-

Posts

2,279 -

Joined

-

Last visited

Posts posted by Adoom

-

-

- Popular Post

- Popular Post

Giving the mini project some love.

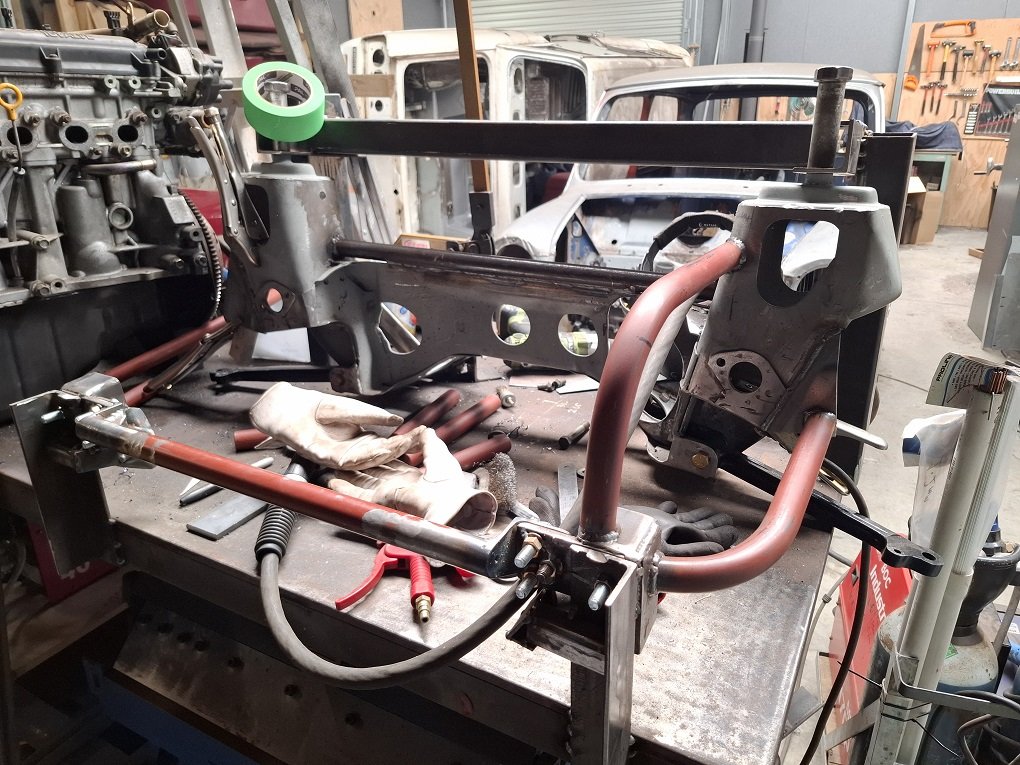

On the car, I made some cardboard templates and marked limits of where tubes could end. Then rough cut the tubes to just longer than the correct length.

Then wrestled it out past the engine and bolted it to the jig on my steel table.

Once I got the pipes in where I thought they needed to go and welded enough that they would stay in place. I trial fit it in the car again.

