Escortn

-

Posts

138 -

Joined

-

Last visited

Posts posted by Escortn

-

-

-

Hey guys,

I'm after a bit of clarification on the driveshaft loop thickness requirements. Been trolling this for a while but can't really find anything to confirm.

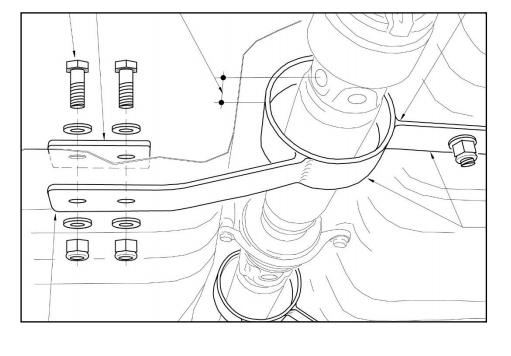

The lvvta states "Material Specifications:

A drive-shaft safety-loop should be made from either flat-section material at least 50 mm x 5 mm, or tubular-

section material of at least 22 mm x 3 mm."Now what I want too know is can I cut, roll and weld some 3mm sheet to the required diameter and this is fine?

Also can the mounting brackets be 3mm material as long as they have the required contact area or do they have to be 5mm?

-

Have gone down the keep it equal route.

Managed to get everything tacked and the collector on. Fitted it to the motor I have and thought they sat way to high.

After this I decided to take as much as I could out of the tops.

Since Runner 1 is the shortest when it comes to height it determines how low I could go.

Managed to get 26mm lower out of all of the runners and visually it looks like it will be sweet

Will be test fitting to an S15 in the next few weeks just for safety sake, then I can finally get stuck into fully welding.

-

9

9

-

-

11 hours ago, Roman said:

Interesting thought - you can have equal length but not equal volume.

As a straight pipe with the same centreline length as a 90 deg bend has a different internal volume.

Fussing over +- mm or 5 of length might be a moot point if you have different volumes in each.

Ah yes, I see what you mean.

I have managed to use the same amount of bends on each runner, main intention of this was so that I didn't have to muck around trying to cut up a heap of different degrees.

Every runner has a total of 4 90 degree bends and on each runner one of the bends has been cut in half to get 2 45s.

Based off of that I think I've unintentionally gained equal volume as well?

I think I've decided to go with equal length (the majority is that way also) but ill see if I can still get a decent slope on the runners.

-

2

2

-

-

-

Lads and ladettes.

It's been a while since I've posted here. I've missed you all dearly.

Straight into it then aye.

I recently acquired a buggered head from an SR20DET to mock up some hi rise headers I've been wanting to make up.

I don't have a project or anything to put them on it's just something I've always wanted to fab up.

Anyway, after modelling in Inventor to get my rough shape I've mocked everything up but now I've run into my dilemma and I'm after opinions on which router to take.

Yes I'm asking for the internet's opinion on something.

As they stand now I have the hi rise sections on a nice even slope, 4th being the highest and 1st being the lowest.

This looks good but they are not equal length.

If we treat Runner 1 as 0mm then Runner 2 is +13mm, Runner 3 is -13mm and Runner 4 is +11mm.

I can achieve equal length by raising the rise on 3 and lowering 2 and 4 but I will lose the nice straight slope.

So my question is should I chase looks for clout or the bragging rights of equal length?

Photos because that's what we're here for. Just note that this is before I lowered 2 and 4 15mm to get the even slope.

Ta.

-

1

1

-

-

Hi, I seen your Cortina on trademe, it is realy nice the way it's done. The flares and the front spoiler look great and the way the centre console is done is very clever. I have also got a Mk3 but mine is a English 1972 two door XL. I also made a centre console for my mk3 using Mk3 GT gauge cluster. But the way I went was I used the console out of a Austrailan TE Cortina and modified that to suit the GT gauges. I did have the sloping dash in my Mk3 but did not like that so I got the dash out of Ml5 and fitted that and used the dash gauge cluster that has the clock in the centre and fitted the Cortina Rev Counter on the left hand side where it had the fuel and temp gauge. Cheers Parbhu

Cheers mate, I'm still not positive I want to sell it haha and after all the interest on trademe I'm not sure if I want someone else to have it.

