-

Posts

1513 -

Joined

-

Last visited

Posts posted by ~Slideways~

-

-

Lockdown means a bit more time for projects.

Put these on, a 2nd set of factory 15" Enkei's. Really light, the tyres are a bit old but will do for a while.

Monster truck ride height, mostly due to not settling...he tells himself.

Also have two spare Momo steering wheels, the stock steering wheel is a bit big and the top part moves/twist around a bit which is annoying.

Choice of an old Momo competition model from the early 90's I think, slightly smaller than stock but nice thick grip.

Or the Momo Corse like I have on the 200sx which is smaller than the Competition. The photo makes it look bigger.

Can see the Corse on top is smaller:

Decided to try the Corse first.

Stock wheel, nice day:

Momo Corse, overcast next day:

Moving it around on the driveway and its definitely a bit more work due to no power steering but feels good and much more solid feeling than the stock one which had some flex.

Also decided to grind back the cracking paint on the drivers side guard, which is where it was dented and I'd hammered it back out. Put some brunox on it for now.

Not that I have any kind of top coat to suit...

-

6

6

-

-

Since the last update I've put a few thousand km's on it, every time I am impressed by how responsive it is with the relatively big HX35. The exhaust manifold with the small runners must have really helped make it spool early, most likely meaning some restriction in high revs but man it's so good.

It STILL has the mystery intermittent misfire. It has a brand new genuine Crank Angle Sensor and I've borrowed a spare R35 coil and tried it in all six position with no change. Takes ages to test since it sometimes will not have the misfire until 30min into a drive, sometimes within 2min.

Every time, it goes away if you let it drop to idle. i.e. doesn't come back immediately no matter what the conditions are. But if its doing it and you increase revs, even with clutch in, it will continue to misfire until you let it drop to idle. Bloody frustrating.

So I guess I've confirmed it isn't a faulty coil, unless its more than one.

Next I'll be trying a temporary constant power to the coils to bypass the relay and loom.

The heavy duty clutch, went in earlier in the year and it went on the dyno again. Developed a misfire after being on the dyno for more runs than previous, so likely heat soaked etc, changing the crank sensor filter improved it. Once I came to pick it up, it was still on the dyno and had cooled down. Plan was to show me it misfiring, but it did clean runs, I guess because it had cooled. So I ordered a stupidly expensive genuine sensor.

The sensor has been in for a few months, but too busy to do more dyno time and I wanted to try swapping the known good coil.

So I am enjoying driving it greatly it's just like this ongoing 5% of the time problem type thing. I move onto another project for a while until I have the enthusiasm to do more 200sx testing.

Here are some photo's from putting in the new clutch, took the opportunity to put in some heat shielding since the tunnel gets really hot:

Clutch and flywheel:

The other day it randomly blew the fuel pump fuse, driving home from work and the engine died. I keep a laptop in the car to connect to the Link and everything seemed fine until I realised I couldn't hear the fuel pump.

Really weird failure, it looks like the fuse had been getting hot and melting stuff well before it blew. Work mate suggests it could have been corrosion causing resistance?

This is a dedicated power wire from the battery, which is triggered by a relay and the ecu. Strangely it has been fine for almost 2 years...

Nasty:

I got it home totally fine with a spare fuse.

Have now replaced the whole thing.

Also the clutch took about 1000km to be much nicer to use.

-

7

7

-

-

1 hour ago, kyteler said:

It got to sit with its younger, stronger brother for the first time today

That's a nice pair of cars, I'm kind of sad I never got an rx7 (and others) before the prices got too high. I came really close to buying an FD rolling body but got my 200sx instead, don't regret it...should have bought both.

-

3

3

-

1

1

-

-

I ended up loaning the Laser to someone so have still been using this as a daily driver, so no speeduino testing like planned yet. Soon will hopefully have a ST202 Celica wof'd to take over that idea.

