-

Posts

1,607 -

Joined

-

Last visited

Everything posted by ~Slideways~

-

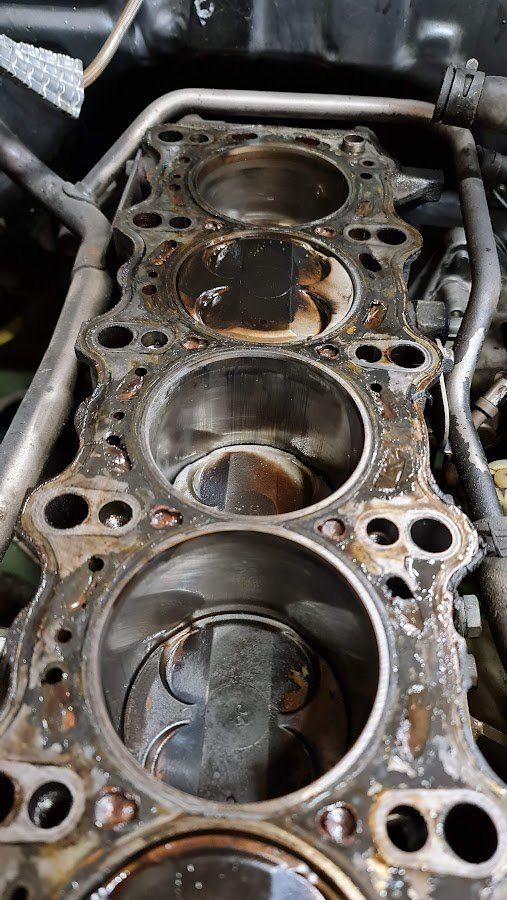

Automotive sadness ensues: The piston looks far worse than I expected. The ring lands look intact too. Another unexpected thing is number 2 had what looks like corrosion on the bearing? And some of the others have scoring which is maybe piston material going through the system since I can now see that the piston particles/melted bits worked their way below the rings. Everything went pretty smoothly with the disassembly except this one bastard allen bolt on one oil squirter. It was so tight that it rounded the inside of the allen head. I ended up having to chisel a groove into it to use an impact driver. No other damage though so just need a replacement bolt. Going to send the ECU off to Link to see if they can test the injector driver on number 4. Will contact to find out what can be done, even just paying to have it replaced just incase. Dropped the injectors themselves to be tested late last week.

- 419 replies

-

- 13

-

-

-

I reckon the block needs machining so probably 0.5mm oversize since that is a commonly available OS forged piston. I didn't do a 1NZ double windowed job at least, right?

-

Will still see if the injector is the culprit but it doesn't seem likely as it is all filtered properly and they were cleaned and tested when trying to find the misfire cause. Haven't made much plan for the rebuild yet except looking at piston prices and deciding I don't really need to replace the rods since they are more than enough.

-

While I did build it with Ethanol in mind, E85 was gone by the time it was ready for it so it never actually ran Ethanol, not even E10. Only ever BP98. Good thought though as I changed everything to ethanol safe but didn't think of the fuel rail. The injectors are powered with their own dedicated relay and fuse but no ballast resistor no. EDIT: will be getting the injectors tested again.

-

I ran the Xspurt ones for a while but changed to st215 injectors about 1-2years ago as the spray pattern was better. The Xspurt ones appear to spray directly at the wide port divider on these heads so lose atomization.

-

This would be a silver lining really, finally having an answer for the the intermittent misfire. So much so I feel like a broken record writing the words 'intermittent misfire' so many times. I don't think it was a tuning issue, it has been on the same dyno 4 or 5 times now using knock headphones and the fact that it was only one piston while the others don't appear to have any signs of damage. Right now the most likely theory is that it already had piston damage from it's previous life, maybe ring lands from too much boost on stock ecu back in Japan? Thanks for throwing some of your experience at this, really helps getting my head around what could have happened etc.

