-

Posts

2744 -

Joined

-

Last visited

-

Days Won

3

Posts posted by azzurro

-

-

well a much better day today.

Woke up and checked my brake fluid leak checking paper towelTM on the passenger side - nothing

, check the drivers - totally soaked

, check the drivers - totally soaked

Swapped out the piston and seal for another, and tested by bleeding it and then putting a bit of wood between the piston and the arms, then pressing on the pedal and it seemed to be ok. Excellent.

Wheels on, and then FINALLY!!! a bit of this

:

:and then into town for this:

This also happened somewhere along the way

Is there such a thing as too much Doooooorrrrt?

and this one because WoF:

Merry xmas everyone

-

Woke up this morning hoping to fire her up, back up the ramps, fit the battery tray, test drive and pootle into town for a WoF, and then onto the Burger Fuel meet this evening.

Best laid plans and all...

Got the bigger battery tray in OK with plenty of help from my small assistant who fits in the boot, but hang on, whats this:

(the big patch on the mat is the brake fluid from sitting overnight, the puddle next to it is from taking the wheel off and getting the camera!)

My old calipers that i put back in fingers crossed have bitten me right on the ass.

These have been leaking out the piston.

This is how much fluid leaked, overnight, just sitting - yep, pretty much all of it faaark!:

Somehow they have got worse.

The reason i didnt replace the leaky calipers and put my spare calipers in the first time (like 2 months ago) is this broken bleeder screw:

I thought i was toast, but of course there is nothing that cant be fixed or improved with a few blobs of weld:

And after two or three attempts (the easyout i broke off in there some months ago came out first!) got it out:

Swapped all the innards over, cleaned off most of the crap and they are in and bled now, and hopefully no leaks. Ive left the wheels off andput a towel down to check for leaks over night.

So, no Burger Fuel for me tonight, but I think that should just about be it, pending any further catastrophic failures.

WoF tomorrow maybe

-

I second the killrust, worked ok, and seemed happiest straight on bare metal. Havnt used POR15 tho.

thin it out about 20% (with turps) and it seems to stick better, dry smoother and go further/creep into cracks, you will need multi coats tho and make sure its dry before trying to recoat (it takes aaaages to dry) or you will peel off your previous coat with the brush.

I found if you slap it on thick it can peel or chip off, esp if its over primer (even the wattyl killrust primers)

-

125 failed to leave the shed today, so wont be attending

Have just got it buttoned up now (replaced both rear calipers and a lot of brake fluid), but my wof place is now closed. Dammit, should have got up a couple hours earlier...

-

Got a new battery today, nice big sucker, aheapsa volts.

I was also hoping to go for a test run and final tighten & tidy up before going for a warrant,

BUT

i stalled it and it wouldnt restart

Seemed so sudden (running ok, then nothin)I suspected electrics and swapped all the dissy and leads over (again) to the other set. No.

While fiddling around I also retested the compression while it was warm - 130psi all round, so nice and consistent (better than preior cold/unstarted test), and a good sign of no damage.

Turned out it had skipped a tooth on the timing belt >.< so that wrote the rest of the afternoon off.

Just got it going again, seems to start and run ok, if slightly tappier, so fingers crossed for a test run tomorrow and BF after that!

-

Big thanks to Chris (Abarth) who came over Saturday morning and had a tutuu and got her to run! Yus

dizzy was 180 deg out (doh!) and gave the carbs a basic balance as well.

had to leave it at that with heaps of other stuff on over the weekend, but spent the day on it today and she runs and starts good now, except for a few pops out the carbs from the tight tapppets/shims.

- alternator needed to come out, the brushes had popped out of position so the already crap battery couldnt run it alone.

- ran it up to hot a few times tap in side of the block not done up - woops!

- bled the brakes, including the master, now seem to catch nice and high on the the pedal work better than ever and no leaks, yet.

- took trumpets off (tape already melting off from petrol) and fitted ramflow filters, much quieter

might get socks just for the noise

might get socks just for the noise- fixed wiper park position

- put bonnet and new catch on

- steelies back on for new tyres/no rubs wof

- and fittened the ramflows after some 'adjustement':

just a final fettle tomorrow before getting a new battery and going to the wof shop if it aint raining

Edit: photos

-

-

Thanks to Chris (Abarth) for coming over Saturday and getting this beastie running

dissy was 180deg out (firing 1 when should have been 4), opened up spark plug gaps to .75, adjusted the time a bit, balanced the carbs up much better.