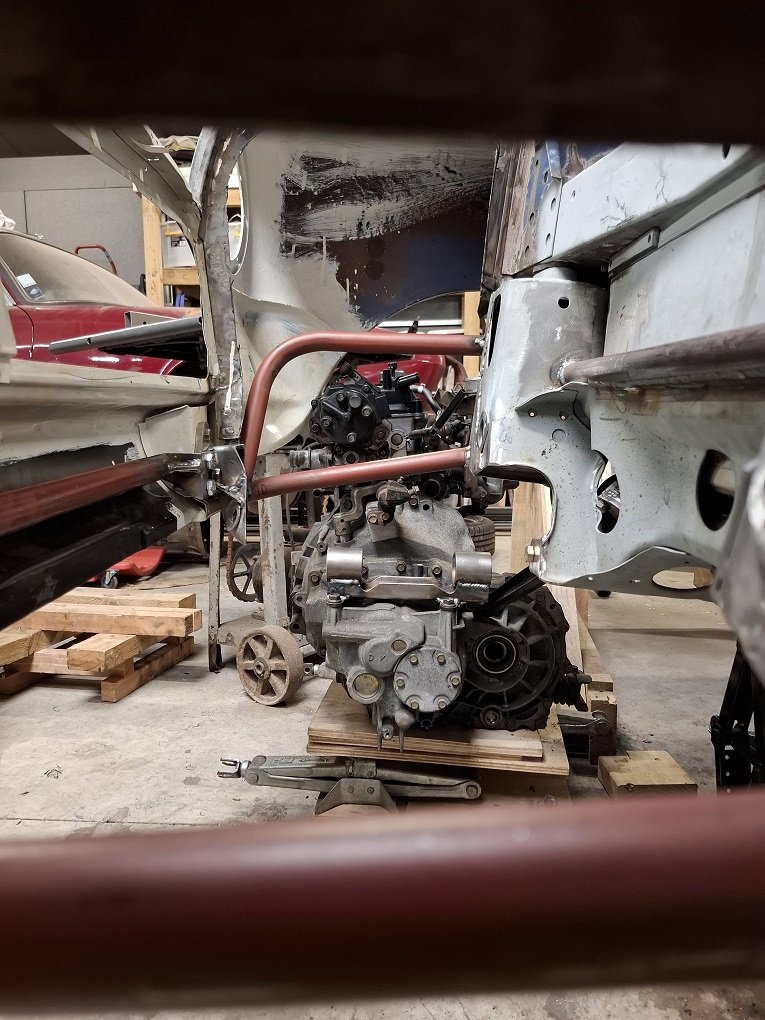

Now how to get the engine back in there....

I lifted the car up even higher on blocks and wobbly scissor jacks, to slide the engine under front the front.Then 3D tetris for at least an hour to get it up into place.

It's tight.

I will need to add some clearance to the box section here. My engine mounts are stiff, but probably not that stiff. An engine steady bar may also be required.

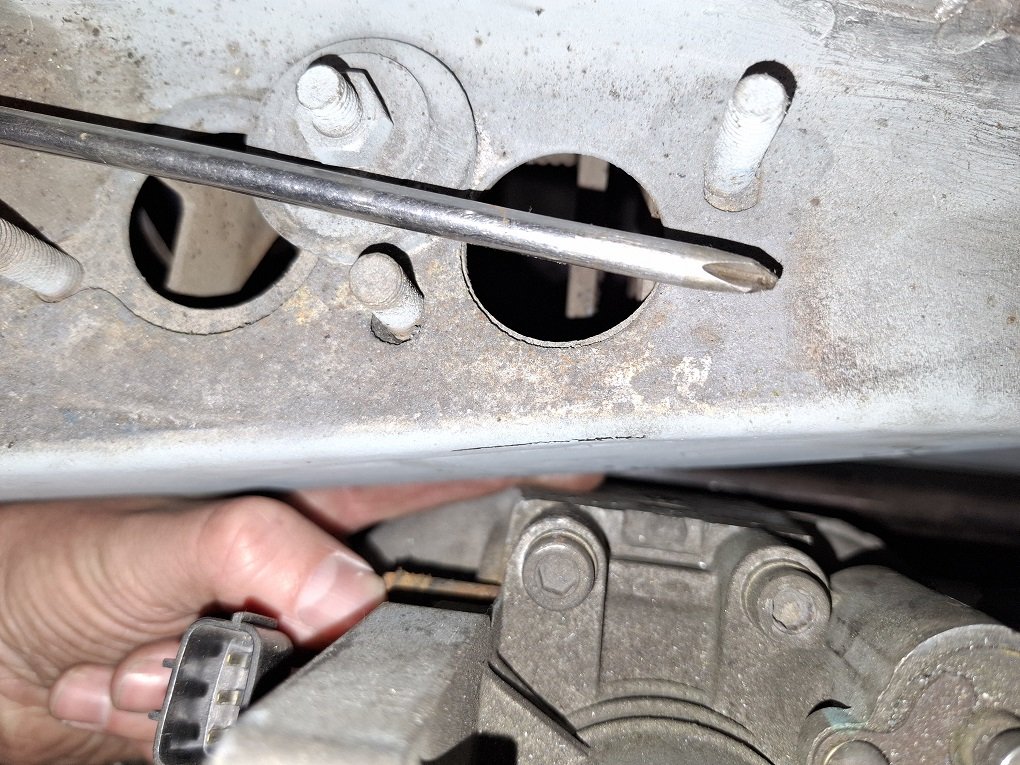

The right side tie rod mount is the main clearance issue here.

