J4m13

Members-

Posts

157 -

Joined

-

Last visited

Everything posted by J4m13

-

I had a bit more progress with my qa1 shock. The steel inserts/crush tubes for the upper shock mounts weren’t the right size so I had to figure out what I was going to do. So I took the easy way out. I pressed out the rubber bush from the original shock. Remove all the rubber from the original shock crush tube and pressed that it. Right length, o.d and I.d bloody winner!!! Im going to try run the other bushes from the other end of the shock and see how things go. They slip in, fit what seems appropriate enough so will have to report back after a few k’s are put on it when I finally get it on the rd

-

That'd be the ticket, ill just run them up the other way and if I come up a cropper, will modify my shock mounts on the body if i need to, at least it'd be minimal as opposed to the modification needed running it right side up

-

I think from memory... 110, or 90 rings a bell for spring rate. I have them here at work so when I go out to press the bushes in ill confirm. What would be the ideal spring rate do you think for a road car?? The shocks are quite long, but i can get a shorter rod from qa1, or machine the current one smaller if i need shorter springs.

-

Yea, I am more that happy to take some material away if I needed to, as there is plenty of meat left after the mod. I don’t have the spherical roller bearings, of got the bushes. But when I’m buttoning everything up I’ll definitely take your advice and extend everything through full travel etc. there seems to be a lot of spring rates out there so I have a feeling I’ll be doing a lot of trial and error research, and there’s a lot of stuff popping up here 2nd hand that I can hand and get he basics. I appreciate the reply mate, cheers

-

Yea, I did a bit of research from the u.s sites and what not. They seem to have had a fair bit of experience modding and exchanging etc. im hoping the hatch will be good, I’ve had a couple, my last one was a 13b bp turbo and was too loose for me. so I thought I’d stick to n/a

-

So with the shock upside down, it fits with no mods... what effect will that have, if any as opposed to the normal orientation?? has anyone done this before and was it successful??

-

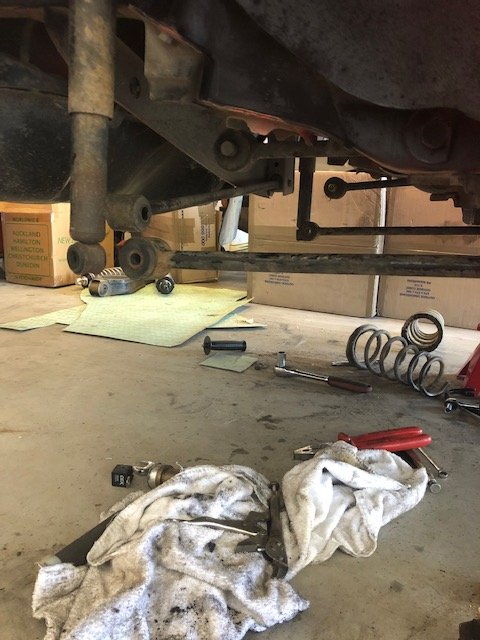

So I got to removing my standard diff today in preparation for the lsd. I purchased a pair of Rear lower Control arms from an rx7 to remove the big ugly 323 ones that incorporate the rear spring perch. After installing them in place of the originals with the standard diff in they’re a little too long, but that’s no issue. I’ll either shorten them, or lop a section out and add some fittings to make em adjustable. i did run into a bit of a predicament with the qa1 rear adjustables. id known they needed a bit of modding on the car, so putting it out there with everyone to gimme some feedback as to wether it’ll work.

-

It wasn't all that hard, just really time consuming. The most difficult part was the tools and lack of, theres a special mazda tool thats needed to remove a nut thats under a few gears, I just cut up the right sized nut, was 41mm from memory, cut a piece of scaffolding tube to the length i needed and welded the sucker together. Apart from that, just ensuring the shims and spacers are in the right order. Give it a crack mate, if you want the website for step by step disassembly, let me know

-

That'd answer it then!! I thought it had some sort of hardening done to it. was hard as fuck!!! once i'd ground down a fair way ai machined beautifully. I chipped the 2 tips trying to champfer the spline, so just resorted to the same method , ground it with the grinder, and cleaned it up with the tooling.

-

I’m not the most knowledgeable fulla out there, just a little bit of knowledge and experience on things. I’m sorta hoping my thread will encourage others to tackle those jobs we usually think as too hard or for specialists only. Don’t hesitate to gimme a nudge and ask how I tackled things, or how/why I made the decision I did to do things. I’m all about sharing and expanding everyone’s knowledge, experience and capabilities. Nothing is off limits or a secret In my world. head over to the discussion page I started and fill your boots.

- 39 replies

-

- 12

-

-

Time To drop it all back in and see if my 12 hour day was a success!!! too right it was!!! In other down times I machined the universal joint/yolk off the driveshaft that came with my LSD head, as well has have some spacers Lasered for my callipers to mount. now I can say the diff is all but done!! Just a lick of paint, seal the head to the housing and install it ready to fill with oil

- 39 replies

-

- 17

-

-

I took my gearbox into work the next day, and with the help of an internet site I stripped the thing right down until the input shaft fell out. put the shaft in the lathe and started machining it down. Didn’t really put much thought into it at first but chipped about three tip tools. Must be bloody hard!! So got the grinder out and used it to take it down to about 1-2mm from final outside diameter And machined the rest. cleaned all the gears, synchros etc in the parts washer then had the job of reassembling it.