Super stoked it was just something simple in the end and not fatal (yet!)

Alternator is now dead (wont run without jumper leads) and need a new battery, but she runs, and like an angry bag of bees too

needs,

-new/spare battery,

-find working alt/voltage reg in spares,

-bleed brakes

- fit air filters,

- wof...

I will try to get the family to BF meet Wednesday

Lincooln, Mal @ www.fiatparts.co.nz should have what you need, OEM quality bits.

or if you know what you need, need quite a bit (to make postage worth while), and can match your engine to the US Spider model years, then these guys are pretty good. www.autoricambi.us. Dollar is high at the mo

-

Thanks guys,

Chris you are most welcome to come and tinker - i look at it too and ponder the unfariness of having a nice looking engine that doesnt go as good as its show.

Compression test is more to see cylinder relativity rather than absolute, but the higher figures are what i would expect to see in a std Twink.

i think 4 is definitly being held open, 3 and maybe 2 are as well, and all the cleances are below spec. Dont know if this is from valve recession, poor shim set up by PO, or bent valves.

Car is in disgrace at the mo, but here is my plan of attack (panding the sourcing of shims and the tool)

1- increase spark gap a bit (currently 0.5, which is factory, but may need bigger gap for fatter spark, max is 0.9, ill try 0.7)

2- recheck firing order/timing

3- check accelorator pump/settings

try to start.

4- try other carb/manifold

try to start

5- take head off, check looks ok, if yes take to a shop, if no swap engines

If i could get a box of shims and the tool, id set them all properly first and then do the rest of the list.

-

cheers chris,

there is no point doing anything more untill i sort the compression issues out.

Ill pull the head off and have a visual, and go from there.

if the valves have recessed or maybe bent or something ill put the other engine in, if they just need new shims, then ill do that. Any suggestions for fiat workshops in auckland that would have shims and the tool?

in other news, received some cheap NOS stuffs i found on ebay today,

bonnet catch, side repeater and a cromodora boot lock, with keys - now noone can steal my battery!

shipping was over half the cost

-

yeah, i was surprised they fitted so sweetly and the tape is definitly temporary only. I was thinking some sorty of V band clamp, but those are even more than proper mesh filters!

gonna have to pull it all off anyway

-

tried the car on a jumper leads, and got a few more coughs and splutters, but nothing even close to running. Spak is good, fuel is good (flooding if anything), air is getting in, so only leaves compression...

Then borrowed my neighbors compression guage,

results are (average of 3 runs on the starter, cold engine (obv)):

1: 135psi

2: 132psi

3: 100psi

4: 110 psi (with a low of 90 and flicking - valve not sealing?)

they all seem fairly low to me (psi/14.7 = 9:1 CR max at sea level???, which is about right as stock these are 8.8CR) but the concern is 3 and 4

Then i checked the tappet gaps (they run a bucket and shim), I had previously assumed the gaps were sweet as there is still numbers in white pen in the cam boxes.

Cyl: Inlet: Exhaust:

Spec: 0.45mm : 0.5mm

(figures are the largest feeler i could get in in mm)

1: 0.18 : 0.15

2: 0! : 0.25

3: 0.15 : 0.33

4: 0! : 0! (ie could not get any sized feeler guage between tappet/shim and cam on In or Ex)

Thats what ya get for assuming someone else did a good job i suppose

My thinking is that If the valves had bent if they would not stick high up (i guess this could happen if they have been bent and then jammed up by the piston with the valve shaft jamming in the seals???)

I guess normally, bent valves would have oversized/bigger shim gaps due to the flat of the valve bending up and holding the end of the valve away from the tappet when the cam is not in action?

I figure I Have a few options

1. pulling the head off to have a look, and then ill know what ups (but ill need to replace the head gasket and do # 2 anyway)

2. just doing the tappets (need a box of shims and that special tool!), or

3. tidying up the original engine quickly and chucking that back in (with most of the stuff ive bolted onto the engine in there now) just to get it running before xmas and do 1 and 2 anyway.

sigh.

