-

Posts

118 -

Joined

-

Last visited

Everything posted by tehnzbrad

-

chucked the motor back together everything covered in grease with no pistons in it just to mock everything up and get the bulk of the welding etc done, just gona post heaps of photos now to catch up haha if you have any questions feel free to ask

-

front panhard pretty much done, set it up to use an adjustable gq patrol one, quickly pulled down the ls1 to see how bad it is, bored look mint still really clear honing marks but looks like its had a crank fillet not machined correctly and its done the crank so i will need to find one of those. plan is to have a nice angry cam, high compression and lots of revs OR just slap a big ole single turbo on it and blow gearboxes every week i havnt decided yet

-

pretty much finished the triangulated 4 link, not going to massive write ups of how everything is done as theres is enough people who have done it before me and have posted detailed methods on google... and have started finishing off the front end panhard mounts, steering stuff.. scored a rebuild ls1 off TM for $500

-

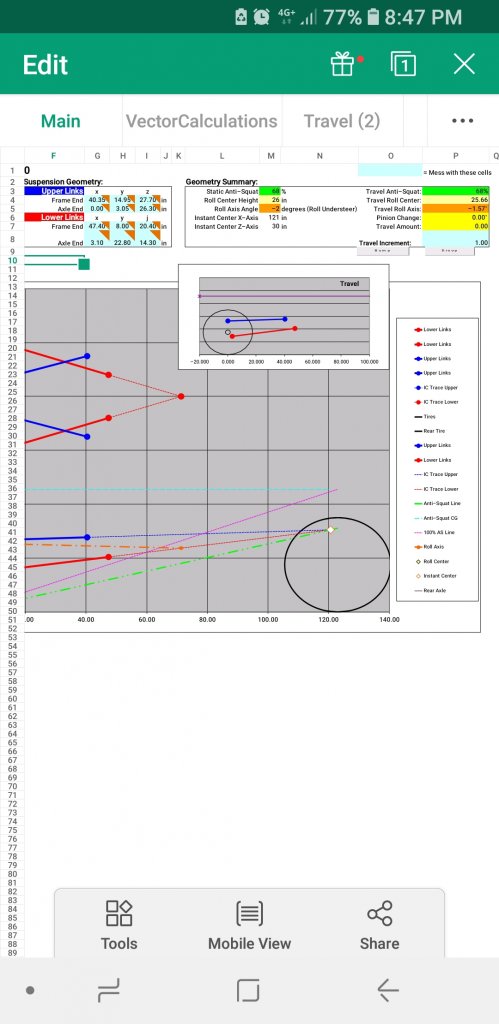

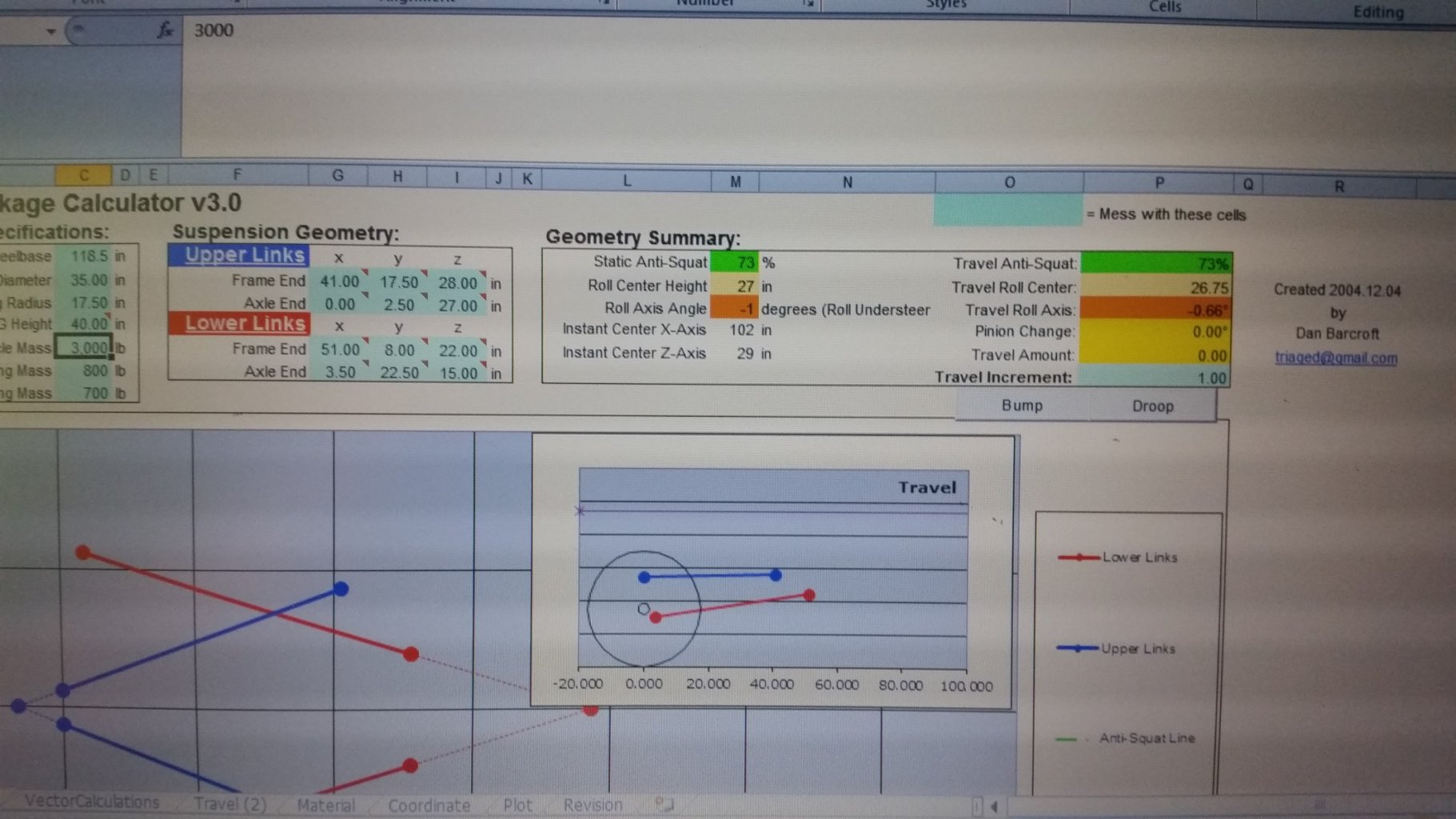

here are the final rear 4 link numbers, this is what ive come up with to suit my application after reading alot of others outcomes and stuff has a small amount of adjustablity but i hope it works.

-

got some standard patrol front radius arms and put a m24 thread on the ends, and then had a custom threaded sleeve welded onto some 3"currie johnny joints to try get some extra flex and freedom of movement over the pin and bush setup, dont have many pictures of this part but here are the beefy mounts to the chassis i made

-

decided on final 4link numbers and the link mounts showed up so i started tacking them up and welding then together.

-

the good thing about a chassis is its light enough to flip over by hand so no overhead welding which is a bonus.. starting to get over fabrication..could never do it as a full time job

-

i guess its fairly industrial? all 5mm plate right about now my welder broke so had some down time while that was getting fixed and ordered some custom beadlocks which you will see later on $$$$

-

also had to do a similar thing on the rear diff to get that upper link mount high enough to achive the right numbers in the 4 link calc

-

my rear lower links ive designed to mount off the existing xmember, but to get the numbers i want in the 4 linl calc i have to drop them abit lower than what the xmember is, was sorta just winging it here with internal gussets i doubt they will break off

-

while i waited for all my univeral link mounts i carried on with power steering box mounts ( gq patrol steering box) and just playing around with numbers in the 4 link calc and ordered all these FK rod ends heim joints from summitracing, these things are massive, sorta lame they took 3 months to get here though slowed the whole build down

-

the conversion kit arrived from marks adapters in ozzie (ls1 to hilux R series 4x4 box) and i ordered all the universal link mounts and engine mount kit from usa, cheap as all laser cut slot together parts out of 6mm plate too easy!