I did cut up the spare stock 1.6 exhaust manifold though, I plan to reuse the flange to make something that flows a bit better. Kind of keen to make a stupidly long bendy spaghetti thing just because.

It's strange that they put the tube inside the hole instead of outside so it would match the head ports? Maybe its easier to weld?

The flange on the other end is necked down to about 41mm or 1inch and 5/8 other-inch-parts once you account for the internal welding again. Again, pretty small considering the ports work out to be about 38mm.

Out of interest I cut it off at the collector to see how bad those squished tubes are, and while this looks bad:

Its not actually THAT bad, at least they are shaped to meet in the centre I suppose:

The ports measure to about the same as a 38mm tube so I'll probably just make something out of mild steel mandrel bends.

-

3

3

-

-

A dead one at PaP Lower Hutt.

*Includes shadow of dingus awkwardly taking photo while holding parts/tools.

-

1

1

-

1

1

-

-

1 hour ago, Roman said:

Yeah you can do it in bits that slot together.

240 and 110 deg will likely be fine. Main thing is stopping drafts.

I've not tried printing the carbon nylon stuff because it's a real ball buster of admin work to keep the matieral ok for printing.

You have to bake it before your print it to get the moisture out, then it reabsorbs moisture so quickly from the air, that you need to keep it in a dehumidifier box while it prints.

A smaller printer is considerably considerably easier to work with with way less headaches.

I'd say 70% or 80% of the prints I do are under 250x250

Awesome thanks for the info.

-

20 minutes ago, Roman said:

Yeah it's definitely a cool thing to have, I have tits for hands when it comes to fabricating things so it's really bridged that gap for me.

And now I think it's got me thinking more about how I'd actually fabricate something, when it seems intimidating when you dont know how to start otherwise.

I have a Creality CR10-S S5.

So it's a 500x500x500 build size but otherwise a pretty cheap and basic printer.

I wouldnt reccomend how it comes out of the box unless you wanted to print PLA only (material that isnt really usable in hot conditions or for things like manifolds)

To get it to be able to print stuff like HIPS I needed:

-Change to direct drive extruder

-240v heated bed

-build a shitty enclosure

-new controller and firmware that is 32bit instead of 8 bit (It would choke up a bit when there were lots of commands to do quickly)

-solid mount the bed instead of springs

Probably about an extra $4-500 worth of stuff, and shitloads of time calibrating things.

But now it's an invaluable tool for me.

Ah so that's quite a large one! I was looking at the Ender 3 Pro which says it can do Carbon Fibre (not sure if that's the right thing). But the build size is much smaller at 220x220x250.

From what I can find the nozzle can do 240degC and the base 110degC so maybe just shy of what is needed.

I suppose a manifold could be designed in pieces that slot together?

-

1

1

-

-

3 minutes ago, Roman said:

Do you mean for my manifold, or the other bits?

I'm still using the same manifold from day 1, so I'll call that a win.

Once I put the carbon on it, it's been fine since then.

The only real reliability problem is that my throttles are held in my tapping into the plastic material.

If printing another one I'd make the tapped area much longer so it spreads the load more, or design it so steel threaded inserts can be pressed in from behind.

To print this material (HIPS) you need a printer that can get the nozzle to around 250 degrees, and a heated bed that can go 120ish. Then you need an enclosure to stop drafts (this is probably most important part)

then it's still a bit of a bastard to print haha. Loves to warp.

Most off the shelf printers cant go that high for nozzle or bed temp, but these are easy-ish upgrades you can buy for not much.

Yep was meaning the manifold itself, it really interests me since I've been looking into ITB's for my MX5 on and off for a while now. Options are either high end expensive CNC stuff or DIY to keep it affordable.

The DIY path has a few options like 20v ITB's with a tig welded flange onto the stock cut down intake manifold. But its a compromise due to port/runner shapes and spacing. The other is using motorbike ITB's with silicon joiners to the cut down manifold but again it's a compromise with either running out of room or having bad flow etc.

Doing something like you've done makes more sense to me, as long as it lasts a decent amount of time.

