- Popular Post

-

Posts

3422 -

Joined

-

Last visited

-

Days Won

1

Posts posted by NickJ

-

-

26 minutes ago, TimShadboltfan27 said:

Yea man, not identical but a similar setup. We are dealing with hatch which has slightly different covers and few more things to dismantle to get to it. A hoist would be ideal

Nothing I can add but how gross! Quick look through the interwebs about what that "essential" little baggy costs to replace and I want crawl into a corner and cry.

I hope that is an easy resolution.

-

Holy crap, now I see why non-dpf is listed as a selling point in Europe

Is this the same as what you're faced with?

-

1

1

-

-

20 hours ago, nzstato said:

Ooh that is cool....

You're a map person too?

-

1 hour ago, Willdat? said:

Is there a hack for generating the profiles?

Not really, i'd like to say I imported a topomap and draw many lines but thankfully I stumbled on this little project https://jthatch.com/Terrain2STL/

-

1

1

-

1

1

-

-

- Popular Post

- Popular Post

Making some thank you gifts for friends that looked after us on our recent trip overseas, reliefs of the mountains they call home.

Carved out with the cnc to replicate contour lines on a map then run over with the gas torch to highlight the ridges.

-

36

36

-

1

1

-

I was under the impression Li-ion was now at its limits and the main cost driver had shifted to input material costs rather than manufacture cost?

Makes claims of 50% cheaper sound questionable?

-

I've had a three piece do the same, right pain, eventually had to split them, throughly clean the join and put back together (sealant between the pieces was a disaster, i'd not do that again unless someone else has a technique?) 100% what Highlux said is what worked for me on the 3rd attempt. Pretty sure we just used window sealant cos thats what we had.

Reliably sticking anything to aluminium is nearly impossible, the steps required to passivate are not easy for at home jobs but having it proper clean is most of the way there, clean off any scale and depending on the sealant, light scuffing with scotchbrite may also help.

-

9 hours ago, ajg193 said:

Anyone keen to buy this after I put a new X axis belt on it? Machine has done probably less than five hours of work

I know a guy who might be keen

-

1

1

-

-

As always, what do the numbers say?

https://figure.nz/chart/WKssPR8hbahvO8Cx-uRVBYHXQjMLE18H4

This chart lists contributors to lethal accidents, "vehicle" is involved 5.5% of incidents, sure a caveat around the best marker, but to me death is a good first pass. Additionally, how many of these vehicle items would have been wof fails?

It doesn't matter though, The top 6 are all driver related

This says ditch WOFs entirely, its a waste of time, instead start 6 monthly driver training sessions until vehicle causes overtake driver factors.

-

7

7

-

-

I have a 3/4 tin left over from the Datsun + gun you'd be welcome to

https://smitsgroup.co.nz/product/62626/roberlo-stonechip-siltex-800-premium-hs-1kg-black

Just be a few weeks before I can get it to ya

-

1

1

-

-

19 hours ago, nzstato said:

It will be once I build it up, a 'forever' machine.

How might an electronic numpty like me do that? Is it as simple as a switch and a potentiostat to change the feed rate?

Yes there is a few ways of doing it, from simple speed control to encoders on spindle to time everything together.

-

1

1

-

-

So jealous of the horizontal, looks like a perfect diy machine!

servo motor is the only option for the axis drive

-

1

1

-

-

Kinda funny situation with Tesla, fanboys dgaf, any outrage will just be more marketing.

-

1

1

-

-

22 minutes ago, Sunbeam said:

Yeah but do they grip?

Yeah totally acceptable for a road tyre

-

1

1

-

-

I put Nankang NA1 on the Datsun in 205/60/13. Was the only mid range non performance tyre I could find

Seems good for cruising and squeals real loud on track.

-

2

2

-

2

2

-

-

Motor looks pretty darn good, sounds even better!

Congrats, just another weekend away from finished right?

-

1

1

-

-

- Popular Post

- Popular Post

This thread needs a decent pic of the car right?

