-

Posts

2,353 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Kimjon

-

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

Its just an Aliexpress version. About $150 landed with a handful of belts. I can't see a more expensive one offering any advantages over this one, as its just two ideler pulleys and a driver that goes on the grinder spigot. Only thing I changed was a cheap Phillips head screw for a m6 Allen cap screw. Be easy to make one, but at that price why would you. -

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

I got this tool the other day...what a fabulous invention. Its a pipe linisher that goes on an angle grinder. Made my shitty flap disc job look amazing in no time. The photo about was after about a minutes worth of linishing. The tightly curved parts of this sub frame still require more work - I'll buy some of the skinny belts to do that. 10/10 would recommend this tool. -

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

Last photo for today...time to switch off from designing and building stuff. I feel its beer o'clock -

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

-

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

-

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

Main reason for the fairing is to hide all the ugly, like cables, wiring looms, and digital speedo etc I think it looks pretty tidy. It's not actually installed in these photos, just boogied up with cable ties, etc...but gives a pretty good idea of the look it'll achieve. Paint will tie it all back together when its done. Looks a bit disconnected at the moment. -

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

-

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

-

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

Im on the fence regarding this. Its cable tied there badly for the purpose of the photo. Obviously I need to cut it up, to get it sitting better etc. The only reason I'm thinking of the fairing is to hide the ugly of my digital speedo. If I could get a small speedo I'd probably shift away from the fearing. 50/50...will give it some absorption time to think about it some more. -

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

Smaller headlight. Its not quite where I want it, but it gives me a starting point. Mini fairing on order too, so this is plan B. The fairing could offer nicer way of hiding an ugly instrument display, so might be a winner. Keeping an open mind until I can play with both ideas. -

