-

Posts

16 -

Joined

-

Last visited

Posts posted by 30DegreesRetarded

-

-

I ended up drawing an outline/stencil of the spring and marking the top end of the springs because my eye gauge couldn’t tell them apart. One I think is about 10mm longer. Springs 2years new, only done 50km one em. Both towers have their own spring perch and Haynes manual has them at top of tower (which I’ve done). Hopefully this has it covered. I’m reassembling again now so let’s see.

-

I’m stumped.

so I’ve sorted all the dust boots, reassembled to what I thought would be exactly the same set up. But no the passenger side assemble sits lower than the drivers side. (I finger space vs 2).

pulled apart again as I read potentially have left and right spring around wrong way…pulled springs and shocks out but I’m dammed if I can tell ‘em apart.

springs are HQ 6cyl with identical markings. Spring perch is the same. Would camber spaces/shims have anything to do with it?

now that I’ve looked at the dam things so long I can’t remember which one was in the left or right.

-

3

3

-

-

On 30/12/2023 at 16:06, GregT said:

Is there an Autolign branch up your way ? I've found them way better than Repco.

Na chch and Wellington. I give em a try though cheers

-

I went to Repco Blenheim with all the measurements and even the ball joints. They looked at me like I was at a beauty salon … walked out of there.

Went and saw Bert at Repco Nelson and managed to get the tie rod ends off shelf but not the ball joints. The D21’s fit but they don’t sell just the boot, need to buy the whole joint.

im going to try the local BnT & Supercheap and then start looking through wreckers.

-

1

1

-

-

Pulled front sus out to take a look and try replace damaged/non existent dust boots. Tie rod ends were easy to measure and replace from shelf.

bottom & top ball joint has a complete replacement (apparently) but the taper is bigger then my H330 measurements.

instead I purchased the Nissan Terrano bottom ball joints just swapped out the dust boots over. Cost me a whopping $12 for the two so they were easy purchases.

I have 2xD21 bottom ball joints going free if anyone wants (minus the dust boot of course).

im still on the hunt for some dust boots to fit the top ball joint. Can’t bring myself to buy a brand new D21 single for $90. Will try the wreckers first.

im trying to decide how fussy I should be with reassemble of suspension ... Do I completely strip clean, powder coat etc or just give a clean and reassemble.

Left one is the D21. Right one is the H330 with stolen boot. 12mm holes and larger taper, shame it’s not a complete swap.

-

8

8

-

-

Fresh WOF and Rego.

Hayden (unsure of his old school name) just welded a 10mm plate to either side of the lowering blocks. Def looks like it needs another 1” to get rear low enough but good for the moment. New 2nd Hand bump stops on front and rear. Job done.

Was struggling a little mentally with putting car seats in so figured I’d send to a Nissan mechanic to look over for peace of mind. Really glad I did as what they found was:

1. Front left bottom arm loose as a goose. Tightened up. 2. Both front tie rod end boots fecked, actual rods all good. They suggested replacement. 3. Park not locking up, readjusted rod from stick to transmission. Park now locks drivetrain.

4. Rear brakes backed off and readjusted (were way unbalanced). 5. Freed up handbrake cable a little more and adjusted to work.cost to wallet… FREE absolute legends.

The front bump stop distances between stop and contact point (unsure what it’s called) are uneven. One has 2finger space while the other has less than 1finger between. Springs are brand new v6 HQ. Is that normal?

-

7

7

-

-

- Popular Post

- Popular Post

-

- Popular Post

- Popular Post

And we are back together.

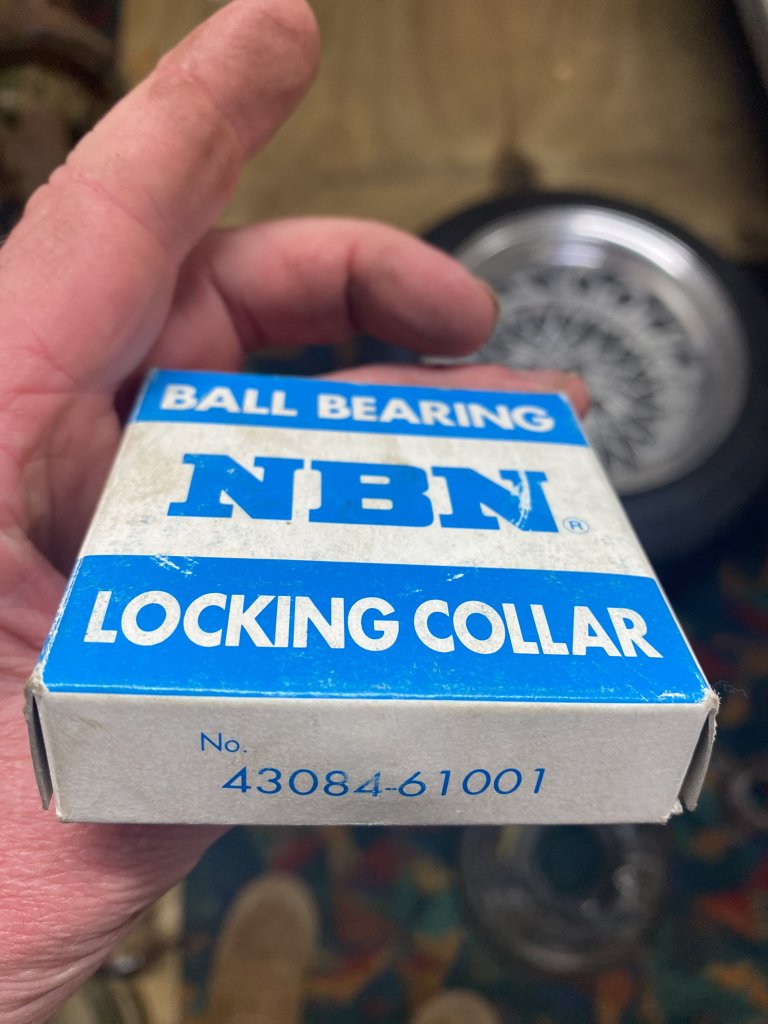

Spare axle went to MS Coombes in chch who disassembles it and moved it onto gear cutters to match up the new axle and then back to Shane to reassemble. 11T of pressure later and locking collar is on.

