-

Posts

53 -

Joined

-

Last visited

Everything posted by wildcat_lgf

-

Oh - and nearly forgot to mention - we got building consent for the new shed, so I'll have a bit of extra space for the projects without cluttering the garage and tracking dirt through the house. I'll be done piece-meal as we can afford it, but I just want to the get the concrete pad down before winter...progress so far: Sand pad getting cut out...basically a double garage plus a single garage going the other way (kinda an "L" shape) and then Lisa's art room and a bathroom behind. Sandpad cut and roughly levelled...profiles put up and strings run...just waiting on some sunny weekend weather to box it up for the slab. It will be a ribraft slab - hence the pad is level and string heights quite high. In the meantime I bought a new tool for the shed - and had to store it over at Dad's place for now. 20T press. Its pretty good and has the added bonus of being local so pick-up was easy, and also having the connection for the air hose so I don't have to manually operate the jack. It works really well, and I used it put the front wheel bearings in....more about that later.

-

Took the front control arms out and tidied them up - replaced the trailing arm worn rubber with poly bushes - should be much less sloppy. The rubber bushes were completely worn out. A bit of time with a stripping disc on the angle grinder - plus a coat of KBS Chassis Coat. Looking much better now, and should withstand all the road grime and muck. I opted to just replace the control arm rather than get the ball-joint rebuilt. It was a bit over $100 for the ball-joint to be rebuilt in Chch, and only US$30 for a whole new control arm...easy decision. Totally impressed with the KBS product...the kit comes with heaps of product and seems to work really well, with a good finish. Way better than the Hammerite I tried before.

-

Then I got distracted and thought I might as well pull the suspension and steering box out and clean them up. Decided to shorten the springs and bought new struts which I will shorten to suit as well. I was a bit dubious at first, but quite a few Fiat guys have done it with good success - the key being to keep the spring captive. Luckily there is a set of proven dimensions and steps to follow online. New goodies - new struts, new uprated topmounts, and reinforcement plates for the suspension struts - known as "Plaia" plates for the guy (Mark Plaia) who designed them and first made them available for the X. Also visible at the top are new roller bearing pivot mounts (also known as Plaia Pivots)... So out came the hacksaw and the gas torch...works really well with the heat shield! Then in a moment of inattention - I picked up the wrong end of the spring...and this happened! Major blister

-

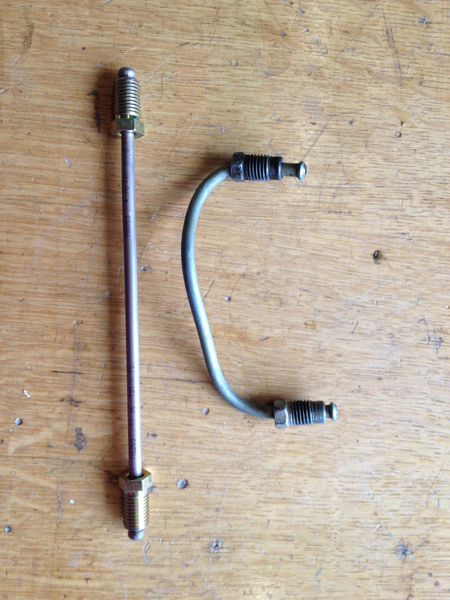

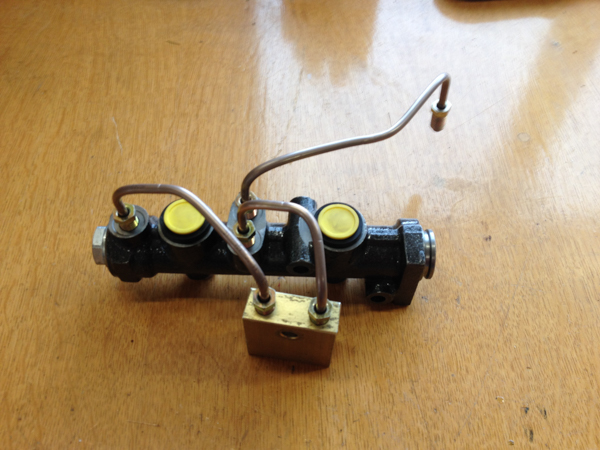

Overall they look pretty good - but the tube pliers I bought leave a few marks in the pipe which is annoying. But the lines fit ok. The real test will come when I put it back together I suppose. New versus old (new pipe on the left before I bent it up). And new line shown on top versus old underneath. Brake MC back together and looks like it will bolt up fine.

