-

Posts

2,279 -

Joined

-

Last visited

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Adoom

-

Yesterday I discovered a long hose attached to the thermostat housing... It was just hanging out on top of the cross member and is blocked off at the far end. It's at least a meter long!!!! Why you no cut it shorter Barry?

-

Well I made it over the hill no problem. The horn has stopped working... I'm sure it worked when I got it, made a kind of paaarp noise. Another thing to add to the "And this is broke" list.

-

Bled the brakes again tonight using the Kyteler Hemi method and followed the books advice and did slow pedal strokes. Pedal seems better. I will drive it over the Rimutakas tomorrow to put it in the new shed. Taking a fire extinguisher..... not positive the fuel leak is completely fixed. Looking forward to having it on the flat and dry.

-

Right rear is furtherest away from the master in this case. The line to the back goes down the left of the car to a 3 way union, then over to the right wheel. I have a one man bleed kit, I think there is a one way valve in it. The bottle is laughably small, a few pumps will overflow it, so I use an old brake fluid bottle. But I will try the open nipple, pedal down, close nipple, pedal up, repeat method. I would normally use the method kyteler and hemi use.

-

Car is on a slope with the arse at the bottom. But when the rear is jacked up, it's more or less horizontal. Attach bleed hose to right rear nipple. twist nipple open. The assistant pumps the pedal, possibly too furiously, until I say "stop" and the pedal stays down. twist nipple closed. periodically check reservoir level. Repeat on left rear, then front right, then front rear.

-

It's got "automatic" ratcheting adjusters. The shoes seem to be snug inside the drum. I've manually adjusted them with the drum off until I can 'just' get eh drum back on. If I press the pedal, then press the pedal again, it feels better. So mechanical slack, or air? I think I will bleed them again.

-

I got some taper nuts for the spare steel wheel rather than use the shank nuts from the alloys. I also tried the remove handbrake cable, then pump brakes to get the shoes to adjust, then reattach the handbrake cable method to see if it helped with the pedal height. I don't think it made a difference. Why is my pedal so low??? I also discovered that when I put the compressor air gun on the master cylinder reservoir to try force the fluid into it, when I couldn't get it to bleed.... it was too much pressure, woops and cracked the reservoir a little at the base so now it leaks a tiny bit. Fortunately I have a spare. I sprayed a bunch of carb cleaner into the float valve and spun it around in its seat a bit. Seems to have stopped leaking, for now. I ordered a new valve and seat. $32!!! They are $10 in UK! But then the other one looked like it was leaking... but I think it stopped.

-

Bled the brakes. Fucked around a bit trying to get it to pump fluid, I think the master cylinder was full of air. But now it pumps nice clean fluid with no bubbles. Worked out I needed to remove the drums and pump the pedal to get the adjuster to tighten up the shoes. Now the handbrake works. The brakes still feel a bit meh, like the pedal doesn't do much until it's almost on the floor. Is there like a pushrod I need to adjust? The pads and shoes still need running in I suppose, that might make it 'bite' better? What should the brakes feel like? It's still overflowing from the rear carb float chamber. But the needle valve looks fine, clean as.

-

I finished assembling the master cylinder. I'll bleed it tomorrow. It's getting dark, which makes it hard to put the wheels back on. As requested, here are some shitty photos, cause the car is only half in the sun....

-

I got another brake master cylinder thanks to Threeonthetree and Tumeke. I pulled it apart tonight. It's been sleeved in stainless before and looks pretty good. It was full of black gunge still. There is a ring of something deep down in the cylinder that I cannot tell if it's dirt or damage, so I will get MP Autoparts to run a hone down it. There are two pistons joined together with a metal... strap thing and a spring. Two tiny roll pins need to be knocked out to separate the halves and get the seals off. I spent most of my time fucking about trying to remove the roll pins. I broke the small punch. The most effective tool to knock them out with was an allen key clamped in the vice and a bit of chip board to stop the hammer damaging the pistons... the roll pin ends up embedded in the chipboard. I got the piston set back together with new seals without fucking anything, just need the okay on the cylinder.

-

Looked at fitting my spare 14's, I think they are from a cressida. I found a photo of them. They are crusty now, the paint is being lifted by oxidation because they where stored in a damp place. Buuuut, I found that they need a shank nut that is shorter and a larger diameter than the ones for the hotwires.

-

Finished assembling the calipers tonight. Then thought, "I'll just put them on, it won't take long, outside, in the rain, as it's starting to get dark.". I got a bit wet, but they are on, as well as the new brake hoses. Just need that master cylinder.

-

Should I remove the foam/whatever insulating thing from the firewall? It just looks like an invitation for rust...

-

Thought I would assemble the drums and the calipers tonight. Started on the drums. Cunt cunt fucking fuck cunt what fucking fuck cunt bastard designed these fucking fuck things.... almost 3 hours later drums are assembled. Most of that time was spent trying to get the damn springs on. They must assemble them on the back plate at the factory, then put on the drive flange... or something.