-

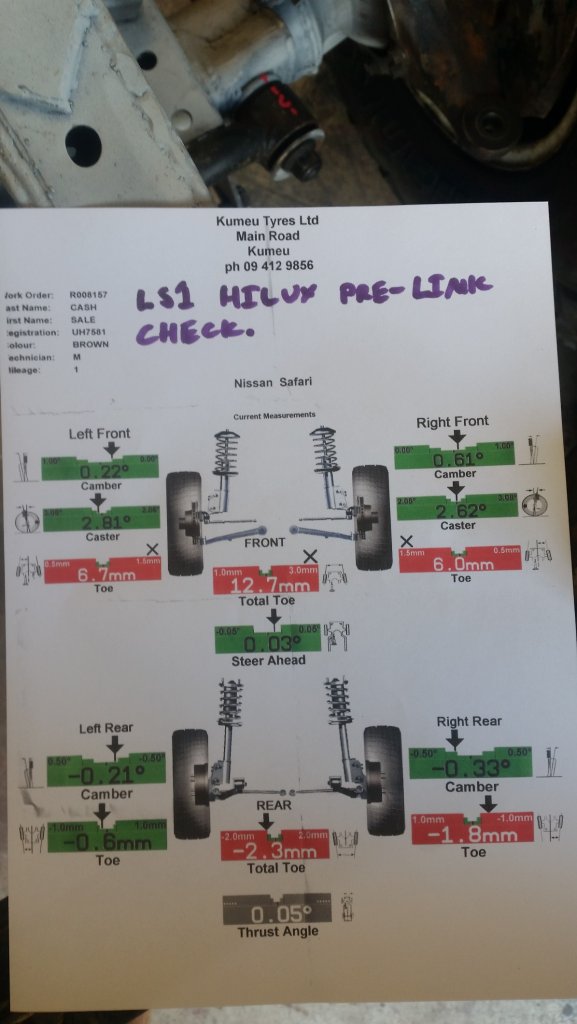

some where along the way i got some GQ patrol diffs which a far wider than the hilux ones, and much larger and stronger, the certification part of the build comes into play here as i do want this thing on the road if i can, so i cut all the mounts off the patrol diff and jigged them up under the chassis best i could. using a 300mm digital spirit level and the old stringline i managed to get close as to the same alignment as a factory Patrol (fluked it i think) apart from the toe but thats easy as just adjusting the track bar. for the front diff i had to cut off rotate the housing and reweld up the radius arm mounts to achive the correct castor for the ride height i want (about the same as a standard hilux) i threw some trusses on them also for jumps

