-

Posts

352 -

Joined

-

Last visited

Posts posted by 1963 AP5

-

-

-

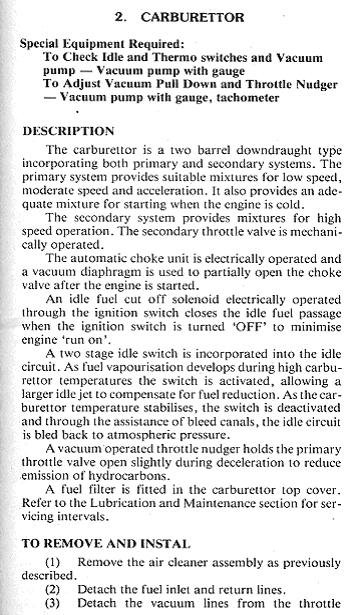

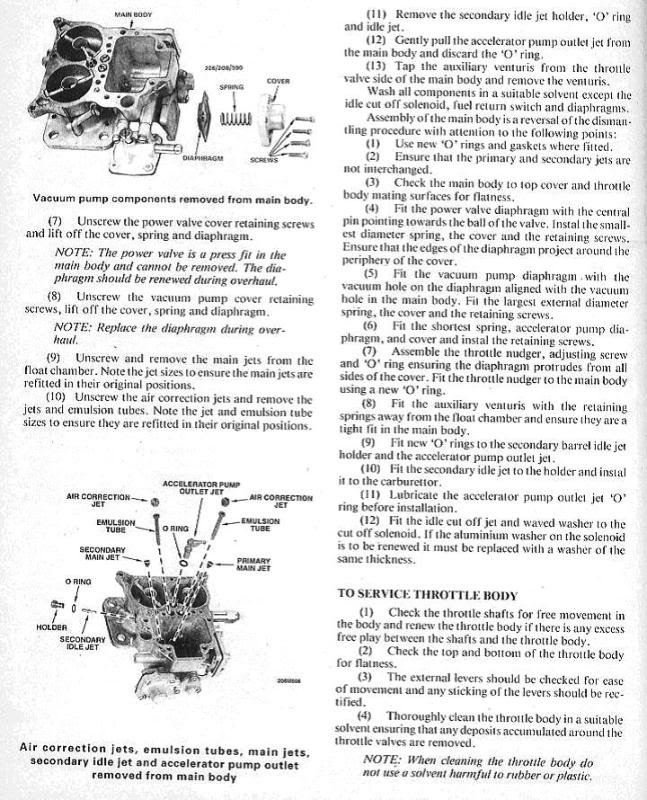

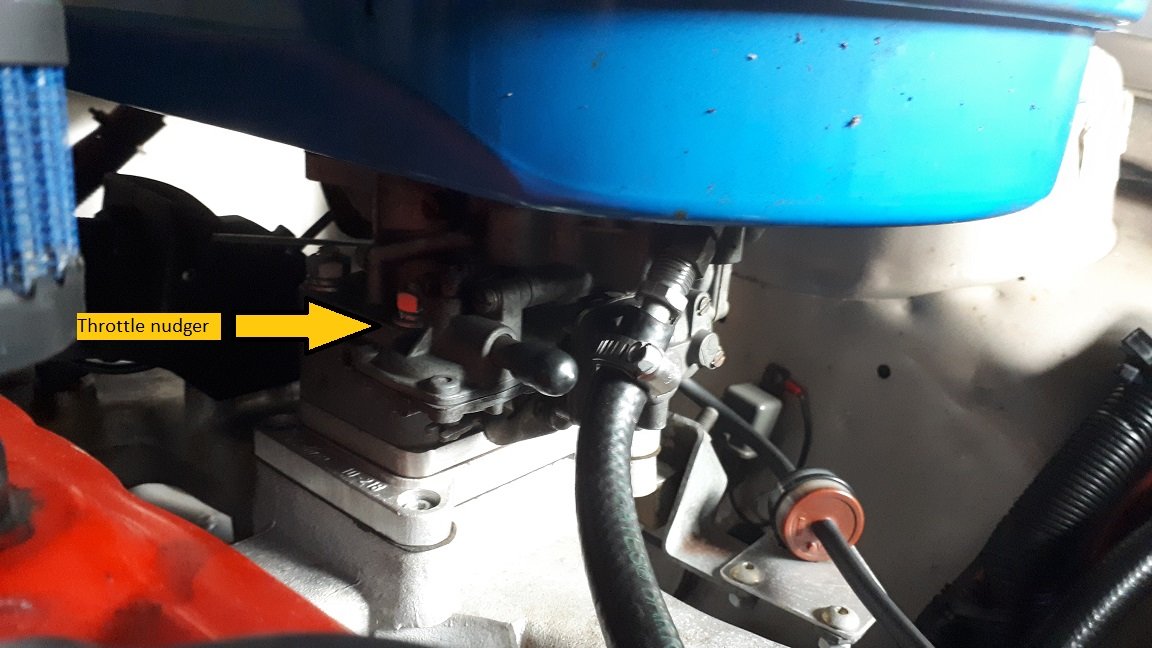

One more pic showing the other side of the carb. I have the throttle nudger blanked off on my carb, I think this is supposed to hold the throttle slightly open momentarily if the throttle is snapped shut suddenly to smooth things out. On some models it may also have been supplied vacuum as an idle up system for air con etc. The diaphragm can fail and cause a vacuum leak and most of the carb rebuild kits don't include this particular diaphragm. You don't need it so I just capped the rather large vacuum port.

-

This may be useful to you to as well it shows the correct jets for the carb in stock form and this is exactly what I run in my car. These carbs are getting old and often people have messed around with them, changed jets for a particular application or drilled the jets. You can get tools for measuring the jets to ensure the orifice is the correct size, they are cheap and a very good investment.

-

2

2

-

-

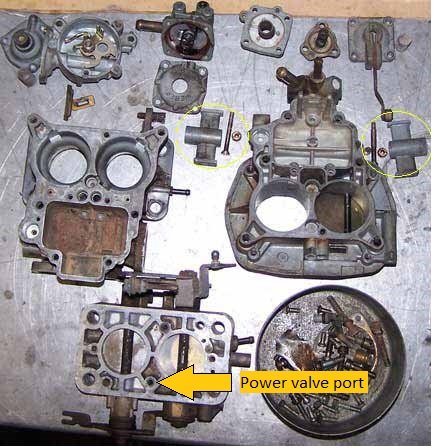

Second trap is the one that catches most people out.

The vacuum port for the power valve is in an odd place on these carbs and some off the shelf adaptor plates will blank it off causing the engine to run on the power valve all the time and run very rich. The port is actually under the base plate and is not open to either of the carb barrels.

The common adaptor plate available for a Holden 6 is a redline product designed for a 23/36 weber and there are a few problems with it when using a 34 ADM. The first one is it too low and the accelerator pump lever hits the adaptor. Secondly the barrels on a Weber 34 will not align with the adaptor. I chose to make an additional spacer to adapt the carb to the adaptor. Yes I know it seems silly to make and adaptor for the adaptor but it worked and solved both problems.

You need to drill a vacuum port for the power valve in the adaptor plate and this port needs to also be drilled all the way through the stock manifold. If this port is omitted, vacuum will not be supplied to the power valve or the accelerator pump boost diaphragm and the carb simply wont work properly.

If you look at the underside of the carb you will find the port (it might even be blocked with crud). The port is located between the primary and secondary bores and continues up through base and into a tube in the carb body. The tube also acts as a locating dowel and can sometimes become damaged and obstructed if the carb hasn't been assembled correctly at some stage in the past.