Where I went wrong was heating my collar in the oven and driving it home with a steel tube and brute force. Apparently the heat damages the hardness of the collar and it doesn’t shrink/hold its original shape. So in theory we should be legit. Lesson learned.

I cleaned up the diff and leaf springs while out. Nothing professional but looks better than before. wire wheel rust primer and paint.I took it for quick test drive. Sounds good at 50kmh so maybe take for a WOF. Thinking it will likely fail but who knows. Definitely need to adjust handbrake

-

31

31

-

2

2

-

- Popular Post

- Popular Post

Last nights efforts, I got a little motivation to pull the rear out. Will send to chch on the next road trip.

Usual expectations with the metal shavings in the diff oil. In my journey doing this, I made the mistake of stepping in the brake while the drum was off…so now I need a rear brake cylinder seal repair kit.

For those curious, current diff is 100mm shorter than stock.In other news I also replaced the exhaust gasket and two into one gasket. Quiet as now.

-

14

14

-

-

I had no issues with that axle collar when I collected from Denham. Drove it from Palmy all the way to Blenheim no probs. It was awesome, but it just made a shit annoying noise that I wanted gone.

It was only when a purchased a new 260c bearing kit from TradeMe and replaced the axle from another Datsun that my troubles started.

I talked with Denham and a heap of other dudes from the Datsun club but at the end of the day, I’m no mechanic just a hobbyist.

This was the homemade way I pressed on collar. Heat it up in the oven 180degrees and drove it home with the steel tube. I tried to upload finish pic but file size won’t let me.

I talked to another Datsun/prince owner that had an issues with bearing supply and telling their supplier (Auckland Bearings) they were too big. They were smart enough to send to an engineer friend before installing.

At the end of the day. I prob should have had it machine pressed by someone in the know. .. so it’s off to CM Coombes to machine a new axle and instal.

-

Datsun wagon goodness

-

- Popular Post

- Popular Post

So currently after getting some serious anxiety after having my family in car after said event,

it’s waiting to have the whole diff sent to engineers to rebuild axle. It is now currently sitting in the garage waiting for house projects to dry up so there’s money to spend on diff.

plan is to get road worthy again and drive.

-

15

15

-

6

6

-

- Popular Post

- Popular Post

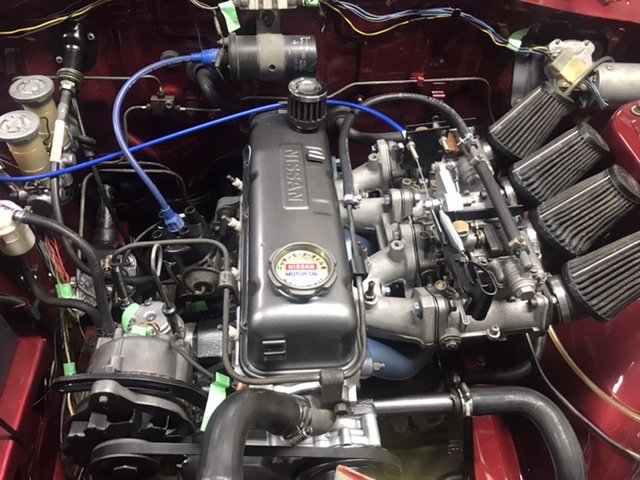

1975 Datsun 260c H330 wagon goodness. I purchased this wagon from Tauranga and shipped it to the South Island.I put the original suspension back in and took it for a WOF.

ride height made it a boat but at least I was out driving. 3 speed auto is awesome to drive on the roads. Not so good on the hills or corners. Made a shit noise in the back left wheel which I assumed was the wheel bearing. Replaced bearing, same issue. Axle was bents, found a spare from my buddy and got it machined to match. Drove it all of 20km and lost the axle locking collar while out visiting a 240c coupe.

Sourced another locking collar thinking I installed wrong. Same issue. I’m pretty sure MyTools.com supplied an I correct size but I’m no engineer so off it needs to go to be assembled where it can’t fail. 80km/hr on state highway 1 with the kids in the back wasn’t fun

-

10

10

-

1

1

-

- Popular Post

- Popular Post

On 29/10/2004 at 19:19, zep said:Name: Anthony

Location: Blenheim

Cars you own: 1985 Datsun 1200 LWB Ute & 1973 Datsun 1200 sedan

Mods to them: Paint, coupe dash, lowered and A14 w 5sp. Sedan is currently a project waiting for funds.

How you found out about oldschool: I was chasing info on how to curve distributor and this popped up. Trying to kick the old book so need more car projects to read up on.

Anything else you want to add: 10 years ago I didn’t know how a distributor worked, the quote 30 degrees retarded was what I thought a mate was calling me after my first lesson on timing.

-

16

16

-

1

1

!!!!!!Hanmeet 2024 23rd-25th August - Entry Form is up now!!!!

in South Island Region

Posted

I can’t, we’ve got a chch trip booked that week with the wife and kids.