This pipe is way out here to clear the front pulley(by 8mm!) but I've realised it will interfere with the lower shock mount. So I'll be adding a bend. That flappy plate will get gussets later so it can't bend.

The other side might need the same treatment, but it doesn't stick out nearly as far.

I'm hoping, when I'm done, I'll be able to install the subframe on the engine, the lower the car onto it.

-

16

16

-

As far as I can tell. It's not canbus lighting. And it doesn't sense the current to see if a bulb is blown. I think it was just put there by the towbar installer because he assumed. He also didn't know subaru provided a plug in the loom where the factory optional trailer light loom goes so he just hacked into the wiring behind the light.

I has deleted it.

Discovered brake light bulbs are both gone. Only the high stop light was working. No warning lights anywhere. Wonder how long she's been driving around like that....-

2

2

-

-

1 hour ago, tortron said:

https://www.gore-research.com.au/trailer-towing-adaptor-modules.html

Tldr

Car sends pulses to.check the bulbs are OK. If the trailer is drawing extra load on the wiring the car might get upset and throw a lighting code

Hmmm, but this doesn't have a separate power wire.

But I guess it must serve the same purpose.

-

The trailer plug isn't working on 2012 Subaru forester. The terminals were rusty, so I replaced the plug. But still no power. This thing is inline in the cable. I'm testing for power on the tail light circuit. Power is not getting through this thing. It wasn't sealed and had some oxidation I cleaned off.

Wtf is it? Can I delete it? Car doesn't have LED bulbs if that's what it's for.

Wtf is it? Can I delete it? Car doesn't have LED bulbs if that's what it's for.

-

12 hours ago, yoeddynz said:

There's some aussie made alternatives to por 15 that I have found to be better and a bit cheaper.

Bilt hamber stuff is great. Wins a lot of comparison tests etc. Unfortunately no one is importing it into NZ. When I moved back home from the UK we brought over a whole box of cans of bilt hamber cavity wax. (dyna S50?) Best stuff I have used yet.

I'd just use Epotec 408. But it's a bit of a pain to mix up a tiny batch for small things like this.

Any brand names of the aussie stuff?

I used some eastwood platinum and thought it was pretty good. But AFAIK it's no longer available in NZ.-

1

1

-

-

- Popular Post

- Popular Post

The inner arch. This took ages to get the right shape.

See how much frilly I had to replace.

Fortunately it's not really visible so I'm not going to grind the welds down.

POR15 really is shit on new steel and the surface has no 'tooth', just peels off.-

11

11

-

1

1

-

3 hours ago, Nominal said:

We got some of these (probably a bigger size)

100Pcs Fruit Protection Nylon Mesh Net Bags with Drawstring-M | The WarehouseWorked pretty well in keeping the birds off long enough to get some grapes to eat.

I got some last year. From an OS recommendation, possibly from you.

Should have got a larger size. Found the drawstrings didn't like to stay tied and some fell off.-

1

1

-

-

- Popular Post

- Popular Post

So the new shoots of my grape vines keep getting fucked by late frosts. I had no luck at all using frost cloth. It's also super tedious to put on cause I've got 40m of grape.... erm fence.

So this spring I made a thing.

Frost doesn't like water cause it's warmer than ice so I put sprinklers over them.I put some extra sprayers at low spots to drain the pipe when it's off. I don't want the water freezing in there making it useless.

But I'm not gonna manually turn that shit on early in the morning.

So I dug up an old arduino board.

And bought a relay thingy and a waterproof temp sensor and a 24 volt solenoid valve thingy(not pictured) for the outside tap.

And hot glue. Lots of hot glue so stuff stays plugged in.

Old laptop power brick is perfect for the solenoid valve.

My sketch checks the temperature every 10 seconds. If it drops below 0.5 degrees it turns on the water for 60 seconds. Then turns it off and waits 5 minutes before looping back to checking the temperature again.

I had some 'stunt frost' for testing.The brass solenoid valve is screwed directly to the outside tap which is attached to the brick facade of the house. It's pretty loud when it thumps on, I think it might be loud enough to wake me up.