Useful info on this can be found here

http://www.mbs.id.au/tuning/Carburettors/Weber/34ADM.htm

I wish I had documented this part of the process better and taken photos but I will try to show this with pics from the internet.

-

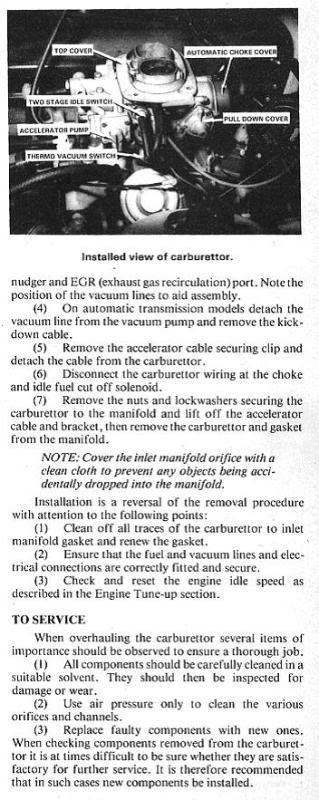

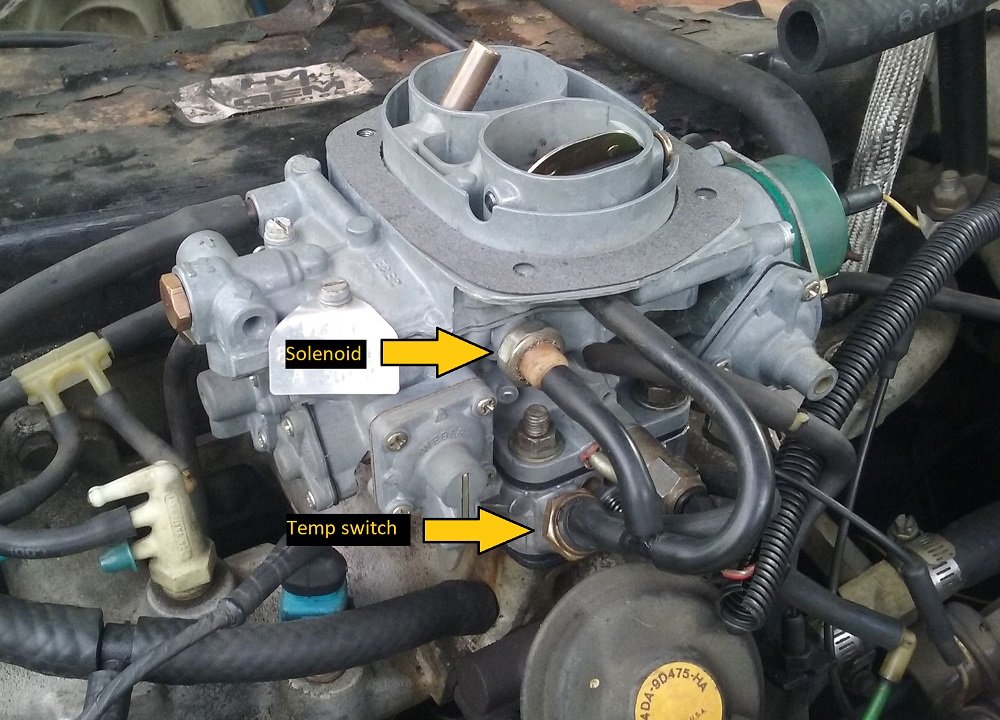

Here is some info on the Weber 34 ADM carb as found on the XE/XF Falcon. This was a popular carb for retrofitting onto other vehicles but they are have a couple of little quirks that can cause problems if you are not aware of them.

