body will be rust treated and painted prior to being installed. The cars a vauxhall viscount. Cheers, Gaz

-

Over the weekend in between fitting a kitchen to my new house I gave a big push to trying to get it started. The 1st step was dropping the shipping oil that the engine came with, there was next to fuck all in there to be honest, not even 100ml. after filling it up with the required amount of oil, some fuel and messed around with the carb it fired up. I still need to tidy up the front end of the electrics and get the wiring stashed away in the headlight bucket. I grabbed some more goodies from Andy and Wei from mbike like taller shocks, rear tail light and rear sprocket, you might notice a new tyre which is from trademe.

-

Over the weekend I made a push on the last of the welding that needed to be done so I can bolt the engine in for the last time. The engine adapters will be powder coated sometime this week

-

last week I started the dark art of the electrics. I bought a 'plug and play' Monkey Bike loom and had to swap over nearly every pin but got there in the end. I guess you have to expect that from parts from different manufacturers. So I had Roxettes Greatest Hits on repeat and a 6 pack of Boundary Road Hazy Pale Ales and got it knocked out, still some extending of the wires to go from the hand controls to get them to go through the handlebars. I bought a battery and folded up a box for it to sit in. I used a M6 countersunk socket head bolt and a piece of thick steel which I countersunk to use a makeshift dimple die so that the battery wouldnt rub against them At the Mcleans Island swapmeet I came across a 14 inch NF75 wheel with a tyre thats pretty mint, haggled the guy down from $20 to $15 and got it swapped over today when it was nice and warm so that both tyres were nice and soft to get off and on. I put on the correct front brake cable too.