Hopefully I'll get some grapes this year, if the birds don't steal them all.

-

14

14

-

1

1

-

- Popular Post

- Popular Post

Saw this on a farm while on holiday in Waitomo. "I'll just go look around to see if there is a kitchen scraps compost pile outside"

I did some googling. It's a 50's Austin A40 pickup. The missing badge would have said "Austin of England".

I suspect it's still there for the purposes of "art".

I suspect it might be seized.-

14

14

-

-

33 minutes ago, Muncie said:

What's the go with narrowing track on an independent rear car? If you've seen my commodore thread I've been mucking around with BMW wheels to get the width I want under the ass. How much hard work would it be to cert rear arms if I were to cut back the mounting flange have a new one laser cut and basically remove 30mm track per side to get the tyres tucking back under?

Yes I know it sounds like a lot of work but for me any chance to break out the welder and "meditate" is a good thing 100% reversible unlike pumping the guards etc

You'd need to go through design approval because changing the lengths of the arms can mess with the geometry. You will need to accurately draw, with measurements, the modified suspension. There is a specific form for custom/modified IRS. It's in the documents section of the LVVTA website.

On my Triumph(they are quite narrow), I narrowed a nissan IRS, so the arms and geometry were original, the inner pickups were just closer together. No design approval required. Your cert man just needs to be happy it's constructed "in a workman like manner". It was still a lot of work/measuring/thinking to get the subframe aligned and make new body mounts. And make new diff mounts.

In both cases you will need custom length drive shafts made.

It'd be WAAAY less fuck around to just use different offset wheels. Possibly cost less than the custom driveshafts alone.

EDIT: Not sure if you mean, "make new arms", or "move existing arms inboard". I had assumed the first one. -

1 hour ago, GARDRB said:

Just a thought this afternoon as we were discussing narrowed IRS setups. Does moving the suspension pickup points inward do anything to the suspension geometry?? I can't see why it would, but I'm also second-guessing myself. Part of me says that the inner suspension pickups being closer together would change the roll-center.

I hadn't actually thought of that. Referring to one of Allan Staniforth's books, moving the inner pickup points closer together would lower the roll center slightly. That's good, I think.

I don't think it would do much else, or at least anything I'd notice.

-

1

1

-

-

- Popular Post

- Popular Post

Just in case someone else needs longer front wheel studs for a 2500 because they have gone from alloys that use shank nuts to alloys that use taper nuts and there is not enough thread engagement.

And they also want to go metric because they installed nissan rear suspension.

These are the only solution I found. Fuck all wheel studs have a tapered head like that. They are from a Landrover Freelander. I got them from Rimmer Bros in the UK.The OD of the knurl is the same as the originals but as you can see from the photo it's a coarser knurl. They are M12X1.5, a little bigger than the 7/16th original ones. I'll have to change the nissan studs too because they are M12X1.25.

They pulled into the hub fine using a spacer, a washer, a shank nut and the impact gun. They are TIGHT.

-

21

21

-

- Popular Post

- Popular Post

-

9 hours ago, winstonwolf999 said:

Wow I can’t believe I’ve stumbled on this resto!!!

Not seen any decent pictures or info related to the Victoria early model.

following with great interest and hats off to you for getting in there!

any idea what the gross weight is?

I should update this. Did I forget I made this thread? Hopefully I have more photos.

It's not really a resto. More of a cleaning because it was just packed with grease and gunge.

It's supposed to be about 1200kg. Do you also have one?The gearing for the knee seems REALLY tight, up or down. It's a two handed job just to turn the small hand wheel. It's like the gears are meshed too closely, but there's no adjustment. I'm planning on making a flip out handle so I have more leverage. The later and bigger ones have a long handle rather than a small wheel as far as I know.

-

- Popular Post

- Popular Post

Driveshaft hoop!

The ring is 8X50mm. The spreader plates are each 80X60X3mm. The bolts are M10. The bracket off the ring is 160X60X5mm.

AFAIK that fits with the specs.

-

21

21

-

- Popular Post

- Popular Post

I then made the cover for the hardlines. Might be overkill, it's pretty sturdy.

Still thinking how I want to mount the driveshaft hoop. Can't really bolt through the floor there because there is a cavity. I'm thinking I'll make some strut things that go forward to the box section dealie, maybe won't make it removable.

