-

Posts

3422 -

Joined

-

Last visited

-

Days Won

1

Posts posted by NickJ

-

-

30 minutes ago, ajg193 said:

How did you hold the sheet metal in place?

I've found the chinese small carbide end mills last 15* longer when using some coolant with them. You'd be surprised how few linear metres of cutting a 2mm end mill can do before it goes blunt. Still cheaper than paying a dude with a laser cutter though.

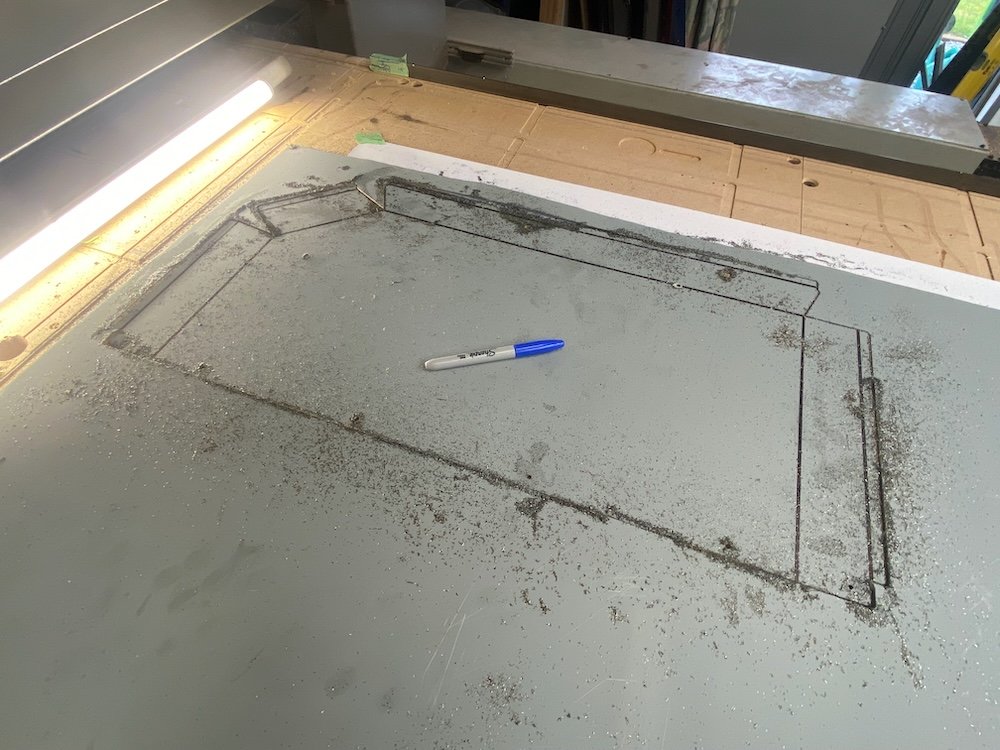

Basic clamps to start with, first op pre drill rivet holes and use these for extra screws. second op draw fold lines, can throw in additional screws in scrap material here too, third op chop out.

Used cutting fluid to start with but settled on backing off feed rate and using crc + nozzle extension cos easier.

Chinese carbide is 100% the go for DIY, this is awesome for my pottering about, i'd still go laser for multiple parts though.

-

6

6

-

-

- Popular Post

- Popular Post

Had a test run with 1mm sheetmetal in the router today, 2mm endmill chomps it out easy, bonus points that I can also mark fold lines too.

-

13

13

-

1 hour ago, igor said:

Come anyway Nick. Someone'll give you a ride.

99% sure i'll be there, just with one income and the new garage build on, discretionary spending is currently limited.

-

7 hours ago, RUNAMUCK said:

I tagged everyone who voted yes.

The relentless badgering of everyone else will commence shortly.

I'm keen as, just fully 100% unemployed at present

Reasonably optimistic income will be non-zero by August.

-

yeah it had legs, sketchy as folded steel? They went to scrap early on and totally forgot about them

-

1

1

-

-

11 hours ago, SOHC said:

I got given a Tanner saw bench that has like a spindle molder on one end of it to, it came with all the attachments.

Like this one?

Has a third position and a table on the opposite side to the jointer but all the mechanicals were gone by the time I got it, good saw, did our kitchen with it, just comically small and had to build it into a bench to make it useable.

-

3

3

-

-

looks nasty as! 3phase?

-

Lift arc was super annoying for me as a learner, having a foot pedal and 2t/4t options really helped to let me focus on the task than trying to learn all at once under constraints, I found I enjoyed learning on work's fancy machine way more than persevering on an arc welder with lift tig tacked on.