-

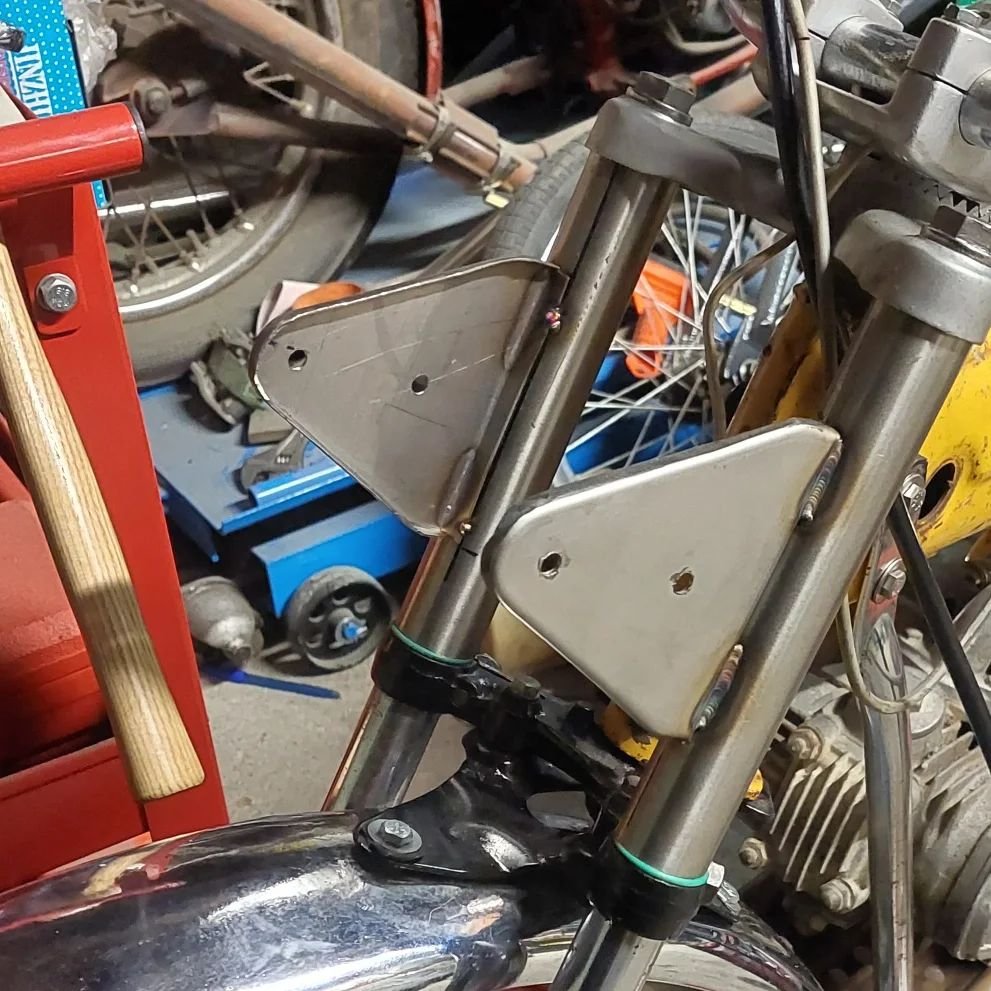

I wanted to keep the original air filter and box as it looks really cool and adds to the appeal of the ST, but the inlet manifold that came with the Lifan motor was clocked wrong, was too long and too tall. So I cut the flanges off and shortened and narrowed it. I made a start on the exhaust too so I ordered some 32mm stainless bend and started piecing them together. The diameter of the muffler is 38mm so I had to make and adapter. Ive just got the bends and pie cuts tacked into place and will fully weld it at the weekend. I tried to get the bends and tubes to match the lines of the engine and frame as best I could. Here's the adapter plates I made for the support brace . I didnt want to drill or weld anything to the frame incase I want to put the bike back to original, so I made some plates from 3mm stainless and offset and tapped the 6mm holes Here's a quick shot of the adapter plate for the engine mount which includes the mounts for the original footpegs and support brace. It bolts to the footrest mounts of the lifan and is welded to the tube that the brake pivot passes through

-

I recently bought a new place at the end of July and after a few weeks of unpacking and organising I thought I'd get stuck in to dads ST90 again The engine turned up from mBike so I adapted an old scissor jack to help raise and lower the engine whilst I make new engine mounts as I wasnt happy with how much lower and forward the adapter plates I made the engine sit. I'll take some photos of my design one I'm happy with how it looks and works. Along with buying a new house a treat myself to a new to me lathe for my birthday. Its a Boxford AUD 4 1/2''. It suits me perfect for what I need in my workshop, anything bigger I'll use the Colchester Triumph 2000 at work I swapped an old hot dog muffler and a small welding job for a mate for the delivery of the lathe and this small black muffler. I'll get some stainless bends at some point and start making the header pipe for it Next job is to make some small offset plates to bolt the support brace to the frame so they're not under constant tension from being in its unnatural position

-

One of the main things I was missing was the seat hinge. I had a rough idea what it looked like but had no measurements to work from. So I fabbed one out of some 50x3mm and 25x3mm stainless plate (incase I felt like polishing it) and just kinda joined the dots to where it needed to be. The indicators arrived so I threw them on too

-

mBike to the rescue again as I got a new headlight and speedo from them yesterday and fitted it today. It was already painted black too so thats 1 job less to do. As I was going through my stash of indicators and tail lights I came across these The indicators and tail light were a swapmeet find. Unfortunately I only had 1 pair of indicators so Ive ordered another pair for the front from trademe so they should be here within the next few days. I think the tail light really suits the shape of the guard. I'll make a bracket for the numberplate to bolt to.

-

I'm still looking for a headlight and bucket but have sourced a speedo. So in the meantime I made some headlight ears that will also double as indicator mounts. The original indicators clamp to the knurled sections on the handlebars. I cut some lengths of 31.8mm stainless tube from work then hammer formed some 18g stainless to make the ears and glued them together

-

Whilst the blue panniers were a great addition theyre just too brittle and small parts kept breaking off after every ride. So I bit the bullet and decided to start making some from steel. To start with I made some channel out of 18g with a slight radius, not a breaked edge. Then I had to modify my shrinker stretcher stand as once I got to certain point it would hit the stretcher stand upright. so I moved them apart . Using the shrinker I incrementally started shrinking the sides. Shrinking one side then the other so they'd both be the same. One end is 90 and the other is just under. Next is to make the sides and get them welded in

-

Not a huge update but slowly chipping away at dads ST whilst waiting for my engine to arrive from overseas. In the meantime Ive reinstalled the original engine so to stop me from tripping over it everytime I walk past it, and also make it easier to move when I move house end of July. Swingarm is painted satin black to match the guard. The tool holder was stripped and painted too.

-

The rear shocks on dads st were pretty poked so I got a new pair of Thai style from mBike. But when i went to install them I found out that a 14mm bolt had been used as the lower shock mount. The shocks I bought from mBike are 12mm. So I cut off, ground it flush and beat fuck out of it so it could be replaced with a hi-tensile M12 bolt. The traces of gold zinc left on the bolt and my argon bottle nearly empty made it a prick to weld I made some adapter plates to mount a lifan whilst still keeping the original mounting holes incase I ever want to put the original engine back in, same with the mounts for the original foot rests and bashguard. I gave the plastic mudguard a paint of satin black to tidy it up whilst i look for an original metal chrome one. The swingarm has been painted satin black too but Im waiting for the paint to harden before I mount it.

