-

Posts

2,353 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Downloads

Events

Gallery

Posts posted by Kimjon

-

-

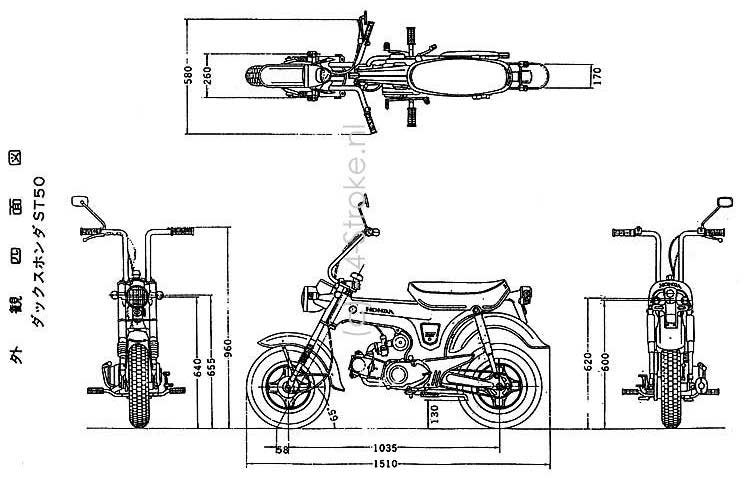

Dimensions are frighteningly small...

But that's kinda the point of these. I'm going to hold onto it, get it going etc...think about what direction to take it i.e restoration or JDM cool...?

-

1

1

-

-

Next adventure...1969 Honda Dax. I'm collecting it from Waiheke Island next weekend, which just adds to its story.

From what I can see in the photos it looks like its all there, including the easily lost parts like the chain guard and original exhaust etc.

I'm kinda excited about this wee project. Shouldn't brake the bank and will be hella fun to ride.

-

14 minutes ago, 440bbm said:

thats the 2nd gen of the moto4. the first was a 225 with a way more vintage look, actually better imo. had both and they're sweet bikes. i do prefer the first model though.

Cheers, good to know thanks.

Its a fun little machine to play around on. I've been riding around my lifestyle block and our neighbours farm, so far it's climbed every hill I've put in front of it.

Its got 40 years of quirks, work arounds and dodgy repairs to unravel. But it seems mechanically solid, so maybe that's all I need. Sometimes you gotta know when to stop and accept the win.

-

-

-

Another distraction enters the room...poor Ape, you'll never get finished with the way this story is unfolding.

But come one, a 1980's vintage quad bike. This is the first Yamaha quad made, after the 3-wheelers and probably a lot of litigation in the courts over the safety issues of such machines.

Bit of a bucket list item for me, as this particular model (Yamaha moto4 250) is so entrenched in my childhood memories. Stoked to have it in my shed.

-

2

2

-

-

Been ages since I've done any work on this. So today I put 8hrs into it.

Long story short it now has a gas tank.

I centre mounted it in the tray. The vespa should still fit, and it's fuckloads safer than being inside the cabin like the original was. These are renowned for rolling over, so I'd rather not get covered in gas in the process.

-

9

9

-

-

-

-

-

I'd love to do another one, and probably will someday. I'd go more Japanese style, like the bikes from LuckMC. Check them out on IG, they push proportions to the limit...but make amazing bikes.

-

1

1

-

-

-

-

-

And then there's the buell, which is a medium fast bike.

I dropped a cylinder 2 weeks ago. What a fuck around that turned into. First thing I did was check if it had spark, which it appeared to have good strong spark. So I focused on fuel, compression, then back to the coil. All tested well. Yep, full circle - the fucking sparkplugs was the actual problem.

Anyway, got there in the end. Replaced the plugs - back to normal again.

Its challenging swapping between the bikes (BMW v Buell). They're two completely different bikes to ride. I think that's why it feels so sketchy going from one to the other.

-

5

5

-

1

1

-

-

Bmw is running so good now. I've basically been daily riding it for the past 2 weeks.

Unfortunately I'm getting a little complacent with it. It doesn't feel fast, like a modern bike. And in reality it's not...however the speedo tells me I'm actually going faster than I should. Today I nearly lowsided it as the rear end started to drift around a corner.

Its a bit of a wake up call. Tone it down, live to fight another day.

-

7

7

-

-

Carb vacuum guages to sync. It's not an exact science, and due to many factors it's unlikely that opposite cylinders will read the same values on the dot. But from what I could find, if you're within a unit (1kg/cm2) you're close enough. Mine was well below that, so by all accounts a great result.

I didn't care what the values were, so long as both guages were doing the same thing, at the same time (more or less).

I was probably 4-6 units out, tuning by ear and feel. Shows how hard it is to tune that way. One cylinder can be working considerably harder and compensate for the opposite one, which was very much my situation.

Bike runs smooth and no backfiring now. So we'll worth doing.

-

7

7

-

-

I've been rediscovering this bike, after my buell decided it doesn't want to run on two cylinders.

I've been fixing all the little things that drag on forever in these builds. I'm basically there, tuning the carbs to run in sync, wiring, calibration of speedo, etc...etc...etc...

Runs amazing for an old bike. And has a bit of character to it. It was popping and back firing, but that's all tuned now. Bit of a shame as I kinda liked the pop...pop...pop...on deceleration and the truck like engine braking it provided, however the benefits of the tune outweigh the loss of cool sounds and engine braking.

-

1

1

-

-

12 minutes ago, igor said:

What happens if you hit a rock? I hit one with my Hyundai trimmer and it bent the blade then tried to eat the cast aluminium housing thing.

#scrubbarlife ... shit happens, no different to any scrub bar

-

1

1

-

-

1 hour ago, johnnyfive said:

That's great, any footage of it at work?

Also is there a maximum rpm on line trimmer attachments?

No idea on rpm - but its got all the torque this motor.

No video of it, but it's got so much torque it never stalls, or get clogged up. The centrifugal force clears the tri blade and keeps it clean. With the original motor I was forever stopping to unwrap the long grass.

13 minutes ago, tortron said:the triblades are rated to about 12000 rpm, ign cutoff is about 10500 on a sthil

Thanks^

-

1

1

-

-

-

- Popular Post

- Popular Post

This patch was solid blackberry about 2m high. The "widow maker" destroyed it with ease, going over it a few times turning it into mulch!

Fuck its epic. Hardly reached full throttle. So much torque to turn the tri blade.

-

12

12

-

-

- Popular Post

- Popular Post

Kimjon's 50cc (then later ... 150cc and 400cc...then 1000cc) of awesomeness! Oh and a 2+1 wheeled machine...

in Two Wheels

Posted

Fuck yeah!

Sealink weren't going to let me push the bike on, it was a bit touch and go. Apparently you have to ride the bike on. Given it doesn't go right now, that wasn't happening.

Dude said I'd have to order a tow truck, get it on the tow truck to transport it to the other side due to health and safety rules.

I must have given him my best "tf you just say" face. He then said, well hold on, let me ask the captain if we can do this as you look capable of performing the task. Captan looks out window...no problem...come aboard... yes!!

So happy with this bike, its fucking mint. Its had a bare metal restoration. There's a few things that aren't my taste, but such a good base. Its 95% original and complete. Only some trivial stuff to finish it