-

Posts

1272 -

Joined

-

Last visited

-

Days Won

4

Posts posted by VitesseEFI

-

-

Doesn’t mean the face (with the Tpm marking) left the factory with the same mech it has now…..

Vitesse has a misleading number on the face (which is original) as the workings are from a Dolly 1850 to match the previous gearbox and diff. As it turns out, the speedo gearing was absolutely identical on the Toyota W58 - which was unusually serendipitous!

The gods clearly remembered though as the MX5 box speedo gearing is VERY different from GT6 (reads 40% low), so I really ought to do something about that….

-

1

1

-

-

On 05/05/2024 at 18:34, keltik said:

Crappy idle and suspicious fuel delivery issues... Have you had the injectors cleaned and flow checked?

Especially likely in old cars with rusty fuel tanks that have probably eaten a lot of stale fuel. And impossible to figure out if you don't have an o2 sensor measuring fuel trims

This!! Injectors!!

-

Battery voltage should be measured at least half an hour after they’ve been taken off charge. You’ll always get an artificially high number otherwise.

12.7 is a perfectly normal voltage for a decent lead acid battery in good, fully charged condition. 13v is still normal range but high end. Some modern battery chemistries do seem to give higher resting voltage.

Those kind of voltages will not harm your starter. Hell, they’ll generally survive 24v - for a while.

Could just be the solenoid contacts are shot. Maybe accessible to clean up. Otherwise motor has problems. Hopefully nothing worse that worn/stuck brushes.

-

1

1

-

-

Still A series apparently - would need at least the OE (family) block to be eligible for the historic series it was stickered for. Didn’t see under the bonnet, but definitely at least one Weber in there and very cammy sounding

Owner was not very communicative. Treating it as a test and set-up day (fair enough) and not interested in mixing with we Triumph plebs…..

-

3

3

-

1

1

-

-

And this. Fast little bugger…..

-

6

6

-

-

And some Triumphs

This lot were playing

This lot were not….

-

6

6

-

-

- Popular Post

- Popular Post

Coolest race car and tow rig of the day

carried this sticker too

-

20

20

-

- Popular Post

- Popular Post

-

It is some kind of super car…..

-

1

1

-

-

Spotted this morning in Cornwall just 1km apart

Then saw the Mk1 GTI again in passing this afternoon and realised I’d already had a conversation with the owner before I’d even seen the car - life is strange sometimes.

Nice older gentleman with an expensive camera and lots of lenses.

-

7

7

-

-

My Dad had a new one of these as a “company” vehicle in 1979 in Swaziland. Bench seat and column change IIRC. It was an enormous improvement over the Marina van it replaced which, at the grand old age of 5, was already largely defeated by Africa.

The 620 though was ridiculously easy to get stuck when unladen. On one memorable occasion, 11 year old me had to get out and push after he’d pulled half off the tarred road to avoid a lorry and the left hand wheel just spun uselessly on the gravel shoulder.

A colleague borrowed it one day and hit a cow with it, dead centre. Colleague considerably messed up (wear your seat belt!), truck also considerably messed up. Cow allegedly fine. Dad back in the Marina van for 6 months while the 620 was “fixed”. It never was the same again though. Africa wins again.

-

1

1

-

-

Ref the different floorpans….. IIRC the really early MK1s had a transverse exhaust box tucked into that space (some Dolomite variants did too). That arrangement was dropped quite early on for the more familiar crazy afterthought hodge-podge, but seems they never changed the floor pan pressing….

-

4

4

-

-

Yes, good point, Stag info should work.

-

Sorry, don’t know. Many/most LHD cars had it but RHD is pretty much an Oz / NZ only thing, I assume due to local regs. Never seen a dual circuit one in the UK, though they may exist. Bit of poking around my usual sources has draw a blank.

What I do know is that you will struggle to bleed the clutch, just because it’s a Lockheed M/C. Devils work they are. I’d run that line below the reservoir if at all possible as I think there’s a risk it’ll unbleed itself like that.

-

15 hours ago, GregT said:

I was told that 90% of the cast iron blanks come from Turkey

Dunno about quakes. I do know that QC can be an issue. Previous company went through a fairly short phase of source CI pump casing parts from a Turkish foundry. Sizeable voids stuffed with car body filler and painted over don’t hold pressure very long!