-

so i spent $15.60 for 12 'mesh filters', instead of about $30 for one

needed a bit of modification, (that is snap off crappy spot welds, invert the mesh round the other way) they even have a bell mouth shape and they even line up with the rams nicely too

the fitment method is hardly OEM but it is blue...

thell do for getting it started (!) anyway and hopefully keep small children and logs from getting sucked into the carbs

thats the only good news this weekend however, couldnt get the $%(#ing thing to start.

It did pop back though the carbs a couple of times early on but other than that not even a chuffle

nice looking fuel pump was a dud, so changed that out for the orignal one, but then the carbs leaked, tightended them up.

set timing about 3 times, 180'd the dissy, swapped leads, sparks, and dissy over, still nothing. multimeter checking all sorts, every thing seems to be getting power, everything seems to be int he right place, its just not catching.

there way a lot of this today.

I think its possibley

not enough spark to catch though all the fuel (voltage drop when cranking?)

not enough crank speed to atomise the fuel? (battery too flat/too far away)

Maybe those cams have too much overlap?

not enough compression to work no matter what

(bent valves?)

(bent valves?)I will get a compression tester as it is much easier to crank over than the oringial engine even with the sparkplugs in.

Maybe some starting spray as well to see if it fires?

Battery(s) are really struggling now esp from the boot, so ill try craking it on the jumpers from a runner tomorrow. Its always been a bit funny so it may be a drain on the secondary batter ive been using int he front closer to the starter?

If the compression test is ok ill try it with the old single carb, otherwise the entire old engine is going back in.

BAH! Goddamn car. :bomb:

Fingers crossed its just something silly

-

illegal?

unless of course you own a black later model falcon with the factory louder exhaust package and then they are compulsory

-

1

1

-

-

Spent a few hours at home midweek fiddling with the car, so i can spend the weekend doing other stuff for a change.

doesnt look like that much, but there was a hell of a lot of messing around with the hundreds of little things required, but especially

- the top 2 engine/tranny bolts (1/6 of a turn at a time x about 1000000, lying on the engine with one arm jammed in to place the spanner, the other to turn it), repeat on tother side but kack handed

- the clutch cable (needed an extra spacer in the end?), will see when it runs

- starter (its hard enough to install with a single carb, I do not want to replace this one, even connecting the wiring was a pain!!)

after that filled the gbox and engine with oil, installed the radiator and fan filled that up, and lastly attached the carb linkages and adjusted them. That leaves up here:

pretty much just needs the dizzy timing set (there is very limited adjustment) and ill try to fire it up

I have run into an semi-unexpected issue tho, i have some K&N pancake filters that i wanted to run, , they dont fit as the outside bottom edge of the filter rubs on the fender.

I also have some ramflow ones as a backup I was kind expecting this problem (the round profile avoids the rubbing), BUT they wont fit either as the carbs are set too close together and the backing plates over lap! Bah!

As i have the backing plates should i use a foam type of thing? I have some springs for filter socks but I dont really want to pay $100 for some and i hear they are quite restrictive?.

Id prefer something like this:

http://www.sbdev.co....Air_Filters.htm

A blank plate cut to suit and a foam over meash type thing that would allow the rams to stay on (both the K&N and Ramflows require the rams to come off.

Any suggestions? This is how close the rams are (45mm) to the fender. BFH is an option but Id prefer not to do that to my fresh paint (shouda test fitted before Painting!).

-

got my water pump pressed today, and installed that after work and got the gearbox in tonight. Was a family affair with all hands to the pump, and was still a real struggle untill i undid the engine mount bolts a bit to allow some more engine tilt for that last 5mm and pop!

my boy said its just like lego only heavier. And greasier.

Thats the last major component to be reinstalled, just fluids and radiator to go in really before cranking her over

(note to self - dont forget to bleed the brakes!).

also, pretty surprised and humbled to be nominated for project of the year

was not expecting that as there are some mad projects on here!

http://oldschool.co....uring-the-year/

hopefully next year there will be a distinct lack of updates as there will be nothing to do on it and it will run economically and reliably

dont forget to vote in all the polls

http://oldschool.co....neral-car-chat/

ive got some project freds to read though.

