-

Posts

1136 -

Joined

-

Last visited

Posts posted by Esprit

-

-

Just out of interest, here's the dyno-plots from the run-in. Bearing in mind this was a conservative tune on 6-month old fuel, with a failing gearbox and not much attention paid to ironing out the kinks. It's not too bad. This dyno session was more about getting the engine under load ASAP and bedding it in. After the run-in I hope we can add another 15 or so bhp to these figures.... which should be achievable

@Rear Wheels

@Engine

-

Nice that she's back running. Perhaps a mapping session is in order for the Link?

-

Of course, this all depends on Quaife.... I'm going to shove a rocket up their sphincter tonight and make sure they move heaven and earth to get me my parts in timely fashion.

-

More than balls deep... all that's left exposed now is my head and ankles.

Found the fault with the gearbox and someone else will be paying.... clear traceable fault. Won't say any more since I've people to talk to tonight but hopefully a repair will be a matter of just getting some new parts from the UK, hopefully within a week or two. Aiming now to have the car on the road October 1.

-

Yeah I was a bit fuuuuuuuuuuu. But what can ya do? Too far down this road to quit now.

-

Right well it's been a little while since I've updated but things have certainly been happening. Sadly it's not been going entirely to plan and we're back in a bit of a hole, drama drama drama.

I got the engine all primed up a couple of weeks back but was disheartened last weekend to return to the car to find a puddle of coolant under her that had clearly leaked out of the head gasket. This was an initial worry and after a few days of panic, I found out that sometimes these MLS gaskets on the K weep a bit until they've been through a few heat cycles. We decided to chance our arm and run it on the dyno and see how things went.

So, on Friday, I loaded the car up on the trailer and headed north to hopefully get the car ready for the road.

Got up to Glenn's and we got the car bolted onto the dyno and quickly warmed up and under load. Thankfully, the water leak cleared up right away so our hopes of having the engine seal itself up worked out. Things were looking good.

The engine however was making hard work of things. It was off-song, and while it was making more power than it was last time on the dyno (with the knackered valves) it was still a mile away from what it was before Christmas with the initial engine build. We pressed on working the engine hard to ensure a good bedding in of the rings.

We were feeling a bit down over the engine power when the gearbox started jumping out of 5th gear on the dyno. It had done this a couple of times before, but was now doing it consistently... strange as it'd only done this on the dyno. Glenn ended up having to try to hold it in gear as we were doing the large pulls and even then it was kicking out and getting worse. Obviously this bent a selector fork or something as it then jammed the gearlever which then took some freeing.... we then couldn't select 5th or 6th gears.... the gearbox was toast.

Despite this we had a bit of a brainstorm as to what was causing it to be down on power. We theorised that the box was probably on the way out and was dragging... however on a hunch I decided to look down the trumpets at the manifold gasket since I did a lot of work cutting the ports out on it prior to my first build. As I suspected, this hadn't been done on the new gasket I'd had fitted and this was partially shrouding the inlet ports around the injectors.

We stripped the inlet manifold and roughly butchered the gasket and reassembled. We ran the engine again expecting to maybe gain a few horsepower and miraculously the engine came right on song and gained almost 30! Obviously the obstruction was causing some nasty turbulence that was killing the flow.

A bit more tweaking, and despite running it conservatively and only running it to 8000RPM, we made 192bhp at the rear wheels or 211bhp at the engine (assuming a 10% drivetrain loss)... not bad for an initial tune on 6-month old petrol. This bodes well for the engine to make 225bhp or so (205bhp at the rear wheels) once it's fully run in and happy, which is somewhere around my goal of 220-230bhp for the engine on the stock exhaust and throttles... which isn't too bad.

Sadly though, it was a bad day overall with the gearbox issues so we're back to pulling the engine out for the umpteenth time to split the box and rebuild it. Already the engine is about halfway to being back out of the car and a good garage session in the morning tomorrow should see it swinging from the crane again and the gearbox parting company. We'll strip it ASAP so I can figure out what's gone wrong and how to fix it.

I'm unspeakably pissed off about the whole business, but hey, at least the engine is playing nice now... just the gearbox to sort then I can hopefully start to run the car again..... at least until the next fuck-up!

-

Another day and more progress.