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

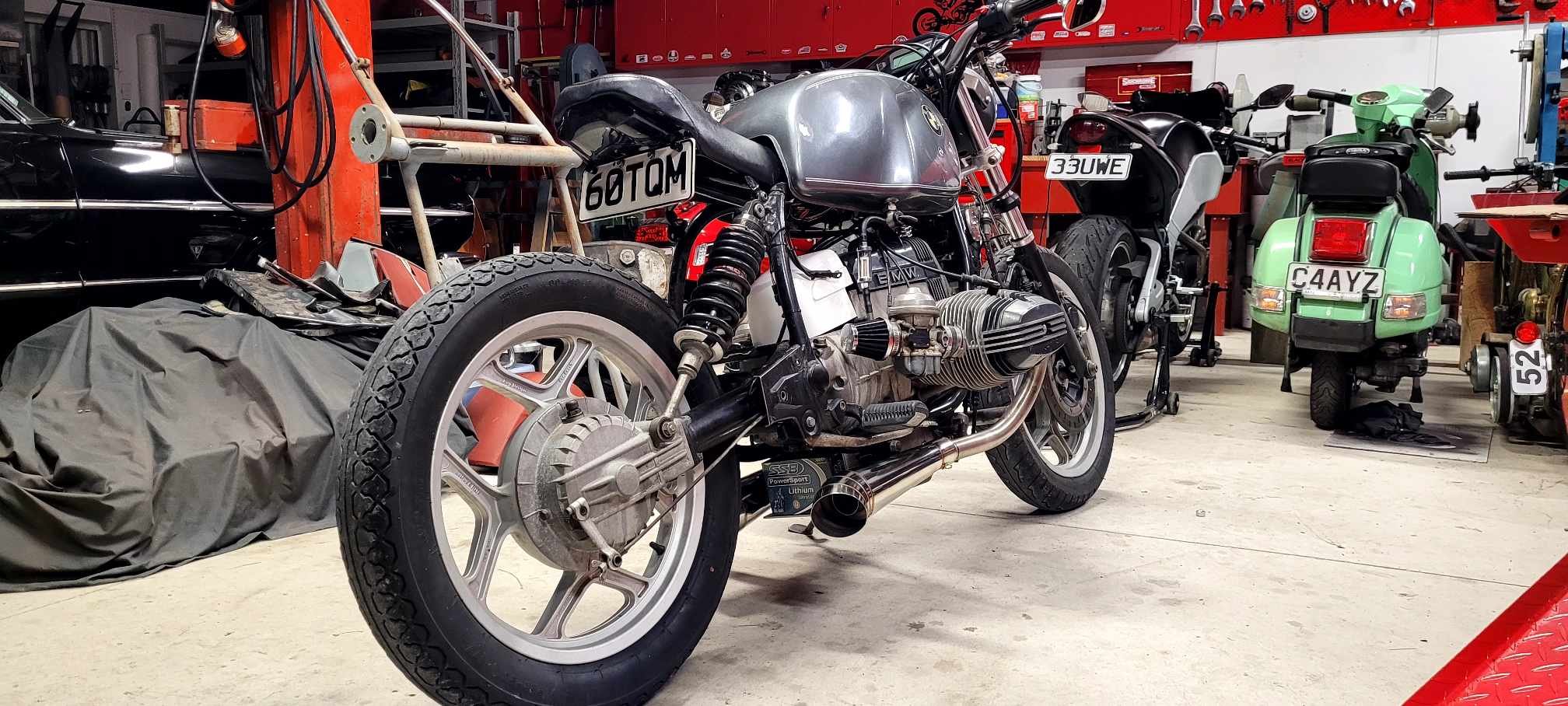

New small headlight on order, grips, small 1/2 front fearing (but not 100% committed to this idea). Want to lower bike a touch in the front too. But overall I'm pretty happy with it so far. -