-

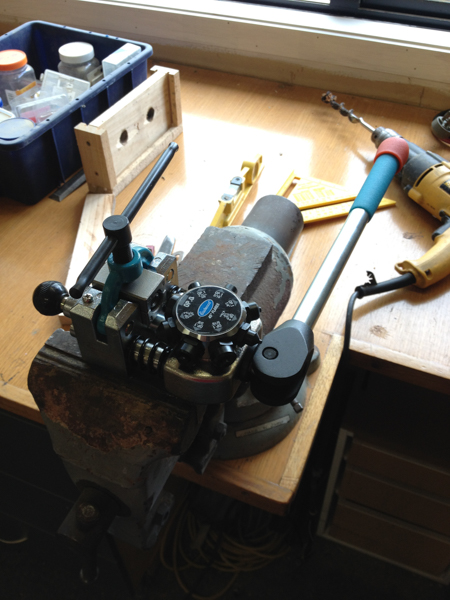

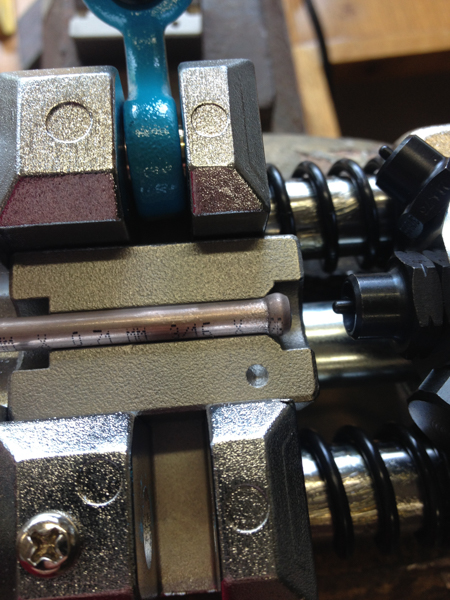

So it's been a while between posts - but I have been working on the X I swear! Slowly slowly... Bought a few goodies - EBC brakes from the UK, and got a good price on some SKF wheel bearings from Amazon The brake flaring tool arrived from Eastwood - very pleased with it, and takes out the "user error" that would probably occur if I was using something simpler. Does a pretty good job by the look of it, and can do single flares, double flares, bubble flares (as per the photo), etc So I made up a few brake lines so I could put the pedal box back together...

-

wildcat_lgf's 1978 Fiat X1/9 - Discussion

wildcat_lgf replied to wildcat_lgf's topic in Project Discussion

yeah, it didn't flatten as much as I thought...maybe if I had thinned it a bit - but it might've just gone streaky. Overall looks ok - probably good enough until they need another re-build... -

Re-built the fronts with new seals - luckily the pistons are in good condition, and put them back together...with a slight change in colour. I used gold Hammerite paint as the advice I read suggested it was as good as any specific caliper paint - and way cheaper. I was a bit disappointed in the finish of the paint - it supposedly flattens down, but brush strokes are still evident even on the rough casting finish. If I were doing it again, I'd buy the spray can instead and spray them...although this would be more expensive. So now, I'm just waiting on the brake flaring tool to arrive - then I can re-do the brake lines and re-install the pedal box with the new cylinders...

-

Stripped the brakes down - wire brush and patience! I thought I'd done a pretty good job - but decided I'd get them blasted just to be sure I'd got all the oil/rust etc - wow! what a difference! Don't waste your time scrubbing with a wire brush, just get them bead blasted - came up mint! I used the air compressor to pop out the piston - and put a block of timber in the caliper to make sure I didn't damage the piston. A word of caution - don't get your fingers in the way! The piston comes out fast and hard!