-

Not a great deal of progress but every little counts. Whilst some parts were away getting vapor blasted I concentrated on stuff i could do at home. So I stripped and painted the lower fork yokes and swingarm and painted them with gloss epoxy enamel . I picked up the rear wheel from my mate dave who does vapor blasting locally and reassembled it. the bearing were fine but I put in new shoes and springs I sprayed anything that was vapor blasted with Lanolin to prevent flash rusting and further corrosion

-

I was pretty adamant that I was I was going to get tattooed this month after a good few years of not getting any. After a few st90s came up for sale on a group chat I thought I wouldnt get one for the price it was offered again but can get inked anytime. So I bought with the plan to repower it and give it to my dad so he can come out on the small bike rides with me and the rest of the small bike community. My initial plan was to blast everything and repaint the frame and powdercoat everything else that isnt chromed. I'm going to leave the frame as it is and just give the bike a general tidy up. Replacing cables, bearings, bushes and brake shoes. The front guard was pretty hammered so I fettled it a little with my planishing hammer, it came out surprisingly good.

- 12 replies

-

- 17

-

-

I got the chaly registered and road legal and took it out for its first shakedown run a few weeks back around the hills and through Lytellton to Wunderbar. Those side boxes I got from the swapmeet last year were on the back of my mind so I pulled the pin and started making some brackets for them The boxes themselves are pretty rough and have a few cracks and pieces missing, so I'll address them, paint them and maybe add some gas struts.

-

Its normally the smaller jobs that take the longest, but im gradually ticking them off the list. 1st up is the painting of the air filter cover 2nd is the air filter cover. I found some old mag wheel centre caps at work, drilled some holes and put a 6mm rivnut in the air filter. 3rd is the kicker pedal I fabricated out of some flatbar, plate and an old vans phone case i had hidden in a drawer. Lastly I bought some side boxes at the winchester swapmeet last year when swapmeets were actually a thing and you could go to them. Just toying about with the idea of them but Im pretty keen to make some brackets, colour code them and have them fitted ready for syds run this year to store some tools, spares and a few BRB Hazy Pale Ales

-

This thing is nearly complete now. I just need to make a bracket for the horn which I'll do tomorrow. I put some feelers out for an air filter cover, to no avail. So my way of thinking is cant find it, make it! So thats what i did. I used a combination of pressing and hammer forming. I used 2 75mm OD 6mm thick discs and 1 2mm 75mm OD disc cut to the profile I need. It just needs some minor massaging then prep it for paint. The last major piece of the puzzle was the seat which I got this morning thanks to Andy and Wei at mBike. Bolted it on and couldnt be happier then took it for a hoon down the street

-

The battery box has been powdercoated at work and installed, I used those cable tidy velcro straps from Bunnings to hold the top down. Also a sneak peak at my kicker pedal I made, its getting pinstriped tomorrow to finish it off.

-

As the weathers been pretty shit here in CHCH over the weekend I got stuck into the chaly. Another trip to mBike and a good few dollars lighter I walked away with a tinted windshield and some widend rims. the front is 3.5 inch and the rear 4 inch.

-

On my lunchbreak at work I knocked up a rear brake adjuster on the lathe, its an old 3 phase colchester and runs like a champ. I made up a battery box that also held the voltage regulator and the flasher unit. I'll get around to powdercoating it at some point

-

I really wasnt feeling the tiny side stand and it was pretty pointless to be honest. So I opted for the centre stand. With it being lowered quite a bit it lifted the rear wheel so far off the ground it became unstable. I cut off 25mm from the bottom and made new pads from some 25mm shs. I purchased a chaly big bore exhaust from mbike, its for a standard chaly so the rear mount doesnt meet up due to the bigger engine. Other than that it looks pretty sweet. To stop the centre stand from hitting the swing arm and the chain i whipped up a small stainless bracket with a rubber stop and bolted it to where the passenger pegs would go. I tried the kickstarter from my C50 to see what the fitment would be and it was touching just by millimeters. I didnt want it scratching my new exhaust everytime I kicked it over so I managed to get an old c50 kickstarter from my mate Jeremy, pie cut it and bent it forward and tig welded it up with stainless rod. Plenty of clearance now!

.thumb.jpg.33541c16de6eacd0b40682167dedec88.jpg)

.thumb.jpg.68a414964d253c966ed47d6c4b27fe98.jpg)