-

Posts

463 -

Joined

-

Last visited

Posts posted by Metalhead96

-

-

Wheels aquired, from a suzuki fr50 but are a 90% fit. The best bit though?

Freeeebie...Zip, Zero, Naadaa

Need to de spring the front and get the whole bike as low as poss, might be able to scrape the leg sheild on turns (doubt it)

Also removed the motor, its well cooked so if anyone wants it for whatever reason its yours for a crisp high five

Anywho heres some pickys

-

3

3

-

-

Ive been hunting around for a while now but cant seem to find anywhere that can supply them. Mostly found either 13s or 15s but no 14s.

Wondering if its even worth "re-rimming" over banding/widening

-

https://www.facebook.com/share/WsvD4iBUCEHA8iLD/?mibextid=kL3p88

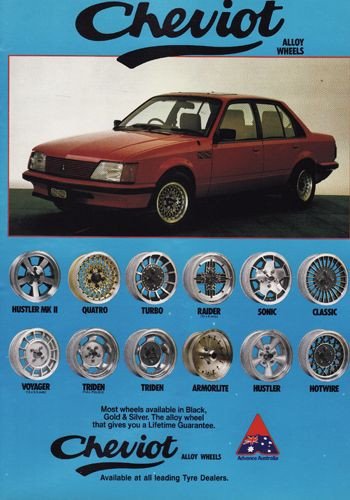

Stumbled across a set of quatros. Not badly priced and even comes with a spare!

-

Rough idea on offset? Could be keen

-

Speaking of getting wheels re drilled, whats the "legality" of it these days?

I remember people getting some alloys plug welded then redrilled to the appropriate stud pattern, I assume it depends on the wheel you start with. taking a 15x7 in 5x120 would be a bit risky to go to say 4x100 since the centre bore would have been too big, also seen quite a few sets where they are slotted for different patterns?

7 inch wide seems to be the largest ive seen them, maybe 8?

Also Turbos are lush as fuck lol

-

Hotwires, tridens, globes ect

Hard finding good info on their catalogue from back in the day. Wanting to find out what the sizing, stud patterns were available. 4x100 seems no existent as far as i know and it seems the wider sizes where more only available for 5 stud ford and holden.

Ideal world, trying to find a set of Raiders, but looks like they are definitely not as common as the rest of the range

Sharn away, im listening

-

1

1

-

-

- Popular Post

- Popular Post

New digs, same shit

Getting a bit fatigued of the old girl. Being putting off certain jobs due to time constraints and possible skill issue. Decided best course of action is screw the rust, I need to drive this

Acquired a second g200w off @CUL8R in much better condition. Need to spin some broken bolts out and give it a good clean down, after I'll buy the needed gaskets and assemble then drop in the hole. Can atleast start the motor in the car before sorting the gearbox.

Speaking of gearbox have one lined up ready to be pulled just outside of Amberley, just waiting on the right time to go out and grab it plus find some pocket change in the couch cushions.

Anyway here's some photos for the thread

-

12

12

-

Have removed the rear wheel, drive hub is still stuck on the swing arm so will need some persuasive action to remove.

Front wheel will be next, hoping atleast the speedo cable is saveable as the brake cable has well and truly turned to crust.

After that the engine will come out and I'll pop the head off, see if it's worth my time. Might have a line on a v50 donk to slap in otherwise will look for a pw80 power house

-

2

2

-

-

-

-

- Popular Post

- Popular Post

-

Update time

Dug into the twincam donk and all is looking... okay? Car it came out of had been parked up for about 20 years and going off the head gasket I pulled off I can see why. Completely blew out number 1 and number 2 and 4 were not far behind. Checking over the block, head and pistons etc it doesnt look like its done any damage which is good. Cliff bond has a gasket kit on shelf (un-bloody-believable) and various seals etc, coolant galleries need a serious clean out though as they are full of shmutz. Seems alright though so onwards we go.

Loom is in place too and as far as I can tell I may not need to do any surgery to make it work.

Have confirmed that i need a diesel rodeo/bighorn bellhousing from a c190 or c223 to work with my gearbox.

Picked up a random panhard bar today to make fit as mine was bent like a banana and to be honest pretty skinny.

Latest goal is I want this on the road by my birthday. At this stage its pretty obtainable if all goes to plan.

chairs

-

8

8

-

-

Righto, anyone here done spray mig before? Specifically on a lap weld

Got my machine dialled in and goes great for doing butt, fillet/tee join but lap weld is difficult. Main problem I'm having is the top of the weld is always undercut

6mm plate, 1.2mm wire, 29.5 volts and 180 amps. Have tried changing positions, moving the gun around and tried doing a root weld first then going over top. Still have the same problem.

Any helpful tips n tricks? Not something I can see myself having to do in future as its only really used for think metal but is the last hurdle I have atm at course

-

-

-

-

Well hit a snag in the road but its not all bad news.

After not being able to attend nats the next closest deadline was to have this going for my mates wedding, plan being to get the g200z back together and atleast running, needing a couple of things on the head tidied up so drop it off at the machine shop.

2 days late the phone rings

"yeah mate, heads fucked, bent by about 1mm"

faaaaaaark, no more wedding cruising.

So now the twincam swap can commence

Knowing what i needed to clean up the motor I set about making a list and getting some pricing together, found all the bits im needing aside from needing a MSG 5 speed bellhousing with the starter on the passenger side, plenty of options there so no dramas.

Then comes the fun bit... Wiring

With the G200W I also snagged the entire loom except for what runs to the back of the car plus the ECU, digi dash and the control box for it. Needed to take the dash out anyway so whipped it out and somewhat laid the new loom in place closely to the old loom in the car. Man If looking at one loom is daunting two is even worse.

Going through I found a few things that didnt match up. One being that the plugs to connect the front half of the loom to the rear doesnt match what in the car, the pods either side of the dash cluster have a couple of different plugs too but this could be from the donor vehicle having cruise control which I wont be needing, wiper motor mounted differently so will need to extend that part to reach.

Have started pulling the old loom out and labeling as I go, once out i can play the fun game of matching up what is correct and what needs changing, fingers crossed I can de-pin the plugs I need to change and swap them over. I managed to get myself an early workshop manual complete with full diagrams to help with some of the problems.

Other than the the rust has been put on hold as the goal is to atleast drive this to my new place then worry about the rust once there.

-

5

5

-

-

On 23/01/2023 at 22:44, myk00l said:

Pak'N'Save were out of iodised table salt. Supposedly can't get it from supplier.

Now that's just taking the piss

-

1

1

-

1

1

-

-

Asking for a mate before ringing around wreckers but on the hunt for a k11 steering rack.

Haven't looked at it just been told it needs one.

Any micra fiend have one around or know the best spot to get one?

Vehicle is still driveable and ideally doesn't want it on jack stands in the drive for long so no to getting his one reconditioned

-

-

Sweet as, just kept buzzing me out cause every other one I could find had some sort of retainer clip to hold it in place

-

-

Graffiti sticker on the back window is essential

Did they make modgies in 6 stud?

Edit: just saw the OG. Very noice

-

Best methods to removing a windscreen?

Mate needs his pulled so we can fix the rust around the screen but no one will come do it unless he makes a claim.

For Questions Regarding WOFs/CERTs/NUMBER PLATEs

in Tech Talk

Posted

Dunno if its come up before but i read on the lvv fb page that someone said that guard rolling is no longer legal in regards to wof? Reason being that it "structually affects the vehicle body" and thus is now a cert issue?