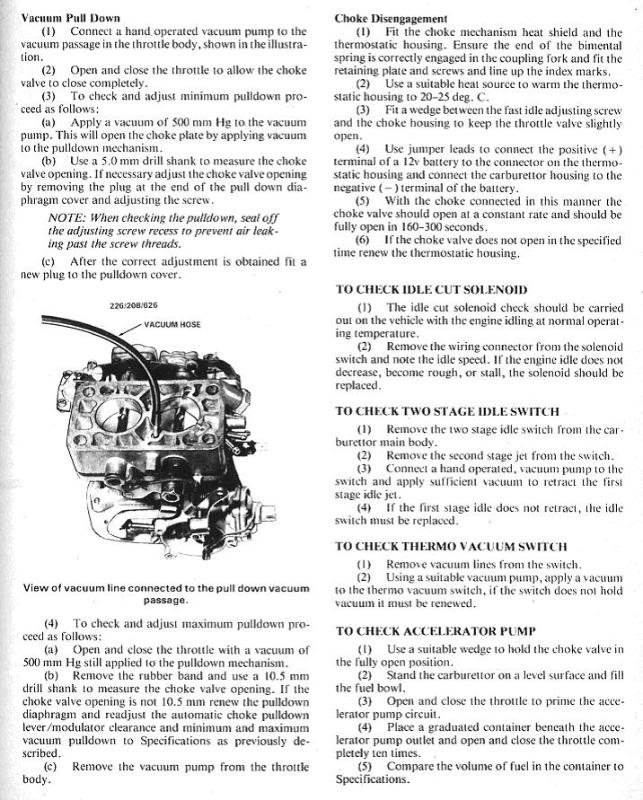

Firstly there is the 2 stage low speed jet solenoid. This was an emissions control system that allowed the engine to run with one jet size when cold (think it was a 70) and when the engine warmed up it switched to a smaller jet to reduce emissions (possibly a 55). Problem is they get old and the little diaphragm inside fails allowing fuel to flow from the primary low speed circuit through the failed solenoid and into the line that supplies vacuum to the system. this causes the engine to run super rich. But don't worry there is a solution.

The products that solve the problem can be found here.

https://www.weberperformance.com.au/product_info.php?cPath=6_268&products_id=631

https://www.weberperformance.com.au/product_info.php?cPath=6_268&products_id=1345

This is a larger jet holder that deletes the solenoid and the appropriate jets to go with it. You will need to mess around with the jets to find the right one for your engine. I think I ended up with a 60 or 65 in mine.