Foot pedal helped learn settings, just added 20% to what I thought and could ramp up or down if wrong.

2t/4t meant with harder geometry I could hold the torch in a few more ways and the ability to back off if settings were way off.

-

2

2

-

-

57 minutes ago, waspman said:

What solution did you find for your pneumatic issue on the feed?

Kick the can down the road is unfortunately the current fix

Went into a number of different outlets, all real helpful but ultimately none of the solutions offered will work, looking like turning up a custom fitting to accept standard lip seals.

After some digging and further troubleshooting the most leaky circuit is for the down position, currently using gravity for this function temporary/permanent.

-

2

2

-

-

12 hours ago, BlownCorona said:

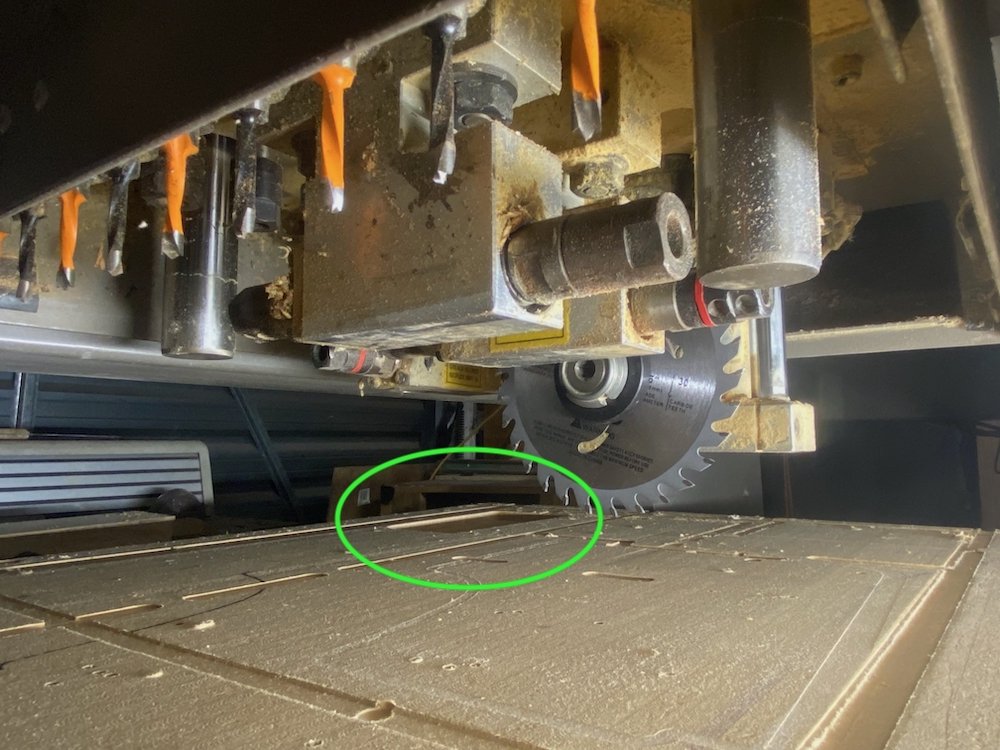

thats going to be scary if you fuck up the z height.

dont fuck up the z height

Me? Never.....

Old me may have fucked up the Z once......

While reaching for the E-stop in what felt like slow motion I realised the machine didn't give a toss so just watched it chew a pretty big hole in the part and spoil board.

But yes, i'm more worried about catching the blade than the blade cutting something it shouldn't, it does retract ~100mm from that position which "should" help.

-

1 hour ago, Leone said:

Found a Mark Sheehan on FB, whose profile which looks exactly like the type of person you descibe above.... so sent a message

fingers crossed haha

Mean, in a kayak + lab? thats him, hopefully you get in touch, really nice guy and good for a yarn or two.

Spam sharns:

He is bit of a humble legend of the area, years ago there was this thing called the World Heli Challenge, where snowsports folk would hang out in Wanaka to do silly things on helicopter accessed terrain. Rip Curl was key sponsor so for shits and giggles they added a surf day into the schedule, most of the crew were pretty accomplished surfers along with some token pros they brought over, it wasn't a token bunch of kooks being let loose on a gnarly west coast break, was lining up to be a pretty impressive day.