-

So over the last month or so I've been gathering parts and tools for a few jobs - mainly concentrating on the brakes... The master cylinder (or so we thought) was leaking, and slowly ended up with a puddle of brake fluid on the drivers floor. On 2nd thoughts it might actually be the reservoir hose - as it looked a bit perished and worn. Removed the pedal box and master cylinders from under the dash - luckily I'm still small enough and flexible enough to wriggle under and get the box out...a bit of a nuisance job, but finally its out and on the bench. I ordered new master cylinders (brake and clutch) as well as a new clutch slave cylinder - fairly cheap from the USA. Re-sleeving was going to be ~$150 - considerably more than $34USD for a new one. So while I wait for those to arrive - I have been sourcing new reservoir hose...the pedal box uses both 1/4" and 5/16" (6mm & 8mm) hose. 6mm seems easy enough to get, but 8mm was a pain. I really wanted red coloured hose to keep it similar to the original (red fabric braided hose) - what a mission that turned out to be. Gates don't supply red hose or 5/16" hose here in NZ (and AUS weren't interested in discussing anything, or helping out). I could get 6mm black hose, but no 8mm... As the hose is being used for brake fluid it needs to be SBR or EPDM (not Nitrile). In the end I found I can use acetylene hose - but had to buy it in the "twin hose" configuration. Still a bit cheaper than buying specific Gates hose separately (unavailable). So fingers-crossed it works ok. The twin hose is easy enough to pull apart - and should look fine...its mostly hidden anyway. Next I've bought some Kunifer Nickel-copper brake line (3/16) and will re-do all the brake lines...for some reason we had no rear brakes, and they wouldn't bleed through at all. Possibly something stuck in the distribution block or somewhere in the lines - so I might as well learn a new skill and make some brake lines...a few goodies starting to arrive: Kunifer hose So while I wait for the flaring tool to arrive I saw some Uno Turbo front brakes for sale on TradeMe. These are a bolt-on upgrade which allow me to use the vented front discs from an Uno Turbo - a much better option...then low-and-behold a Fiat 125 shell was listed and I bought the rear brakes from that - so I get an upgraded braking system front and rear for not too much $$$. Had to outbid a couple other Fiat guys for the Uno Turbo brakes (sorry Maurice)

-

wildcat_lgf's 1978 Fiat X1/9 - Discussion

wildcat_lgf replied to wildcat_lgf's topic in Project Discussion

A great thought! definitely keen on doing something like that in the long-term... -

wildcat_lgf's 1978 Fiat X1/9 - Discussion

wildcat_lgf replied to wildcat_lgf's topic in Project Discussion

sorry guys - i haven't had much time lately... The shed is on a farm in Nelson - it's his brothers farm I believe...most of the other X's are de-registered, but if I lived any closer I'd be at risk of buying them for parts. I had to twist his arm to sell me the green one (luckily rego still on hold)...but he might be persuaded on selling another - he's notoriously busy and un-reliable at replying (either email or phone). He's got my old X1/9 - which I sold him about 8-10 years ago. It has an unfinished dallara kit, Uno Turbo engine with a few nice mods, and was very rust free. Unfortunately he's had it sitting outside under a tarp and I hate to think about its condition now! -

Fiat X1/9 discussion: PROJECT BUILD UP:

-

After many years of not owning an X, it looks like I'll be rejoining the faithful few. A 78 serie speciale was my first car about 18 years ago, and I've had a couple since then. I kept in touch with the guy who bought my last X and recently caught up with him. He agreed to sell me the green on e in the middle - but freight between our north and south islands pretty much doubles the price. Maybe it's a sentimental buy - but I wanted a serie speciale again, and a project - and it's definitely a project! Been sitting for at least 5yrs it's it's current location - and another 5yrs prior to that. So, its been a few weeks since I negotiated to buy the car, and we managed to pick it up over the weekend...it was a great 800km trip! We managed to get it running after a few hours, got the brakes and clutch bled, and away she went... The only issue (thus far), is that the battery light comes on and the battery doesn't get any charge. We spent about 4hours trouble-shooting the issue (power going in to the alternator, but not out), and took the alternator out, apart, and put it back in - with no success. Then we had an epiphany that we would try bypassing the voltage regulator, which worked and the battery gets full charge now. So a new voltage regulator is in order I feel. Anyway, she's parked up in the garage now - and I'm deciding what to tackle first. I need to stop the spread of any rust fairly quickly (although overall it looks not too bad), and then will probably move to getting the doors/windows adjusted so they open/close properly, then move on to some interior items to get the seats moving properly. I'm thinking I'll keep it running for now, and just tidy it up for a wof. Then slowly start stripping it back down for a proper restore... DISCUSSION THREAD:

