bonkas

Members-

Posts

370 -

Joined

-

Last visited

Everything posted by bonkas

-

Think I found it, will need to convert into a dxf file for laser cutting, will see how we go.

-

Does there exist a drawing of a flange to mate up to a Weber DHLA 45 carb?

-

bonkas tired old Lancer EX - Engine Swap/Build Thread

bonkas replied to bonkas's topic in Projects and Build Ups

Another minor update. These arrived: Still struggling to find a pulley for the 12mm oil pump, can't really go any further without this which is a bit dissapointing. -

Is anyone in a Mitsu parts department who can tell me the shaft size on MD124762 - Superceeded with Part No. MD135005

-

@mjrstar yup absolutely right, I "could" make this work by turning it down shorter ( the locating dowel looks to be in exactly the right place). The only issue is the wide shoulder on the old pulley which keeps the belt in place, there is also a plate which covers the other side of the pulley so the belt cannot wander in either direction, I may be able to make up a plate to put in the side with the missing shoulder. Will wait for this pulley to turn up in the mail, it may just fit with no modififications. In the mean time I have alot to get on with on this build.. Intake, Carbs, Distributor Tuning, Exhaust etc etc...

-

bonkas tired old Lancer EX - Engine Swap/Build Thread

bonkas replied to bonkas's topic in Projects and Build Ups

Block, Crank, Rods and Pistons are together and torqued up to spec with the new studs. Now I have issues of mis-matched pulleys so trying to scramble together a full set that will work. I managed to machine down the oil pump pulley from @mjrstar by shortening it and increasing the ID of the very last 10mm or so on the pulley and it now fits but sits about 2mm proud of the old pulley. Wont know if this is going to be a problem until I have it all connected up with the belt. Will also need to source another of the pulleys as this one has a few chips out of it but was a good proof of concept that it "should" hopefully work. I also managed to get a crank pulley off @mjrstar but after comparing these it doesn't look like I can make this work - Do you want this back mate? As per the thread above I may have sourced a crank pulley with round teeth which is identicle to my original pulley. In the mean time I will be scanning a copy of the intake gasket and drawing it up on the computer to send off to get it laser cut in 12mm plate steel/aluminium so I can start building my intake manifold for the Weber DCOE 45 Carbs and water routing. If anyone knows what format these drawing should be in please let me know, would like to get done ASAP. -

Looks like I found the crank pulley I need, if you notice it has the round teeth and not flat: This is listed as "Generic Forklift 4G63 Timing Gear Sprocket MD120373" Does anyone have a Crank gear laying around from a later model 4g63 or similar you can take a picture of for me?

-

The EVO one from @mjrstar fits.. just. I had to shorten it by 4mm and machine down the ID on the end to clear the pump housing itself. That enlightened another dilemma... The OEM Cam Pulley is square tooth, the Adjustible Cam Pulley I got from @ToMitz is Round tooth. The New pulley from the EVO is round tooth. The OEM Crank Pulley is square tooth. So I have two options: Find the correct square tooth 12mm Oil Pump Pulley with square teeth and run the OEM Cam and Crank Pulley's. - If there is such a thing. Machine the OEM Crank pulley to take a round tooth belt and use the adjustable Cam Gear - This is prefered. Find a Crank Pulley from and EVO (90's and up 4G63) and see if it can be modified to fit or may just be the same... Here are some pics of the crank pulley which if I remember is 36mm crank. Maybe someone has something they can compare for me.

-

I have confirmed it is a 6-bolt sohc pump for years 87-92. They have also told me the 10mm pump is NLA and has been replaced with 12mm, I would have thought it would be easier to track down a 12mm pulley if this is the case.

-

@mjrstar My new oil pump has a 12mm shaft, where-as the old one has a 10mm shaft so I need to find a 12mm drive pulley. Hope I dont have to order another pump with the 10mm pump gears/shaft... bugger.

