- Popular Post

-

Posts

3266 -

Joined

-

Last visited

-

Days Won

2

Posts posted by kpr

-

-

someone doesn't like the metric system. but looks ballpark, long as there aren't any other compensation or 4d maps adding to it.

All the stuff from the states is super expensive atm, prices gone up and bad exchange rate. Looked into any of the jap brands? quite a bit cheaper getting stuff from japan if there's an option worth considering

-

1

1

-

-

Vac tank with 1 way valve, and 3 port solenoid would be way to go

-

2

2

-

-

looks like should nicely fill that dip at 6k

another run with those long bendy intake runners please

-

Was more meaning like in this picture rather than number 2. not the scratches but the textured look. should be able to look up and compare to some pictures what it means.

this is one of the mains i assume? number 2 looks like something else again

Either way it looks like it was knocking right up until failure, the way the piston is so clean in damaged areas. weather that was due to some previous damage. causing oil contamination in that cylinder. or a fuel/ignition advance issue is the question

I'd do a roman dave milk bottle injector test. That will test the ecu, injectors, wiring at the same time. give the loom a good jiggle around in the process, see if any injectors play up.

would work just as well / better than sending everything away to be testedAny chance we can get a screen cap of the ignition map?

-

2

2

-

-

Nar nothing like that on this engine.

the throttles are cracked open for idle speed. which is a little more than usual due to cams. I could probably run an isc and shut the throttles completely. make sure the isc is locked out at high rpm.

but rather avoid any extra stuff on this setup. also seems to be more something that happened to the box or engine thats in it atm. as wasn't as bad on the other engine. i dont recall having issues changing at 9k before, now about 7k is best it will do without waiting for revs to drop wayyy back. -

so helpful haha.

But yeh some tuning stuff is sure to help to a point. Swapping engines soon, so will throw the new parts in box at same time. maybe a combo of things is making it trash. kinda hoping the spigot bearing is screwed in the junker engine too.

-

2

2

-

-

yeah few places do them, but would rather try a j160 than spend 3k on close ratio gearset for t50.

I did come across another issue related to the junk engine in it. It real sloppy on deceleration, due to poor ring seal. its like popping neutral on overrun compared to the good engine.

So revs will be hanging longer than they should.Also looking into super light clutch/flywheel combo.

-

1

1

-

-

weird texture on the bearings can be signs of knock. i assume number 4 big end bearing is a pretty beaten up? what do all the others look like?

-

1

1

-

-

Yuck ^

17 hours ago, GARDRB said:It’s a pity it doesn’t log how many times you’ve loosened and tightened the cam caps, that number must be up there?