-

Quite a lot of modern Euro stuff has camshafts lobes that are either shrunk fit or have a hollow shaft hydro-formed under them. The lobes occasionally move - bad things happen. Destruction. General mayhem. Shrapnel….

-

1

1

-

-

He’s quite right obviously. I’m pretty confident that this aspect is good and the initial measurements I did tended to prove it. Will re-measure more accurately before refitting and may even plot a graph…..

Other thing is that I have had it working beautifully in the past ….. Even this particular collection of scrap worked very nicely when first installed. I’m coming to the idea that this failure was mostly due to crap parts.

-

1

1

-

2

2

-

-

On 13/03/2024 at 01:10, Roman said:

I've blown up shitloads of Bosch 4.2 and 4.9 sensors, so changed to the 14point7 Spartan controller, with the LSU-ADV sensor.

It lasted the entire lifespan of the echo without blowing up a single sensor, and was running it "hot" on cold starts as well.

(As it's designed to be more compatible with cold starts than 4.2 or 4.9)

Compared to, I think my record with a 4.2 or 4.9 sensor for worst lifespan was that one lasted 3 days.Reckon this is heavily influenced by sensor positioning. Given that my original 4.2 has lasted well, l’m assuming my sensor positioning is good……

I’m a bit foxed by the Spartan website which seems to most of their models as NLA….

20 hours ago, Muncie said:I’d probably put it in middle pipe section with the wire pointing to 1 o’clock, could swing it round pointing out of the pic if it helps packaging. In downpipe below blue cap probably fine too.

-

- Popular Post

- Popular Post

Update on this.

Checked crank endfloat. 0.2mm. My build notes say it was 0.17mm when first assembled 28k miles ago. So that’s good.

Did some testing using the mill

That’s the combo that’s just come out. The friction plate is only about 1/2 worn at 7.35mm. It starts to release about 6.5mm but needs 8 to fully release as the spring has gone lopsided. That, with sticky splines will be the wide biting point I think. The same friction disc with my new Sachs cover starts to release at 3.5mm and is fully free at 4mm.

I gathered up the wreckage and took it to my localish clutch shop. He was very polite, but I think he was telling me his competitors friction plate spline was made of cheese. No doubt on his thoughts on the QH cover…. Bin food (that was before I fitted it!). They made me a replacement friction plate in an hour…. And it was half the price of the last one. Top service!

The new friction plate is 8mm thick and with the Sachs cover needs 5.5mm to start to release and is fully free by 6mm.

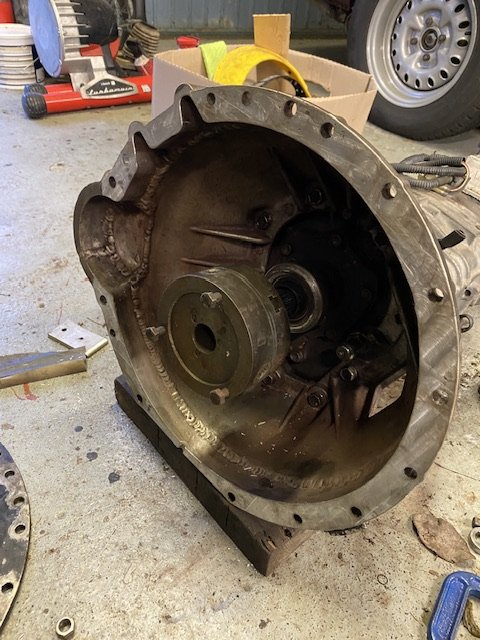

Meanwhile, I put my hybrid bell housing on the mill. Engine side face was a little wobbly so I faced it. Took less than 1mm to clean.

Fitted the backplate, flywheel and bell to my spare engine. Then posted the gear box in from behind. Spigot picks up in the pilot bearing first then the gearbox/bell dowels engage. Little bit of a wiggle and shove and on it pops. Alignment can’t be too bad.

But to check another way….