-

I will have to double check the fitment but all the bolts on the block line up, crank and balance shaft locations are all correct. If I can confirm the sump bolts up OK I think just getting another larger pulley to fit the larger shaft will work. I also found an article where Mitsubishi changes oil pump housings even on the 6 bolt stuff to helical gears - This involved changing the oil pump housing and gears but keeping the front plate - I am hoping I have a 6-bolt plate with 7-bolt housing. NO.: TSB-92-11-002 REVISION 2 DATE: November, 1992 MODEL: See Below This bulletin supersedes Technical Service Bulletin # TSB-92-11-002 REVISION (Dated June, 1992) and Advance Technical information Notice # ATIN-92-11-001 (Dated July 31, 1992). Please discard the superseded TSB and ATIN. New information includes: - Deletion of 1983-89 2.0L Truck from Vehicles Affected list. - Addition of new drive gear for 1983 Cordia/Tredia (1.8L and 2.0L, SOHC), 1985-87 Galant (2.4L, SOHC), 1987-90 Van/Wagon (2.4L, SOHC), and 1990-92 Truck (2.4L, SOHC). PURPOSE This Technical Service Bulletin describes a new oil pump/gear assembly that may reduce engine noise on some 1.6, 1.8, 2.0, and 2.4 liter 4G6-Series engines. VEHICLES AFFECTED 1983-88 Cordia/Tredia (1.8L and 2.0L, SOHC) 1987-90 Van/Wagon (2.4L, SOHC) 1985-87 Galant (2.4L, SOHC) 1989-92 Galant (All) 1989-92 Mirage (1.6L, DOHC) 1990-92 Eclipse (2.0L, DOHC) 1990-92 Truck (2.4L, SOHC) 1992 Expo 2.4L, SOHC) DESCRIPTION On some vehicles equipped with the 4G6-Series engine, you may receive customer complaints of a high-pitched whining noise coming from the engine. This noise most likely originates from the engine's oil pump and is particularly noticeable during cold starting. To help reduce the noise, a new oil pump is available. The new pump has helical gears as opposed to the former pump's spur gears. In addition, modifications were made to the engine front case to accommodate the redesigned gears. All 4G6-Series engines built from 6/11/91 with identification code LX8939 and up, have been assembled using the new oil pump gear set and front case assembly. When installing the new oil pump on a vehicle, be sure to replace the drive gear, driven gear, and front case as a set. These parts are not interchangeable with the former ones. For information concerning the replacement of the engine oil pump, refer to the applicable service manual or engine overhaul manual. PARTS INFORMATION WARRANTY INFORMATION Position Code: 121010. Use standard warranty procedures.

-

Yup it's the drive pulley on the oil pump, not the balance shaft. I will measure the shaft and ID of the pulley as you can see a "flange?" in the pulley also that needs to fit withen the seal. I am assuming there is two types of pulleys - The pump I ordered was supposed to definately for the 6-bolt engine so not sure why it is different, but if I can get the right gear and it fits right on I can move on. @fuel and others - Is there any differences in the 6-7 bolt front covers/oil pupms that would cause concern with oil flow? as far as I can tell all the bolt on the block line up but readig online the tensioner mount may be different?

-

bonkas tired old Lancer EX - Engine Swap/Build Thread

bonkas replied to bonkas's topic in Projects and Build Ups

Have Crank, Rod and Pistons lubed up and fully installed. Ran into issues with Oil pump which has stopped me in my tracks. Thread about it here: -

Hey guys, have run into a bit of a snag in my 4g63 build. The oil pump I have seems to be a higher flow pump and the shaft where the drive pulley fits is too large and will not accept the drive pulley from the old pump. When I purchased the pump I was sure to order the pump that listed the -g63b motor as all other were listed for years '92 and up. Can I grab the pulley off an EVO or similar vehicle? Or if someone can identify the pump I have by the gears, see the differences below. The housing is the same bar the pump housing being a bit larger to accommodate the larger gear and additional bearing. I had thoughts of machining the pulley to fit but it may weaken it too much by doing this. @fuel maybe you are able to shed some light?