Number would be up there if it logged how many liters of oil it used

-

3

3

-

-

Takumi still using it bro

-

1

1

-

-

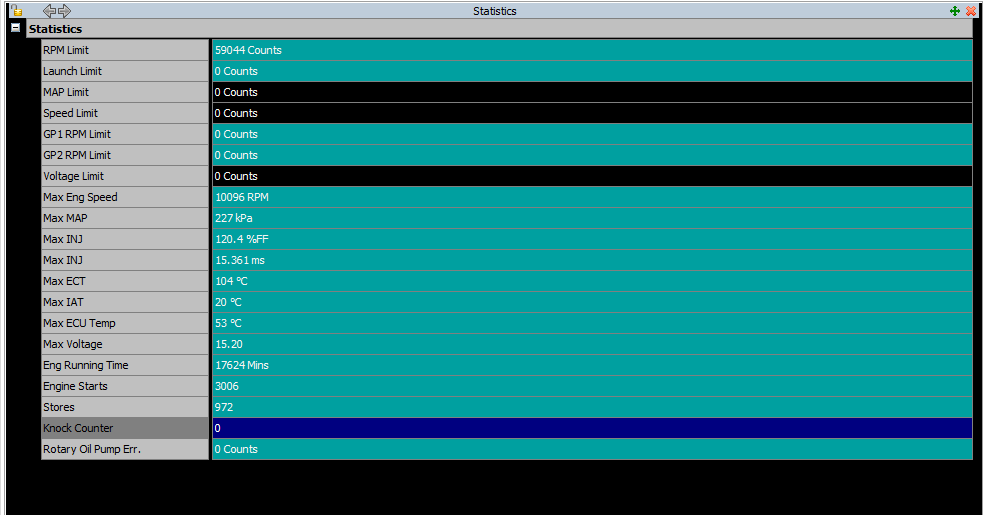

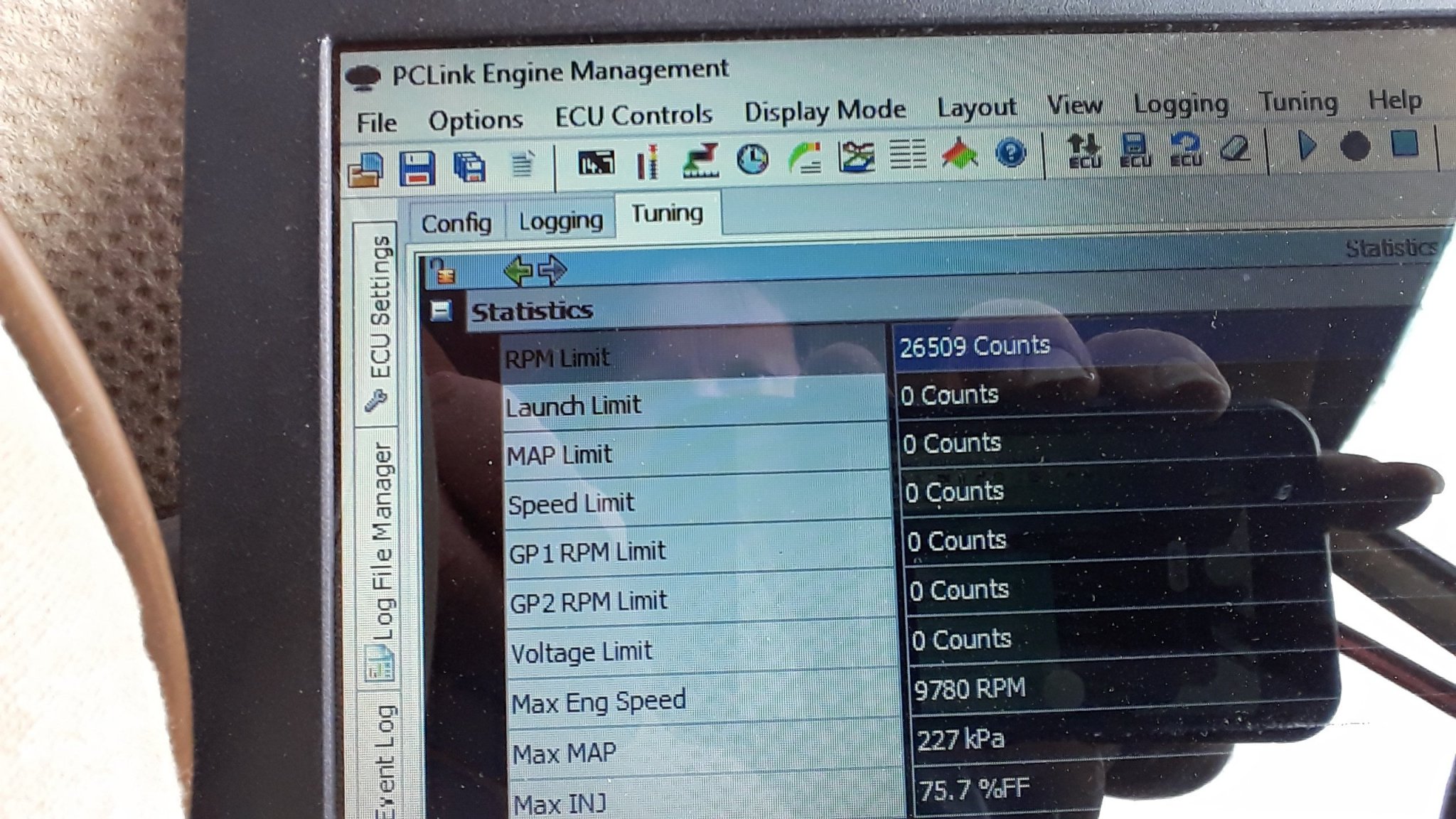

Unsure how often it reports a "rpm limit" I shall do some testing next time its running and report back. in the meantime here is a more recent one