Plus the option of printing different trumpets etc is pretty cool.

What kind of 3d printer do you have? Do you recommend it?

-

I'm not sure if this has come up but what kind of 3d printer do you need to do this sort of thing?

How is durability now?

-

-

- Popular Post

- Popular Post

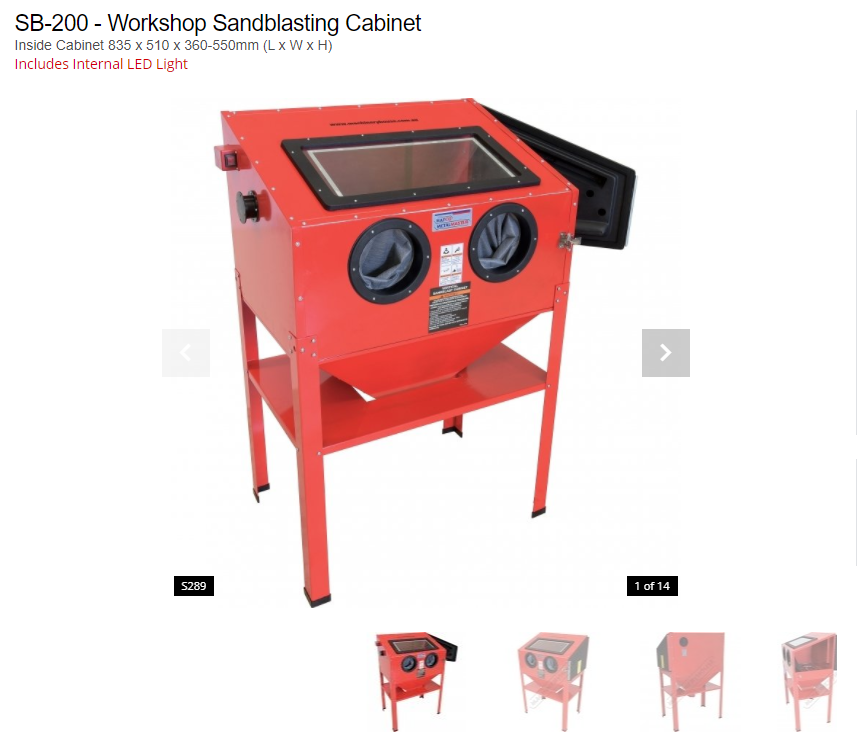

I bought a cabinet a little while ago from Machinery Warehouse. Slightly different design but probably made in the same place:

I found that the pick up tube is terrible, its just useless. Any pressure from 50psi to 120psi and a big air tank, it just barely works. I tried all sorts but it just wasn't very good at picking up the media.

So I modified it like this so the sand pick up is from the bottom trap door, using 40mm steam pipe and some 19mm heater hose back to the gun through a hole drilled in the side of the cabinet.

Got the idea from these 'metering valve' kits people sell to do exactly this:

It was made from what ever I had available to test the idea, that nut welded on the top had a ball valve tap on it but it was too small to let enough air in. Works great without the valve.

Now it works awesome, constant flow of garnet. Now its actually fun to use and not constant frustration.

I do still occasionally have the gun getting clogged so just cover the outlet and let the air bast backwards through the feed tube and then its good again.

I'm currently fixing up a ST202 Celica, some parts could fit in the cabinet:

-

17

17

-

1

1

-

-

3 hours ago, Stu said:

I'm not entirely sure yet if Im honest - it needs some body work and I'm about to pull the trigger on getting it done then back on the street, but would obviously want more for it then. I'll have a think about - send me a PM if you are genuinely interested.

Done

-

1

1

-

-

3 minutes ago, yoeddynz said:

Yes. Must have been a facelift 2. Some of those had a 1400cc engine with direct spark.

But why no photo?.....

Haha I'll see if its still there tonight.

-

2

2

-

-

That starlet is pretty cool, would make an awesome daily... I currently have 10 fckn cars but what's it worth?