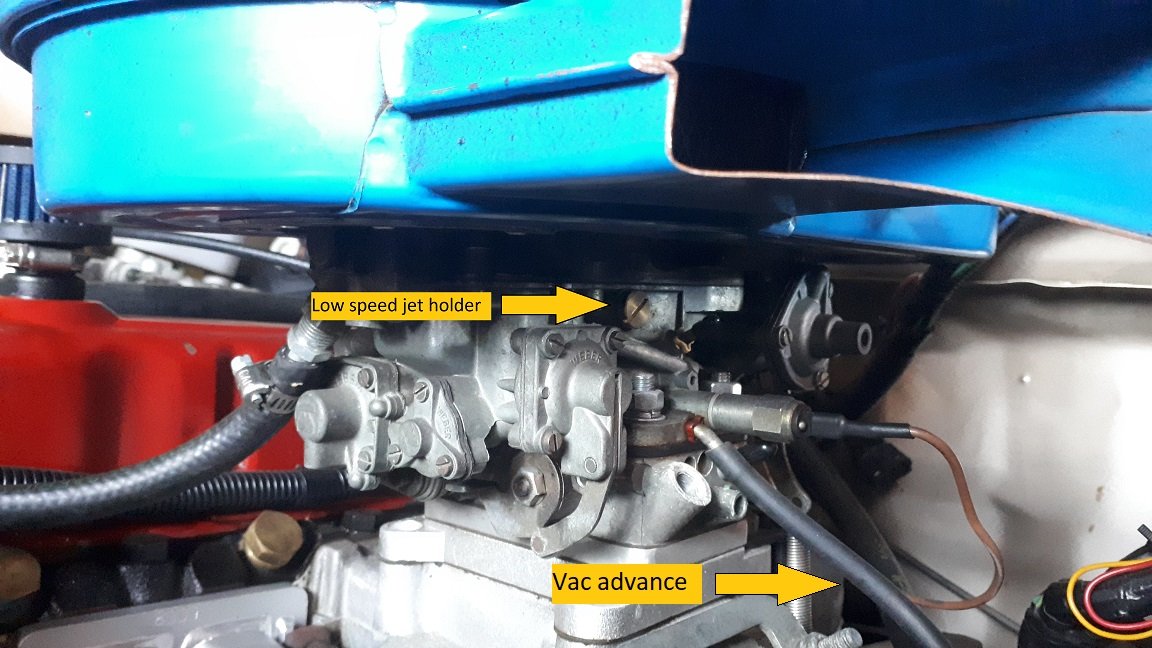

Here is a picture of the system on the standard carb and another of the carb on my car with the system deleted.

You will note that all the vacuum ports except the vacuum advance are simply capped off because all the emissions control stuff is gone (EGR etc).

-

1

1

-

1

1

-

-

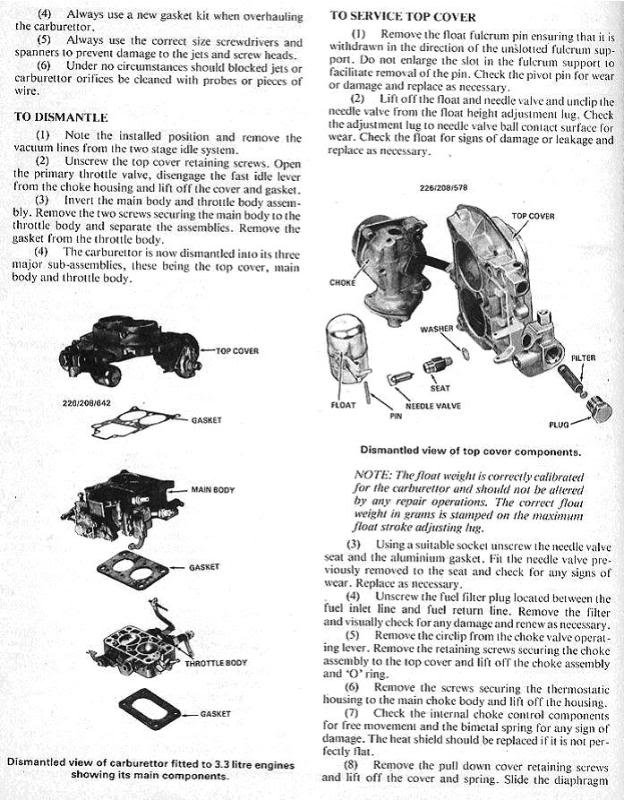

Yes the Weber is on a Black 6 in a VK Commodore.

I did the conversion as an alternative to dealing with the original Rochester Varajet. This particular carb is a Weber 34 as found on the XE/XF Falcon. These OEM style Weber's are actually pretty good but getting hard to find these days. I think the 32/36 carbs are more common.

-

1

1

-

-

I think when people on the internet say Weber and Holley carbs drink too much they are actually saying that they don't know how to set them up and tune them properly. If you get a Weber or a Holley set up nicely they won't use too much gas.

I have both conversions on cars I own and they both work mint.

You do need to be careful when you install the adaptor plates especially with the Weber. Some Weber carbs have a vacuum port in the base for the high load enrichment circuit (power valve). Some adaptor plates will blank off this port causing the power valve to be open all the time and then they certainly will use way too much gas. The Weber 34 is like this and you need to drill the vacuum port in the adaptor plate and manifold and punch holes in the gaskets to make sure the port is supplied with vacuum. I like Weber carbs they are actually pretty simple, it's just a matter of doing your homework and understanding how your carb works . Honestly the Holley works great too, it's easy to tune following the tuning guide supplied with the carb and way more configurable than most people think.