/spam

-

4

4

-

-

- Popular Post

- Popular Post

-

Its just a G4 ecu. The gear cut control looks pretty basic

Pretty sure its a mechanical issue. as never once got it to change at high rpm.

but yeh that would be a good setup to have, to take bit of human error out.

Have some new parts on order to throw at it, hopefully will make it better

-

2

2

-

-

Possible has had some previous damage. and has been your misfire issue all along. if that hole was burning a bit of oil. which looks like it has been, would be more prone to knock. Which will have been what ended it for good, you'll probably find the ringlands just floating around in there when pull the pistons.

you can get all fancy and egt every cylinder. but making sure isn't set on the edge of knock when tuned is the main thing. checking the plugs after few pulls is good idea also.

Not saying it was a tuning issue. but also make sure you tuner is using knock detection and not just using ign map numbers that worked on another engine the same.

-

3

3

-

-

I tested it with a crappy supercheap compression tester awhile back before put the trd head gasket on it. 130 , 130, 100, 130. can only assume its worse now. with factory cams, no body home on 3 at idle. with the bigger cams idles like junk anyway so easy to ignore.

end game is to build the long rod engine properly. with the head off the 150kw engine along with vvti. around atlantic 4age numbers but with a massive power band and reliable is the goal. looks doable at this stage

turd will be coming out soon, and in the meantime will be putting 150kw engine back in. probably put a vvti setup on it also

8 minutes ago, Stu said:We need a video of the blue plumes from outside the back of the shed

Too many bits of pistons and rings coming out the exhaust, might break my camera

-

4

4

-

-

Yeah found the same thing. looks like couple of them maybe the same was w/g box. but not much coming up for them either

dog box way out of my budget. Think i'll throw some new oem parts at it if cant find anything else. I probably didn't put a new spigot bearing in the end of crank, when put the junk engine in. so probably a suspect worth looking at that could be causing some drag if its toast.

It used to work fine with 9k limiter and bigger 212mm clutch. so thought another 1000rpm wouldn't be too much to ask.

-

1

1

-

-

Only oem by the looks

-

^ clutch was adjusted like that, to the point thought may have not quite been releasing. so gave it a little more, no dice

It has the small 200mm friction plate. but will see if anything "light weight" is available without going too silly.

Maybe will throw some fresh syncro rings and sleeves in it

-

my poor old t50 doesn't want to shift gears at 10k rpm. around 8k seems ok. just that bit more is a no go. All the gears seem about the same

So yeah probably not a very common thing. But trying to figure out if its a limitation of the box, its just old junk i can fix. or if can modify it to work better. have heard of people filing the teeth down on the synco's or the likes

Or same deal with J160 boxes. anyone used them at 10,000+ rpms? could be an option to swap to.

Have tried the usual stuff btw, adjusting clutch etc.

-

"forged" likely the same process as toyota has been using since forever, they just started making them lighter in the late 90's. not like the 80's-90's stuff that you can run a zillion hp on factory bottom end

-

1

1

-

1

1

-

1

1

-

-

can you get in there to measure the valve lift at tdc with dial gauge or even by eye? should give you a pretty good idea if cam timing is right.

-

How much are you guys paying for a 90deg 3" from autobend? or any 90deg for that matter. I can sort roman out with some stainless, is about double the price of that sta stuff for bend. but sta stuff also sounds like it should go straight in the bin haha

-

I have no idea what happened to that engine. seems ive owned 3 20v's in my life, for shame. although only ones made it out alive

-

1

1

-

-

- Popular Post

- Popular Post

Can someone tell me if this a normal amount of smoke for a 4age? seems about right to me?