-

10

10

-

- Popular Post

- Popular Post

I need to make the driveshaft safety loop. I've got no 5mm flat bar, but I do have a whole lot of 8mm...

But how will I make it round?! I'd need a press or something.

...WAIT! THE WEED WAND makes fire!

And I have this convenient round thing.

After a while the zinc on the 'heat shield' starts to melt...

NICE!

Only took an hour.

Here's what it sounds like. I added a clickbait title so I can go viral.-

17

17

-

- Popular Post

- Popular Post

Took hours and hours to mill all those little clamps. Most of the time was spent on setting up for each one.

I'm not winning any awards for neatest brake and fuel lines.

I'll make a bolt on cover to hide the mess.... 'protect'.... the lines where they cross over the chassis rail. The gearbox cross member offers some protection already because it's about 40mm lower.

-

17

17

-

I don't know anything about the dimensions of a rotary, they hang quite low?.... The triumph steering rack is quite high. I had to lower mine by a lot to fit a 1UZFE and I still had to modify the sump.

Moving the rack involved lots of measuring and jigs and trial and error to figure out where the outer tierods needed to be so I could machine custom steering arms to correct the bump steer.

The whole moving the rack exercise was a huge PITA that took months, I wouldn't want to do it again.

So, definitely work out if the engine wants to occupy the same space as the rack.

-

3

3

-

1

1

-

-

4 minutes ago, NickJ said:

LIke that?

Yes. Thanks!

-

1

1

-

-

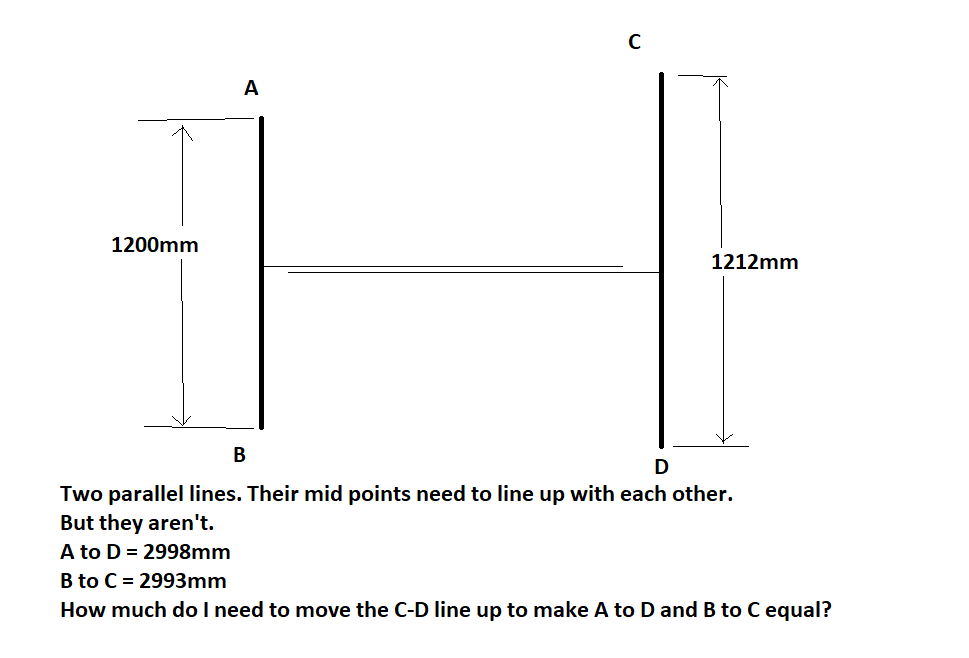

This has me stumped. Can someone stick it in CAD and get the answer easy as?

This is the measurements between the front and rear balljoints... trying to make sure the rear is straight.

-

- Popular Post

- Popular Post

-

18 hours ago, cletus said:

Looks ok to me?

As long as it doesn't touch the driveshaft, should be fine.

If you are worried about it you could make a hook or similar to keep it from getting closer

Local cert man, Julian, said much the same. "as long as it doesn't rub".

Tech Spam thread - because 1/4" BSP gets 5 hand spans to the jiggawatt

in Tech Talk

Posted

You have definitely removed ALL the bolts, right?