Thanks to my good friend Richy, today we managed to get most of the rest of the engine peripherals hooked up.

In connecting things up, we found that the reverse light switch on the gearbox has taken a knock during transport and ripped the wires out. Due to this, I'll wait until next weekend to fill the gearbox because I've now got to sort this out as well as change the driveshaft seals. I'll try to track down a replacement this week and I'll get Glenn to wire it in for me when it goes up to see him for the dyno.

On the good side, most of the rest of the sensors are hooked up and I got the engine mounts all torqued up.

I managed to get much of the old synthetic oil drained out of the oil cooler lines as well.

I got the engine refilled with coolant and static-bled and I then filled the engine with the running-in oil. A hearty chunk of cranking on the starter without the plugs or injectors connected got the oil pump primed.

Once I had oil pressure I was able to remove one of the oil cooler feed lines from the oil thermostat and purge the remainder of the old oil and air out.

Just before packing it in for the night I got the gear selector cables reattached.

Mission for this week is to get hold of a new reverse light switch for the gearbox and to HOPEFULLY receive the new driveshaft seals. I'll swap these over as soon as I can before filling the box with fresh MT90.

Once that's done, next weekend will involve getting the driveshafts back in place, the rear suspension bolted back together and finishing off the engine peripherals by fitting the airbox, throttle cable and remaining sensors.

We'll then see if we can get the engine to fire, which should hopefully be fairly straightforward.

As soon as it fires, we'll shut it down and get the rear clam and undertrays on. I want the car complete and ready for the road before we trailer it to Glenn's to break the bitch in on the Dynapak. At this stage we're looking pretty good to have it done by the first week in September or thereabouts and I can get to work putting the miles on it with limited RPM to get it all run in.... hopefully this time will have a happier ending than last time....

-

Right, it's been a busy week in the garage. First off, was to get my new extinguisher bracket anodised, tested and fitted. It turned out working quite well. I've still got to figure out where to mount the remote charge cylinder which will be a challenge, but so far it looks good!

Next I had to pick up my completed engine:

Then today I stuffed it into a hole with the help of my friends James and Nikki Colverson.

As it sits now I've still got to torque up the mounts but I've got about half the lines and wiring hooked up. Should have that finished tomorrow.

I'm still lacking the new gearbox output shaft seals as one of the old ones is weeping. I've yet to decide whether I'll get it going with the old seals then fit the new ones, or whether I'll just hang fire and fit the new seals this coming week and get it running next weekend. I'll figure it out I'm sure

-

Well it's been a busy few weeks and not nearly enough of that has been on the car.

I spent a while last weekend designing up a new bracket for the extinguisher to allow it to mount in the same place as the old one without having to drill or bolt anything else to the chassis. It's being manufactured and I'm waiting to get it back and then send it for anodising this week.

Today I set about mounting the nozzles. I'm holding fire (pun intended) on the engine bay nozzles until the engine's back in so that I can see where they need to be positioned to cover the engine with no shrouding.

The interior nozzles were a no-brainer though as these had to mount in the middle of the car firing directly outwards into the footwells. This is the way Lifeline mandate them to be to achieve FIA rating.

After tossing up a couple of options, I decided to pick up on a couple of pre-existing holes under the dash in the middle of the car. I think these holes are used for mounting the HVAC console in the air-conditioning-equipped cars... meaning in mine they're ripe for other uses.

I went into work and designed up a simple bracket to hold the nozzles, and then cut and folded it in 1.2mm sheet-alloy.

I spent a little while getting it really tidy before I mounted the nozzles on.

Here you can see the nozzles mounted into the bracket with the tubing lines attached to the tee.

To this, I then added the fire-resistant braiding:

From here it was an hour upside down in the footwell mounting the nozzles in. The end result was worth it though as they're perfectly placed, yet completely invisible unless you're looking under the dash for them. They're also very tidy when you do stick your head under there... thus satisfying my OCD

I ran out of time to run the line from the extinguisher up to these nozzles, but it's going to be a nice easy run up the centre console. One evening this week I'll pull the centre-divider out and run the line, and it should all look just right! Hopefully by then I've got the extinguisher mounted in too and I can figure out where I'm gonna mount the charge-canister and run the wiring.