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

-

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

-

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

-

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

-

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

-

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

-

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

-

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

-

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

-

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

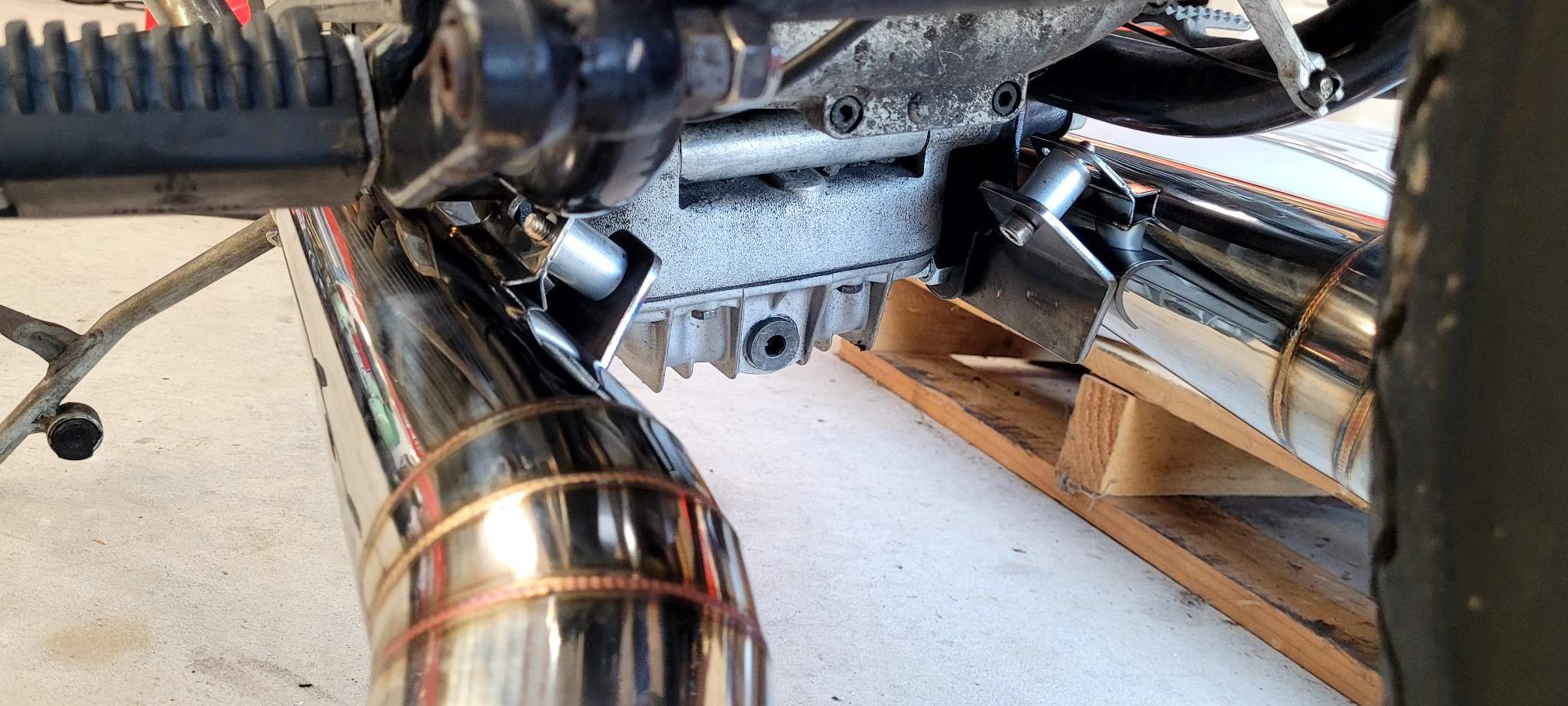

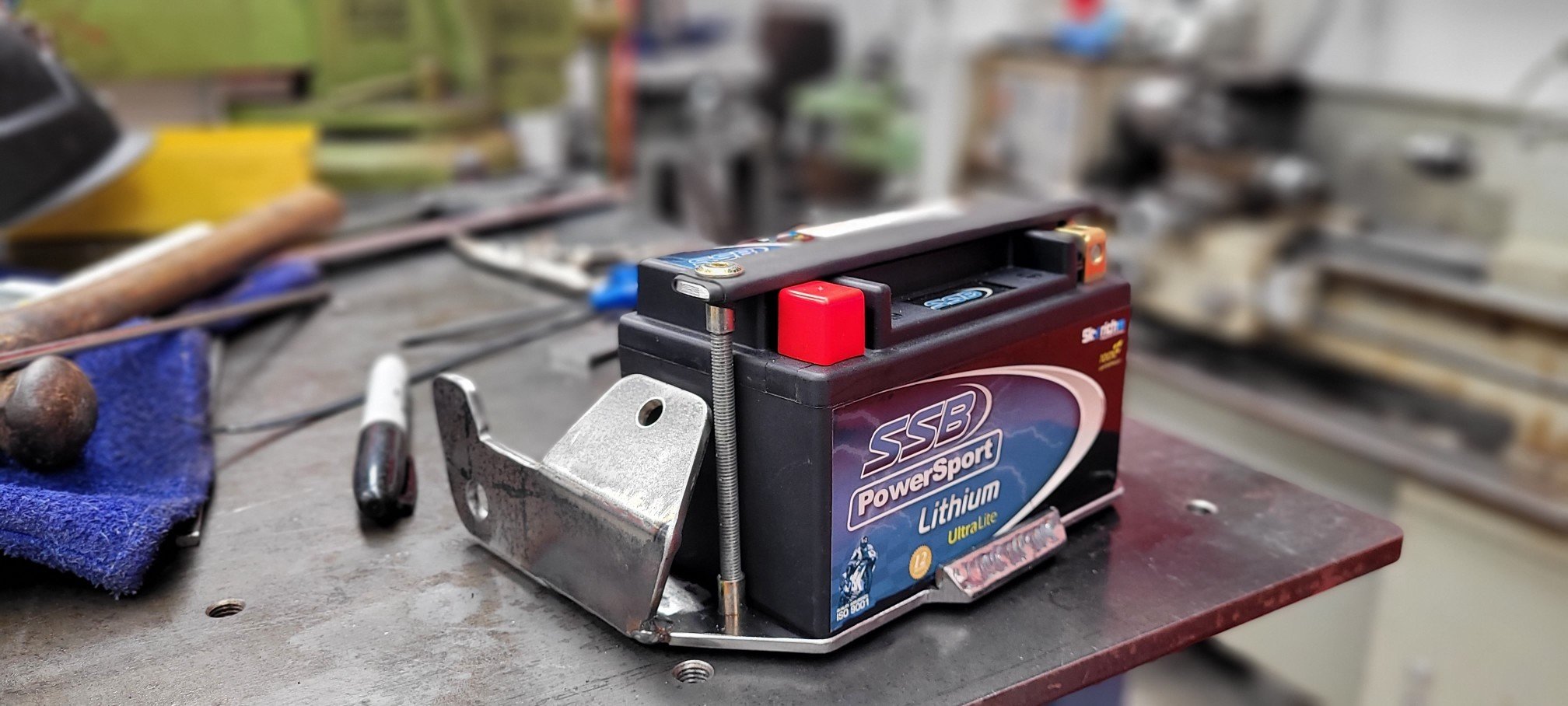

Rear sub frame underway. Waiting on mandrel bends to arrive so I can finish it. I've rerouted a heap of wiring, plus HT leads through the engine covers. Next I'll remake the battery cables, and charging system, to reach the relocated battery underneath. really starting to take shape now.- 95 replies

-

- 10

-

-

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

Flat out working on this thing. 2 days work, and hopefully no one notices what I've done...should look factory. -

Kimjon's next money pit - BMW Airhead cafe racer build

Kimjon replied to Kimjon's topic in Two Wheels

.thumb.jpeg.ff7b211fbba9d0dc54ce1282be3acdf8.jpeg)

.jpeg.2e0257d3ce6c24d2fac26f86539a51b2.jpeg)