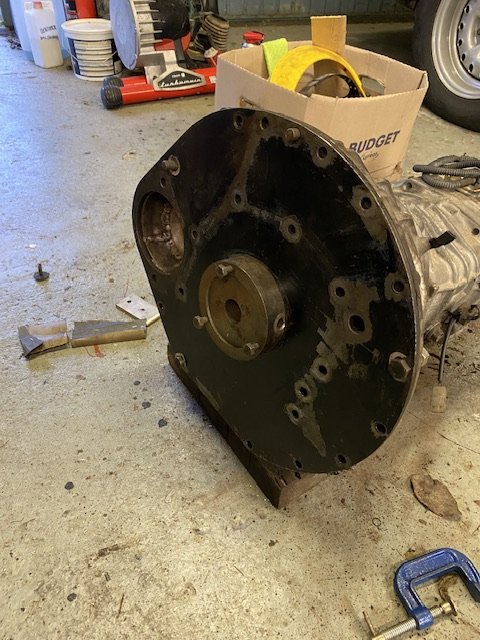

pop the backplate on the bell and it’s very tempting to think that 4” (3.997” in fact) hole might be intended to be concentric….. but is it?

Being both lazy and cheap I spent 10 minutes rummaging through my junk looking for a ready made tool….

Turns out I have this 3 jaw chuck which measures 3.993” and easy to nip onto the spigot.

Pops right on, no wiggles needed. I think she’s good.

Have also clocked the backplate on the mill. It’s a bit dished (0.5mm), but evenly so. Within 0.2mm. Better than my 2 spares….

Made an alignment tool

Running out of excuses not to refit, except I tweaked my back a week ago and the refit is intensely physical…

-

10

10

-

12 hours ago, tortron said:

The English, having never seen a blue sky before, come up with that colour and call it grey

Bit too close to the truth to be funny when sat on the Septic Isle. (Yes, pissing with rain again!)

-

We like grey…. Forgiving of indifferent bodywork / painting skills and doesn’t show the dirt.

Spitty is RAL7031 “blue grey”. Vitesse is Rover “mid grey” which is very similar to Triumph “Dolphin grey”

-

4

4

-

-

As above. For my Vitesse with Megasquirt MS2. Permanent install.

Would prefer with a display. Currently have an Innovate LC1 (Bosch 4.2 sensor) and some random 52mm display that have worked well for 15+ years, but now getting flakey.

TIA

Nick

-

3 hours ago, Roman said:

mathematically smooth brained

Hello….. I resemble this remark (not just mathematically some would claim

)

)

But even I can (mostly) follow Professor Dave’s tutorial

-

2

2

-

-

Thanks. Appreciate the input.

Some of these I can answer, some I’m going to have to check.

The spline was definitely lubed when assembled. Grease used was from a tube of special LUK spline grease that I’ve used on every clutch I’ve done in about the last 15 years. Seems to work elsewhere! There’s no trace of it now though.

Misalignment. Yeah. I’d like to think not but…. What I can say is that when last assembled the engine was out of the car and it went together really nicely. Clack! Straight up to the engine, no pulling it up with the bolts. With the ball-race spigot bearing and the gearbox bearings still being decently tight, I just can’t see that happening without alignment being decent. I will revisit…

Crank thrust I will check. It is a known weakness on these engines - though this one has PB thrust washers so I’ll be (very) disappointed if it’s this.

Hydraulics I’m confident are good. All hard-piped (with a coil for flex) and there’s travel to spare in both directions.

I’ve been measuring the release arm geometry and running it through a full stroke to characterise it. It’s running roughly in the middle of its range. Haven’t plotted the results yet but, quick and dirty, I measured the slave stroke before dismantling at 20mm and this seems to equate to about 9mm at the bearing. I measured a very similar clutch a couple of years back when designing the concentric setup on my GT6 and that needed 6mm for release, so pretty sure I have more than I should need. So “over-throw” yes, almost certainly.

Various stacking heights still to check. Definitely no actual contact between the friction plate and the diaphragm, even with the over stroking.

Release bearing profile is definitely open to question. More work needed here.

-

2

2

-

oldschool spotted

in General Car Chat

Posted

Nice. Rare spot these days.

One of my older memories (‘73 ish) is riding around Yankari game reserve (Nigeria) looking for animals. I remember that it made a nice noise (the origin of my straight six addiction?) and that some of the many wooden bridges we drove over creaked in a way that made my parents anxious!