On the engine front, I'm going to give KW a call tomorrow to remind them I'm waiting on it and hopefully it'll be something approaching assembled by next weekend.

-

Another successful day today on the car.

Mission today was to get the interior and seats in and roof on.

One thing I wanted to get done while the seats and roof were out/off was a little plumbing.

My latest acquisition for the car was a Lifeline Zero360 FIA fire extinguisher system. This arrived in the country last week and while the whole thing won't be hooked up for a while, I wanted to use the opportunity of having the car empty to run the line from the extinguisher, through the rear bulkhead to the engine bay.

I managed to find a nice easy, tidy path from the extinguisher (to be mounted in front of the passenger's seat) to the engine bay. I've run it up the centre console with the wiring and I follow the loom across the top of the fuel tank and I'm using a previously-blanked hole just behind the left-hand door.

Once this was done, I was able to reinstall the rear fascia:

Followed by the seats. Here you can see the extinguisher just sitting in situ for positioning.

So the car's now pretty much ready for the engine when it's done. I'll keep busy the next couple of weeks making up more bits for the extinguisher system (brackets for nozzles, the cylinder etc)

Onwards!...

-

And another useful evening in the garage tonight.

First I managed to get the Lava Mat patch trimmed and stuck onto the firewall in the right position. This is to handle the more extreme radiant heat that gets past the exhaust manifold heat shield. This stuff was surprisingly easy to apply and I've got bags more of it I'll be using in the future for other shields.

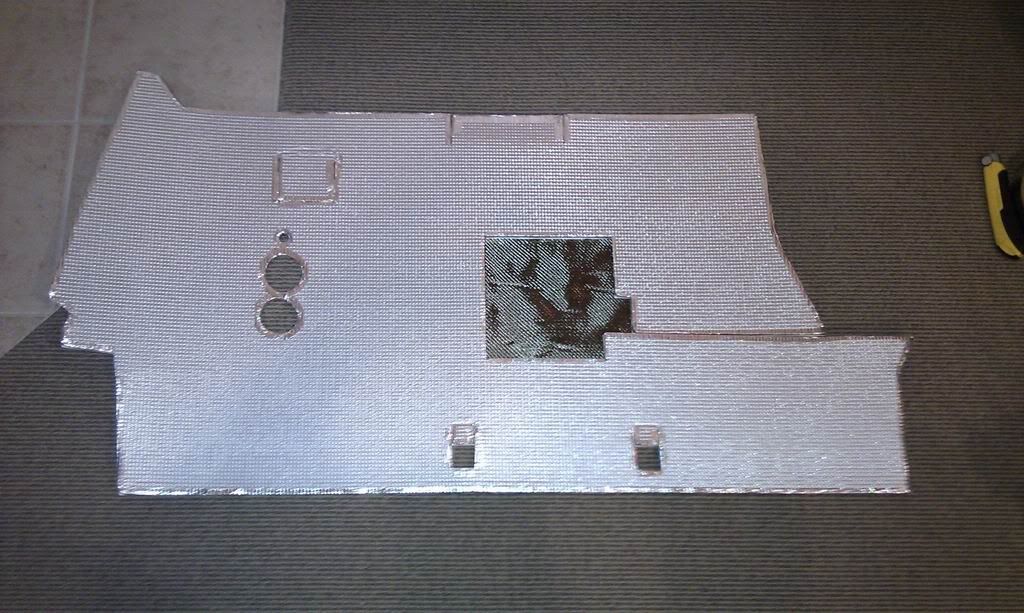

Then it was time to finish and fit the foam heatshield. The end result was very good. I didn't get it QUITE right around the left hand side of the firewall as for some reason it came up about 6mm short. But given that it was the same size as the last one, it's all in how it's stretched during fitting. Sadly its a one-shot job so you can't reposition it when it's in place so it's staying put. The rest of it is spot on though and looks even better than my original attempt. The aluminium tape around the edges really finishes it off and it was much more robust-feeling when I was stretching and squeezing it into place.

Here's the finished article so you can see how the whole lot comes together. Looks rather good I thought!

Job done!

Tomorrow I'll route the line to the engine bay for the extinguisher, get the interior bulkhead panel back in, get the seats in and the roof on. Then I'll tackle where to / how to mount the extinguisher in the tidiest possible way.