Awesome, you should throw some pics up of your one. Don't see many 2 doors around and it's always good to have a perv on other people's mk3s

-

I'll have another one at some point haha.

Any one of those motors would be so sweet to see

-

Yea, life decisions and lack of space means I gotta pass it on unfortunately

-

Saweet score man! Looks tidy

-

Through the back window of that escort

and the tubs of the esky

-

7

7

-

-

It comes off easy it you cake it on. Took me forever to peel it off a few pieces because I hadn't put enough on in the first place

-

I just found out about this today. Thought it would of popped up on here earlier (I'm probably looking in the wrong places)

It's at smales farm on the shore.

I'm hoping to take my Cortina, would be good to see a few other old Ford's from here in person

www.fordday.com

-

Been getting a bit slack on the updates with this.

Have been getting things done however.

Pulled the steering column out to replace with one out a mk4 cortina that has no play at all, so much nicer to drive with this one.

While the column was out i also put in a rev guage i got from here a while ago. I put it where the gas and water temp gauges usually are because the GT centre console i put in has all those guages.

Centre console isnt fixed in at the moment, need to tidy up all my shit thats in the car before i do that.

The mk4 steering column is a bit longer also but its actually nicer to drive with where it is now, not the prettiest mind you.

This thing brakes now aswell. I ended up clearing all the fluid out, putting in the braided brake lines and then bled the whole thing starting with the master (which i didnt do last time so thats probably where the issues were)

Lastly i Bought some more widened steelies,

13x8 for the front and 13x9 for the rear

This is the 8

Seller only had one 13x9 rim but threw in a standard rim with the same centre so i can get that one widened to match.

Fronts have tires on at the moment and look great.

I really need to take this somewhere else to take photos of it other than my driveway.

Been looking into different alternatives on the guard flares, want something that matches the guards alot better and looks more flush. Turns out its alot harder to find something to suit than i thought

-

Haha same here.

I bought the shell off this guy and got it going //oldschool.co.nz/index.php?/topic/21075-mpostas-1979-mk2-escort/?fromsearch=1

-

Yeaaa im not gona disagree

-

2

2

-

-

Not really on par with the awesome manifolds above but i rigged up a rear strut brace for my previous c35 Laurel, had a front one aswell but didnt take pics.

seemed to do the job, trying to figure out a new one for my daily c35 now

-

-

I've done this before, the front housing will just twist when you slack off the bolts, it's clamped onto the core.

I don't know if it's the best way without knowing torque settings etc, but worked fine for me

-

Saw this at cannonball today, looking good man. I was driving the Laurel that had TUFF4D as the number

-

Column, rack is fine but the column is a two piece thing with a rod that connects the steering wheel to the rack and there's a good amount of play In there

-

The steering column in my Cortina has heaps of play in it.

Does anyone know of anywhere in the AKL area that can rebuild and tighten it up, if it is actually possible to that is.

Cheers!

-

The diff that the Aussie assembled 4.1L mk3 4 5 cortinas is what your after but they don't come up for sale often and when they do there not the cheapest. I've heard of falcon diffs working before but I think that might be something to do with the falcon head in the 4.1 Cortina housing

-

Awesome. Have a Hell of a soft spot for the old Mk3 Cortina.

Keen for some interior pics.

Also try adjusting your rear brakes and silly question but did you put the callipers back on the correct sides?

The bleed nipples need to be at the top.

Good work man.

Cheers man,

Haha I nearly put them on the wrong sides actually, luckily I'd bled them before and remembered how it all went.

That's a good point, I'll give it a go this weekend, cheers.

I've just been pulling my steering column out to investigate all the play in it so I'll get some interior shots along with that mess

For Questions Regarding WOFs/CERTs/NUMBER PLATEs

in Tech Talk

Posted

Ahhhhhhh yes this makes sense now.

Legend