Here is the Weber 34 on the wagon and the 350 Holley on the Valiant.

-

5

5

-

-

Yes I think the kit I purchased was around $100.

I have also purchased Weber parts from Weber Performance in Australia, they are awesome to deal with and are happy to ship to NZ. They have a good range of service kits, jets and nearly everything else.

Have a look here

https://www.weberperformance.com.au/index.php

-

1

1

-

1

1

-

-

You could get a genuine Weber second hand and rebuild it yourself. I did this a while ago, I picked up the genuine weber carb for under $100 and got a rebuild kit and some jets from Weber Specialties. I found the chap at Weber Specs to be very helpful, he even gave me some tips on jetting etc (maybe you just need to catch him on a good day). The carb is perfect after the clean up and rebuild. If you are going to need to strip and rebuild a new Chinese one you might as well rebuild a genuine one, I'm sure there are plenty lying around out there.

-

3

3

-

-

-

The Valiant never missed a beat all weekend, not bad for an old girl. I think the car was in better shape than I was at the end of the event.

-

It was great to see this car on Gumboot Rally, I was very impressed with the quality of the engine build and there is no better way to prove reliability than running a GR!

-

On 06/03/2019 at 19:12, Valiant said:

@RUNAMUCK, the owner of this used to be on here didn't he?

Yep that's my AP5.

Well spotted.

-

2

2

-

-

-

-

Unfortunately I can't make the Christmas get together, hope you all have a great time.

MERRY CHRISTMAS OLDSCHOOL!!

-

What diameter is the sender seal?

This type of problem is common with old Valiant's and you can get a special reproduction seal that is a little thicker than original to sort it out.

The Valiant ones are 3 inches diameter, if the Falcon ones are the same size (or very close) you may be able to use one of these.

https://www.pentastarparts.com.au/store/index.php?l=product_detail&p=1931

-

1

1

-

-

And this week it is...............

Boring routine maintenance

Changed oil and filter, checked plugs and points etc.

Took it for a drive after maintenance and found that the fuel gauge was acting up. It intermittently flicks to full scale while driving. I thought I may have disturbed a connection during maintenance activities but after checking and cleaning connections the problem persisted. I figured the sender unit must be the culprit so I measured the resistance of the sender with a meter and made a sender unit substitute from some resistors that I had lying around.

I fitted the dummy resistance in place of the sender and the gauge sat nicely around half scale.

Took it for a good drive and the gauge was perfect so that confirms the sender unit is crook.

Will need to remove it sometime and see if it can be repaired.

-

2

2

-

-

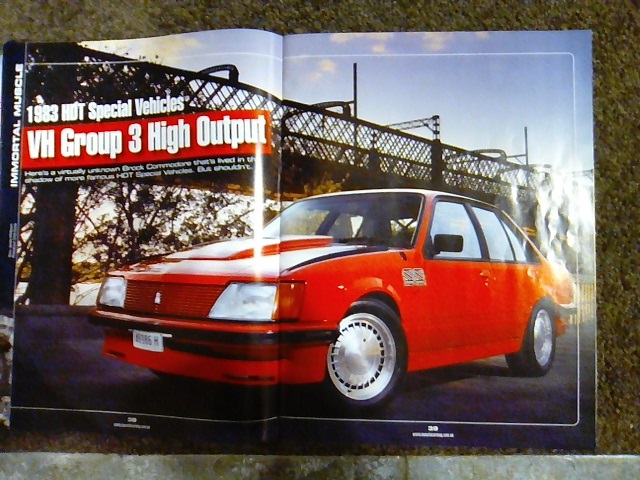

That's an amazing car you have there, I understand that the group 3 cars are quite rare.

Australian Muscle Car Magazine did a full feature on a similar car (issue 89)

If you are interested I will scan the full article for you

-

- Popular Post

- Popular Post

Update on the work I did a couple of weeks ago.