Really want to go get some sunrise/sunset pics, but that will need to wait til daylight savings pulls the sun back to more gentlemanly times, for now, a not so potato pic

-

37

37

-

-

- Popular Post

- Popular Post

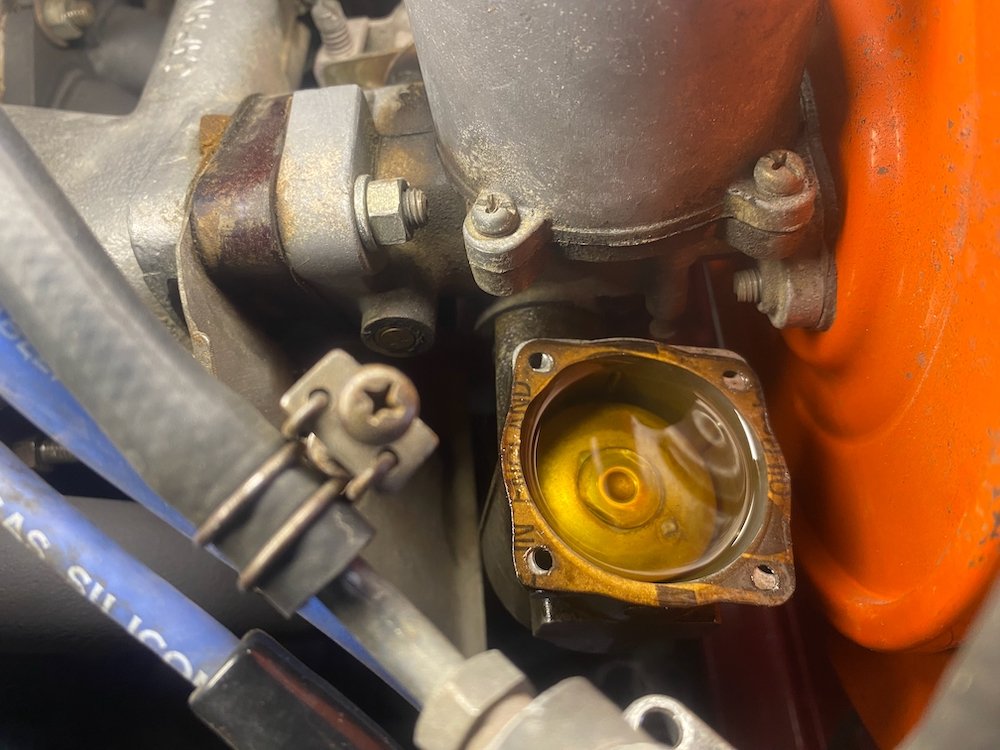

All running and driving, or so I thought

Had a the plugs occasionally foul on start up and the engine now and then would start running super rough, running through the options didn't find much until after one drive I could definitely smell fuel, queue a case of the o shits etc. Leak was from the forward carb overflow, popping the lid off the float chamber was evident

Seems we have a slight case of the oceangates....

Brass float had cracks all the way around.

When I brought the car I also received a pretty good spares package so picked out the best looking float and threw it in.

WOF man then failed the inspection on a number of minor issues, brake balance wasn't up to his expectation, small exhaust leak at a joint and rear brakes grabbing, managed to solve all in quick succession after work and sticker status returned!

I haven't worked out the number of days but approx 3 years after taking the car off the road I can now legally drive again, while no where near finished in my mind, it is a giant relief to not have a pile of parts in the way!

Still to go is interior re-trim, carpets, door seals, paint detailing, polishing, wheel refurb etc, mainly tidying up the cosmetics.

But for now, lets go for a hoon around the neighbourhood

-

38

38

-

2

2

-

yep, looks really similar to the 70s Datsun ones

And Land Rover........

Both only have two levers though.

-

I also have a small scope that would happily see that, won't be until next weekend that I would be free though.

-

1

1

-

-

I'm out of town that weekend but want to express admiration for this initiative, big thumbs up