-

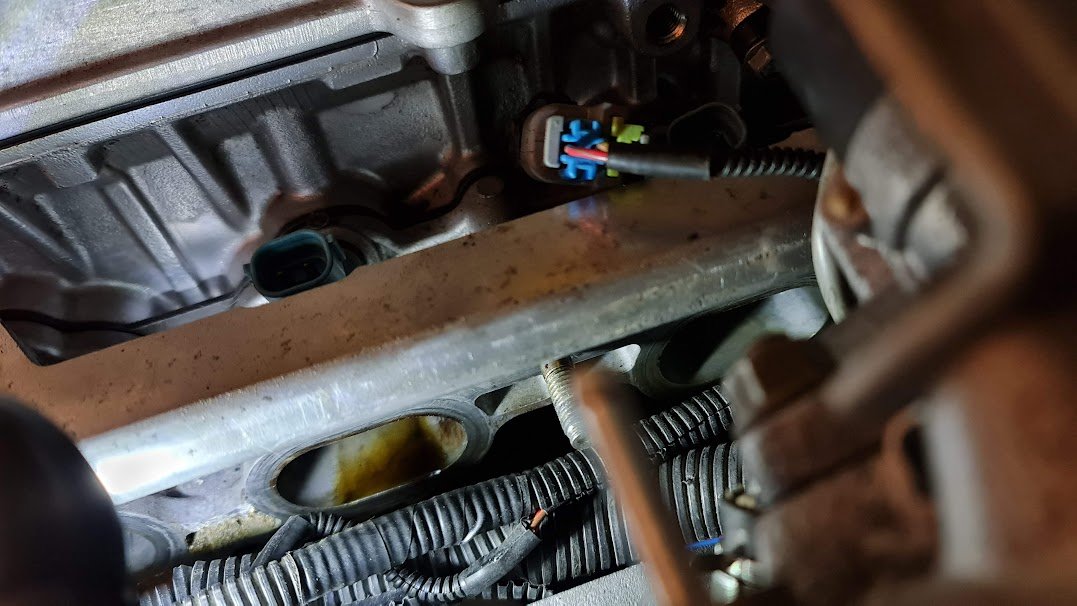

It does seem like it was gradual yeah. And it makes some sense that it just got to the point where it let go. Cooling looks ok but haven't had a good look yet, the thin black layer of the metal headgasket has stuck to the head and makes it look like the cooling passages are partially blocked but its just that thin later left behind. Will have a better look though. I imported the engine in a car from japan (jzx100 earlier in this thread), drove it around the block and compression tested ok. It had the stock turbo and ecu but it was a basic amature drift car type thing so more than likely had the boost increased. So maybe it had a cracked ring land all along but was able to hold compression most of the time? Never had the head off no, didn't have a reason to. Would have been interesting to see if there was any damage that slowly killed it though.

-

Took the exhaust side off and did the kerosene test there too and it looked fine. So took the head off and found this, fuck. Number 4 is melted on the exhaust side and pitted on the intake side. All the other pistons look fine. The headgasket looks fine too. So I'm guessing it went lean on just one. But was this a short term thing or long term? The bore has light scoring when the others don't. It feels smooth though so not too deep. You can see the exhaust side of the cylinder has a build up of what must be melted piston. It's like tiny bits of the piston built up since it protrudes from the cylinder wall rather than eaten into it. It does look to have removed a coating from the wall, not sure what's going on there. The same build up is on the head. It doesn't look to have eaten into the head material though. The head looks worse in the photo than it is. Hopefully skimming it will be enough. As you can see, the valves look good and were likely never the issue. So at this stage I am leaning towards the injector on number 4 having a flow problem. But am open to suggestions. At this stage I think I will go with oversized forged pistons and use the stock conrods since they are meant to be plenty strong for the kind of power I wanted from this. The intermittent misfire could be the cause, if I only knew what caused it, not from a lack of bloody trying... The same thing happened with the Xspurt 1000cc injectors and with the 550cc 3sgte injectors. Both of which had been through an injector cleaner. Swapping coils with a known good one made no difference either. Or it could be a faulty ECU causing the misfire. Maybe the intermittent misfire isn't the cause since it happened at light load. Either way it needs rebuilding, but how do I stop it happening again?

-

Yeah I guess I'll still check the exhaust side but either way the heads going to need to come off. Cars can be a bit of a dick sometimes

-

*Searches Real Street Performance...