- 11 replies

-

- 13

-

-

Ok, so I haven't gotten very far with the Fiat - in fact its a bit of a sad story... I was telling a friend at church about the Fiat and he got all enthusiastic about it as a project for he and his son to work on as a first car. He's been looking for a while for a classic project, and so in the end I've ended up selling it to him. Hopefully he (or his son) posts up on OS the progress he's making. So far, he's eliminated the nasty squealling noise due to the exhaust touching the driveshaft, given the carbs a basic tune to get it mobile, and taken it on a few spirited drives Sooo...I'm now looking for another project: options are" early Fiat X1/9 Fiat or Alfa Spider MGB (with a v8) Let me know if you know of any...

-

Cheers guys... Yeah 70's Fiat's and rust go hand in hand - using russian steel is the rumoured reason...don't know how much truth there is in that. I'll have to check out the venturi sizes to see if its ok - pretty sure I'll leave them on anyway though. Good call on the MR2 spoiler - it does look similar. It will have to come off I'm afraid. From a preliminary glance, rust isn't too bad. A bit around the windscreen, and a few bubbles here and there. Nothing visable on the bottom of the doors (yet), or sills. Some of the udnerbody seal is missing around the drivers footwell - perhaps previous repair area? I'll get a video or at least audio of it running sometime soon. So much to do - where do I start? I think the plan of attack is: Attack known rust areas on the body. Check underneath and repair underbody areas. Engine/gearbox (general tidy-up and inspection) - the fun part Interior make-over. re-upholster seats (new foam is in order), dash, carpets, door trims. Anyone re-wired their project? Italian wiring is notoriously dodgy, and I've seen a few "universal" kits to upgrade to relays. Is it worth it or does it create way too much work & $$$ ?

-

yeah that was my thought too - of course it could be running sub-optimally with jsut some bolt-on go fast bits...I'll have to strip it down to find out - but that's the easy part. The bodywork is the hard part (for me).

-

Ok, So the link to the build thread is here: Build Thread It looks to be mostly original - or should I say original condition... It's not bad for being 40+years old - just everything needs attention. Bodywork will be the main concern and I've been to scared to take a proper look yet. Also trying to figure out deails/specs about the car: Spoiler is odd - but seems to fit the car properly. Its made of semi-flexible rubber like the front chin spoiler of an early X1/9. Is it a Fiat item? If not, what's it off? Engine should be a 1608cc - will have to confirm with engine numbers soon, but its got a pair of DHLA 45's which I would think to be on the large side? No idea about the rest of the condition Depending on how much is original already (bolt-on add-ons excepted), I'll probably keep it period looking with some minor upgrades. If anyone has any ideas or knowledge about the car I'd be happy to hear them...

-

Just had this 124 bc turn up on my doorstep...I know nothing about it, but put a bid in and at the end I was left holding the baby. So it arrived yesterday, there are a few ugly bits on it like the enormous tailpipe, and I'm not convinced about the spoiler (I doubt the spoiler is genuine? But can't imagine what else it would be off) It's rocking a pair of dellorto 45s which I thought would be a bit oversized for a 1608; but then I know very little, and even less about this particular car. Rego is still live (just put it on hold) so that's a bonus in my book. Original colour - complete with a little rust here and there (surprise surprise) Wheels are 13 x 6(?) Ward mags - I believe NZ made back in the 70's. Ridiculous exhaust on it - and I'm not sure about the spoiler? If the rest of the car were done right it could be ok (only if by some miracle the spoiler were a genuine Fiat item) - otherwise it has to come off. Engine bay - should be a 1608cc , but I need to check the numbers to be sure it still is. Pair of DHLA 45's too After a night on the battery charger and a bit of priming of the carbs I managed to get it running this evening - it sounds fierce! I don't think I could cope with that amount of noise all the time, but it did bring a smile to my face when I first heard it. Blowing a little smoke but pretty happy it runs. Now...where to start? Discussion Thread