-

2

2

-

-

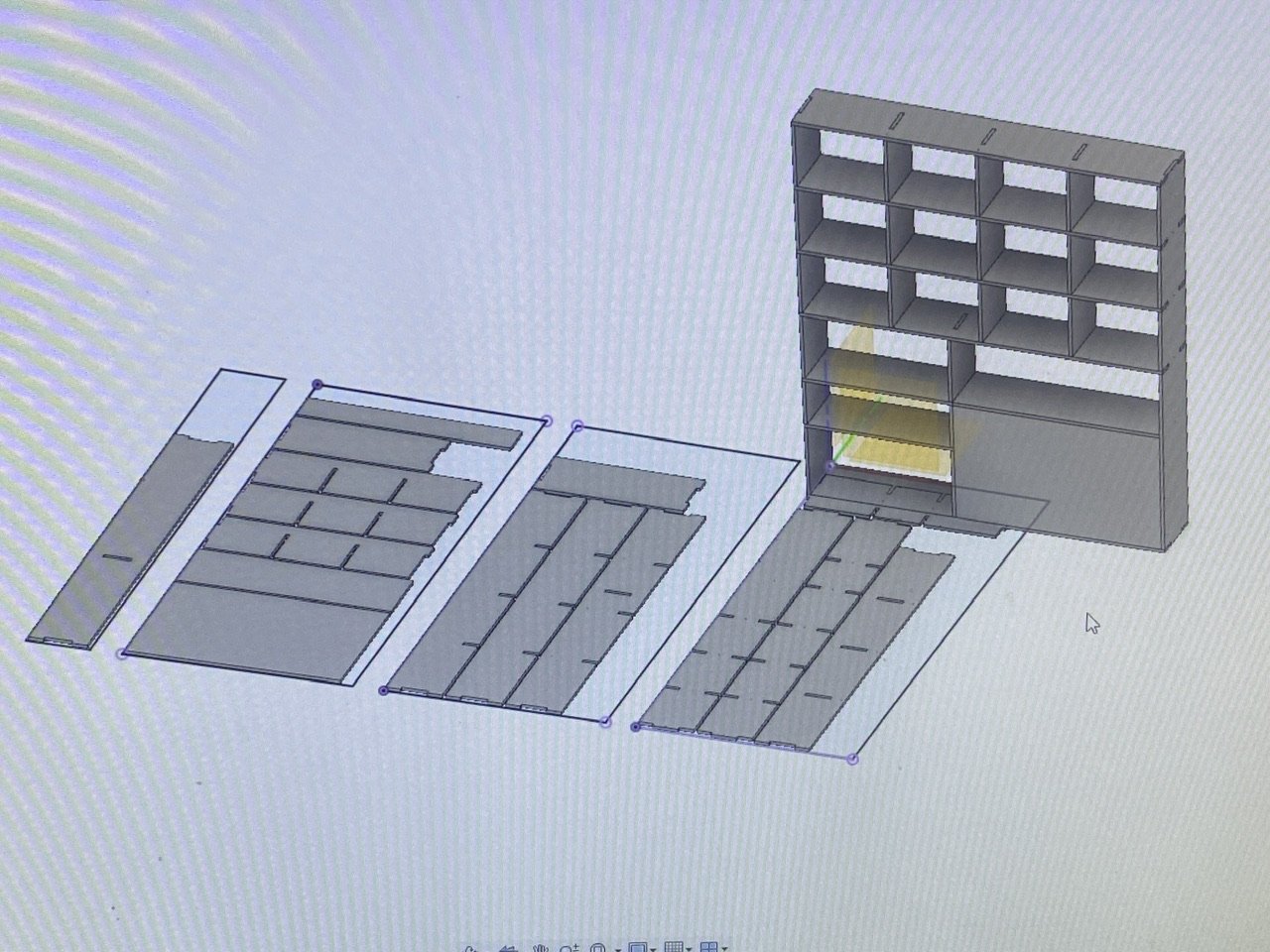

Thats a sweet shelf and suits the room, no way I could have filled the design brief with the hand tools I own, fortunately cnc makes me the carpenter i’m not.Machine is now set up to take a full sheet of ply however the geometry doesn’t allow the spindle to traverse the full 1240mm.

Have you had a play with the arrange tool?

Quite handy for working out nesting from available stock and then makes machining simple (aka all delays are very much self inflicted)

-

1

1

-

-

- Popular Post

- Popular Post

33 minutes ago, ajg193 said:I should give you shit for not accounting for those phone/network outlets on your wall

Hey man, client's design, I just machine to drawing.

-

4

4

-

1

1

-

7

7

.jpeg.dc79046ad09d73b9fdc8de9e6e6d9c09.jpeg)

Nick's Datsun 1600

in Projects and Build Ups

Posted

Interior polishing:

Like most 50yo cars, the dashpad had cracked up pretty bad, long term i'd like to throw the check book at it, but in a budget friendly manner I called on my lovely GF and her knowledge of spotlight. We trimmed off the worst highpoints and double sided taped a layer of tablecloth liner to the pad, the idea here was the padding would hide the worst of the cracking once the vinyl leather was stretched over

This was put on with the bare minimum of contact adhesive to keep the dashpad in close to original shape if needed for proper restoration further down the track.

Finish result blends in well, of course the corners are a bit messy, but far nicer to look at than the old pad.

Haven't been able to make a firm decision on the carpets but had an idea

Chomp out some 7mm marine ply on the cnc, wrap in carpet offcuts from the 4wd....

Floormats that don't shuffle around.