Archers Auto Springs took one and a half inches of camber out of the leaf springs for me

I installed new eye bushes while the springs were out

Modified front mud flaps to prevent them dragging on the ground at new ride height

And all back together

The ride height has dropped about an inch which doesn't seem like much but I think the car looks much better a little lower.

I expect it may drop just a little more as the springs settle.

-

10

10

-

That is a real shame! Kicking myself for not stopping by pick a part this week to check the car was still there, I could have saved you the trip down. They actually had several of those V6 Mazda's in there when I looked a couple of weeks ago but only one of them had the engine you are after.

-

Oh bugger I nearly went down to double check mid week as well but thought that it wouldn't be scrapped that quickly. Let me know if you have any luck at zebra I can lend a hand today.

-

I know fouling of #6 can be a symptom of timing issues. 6 runs hottest and can be prone to pre-ignition/poor combustion if the timing curve is not correct. Vac advance modifies the mechanical advance curve and if it's pulling too much in the mid range maybe it's contributing to the problem.

Like cletus I have had to disconnect the vac advance on a modified engine because it just wouldn't run properly with it connected, that engine also carbon fouled #6 and that's actually what prompted me to suggest disconnecting it.

-

1

1

-

-

I might need to stop by work briefly first thing tomorrow morning but free after that, could probably be there by 10:00. 5th is good if you decide to do it next weekend.

chrisr hz tonner discussion

in Project Discussion

Posted

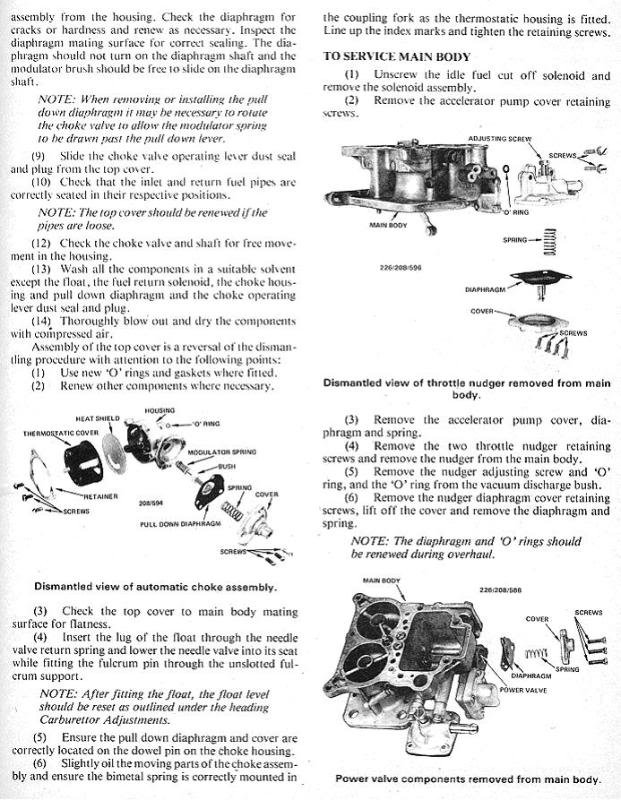

Hey I have been thinking about your carb issue and a comment you made got me thinking.

Can you post a pic of the fuel shut off solenoid fitted to your carb?

I think there are two types of solenoid for the pre and post emission control carb. I think (but don't know) that the early pre emission control carb like yours is supposed to have a solenoid that has the low speed jet incorporated into the assembly as shown in the picture below. The later version like my carb has a separate low speed jet and the solenoid is a plunder type item as shown in the other pic.

I think there is a chance that you have the wrong solenoid and if this is the case your carb will be running with no low speed jet and nil fuel metering on the primary barrel. If this is true I expect it would be running ridiculously rich.

Have a look here

https://www.progas.com.au/portfolio_category/carburettors-accessories/