-

I don't know how it attaches to the lower arm... Is it a hole I can surreptitiously drill, or a bracket that is welded on? Yeh, I'm wondering how it got a wof which runs out in July... so it got one last month? Did they even see the car? I would expect it to fail on: Black/low brake fluid. Shit brakes with a sinking pedal. Brake pads with almost no friction material Two small fuel leaks. Badly cracked alloy wheel. But I didn't notice until I went to undo the wheel nuts. I just picked up: New stainless brake caliper pistons. (rusty) new caliper seals(still some to come) new pads (were fucked) new shoes (worn) reground drums new caliper split pins(one broke) New e-clips for wheel cylinders. (one broke) Cleaned and stripped calipers(I couldn't get the pistons out) New wheel cylinders (got them yesterday) I have ordered: Front and rear brake hoses fuel pump rebuild kit Speedo cable I think I've spent over $500 so far trying to make it not a death trap.

-

I drove 650km on that wheel!!! I have some 14X6 in the container that will fit. I can't remember what they look like, probably don't suit it. I'd need tyres, don't think they have legal tread. It's possible I will be changing the brakes to something bigger eventually. So 14's or 15's would be better.

-

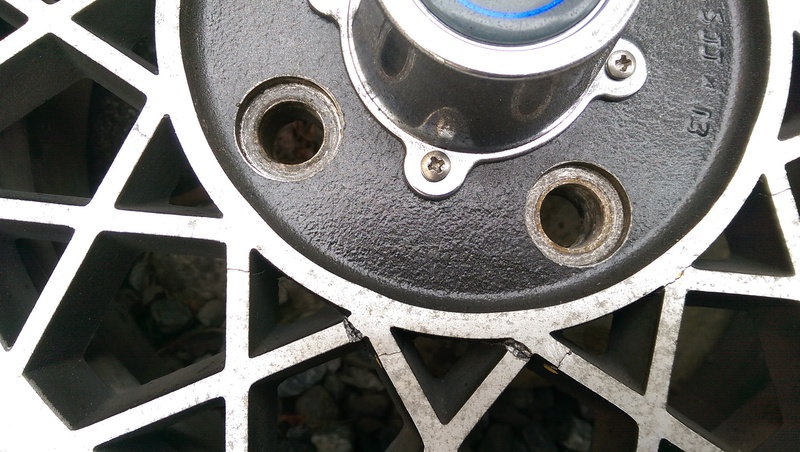

Left the calipers at MP Autoparts this morning. They have disassembled them and the pistons are fuckered. They will clean the calipers and supply seals, pistons and new pads. I'm getting new hoses too. I took the rear drums off tonight, they look okay, same goes for the shoes. The wheel cylinders are fucked as expected. I have two new ones to go on. One of the E-clips for the wheel cylinders broke, so I need another. When I took the rear wheels off... Shits fucked yo. Only one wheel is cracked. I expect it is beyond economical repair?? It has a spare steel wheel.

-

Off the top of my head.... Front anti roll bar and the bits to attach it from an S? Is there such a thing as a dash that is not cracked? Mine is more like cracks with a bit of dash on it.

-

So true

-

Are all the dash's the same size? There is a PI one on trademe, but it looks much wider than mine... I'd like to replace the clock with a rev counter. The clock is also drunk, when the hour hand is on the hour, the minute hand is on half past.

-

I thought it might be, but it didn't seem to make any difference. I will try again when it is dark.

-

What does that knob near the clock do? Need another brake master cylinder. Mine has been sleeved before, in brass which makes it harder to sleeve again. Also, I damaged the piston trying to remove a circlip, so that would also have to be sleeved. Woops. Removed the front calipers. Needs new pads, they are super crusty and very worn. Needs new caliper pistons, they are rusting on the exposed bits and the chrome is coming off. Needs new brake hoses, they are not cracked, but look real old. I ordered a fuel pump repair kit and a new speedo cable from Chris Witor. I got some new rear wheel cylinders, need to take the drums off to see if they are oversize before ordering new shoes.

-

Not even au. Just cruised down in 3rd and let the engine slow me down. Had to give the brake pedal some thrusts to slow a bit more near the bottom. Fortunately, the force was with me, and I didn't need to try stop at the bottom.

-

But it was okay, cause I just drove it with almost no brakes. Like a fuckin boss.

-

How Quick is quick? Yep, that one. Paid $2500 for it. I didn't get the parts car too, didn't really want it, or know how the hell I would get it home. Mine has a manual rack, I thought they were all power steering.... The steering wheel is super manky, it had a horrible sticky gungy Type S cover on it. I've pulled that off, but all that's left is the foam bit which is loose. I'm going to try split it and glue it back on then wrap it with bike handlebar tape or something...