We convoyed over to mussel point near Haast where a decent shore break was guarding access to the waves, a number of the crew got pretty beaten up just paddling out with the lucky few having a good time out the back. Without much fuss, Mark wanders off solo down the beach, few of the crew picked up and started asking what the old fella was up to so a few eyes were in his direction, he casually climbed out along the rocks, with precision timing slid into the water past the shore break and paddled out for a pretty decent wave, zero stress and effort as expected on his home break. Some pretty capable pro surfers got schooled hard and were left asking who the old guy was, good laugh for the locals when the reply was just some tradey who followed us here.

-

1

1

-

-

Correct, belonged to the Sheehan family in Wanaka for many years, their kids both went to the winter Olympics for skiing, no doubt that car played a big part in taking them up the hill.

I used to live on the same road, their dog would wander up to our place to sleep on the couch, Mark would come up looking for the dog and also park on the couch, often talking about surfing on the west coast, that car has lived a life of adventure, don't stop!

-

1

1

-

-

6 hours ago, yoeddynz said:

codswallop

Sorry sun, ol mate Skinner has me sorted

-

2

2

-

1

1

-

-

Found the oddball sized blade on Ali, arrived today, dangerous (but useful) router attachments

-

2

2

-

-

236266080211992572

Expires May 10 -

Trailer brake master cylinder?

-

I recently brought a ER16 collet chuck for the router so it can fit 1/8" shank microdrills

Buy a second to hold the jet and you'd be able to overkill the job without risk of breaking drills or needing good eyesight.

-

1

1

-

-

18 minutes ago, Rookie said:

Conviently the Germans have created a standard for automobile wiring so you don,t have to guess.

https://en.wikipedia.org/wiki/DIN_72552

The 31b pin is indeed a swiched ground, which as correctly stated by the metricnut would only work with points trigger wire.

Mean! Always assumed those numbers had some meaning but never looked into the details, cheers!

-

1

1

-

-

- Popular Post

- Popular Post

After guessing the shape, dad provided me with dimensions and photos of original boot panels, gave the CAD model an update, grabbed a sheet of 4.75mm hardboard and set about probably the most to factory spec part of the rebuild!

Also carved up a gear knob from scrap rimu with the correct shift pattern, scrubbed up real nice with linseed oil too.

-

23

23

-

Thread cutting is like that pile of offcuts taking up a shelf, sure you don't need em, but bloody handy when you do

-

3

3

-

2

2

-

-

27 minutes ago, yoeddynz said:

The ones at hari hari are neat but insane levels of Sandflies both times I've been to them and I don't think we'd squeeze all of us into them...

That place is real cool however..... Last time I did a day mission from chch the river was flowing hard against that bank and straight over the top, could feel the water on the sides was a bit warmer, but no hotpools to relax in, just sandflies to say go home!

Cedar flats is probably my favourite in the area, but a 4 hour walk means its better as an overnight.

-

1

1

-

-

Winter is dry season on the coast, best time to visit, just need hotpools!

-

9 hours ago, BlownCorona said:

just a cheap parallel port card and the stepper drivers that it came with. the para port card is nothing but patching the specific output wires from the DB24 port to the stepper drivers and the limit switches, z probe and e stop but through opto isolators for safety and with the addition of a couple of controllable relays. it relays on the computer itself to generate steps which so far seems to work fine. a large table such as yours may not be so gravy

Oh thats pretty simple! will get LCNC running really fast, all the little details in linux will make the machine really useable, excited for ya! I've just got my head around the PLC side of it, just mulling over how to re do the wiring then I can start looking at getting toolchange working, toolprobe etc etc. Wiring sucks cos once I move that its past the point of no return, up to now i've just been chipping away on another config file.

Yeah parallel breakout won't work with my machine cos closed loop servo drives, needs the Mesa board to do the realtime movement control, which kinda sucks cos I pulled a stack of breakout boards from the previous controller!

-

3 hours ago, rossnzwpi said:

On the topic of correct surface prep.... I have a 1960s engine with magnesium castings that I want to clean (blast?) and have an anti corrosion surface treatment applied. Originally this was a DOW chemicals dichromate passivation that is specific to magnesium castings. Does anyone know a way to do this or a company that does this in Auckland? Datlow - your comment about not dipping Ferrari magnesium wheels in acid wash comes to mind.

When I was doing aviation stuff with Mg, SafeAir/Airbus in Blenheim were the only people in NZ doing it, and somewhat difficult to get a job in, might be worth getting in touch with the warbird guys?

Pog’s X1/9

in Project Discussion

Posted

Was excited for wof achieved update, bummer for the plug thread