-

Saw a 2002 model down my road while walking the dog last night. Isn't that the last year they were made? The headlights looked clear and a slightly different shape.

Why am I looking at these?

-

1

1

-

1

1

-

-

1 hour ago, Roman said:

Bit steeply priced, but there's one on TM at the moment

https://www.trademe.co.nz/a/motors/cars/toyota/vitz/listing/3135567620?bof=wRVSXaqQ

4 door though, booooooDon't mind 4 door too much but yeah, $4500 seems a bit much. There is another locally but its a 1999 for $4k, would really want a 2000+ for 12 month warrants.

I wonder what the solid axle is? s-series? t-series? Do they even still make them?

-

God dammit, now I want one.

-

1

1

-

-

- Popular Post

- Popular Post

Did almost 20,000km in this in the year I've had it, so much fun to drive and change gear more than is necessary.

Currently driving a very boring 2000 Ford Laser hatch (Mazda BJ chassis) with the 1.6 ZM-de, which is the same engine family as the mx5 b6ze from what I understand. Apparently the head will fit onto the B6 block with the only difference being 2 extra oil drains on the later engine. But the port design is different etc, no fancy VVt or anything. But the 1.5 zl-ve does have vvt, so its an interesting concept to maybe fit the 1.5 vvt head to a B6ze?

While it is rated to a similar power it feels very lethargic compared to the Mx5, it's probably mostly gearing but maybe the later head's port angles are more economy designed like FE Toyota heads?

Current plan is to use the Laser for daily duties and then install the Speeduino in the mx5 so I don't have to rely on it for commuting. So basically a daily for my daily.

I swapped on some R888's and later 15's mx5 wheels (enkei's and really light) and drove it rain or shine for a few months. Can seriously throw it around with those on it.

Had the roof down on single digit morning, good way to wake up for work. Hard top back on now with all the rain.

Took it for a hoon out to the coast for lunch a while ago, was a super clear day too:

-

18

18

-

More please.

-

1 hour ago, shrike said:

I get the appeal to go with a period correct engine and twin carbs.

But personally a hotted up (high comp etc) frakenbuild of an original motor setup with an EFI conversion and DBW ITBs would be pretty cool

especially on E85 (maybe a supercharger long term?)

especially on E85 (maybe a supercharger long term?)

Don't know much about the engines that go in these but fully support the goal to relive your younger years

Sadly E85 isn't really an option in NZ anymore.

-

1

1

-

1

1

-

-

27 minutes ago, igor said:

Did you get the impression that she really want's it gone?

Nah not really, I think she found it amusing that I was another person asking. But that fact that she wasn't annoyed at this random person asking is good I reckon.

-

On 02/11/2019 at 11:34, ~Slideways~ said:

Was on a bike ride with my boy and saw a lady sitting in a car in this driveway. Asked what the story was and got the "I'm not the first to ask about it. It's his baby, he plans to do it up one day" answer.

But then said I should come back with some cash and try convince him. I get the feeling they will think its worth heaps even though it's rusting away. It's hasn't moved in the 8 years I've live in the street.

Such a shame because there is a rust hole at the bottom of the rear window so it'll be filling that rear quarter and rusting from the inside.

Wonder if the reg is on hold?

-

1

1

-

-

15 hours ago, Roman said:

Well how much is turbo stuff?

With a budget of 80kg for turbo stuff, that's a lot of turbo stuff to break even!

haha yeah maybe not 80kg's. But at least some of the lightness will be in the plastic intake etc, probably only talking a few extra kg's if you make a simple aluminium one though.

I wonder how strong the engine is? I know Mighty Car Mods's's Yaris didn't last long, who knows what condition that was in beforehand though.

DIY Fuel injection thread.

in Tech Talk

Posted

I watched some of the live speeduino update thing and he was saying that the chip shortage has delayed it and some are unobtainable now, so is having to redesign it. Crazy how many things are being effected now.