Just for good measure, here's a couple of shots of my overcrowded and VERY messy garage at the moment. Hopefully it's not too long before the damn thing can go back together again and free up enough space for me to have a muck-out. It's WELL overdue, I've got so much crap in here!

Note use of duvets to cover the car... which is actually really good as they give a bit of cushioning should shit fall on it.... good if Auckland does what Christchurch has been doing and gets all wobbly!

-

Hey mate could you post up where you get the foam shield from?

Thanks

The foam shielding comes from Forman Insulation and is a product called "FormShield". There are "better" products out there for both heat-shielding and for sound deadening, but this is lighter than all the other options out there and it also most closely replicates the form and function of the OEM shield, which was the look I was going for.

-

Well I've been gathering bits and pieces this last couple of weeks and this weekend is a busy one on the car.

Today I've been fabricating the new firewall heat shield.... the improved V2.0 version!

Here you can see the old heat shielding I've pulled off the firewall. You can see that I've cut a "window" where the damaged area was. You can see this damaged area in my previous update when the shield was sitting on the firewall.

From here, I've fabricated up a new one. I've painstakingly cut it to size and shape and then with this one, I've spent a good number of hours carefully edging it with heat-barrier aluminium tape. This should prolong the life of the shield as they always seem to degrade at the edges. It's also a move I've taken after talking to people who specialise in installation who have said that aluminium-taping the edges will greatly reduce the risk of the foam shielding smouldering in the event of an engine bay fire.

You can also see the "window" of the heat shielding that's been filled with "lava mat" high-temperature heat shield.

This shield SHOULD be a bit more tidy in installation than the last one, and should be both more resilient and effective.

I've still got to cut out the recess for the fuel hoses in this shield, and I'll do this in-situ as I want to cut the shield closer to these this time around. That'll be done tonight when I install it.

-

Hah, my car runs 2.5 degrees camber factory!

-

Well it's the weekend, which means more garage time to spend on the car as per usual.

Today I got the roof off and interior stripped out, which will give Glenn the access he needs to the loom to make the pinout changes on the ECU.

Meanwhile the rear window and surround also came off to give access to the firewall to allow me to remove the heat shield.

I removed this because it had begun to break down where the shield had been all but touching the manifold heat shield that sits right up against it. Despite my ceramic coating of the manifold and the Cirrus heat shielding around the manifold area itself, there's still too much heat getting to the firewall foam heat shield. In the following photo you can see the square of affected material.

The OEM Lotus heat shield failed in this same area so it's obviously a problem, however the OEM shield as well as this one seems to have held up very well elsewhere. Furthermore, in the heat-affected area the foam was still in good condition and it was only the glue between the foil and the foam that had failed... although over time I'd have expected the foam to fail too.

Ever since I fitted this new heat shield over a year ago, I've had my doubts about it. It seemed a bit fragile when compared to the OEM shield and it didn't seem to stick to the firewall quite so well. However, in tearing the thing off, I can see that it's actually stuck bloody well, and it also appears to be a chunk more rugged than I gave it credit for!

I chose it because it seemed to be the closest fit I could get for the OEM shield material-wise, which is no longer available. It seems my choice might not have been too bad after all!

I had planned to replace the firewall heat shield with something like "Thermo-Tec Cool-It", but now I'm in two minds.

I'm now thinking of getting some more material like I've just removed and remaking another similar heat shield. I'll then cut a small "window" in the area where the heat-soak appears to be highest. On the firewall where this high-heat area is, I'll lay a heat shield like Lava-Mat (of which I have some), which should cope with the higher temperatures better.

The bonus is that the Lava Mat is a thin, carbon fibre-like cloth that has nearly zero thickness. This compares with the foam insulation that has a ~10mm thickness. This will allow a larger air-gap between the firewall and the manifold heat shield, which should reduce the heat flux into the firewall insulation.

Te bonus is that this'll allow me to keep the light and effective foam shield over the bulk of the firewall with just a small area of high-temp barrier where it's needed near the manifold. This second time around I'll also try to cut the shield material a little better and reinforce it with some aluminium tape around the edges in the interest of being tidy.