-

Continuing to put the bay back together ready for an engine, put the brake reservoirs on the scuttle, 124 style to keep the fenders clean. Need about 20mm more hose

:

:

Tidying up the exhaust a bit, was quite surprised at the restrictions in the factory parts, but my power file soon showed them whos boss.

The exhaust manifold at the head- as you can kinda see, the manifold was about 2-5mm smaller than the gasket all round which is also slightly smaller than the exhaust ports esp at the bottom of the oval:

marked

smoothed

and the the 4 into 2 collector which was a better port size match but what the?

take that fat blobby welds and crushed in exhaust tube restrictions!

hardly going to change the world with that work, but at least there is no longer big steps in the exhaist flow and its quite a bit smoother so it should actually flow quite a bit better i think. Not bad for 30 mins (and 3 belts). If i had a die grinder i would have spent a bit more time as there is plenty of meat to remove in there if you wanted to to make a better port match esp where the head exits to the manifold.

After some humming and haa-ing, I decided to use the spare engine, instead of just slopping the oringial one back in, as it has been refreshed already (admittedly as an unknown quantity/quality) and has those mad cams in it, and the oringial engine could do with some new gaskets to keep the oil on the inside where it should be plus a all round tidy up.

Swapped a few bits over, like the alternator, starter, early style in-head thermostat and housing (has a single outlet) fitted my new dizzy rotor and cap to the original 124B dizzy, clearenced the inlet manifold a bit more, new timing belt and tensioner and a general tidy up and its ready to come off the stand:

Missing the new waterpump, which just needs the pulley boss pressed on about 5mm more and that can go in too.

into a special engine holding rim to fit the flywheel back on and fit the nice new clutch,

went swimmingly untill i snapped a clutch bolt tourquing them up - FFFUUUU...

Lucky I had cleaned the threads before hand and i managed to screw it in right though and out the the other side:

disaster averted!

so onto the main event.

nice clean engine bay just gagging for it:

bam!

thank you ma'am

Only the gear box & shifter needs to go in plus a long list of fluids and bleeding and adjusting etc before seeing if it starts.

-

first run of paint stripper

welded up the spot weld holes and wire holder holes (I'll use P clips and route the wires a bit different)

primer

azzurro del Mediterraneo

Just gotta put it back together now.

Was pondering putting the original engine back in to get it rolling/wof'ed sooner (summer!!!!) as I know it goes fine, if a little smokey, and the spare one on the stand still needs timing belt changed etc and i dont even know if it goes at all, esp with the grumpy cams in there and the unknown quantity sideys which ive never ever used before.

Just want to drive it again.

but then again grumpy cams and sideys for summer would be choice too.

-

muriwai volunteer fire brigade fundraising quiz nite is at the golf club tonight.

they wont be happy if they called out (again) and get their number ones all smokey

lol

-

quite a bit of time spent after work and stuff but it dont look like much!

Gearbox bushings:

these are the NOS ones - broke this off with my fingernail, and a couple that i did fit fell to bits on my test wobble of the shifter.

Not really fit for purpose, but they were only $2.50 each, so no real biggie.

Mal reccomended cutting them in half and fitting them, but i figure they will just crack out again, given their material

and they are in a shit of a spot to get to with the gearbox fitted when they inevitably do.

There was also no way I was going to pay ~$60 bux for some from Superflex.

The shifter itself also has a heap of slop:

But the bushes for this are not in existence, so nothing for it but to fashion something up.

Went to M10 (my other parts supplier

) and found these likley candidates in the plumbing section:

) and found these likley candidates in the plumbing section:

Some 15mm tap washers (not sure what the 15mm refers to but it aint the OD of these!), two together are the perfect width, but OD needed reducing a bit.

i chose the hardest blue ones to minimise rubbery feel in the linkage (gotta be better than no bush at all tho right!)

And some toilet seat bump stops for under the shifter ball itself

Bump was cut down a bit to fit in the recess at the bottom nicely

cut down the head of a wee allen bolt with the flap disc to hold it in place,

some more cap head bolts around the edge to replace the ground off rivets and filled with grease and all back together:

Peeeerfect

Hopefully the rubber lasts a while, I figure a toilet seat will have a pretty tough life (wee, bleach, cleaner etc)

so swimming in grease and being tickled by the nylon nipple on the bottom of the shifter ball aint so bad!