10200rpm on stock 2nd hand oil pump and 300,000k pistons/rings and crank. seems like the winning combo

Yeah it really needs to come out. but want to put some run time on the vvti setup.

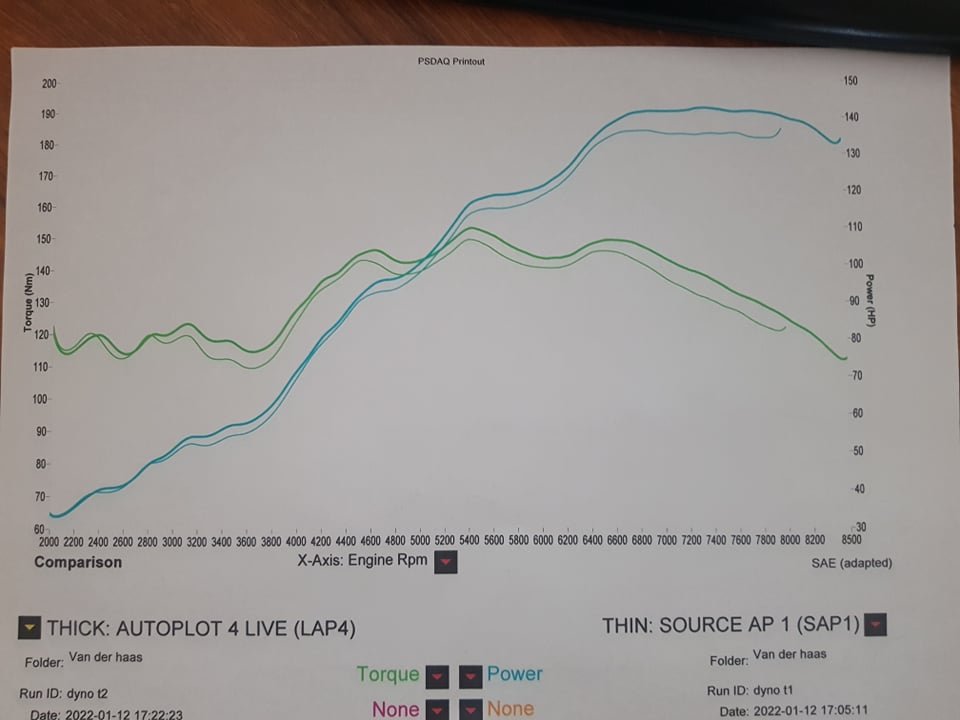

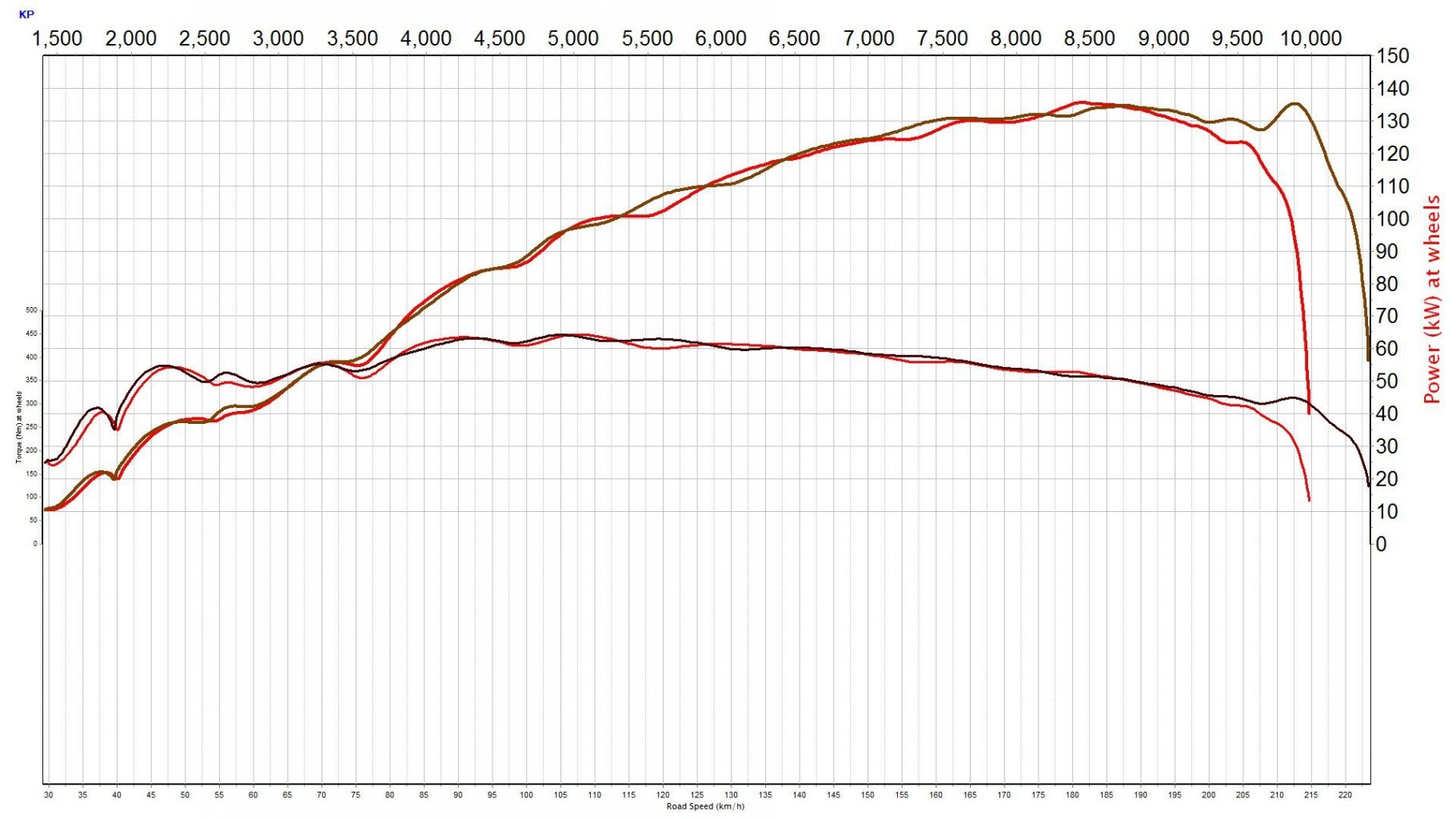

Had a little play with some shorter intake runners. looses the peak off the top as expected, if just jam them on. same deal as with fixed timing. but after tuning the vvti, was able to pretty much match the peak

of the longer runners and gain power after peak. Holding on real well right out to 10k with the little 193b cams. Looking good for the end game setupred is normal intake runner length

dark brown is 40mm shorter - ignore bump at end of run dyno tends to have a frizz up there at that road speed.

Both with vvti dialed in.-

31

31

-

3

3

kpr's kp60

in Projects and Build Ups

Posted

Turd engine is out

Would have liked to run the vvti setup for awhile longer on this engine to prove reliability. But gearbox issues and time to keep things moving

Gearbox issues being; it wont change gears at high rpm. which is rather annoying when engine pulls 10k, but can only rev it to 7 if want to grab another gear.

Decided to throw some new parts in the t50 to attempt to make it better.

Some parts are no longer available. but managed to get syncro's and selector sleeves and a few bearings.

One of the parts no longer available is this bit, the dogs that sit on side of the gear. also happens to be pretty tired on most gears. I managed to pinch one out of my pile of parts, that was slightly better for 3rd gear. The other ones from my parts box (t40) were different design and were welded to the gears. so no go

Angle grinder to the rescue. No idea how well its going to work, and probably should have set it up in lathe so angles were bang on. but cant be any worse than being blended like above. gave both 2nd and 4th bit of a zing like this.

All back together. much easier to work on than a w box

Also got one of these on the way. kinda winging it and hoping it will fit with stock style flywheel and pressure plate. as its from a orc clutch/flywheel combo.

The sprung center in the current one seems fairly heavy. so this plate should cut down a bit of weight syncros have to deal with