I've got a bit more research to do tomorrow before I make up my mind for good. I want to get the new material procured this week so I can begin cutting and refitting next weekend.... it's a hard, boring slog right now but this is a job I'm just looking forward to having signed off and out of the way!

More tomorrow.

-

Well, managed to trailer the engine and box over to Ken today and he's going to start stripping it down tomorrow. First task is to get the codes off the crank and crank ladder so that we can size the bearings properly and get that order underway. Looking at it in better light today you can clearly see the liners of the two cylinders that were a bit leaky in the valves were more glazed than the other two... this reinforces my decision to be a sensible lad and rebuild the bottom end... I'm glad I'm doing it now.

Getting quite enthusiastic about the old girl again now.... quite a nice feeling after a few months of despair!

-

Another stint in the garage this afternoon, and the engine is out of the car again... for the FOURTH time in this project.... let's hope it's fourth time lucky huh?

Here you can see the vacant engine bay. You can see the crinkly section of the firewall heatshield where it sits close to the manifold heatshield.

It's not terribly damaged, but over time, I can tell the foam is going to degrade as it's too thick (and sits against the manifold heatshield) and it's just not up to the temperatures it gets in that local area. Also, because of the potential fire risk of this foam should it continue to degrade I've decided to sacrifice a bit of sound dampening for superior heat protection (and light weight!). It's never going to be a civilised car anyway and it's not going to make much difference at all.

And here's the sorry sight of the engine sitting on my garage floor again.... le sigh!

I'm going to steal the work wagon and trailer tomorrow at lunchtime and get the engine transported over to KW for stripdown. It'll head over with my newly rebuilt cylinder head and a box of bits to rebuild it again. By the time it's all stripped down, cleaned and inspected, I should have the new bits here from DVAPower and it can go together again.

While this is happening, the seats will come out, the rear trim panel will come off, as will the roof, rear window and rear window frame. This will allow me to remake the firewall heatshield and make it look really tidy. It'll also allow me the access to switch a couple of pins on the ECU, since Glenn wants to reallocate the pin of the wideband lambda heater to a different output as it's throwing an error code right now.

If there's a silver lining to cock-ups like this, it's that it gives you the excuse to do those bits and pieces that you probably wouldn't bother doing otherwise.

Time for a beer.

-

Right, well with Toni now in the UK for a month and with my move into her apartment now complete, I've FINALLY got some time, and some motivation to get back in the garage and work on the bitch.

Today was focussed around getting the fluids all drained off, the wiring all disconnected and the shortblock and gearbox ready for removal.... AGAIN.

This all went fairly smoothly and all going well, by tomorrow afternoon, the remains of the engine will be hanging from the crane and will be ready for transporting off to KW to get another rebuild.

Some new liners, rings, bearings, gaskets, seals and head bolts will be winging their way soon from Dave Andrews, who has been brilliant help in getting the engine bits together and rectifying this whole issue.

The head is sitting there, freshly rebuilt and ready to go and as soon as the bottom end bits are here, the engine will be dummy-assembled, clearance-checked and then final-assembled ready for reinstallation.

Here's some photos of the current state of the garage and the car... a pretty sorry sight.

While the engine rebuild is happening, I'm going to pull the roof and rear window out to enable me to re-do the firewall heatshield, which I can do better than I did before. I'm also going to use the Aluminium sheetmetal rear heatshield support I made up as a template for a carbon-fibre piece I'll lay up, which will have heatshield material attached to it. It should be better than the original shield and substantially lighter.

When the engine's in, it'll be filled and primed, and then started. As soon as it's able to fire, it'll get the rear bodywork reinstalled and the car fully reassembled prior to getting trailered up to GDS automotive for a run-in day on the dyno and some extra mapping tweaks. After a dyno bed-in, it's going to get a good few hours of road-tuning before the 1000km road run-in period.

Targeting that in mid-August... so hopefully the car will be in rude health and ready to rock by the time Spring arrives.

Game on!

-

One would assume not.

-

Hehe yeah well I know of 5 Elises in Hawke's Bay and 2 of them being involved in separate accidents in the same area in the same month is quite unlikely for sure. It's funny, this last month a couple of people have asked me questions about Dad's accident.... things like "I heard he was speeding" or "I heard he was being chased by the cops".... stuff I just dismissed as Chinese Whispers getting the story wrong... now I know why they may have thought that! But no, this guy (despite also being an almost identical age to my father) is not my father. I'm pretty sure I've bumped into him before and chatted though although I don't know him personally.