-

Well this throws the intake valve idea out the window, as a test of the sealing of the intake valves on number 4 I squirted enough kerosene into the port to cover both valves and nothing drained away. You can kind of see the fluid here: So I took the exhaust side cam cover off and checked the buckets, they look to moving perfectly and the clearance is good too. Compression tested again and still zero. Squirted a bit of oil down the spark plug hole and it made no difference to the compression reading. So now I guess it is either the exhaust valves not sealing, the headgasket or the rings/pistons/bore. Won't be able to do anything on it for a while now but just wanted to try confirm what the problem was... I guess I've confirmed what the problem isn't. I suppose when the head is off it will make it obvious but I didn't want to take it off until I'd done some testing. Fearing the worst now, bore damage, broken ring lands, something went through and damaged the combustion chamber too. Confused how the leak down test indicated the intake valves on number 4 were leaking into the intake.

-

OK got the intake manifold off and first thing I notice is that number 4 intake port has a decent pool of oil. The other 5 are clean and dry, so that isn't a good sign. EDIT: unless they put oil down the spark plug hole to confirm is the rings are gone? Not sure they would have. So is this coming from a buggered valve stem seal or sucking up past the rings, explaining the lack of compression. Removed the second part of the manifold so I can see in the port, I can see a large area of the valve and they look super clean and I see no damage. But I cannot see the whole surface, its possible the inner edge is where the problem is. Very hard to focus when the valve is open. So the oil isn't a good sign, maybe it really is the bottom end even though the leak down test didn't indicate this. But I guess the next step will be checking the exhaust side or maybe taking the intake cam out and removing the buckets on the 4th one.

-

Have pulled the intake side cam cover off and on number 4 the clearance on both shims is the same and within factory spec of 0.15mm to 0.25mm. Turned it over with the key a few times to see if there was any sign of a bucket getting stuck and it looks totally fine. Compression tested number 4 and it's got nothing, to confirm I tested number 3 and it has good compression. So that at least tells me the bucket isn't getting stuck and keeping the valve open, because its all the way up and there is no compression. Next I'll take the intake manifold off and see if it's possible to see the back of the valves.

-

Yeah I think you might be right, I guess maybe the adjustment is for sensitivity to the swiping over the magnet.

-

Haven't had much time to do car stuff but good news is I've got the 4g15 wiring sorted and it runs now! It was previously firing once then dying, every time you turned the key it was a half second fire then dying. This was after finding the neutral switch wires so it would turn over at all now that it has a manual gbox on the side. Checked everything and found this black box under the dash, unplugged it then it started and ran first time! Yay. So it must be some kind of immobilizer, it has an LED that blinks maybe once every 5 seconds and a rubber bung covering an adjustable knob thing. Looks like maybe a relay at the bottom there with a magnet? On the casing there are two holes above that spot, is it meant to have something sit there to move the magnet? Why does it run when it is unplugged? What is the adjustment for? A mivec controller? But why would it stop it from starting? Weird.

-

I've come across some old forum posts talking about 2jz's having buckets get stuck so this is definitely a possibility, I'll hopefully get into it soon.

-

Yeah definitely will be interesting to see if there is a bigger gap, binding could explain it. That's definitely better than the alternative of the valve being damaged because I'd want to know why it happened.