-

bonkas tired old Lancer EX - Engine Swap/Build Thread

bonkas replied to bonkas's topic in Projects and Build Ups

With advice of engine builder I should be able to get away with running as is. I believe the big ends gave me .003" clearance.. max spec is .004" according to the manual. I would have liked to be in the .0025" range. Going to try a second set of bearing tonight and see if the clearances change, if so It's time to lube up the crank and bearing and put everything together for real. Anyone dealt with Spiral Locks before to hold the pison gudgeon pins in? first time using these and WHAT A PAIN!! that was until I watch a video with a much ebtter technique.. stretch them out and then install. take about 1 min per lock vs 15-20mins. -

bonkas tired old Lancer EX - Engine Swap/Build Thread

bonkas replied to bonkas's topic in Projects and Build Ups

Got the studs sorted, found ones that work. I now have dummy fitted the crank and pistons. I was told by engine builder the crank was within spec but plastiguage says I am riiiiight on the edge of acceptable for the main bearings and there is quite a bit of play in the big ends, again plastiguage says I am right on the limit - I can see a rebuild in it's near future -

Require use of parts washer - Waikato/Cambridge

bonkas replied to bonkas's topic in Upper North Island Region

@66gt Did you end up dropping your stuff to them today? -

Require use of parts washer - Waikato/Cambridge

bonkas replied to bonkas's topic in Upper North Island Region

You don't happen to know who you spoke to there? I gave them a call but was told that is not a service they provide... -

@dwlee Yep I think you are bang on, I never double read the label on these when I bought them, it lists them as '94 onwards. Part No. 207-4203. I bought them from an Ex worker of the engine builders when I was in there getting work done, he assured me "all '63's are the same mayyyyteee" err no they are not, my fault for not confirming and they never bothered to check either. After giving this some second thought after a bit (I was getting a bit worked up about my dissapointment) I think the part numbers above might just work. Here is a picture I took to simulate how far the stud will protrude from the block when fully inserted, with the ~3mm washer it will give 1-2mm of clearance to tighten the nut.

-

It's the block im having issues with, Cant find crank bearing cap studs to suit - Would much prefer studs over stock bolts.

-

Yup they are what I have been able to find online. but they are too long, then need to be half an inch or so shorter in order to give enough thread to tighten down onto.

-

This might make it a bit better to visualize what I mean, im bad at words sometimes. Original bolt on top, Closest Studs I can find (ARP 207-5401 Listed as Pre '94) on bottom

-

bonkas tired old Lancer EX - Engine Swap/Build Thread

bonkas replied to bonkas's topic in Projects and Build Ups

Another snag it seems... Main Studs are not correct, cant find anything that suits. Original bolts are 69mm in length with 17mm head. My HELP! thread is here: -

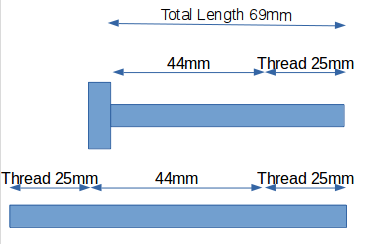

Hey Guys, Have hit another snag just as I am at the point to put this engine together - G63B. The main studs I had bought which were supposed to fit this engine... dont. The Original Bolts are 2.8"(69mm) in length with 1"(25mm)x1.25mm thread. The new studs are 11mm and not 10mm required and also have a total length of 3.8" (96.52mm) - This means the when the studs are installed there is not enough thread to tighten things down as there is only EXACTLY enough thread to tighten the bolt to the height on the caps (Have not tested as they are too large (11mm vs 10mm required so only going by my eyeball and calculations in my head). All I can find in 10mm is the above length which will not fit. Does anyone know a model number of ARP studs which are 10mm roughly 1"(25mm) thread on each end and maybe 3-3.5" in total length. Or even if anyone knows of a ARP dealer in NZ I can call to find something to suit?

-

Require use of parts washer - Waikato/Cambridge

bonkas replied to bonkas's topic in Upper North Island Region

Thats the bit I like haha as I only have a kitchen sink available to me for cleaning, I dont think the Mr's will be too impressed with that