-

Just to clear up any confusion (as some people have asked), this accident wasn't my father:

http://www.nzherald.co.nz/nz/news/artic ... d=10730709

coincidentally, this accident happened nearby to where my father had his accident and they were both in April, but they were completely unrelated. My father's car was a '97 Elise S1, and he was stationary when hit from behind by another car. He was not fleeing from police at the time.

-

Well it's been a while since I've done an official update of my build blog, so I guess this will hopefully be the start of getting things back on track.

I'm down in Hawke's Bay again this weekend visiting my family and it's good to finally see my father outside of a hospital and back mobile again. There's still a few months of crap to endure for him (and us all) but hopefully he will recover just fine in time. It seems to have changed him a little personality-wise, but I guess he's been through a lot so only time will tell whether he gets back to being the same person he was before the accident.

I went out to see my father's car today with him. It was the first time he's seen it since the accident. It's been written off by the insurance company and we were taking a look at it to see whether it'd be worth looking at buying back with a view to eventually rebuilding it. Sadly a cracked glue joint in the front suspension and a massive kink in the left-hand chassis rail where the radiator return hose comes trough it means the chassis is toast and will never be a car again. Our little Norfolk Mustard friend is only worth spare parts value so I don't think we'll be reinvesting any money in her. A very sad end to an 18 month love affair that taught me how wonderful basic S1 Elises are.

Back onto the topic of my car. I've had the cylinder head off and away being rebuilt for the last two weeks. It would seem that the valves were beginning to leak because some of the valve seats had gone out of round. When the head was rebuilt, larger valves were installed, necessitating the cutting-out of the existing valve seats. For whatever reason, during the run-in these distorted or shifted and this has led to them no longer sealing.

The head has now been fully rebuilt here in New Zealand, new valve seats have been inserted, cut and lapped. The head has been pressure and crack tested and given the very lightest of skims. All the valves have been cleaned up, the valves all re-shimmed and re-sealed and the head is now ready to go.

I've noticed that in the cylinders that were weak, the bores appear a little more glazed than in those that were working as they should have been. Due to this, I want to rectify this problem and run the engine in from scratch again. This will ensure that when the engine is FINALLY run in, that it will be in the best shape to be healthy and make good horsepower from the word go.

Given that to glazebust the bores, I'd have to pull them out as well as replacing the rings, I've decided that the best thing to do is to just pop the old liners out and bin them. I'll put new ones in from scratch, add new rings and also new bearings at the bottom of the engine. It seems ridiculous to replace parts that are less than 1000km old, but at least this way I'll have a good idea of what things were like when we removed them and I will be back to square-one on the engine and it'll be like new again... it seems silly to invest all this time and money on getting the top-end issues sorted if the bottom end lets go or has some other unseen issue... I just couldn't take that kind of heartbreak now!

So I'm currently placing an order for new liners, rings, bearings, gaskets, seals and head bolts and we'll get the engine out of the car and reassembled in the next 2 months or so. This will enable me to get it back in the car and straight off to the dyno (at least this time we can get the engine under load from the first turn of the key as the existing map should be pretty damned close). The engine will be run right in under load from the word go and then we'll get t straight on the road for 600 miles of progressive run-in before seeing what power it makes.

Second time lucky eh?

-

Unsure exactly what engine it runs, but it's effing quick

-

Haha all good... they wouldn't melt... i'm not that hard on my brakes...

On track, with semi-slicks, a stock S1 Elise weighing 680kg and only having 120bhp will melt them without too much effort. Given you're a little heavier and a LOT more powerful, I'd not risk it.

They'd be ok for hillclimbs/sprints over short distances though.

You'd have to butcher them to get them to fit though, or make custom hubs... then accept that when you need to replace them you can't buy them except second-hand and they're worth their weight in gold

Black Plates

in General Car Chat

Posted

PM me, I may or may not know if/where such a font exists.

Also, There are moves afoot to offer a retro-reflective black plate with silver characters as a personalised plate option at the moment. It'll probably take another year or so to go through, but it'll happen.