-

I had a sneaky suspicion the motor I picked up from Sydney wasn’t as I’d been told/ expected. And being as I was fucking tired I didn’t do a thorough inspection as I should’ve. Needless to say it’s pretty fucked. I did an inspection with a borescope at work and my suspicions were confirmed. And so my thoughts turned to the gearbox. I made the assumption it to was fucked so bought an mx5 box because all the reading id done said it was an easy fit. Just exchange the bell housing and tail shaft. Cut 10mm off the end of the Input shaft and I’ll be away so people said on forums. Well fuck me, not on a s1 box. so I did the bell housing and tail section with the gear shifter. Had to change the gear shift linkages also. Measure the overall length of my s1 input shaft from the bearing to the end. Sure enough, mx5 was 10mm longer so I cut it off. bolt the box up and it won’t go... fuck me tried again, and again. Wouldn’t do the last 10-20mm. pulled it and the motor out for a measure up. Everything ok. What the fuck is going on?!?! look and the end of the crank shaft and bugger me dead, there’s in imprint of the spline m the end of the shaft where the pilot bearing lives. My predicament from here was to take the input shaft from the rx7 box and change it over, or machine the mx5 splines down. i chose the machine option, these next rusty photos will show you how good condition the 7 box was in

-

I’m not sure if it is just me, but I wasn’t too impressed with how the back half on the inlet ports were filled. I know into the block they were devconed appropriately, but it must be an Aussie thing to only fill it halfway and then put tin foil or steel wool to same a buck or two.... cheap cunts. So I then needed to pull that shit out and seal it properly...

-

So then it was time to fit the LSD head in, which went in a piece of piss. No notching or anything. not long after I found a PP that I thought I’d like to grab.... and a whole lot of other parts mysteriously started arriving at my house that my wife was puzzling about

-

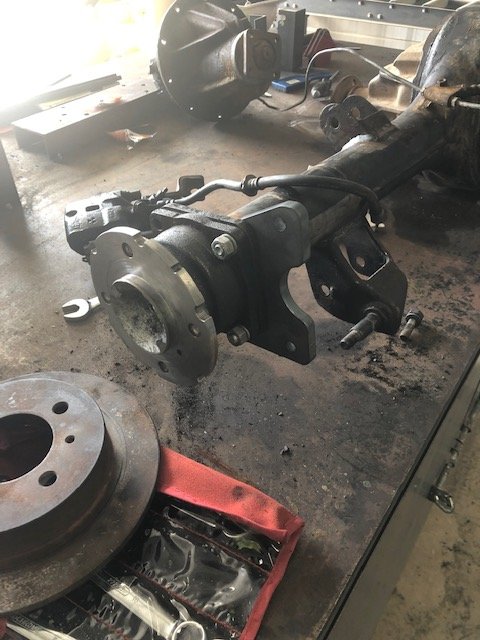

From here I wasn’t sure a 6stud axle was my best choice, so threw the axels n the lather you’re turn me down until the fit the Nissan discs I’d acquired. Also had some brackets/mounts laserwd out of 10mm plate

-

Was a prick to get all lined up properly, and the 323 mounts actually fitting correctly as the 323 housing has a much smaller diameter than the 1600. But after a bit of fettling, they all lined up so I asked a welder friend of mine to glue them back on.

-

So from here I made a basic jig to mount the faces of both diffs on. And please remember, this is the first attempt I’ve had at anything like this so I wasn’t really sure how to tackle it. just used basic angle iron and welded it to the bench and bolted all the suspension components to it. Cut them off, and sat the 1600 diff on the jig and rolled the mounts o to the new housing.

- 39 replies

-

- 10

-

-

Have a yarn about my fuck ups, and poor purchases. even about my machining and ways I could improve!!! Don’t hold back

-

So I’m not sure if many k ow from my rx7 thread. But I live in qld... and there’s no jail bar grills ever for sale here. So I turned to NZ and not a week later of browsing I found one and bought it and had it couriered over. Not long from there I purchased a blown 323 diff and a b1600 diff. Funnily enough from the bloke I bought the hatch off. so started the laborious job of cleaning the old mounts off the 1600 diff in preparation for the transfer of the mounts from the 323. I also made the trek from just out of Brisbane where I live down to Sydney to pick up a “complete conversion package” when I got there it turned out to be a 13b bridgeport with IDA, s1 gearbox and nothing else. of I’d known I sure wouldn’t have driven 24hrs pretty much straight for that. live and learn.... but that wasn’t the last time for me to make a mistake and live to regret it... you shall find out later

-

Pretty stoked to see all the original seam sealer still in place and unbroken on both guards!! And the original parcel shelf there, with factory stickers on the inside of the bonnet. Pretty original I think. feom here is where my parts Aquire and hoarding started.... again

-

Howdy folk... a couple of months ago I pick up a 78 323 for a paltry sum of $2300. it seems in sound condition, with the only visual rust being a bubble in the bottom of the drivers door that hasn’t blistered, and some on the inside of the tail gate where the chrome/plastic trim fixes. Small shopping trolley dents on every panel... Like my rx7 post, I’m shithouse with computers so this will likely be painful but just bear with me. my objective is to do as much as I can myself, have a bit of fun with a basic low budget build. So I’ve converted a b600 diff to lsd, with disc brakes. Built a gearbox for it. Acquired a 13bpp, and 13b bp. And converted most of it. Anyways... enough of this jibber jabber. No prick likes that. I’ll throw up some pics.... here goes

- 39 replies

-

- 10

-

-

Thanks for the advice. Im in qld and took your advice on the nice products. ordered 8 stud n nut sets and came to $52 posted. Cheap I thought!! i just took the measurements of the old studs I pressed out and went to their online catalogue and matched up. Found some about 20mm longer just to be safe. i appreciate the advices!!!

-

I’ve just converted a b1600 diff to lsd and disc brake. I’ve only got machining the pcd and pressing the studs in to complete. what studs would be my best option and where is the best place to source. cheers