-

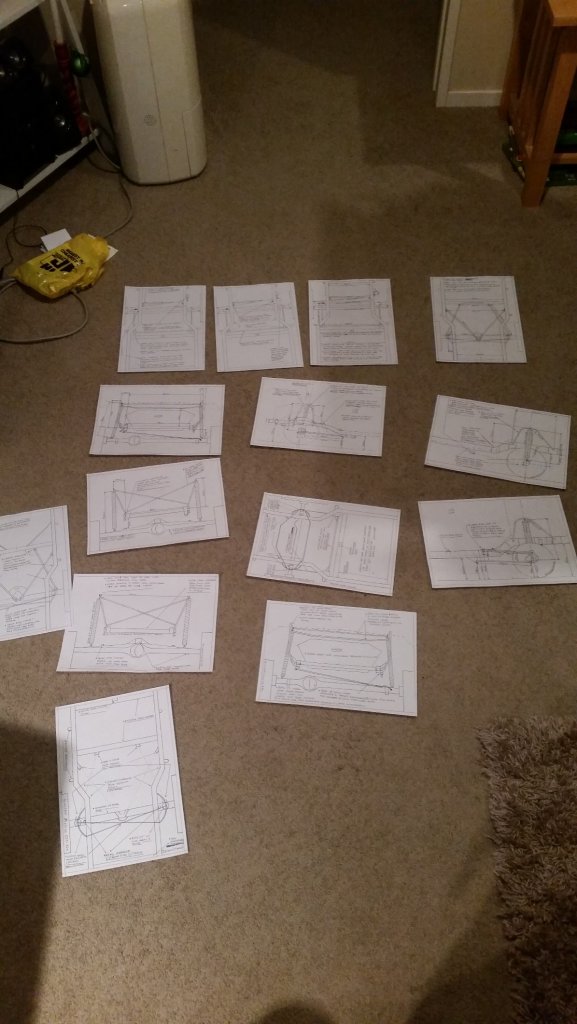

after waiting for the steel to be cut on the laser (so much nicer than old mate with a cutting disk on the grinder) they were finally done and i could start forming them and welding them up to the chassis. now im no fancy engineer but all i am trying to achive is alittle more stiffness and to try keep the chance of cracking to minimum, so at every mounting point or where the rails change direction i fishplated. im also trying to follow the hobby car manual to keep inline with the lvvta reqs.

-

after that i cut all the suspension mounts off with a 18" steel cutting blade on my concrete saw and i had a blank canvas, following my drawings and roughly guessing where everything is going to fit i narrowed the rear section of the chassis to fit in all the suspension wizardry. meanwhile all my fishplates and other related steel is being laser cut.

-

so after i decided on what the goal was and how i was roughly going to get there i contacted lvvta and submitted everything for TAC approval, which was a massive waste of time, basically told me its fully up to the cert dude which is what i gathered anyway... trucking on. sold the 350 chev, box and hilux diffs, stripped everything back and kept what i needed and sold/ gave away what i didnt.

-

so after making it run well i got used to the power and was super unhappy with the factory leaf set up, twitchy steering, axle tramp, no flex, ride harshness and general truck trying to kill driver. decided it needs coil overs... then the baja videos came.. i spent about 2 months measuring, drawing, reading and thinking about how i was going to undertake this, alot of info regarding building anything to do with speed and offroad is kept under wraps so it takes alot of time to get through whats on forums etc..

-

Ive been following Kpr's hilux build on here after seeing a video on facebook of it shredding mud and decided people might want to see how i guess a similar build is going. (not trying to steal spot light just think people might be intrested) bare with me i have like 200+photos and alot of info to type so may take awhile im a drainlayer by trade so deffo not a pro but have had my fair share of building 4x4s and other things. haters shall hate... ill start from the very begining, so after i finished building 2x nissan patrols i wanted something abit more exciting, so feburary 2017 i aquired a certified 1991 ln106 hilux with a 350 sbc with a R series toyota box behind it, it ran like shit when i brought it so the mods began and i got it running nice again with new carby, leads, intake etc

-

yeah i looked into running longer bumps but im trying to put it through cert, trying to let the shocks do as much work as they can before the bump stops come into the equation, ( filthymotorsports on youtube about shocks had a good way of explaining it) also packaging aswell i havnt got alot of space so 2"×2" stops will be a good fit. tbh its abit of a educated guess/ stab in the dark ran the numbers in a spring calculator ( on crawlpedia.com) i should do a build thread on it but super busy

-

yeah i agree and it seems nz and even aus are far behind what people are doing in the usa so theres pretty much no peer support you could say when it comes to it all down under, ive just ordered 16" and 18" travel 2.5" king remote coilovers. factory valving (will play around with it once i get it all finished) and 200lb over 250lb rates on all 4 corners aiming for 50/50 weight at under 2ton curb weight, designed it so 50/50 shock travel from ride height with 2" hydro bumps (probably buy radflo as they are half thr price of kings)

-

oh sweet, theres so much conflicting info on the forums etc such a hassle reading through it all finding something that sounds like it might work, and add to that people not wanting to share info.. cheers man

-

hey man how are those radflo bumps? can you put more than 200psi in them or? other brands i see take like 400