Washers needed a bit of a trim on the 'drill/lathe' and the hole opened out, but they fitted up real nice:

These are some sort of nylon/plastic so hopefully they hold up ok .

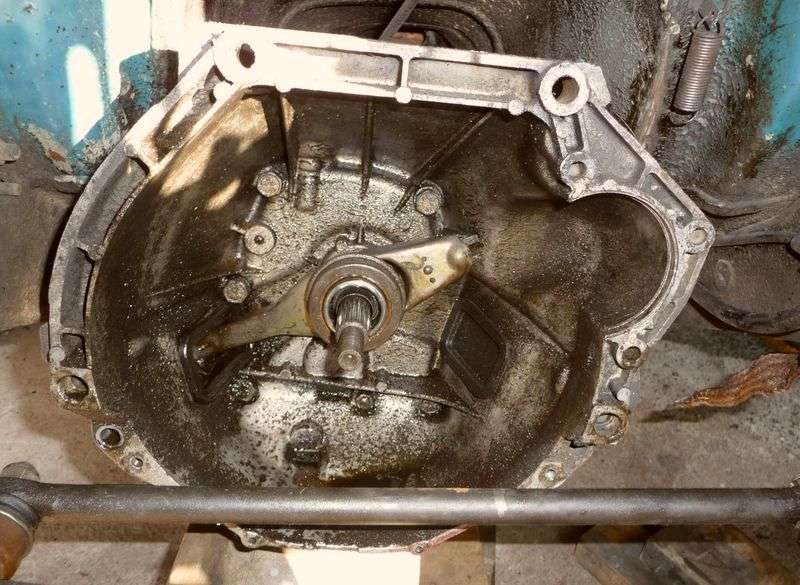

Popped the thrust bearing in the bell housing ready to go, what a difference a clean makes!

Before:

After:

So thats the gearbox all good to go back in, but ill have to keep tripping on it till after the engine is in,

but should be much less porridge stirring when changing gears now!

Also got a nice shiney new clutch kit, hopefully thats the last replacement parts I need to buy for a loooong time!

Its an Excedy and much lighter than the Valeo arrangement that came off the engine on the stand

and isnt covered in oil like the one on the engine i just pulled out:

The engine bay spot weld holes and the single rusty bit all welded up and cleaned back, and bay is ready for stripping the last of the paint, just wondering if i sould fill all the wire clip holes as well:

-

Camera is still on the fritz, I have ordered a NOS Lumix battery for my camera, hopefully it holds a charge/its not the camera draining them in 1 minute flat, otherwise im buying myself an early xmas pressie

Anyway done quite a bit over the week but have no photos to show for it.

- removed battery tray and brake res braket and etc from engine bay, im gonna tidy up the layout a bit, not smoothed or anything, just a bit neater.

- cut out the one bit of rust and plated it up, please that it was all sold in bhind as well, was only in the engine bay skin (oil, mud and leaves and even wasp nest had collected inthere draining in from the rust up in the wing support things + battery acid + brake fluid. Passenger side is solid as.

just needs a few pinholes filled + a few holes from where the spot weld drill and the grinder caught when removing the battery tray. Welder has been playing up for a while, going ok then not ect randomly. found it was just a loose earth terminal, sooo much cleaner welds now

Bit more welding to do still, but glad it wont so birdshitty.

Bit more welding to do still, but glad it wont so birdshitty.- cleaned ali and painted steel on original gearbox, had to use petrol in the end to soak all the oil off inside the bell housing, new guibo bolted on ready to go.

- Unfortunatley the NOS linkage bushings I got looked fine from the outside but had gone all brittle and glassy from the inside out, just like the remnants of the ones in there. I guess they were made of some sort of Bakelite or similar?

Interstingly SuperFlex has only these particular bushings listed for the 125 but they are 12.50GPB each, making them $50NZ for a set without postage, and they are only 22mm OD x 8mm wide!

http://www.superflex.co.uk/products.php?cat=114

Alternative is getting some turned up i suppose.

- i also need a bush for under the end of the gear lever pivot. The gear selection will feel like a totally differnt car if i can find the right bushes to take up all that slop that it must have had - Im surprised i was able to find any gears at all!

- cleaned up all the removed engine bay parts ready for some paint.