-

Put this back on the dyno last week to redo the boost table since last time, which was about a year ago, it was found that the little filter thing on the solenoid is quite restrictive. So it wouldn't allow enough air to be bled for more than 16psi. On the street it goes great on wastegate pressure which is 10psi. Got the call that after 20 runs it started running on 5. Big puff of blue smoke (think there might have been a noise...can't remember the exact description). Compression test showed zero compression on number 4. Leak down test is pushing air back into the intake manifold so it has to be an intake valve problem. Nothing excessive out of the oil filler hole. The spark plug does not show signs of running lean. No knocking or metallic noises. Obviously not what I'd hoped for but that's where we are. Had a big think about it and am wondering if there has been an issue with one of the intake valves since day one. It could explain the intermittent misfire which the long list of things I've tried has not resolved. i.e. something making that valve not seal sometimes and is now worse. Got it home on the trailer a few days later. It runs on 5 with no bad noises except sounding like a Subaru. So I decided to compression test number 4, and from stone cold it immediately made a decent amount of compression? Not zero. I didn't take note of how high it went but it shot up and held it after just the first few turns. OK, so I put it back together and start it up thinking maybe the theory of an intermittently sealing intake valve makes some sense now. It still ran on five, I double checked the injector/coil plugs etc. So I compression tested number 4 again and now it makes zero compression like had been reported at the dyno. The needle barely moves. OK. Interesting. So while this has all been quite disappointing to say the least, I am looking on the bright side, getting angry at it won't fix it. The bottom end is hopefully undamaged (hoping a piece of valve hasn't dropped into the bore, because it was able to make some compression at first). No bad noises. Could it be the spring is bad? The valve spring seat/keepers are loose? Worst case, something melted causing damage to both the head and bore. Middle case, damaged valve. Head comes off and rebuild it. Best case, a replacement valve spring/keepers/seat solves it without taking the head off. It'll be a while before I have time to look at it now but am keeping my fingers crossed. Still looks cool though right?

-

My 200sx 1jz car lost compression on the dyno last week so needed to get the 'parts lancer' off the hoist, so put the 4g15 in and got it rolling again. This combination of transmission jack (500kg rated) to position and lift the engine up in stages plus the hoist to lower the car over it works pretty well. It's in: Wiring is a bit different but have got it turning over at least and confirmed the clutch is all working. Will look at the rest later. Found some amazing twist and tape wiring in a few places: Also here is the fuel filter cut open, this is the one which I suspected might be causing fuel starvation on the mivec/parts car. Doesn't look great but not really as bad as I was expecting. Could still be blocked with tiny particles. Have now moved it out of the garage since the wiring doesn't require it to be on the hoist.

-

Took the manual fwd gbox off of the mivec engine. Cleaned it up, didn't take a photo so just imagine it has less dirt. Put the gbox onto on the 4g15 and confirmed that the bellhousing bolt pattern is the same which is good. Also welded up a crack in the lower radiator support, just looks like someone positioned a jack in the wrong spot. Fixed now and painted. Think there might be a difference in the power steering pumps because the crank pulleys are different between the engines. Hopefully I can mix and match something to work. Mainly an issue because the mivec engine has a non-A/C type bracket for the P/S pump, which includes a idler pulley to tension the belt where the A/C would be. But the crank pulley on the 4g15 might stick out further. Guess I'll see.

-

- 122 replies

-

- 14

-

-

-

Oh and before putting it on the hoist I checked the ign timing, I couldn't find anything about having to bridge any pins or anything in order to check the base timing. But checked it anyway and it's consistently in the same spot on the timing cover mark but didn't go any further than that. It's all coming out and changing anyway. It idled fine but when I went to move it, it would almost die under a little bit of throttle. Like it was running out of fuel (it did the night before I bought it, so I'd put in 4-5L to test drive it at the time). So I put in some more fuel but it made no difference. Coughing and spluttering. Maybe the fuel filter is clogged? I'll check it when I take it all out.

-

Doing more work on the parts car than the 4wd one! Had a good clutch and the correct flywheel for the 4g15 so cleaned those up and installed. Put the parts car up on the hoist and started removing bits. It's a bit rough but it'll be a good car when done. Here is my temporary way of shutting up the exhaust leak for the test drive of the engine that is coming out of this lancer. Fibreglass sheet, aluminium tape and some hose clamps. Worked pretty well lol. Have drained the gearbox, engine oil and radiator. Removed front wheels, found a snapped stud, loosened driveshaft nuts. Quite like the colour too. Don't like the wheels though.

-

Tested the resistance of the water temp sensors from the mivec parts car and compared it to the one of the spare head I bought earlier in the thread. Both react to hot and cold water the same, both have the same resistance at room temp. So I think they are ok. This water temp sensor is in the back of the head rather than the one that is in the thermostat housing, which is definitely for the water temp gauge. So I assume this other one has to be for the ECU water temp. It was worth a try though, could still be related. Maybe the wiring is damaged etc.

-