- did some half hearted wire wheeling and then sloshed the last of my old paint stripper around the engine bay.

Im going to order a clutch kit this week, some flywheel bolts and hopefully a gear stick pivot bush and see what we can do about the glass linkage bushes.

Meanwhile ill finish cleaning up the engine bay and get it ready to prime and paint.

-

pretty keen, have a target date for new engine/gearbox test drive!

-

got the engine out late yesterday, came out pretty easy other than the hoist getting limited by the roller door and where the stands where, and finally got the gearbox out tonight (after swinging it off the speedo cable

)

)they are both greasy as hell, and the gearbox and/or just the bell housing (why??) have been replaced before as the housing has 'Fiat 132' on it in wrecker pen, but the g/box definitly an early 125 4 speeder (ive tried lots of times to put it in 5th!).

not too many photos, greasy hands and I really need a new camera.

clutch is pretty greasy too, and throwout bearing is rough and has worn the clutch fingers

and this is the state of the bell housing:

i guess the crank seal was pissing oil out as the gearbox seal end seemed clean(er) and not as wet, and the back of the flywheel is pretty grim too.

Leaky seals have worked well to keep the engine bay pretty rust free however - its in relly nice condition under the greb:

And so i wont need to do any welding apart from this bit:

Which hardly seems worth all the bother now (not gutted about lack of rust - really!)

Might try some paint stripper due to all the funky crevices and my more recent layers of all sorts instead of a wire brush in the grinder.

Any (paint) stripper reccomendations?

-

Am in the middle of ripping out the engine on the 125, so wont be able to make it.

All going well, should be able to make the next one.

-

I Finally recieved a package i had been waiting for for nearly 4 months!

It contained far less than my original order, as i'd since got stuff in my last order from good ol US of A, but also a contained a few new things that I ordered since.

New 125 Dizzy cap, capacitor and rotor from the original order plus a rear caliper kit (for my spare calipers incase the other ones leak again) some gear linkage bushes (bushes in gear linkage currently = 0!) and a rear brake proportioning valve which i needed to put the bum down again. Rotor and cap for my smaller/newer 128 dizzy are also not obtainable (stupid side exit style only) so will have to make the big one work.

First up, I popped the valve in and bled the brakes up, chucked the wards on just for a change and to see if i like them again or not.

the wards have quite a high offset and rub but only on the drivers side rear. Im sure the diff is offset by about 5mm to one side, and the old one was the same. probably my arch repair on that side contributing as well by pulling it in a bit

Sigh, whatevs, Meshies it is then.

After that, backed it out the driveway, went up to the culdesac head and back again, and then backed it into the shed.

The new diff and shaft seems* to be a big improvement on the old one, (smooth and no vibration) so hoping thats sorted that, but I didnt want to really push it as I had only temporarily fitted the slip joint at the front end to ease gearbox removal which is the next job, and up the road and back in 2nd is probably not enough to tell for sure, but im feeling pretty good about it.

Here is a crappy phone pic for proof - painted up the lines and stuff while i was there too:

Onto the front. Bonnet off:

Radiator out (black) - ill probably bung the polished one in when i put an engine back in and see if the black one can be refurbished. Current one works well in that the car doesnt get hot, but leaks a wee bit.

The polished one has a heap of solder in it too but has slightly fewer missing fins and they also seem to be finer. Its also shiney.

Neither of them will be going back in for a while anyway.

The current engine is very leaky from pretty much everywhere, and the oil was pretty black when i drained it, and uses a bit as well:

Not sure where the oil is coming from to do this (crank seal?) but there you go!

All that doesnt really bother me that much, but 'hiding' behind the exhaust and under this mix of paint, bog and seam sealer is a bit of a crusty hole, which is the main reason for the engine coming out:

T'other side seems solid, but obviously could do with a tidy up too.

This is where im at, got stuck on dropping the gearbox, would only go back about 5mm before stopping hard.

After trying a bunch of time consuming things including taking my freshly installed driveeshaft off again, I give up and had dinner.

Re-reading the manual just now i realised that the lower flywheel cover tin needs to come off.

Probably wont be making it to the Burger Fuel meet in a couple of days then.

azzurro's 1969 FIAT 125 Berlina

in Projects and Build Ups

Posted

more media than im allowed to! what?

Video 1:

Video 2: