-

Posts

69 -

Joined

-

Last visited

Everything posted by Rhubarb77

-

A quick update guys. I sent a PM to Zane from Maxx Performance regarding the stock turbo pistons (he supplied them for the aforementioned Greentop Barra build) and he's run them at 680RWKW on E85 for several years but does not recommend this! My goal is 550kW.

-

Yes these are a factory BF turbo piston I bought complete with 3R rods, sold the rods so the pistons cost me next to nothing. As xsspeed mentioned, they are supposed to handle quite a bit of punishment. I got the idea from the Carnage channel on YouTube when Scotty built the greentop Barra. . This is definitely a budget build! I figure, I give it a go. If it works that's awesome. If it doesn't, I learn a lesson and have another go. That's the beauty of this cheap and abundant taxi engine hahaha.

-

The motor in previous pic was bought from a wrecker and used for test fit. When I disassembled it, unfortunately, cyl 5 had rust in the bore. So I picked up a MK1 FG block with good bores but the water jackets were badly corroded. So finally found a good, well maintained motor from a vehicle that had a front end impact. A local Engineer cleaned the block, power honed & ball honed the cylinders retaining the standard bore size of 92.25mm, surfaced, an crank linished. And 10mm taken off the main caps to fit the Ellis Engines girdle. Youtube is a treasure trove of knowledge for building barras which is why I have opted to do the assembly myself. I now understand why engine builders charge what they do. It takes time! And care! So much process involved and I got caught second guessing myself as to whether or not my second compression ring was facing the right way up hahaha. So out they all came and, yes. I had done it properly. The engine has not been torque plate honed, tunnel bored in the main journals or grout filled. All are highly recommended for engines making big power. The main component I wanted reassurance with was the rods. These are Spool drag pro I Beam. Factory rods have been pushed by some tuners to 800hp but from what I understand, this is only possible due to conservative tuning. I want timing and boost as early as possible to make the power hit very hard. Strong rods will hopefully help me achieve that. Cheers

- 1 reply

-

- 29

-

-

Hi. It's going to be both street and strip but mainly street and roll racing. There's no plans to get it tech'd which means any faster than 10.5sec? over the quarter and I'll get sent home. When it's all working optimally I'll most likely take it for a first and last pass What tyres do you have on your Ute? I'll be using Hero's or Pro Street Radial 235 60 15. I have been told to expect insane torque and performance. Can't wait. Cheers

-

Any advice, suggestions or questions, please post here Cheers. Link to project

-

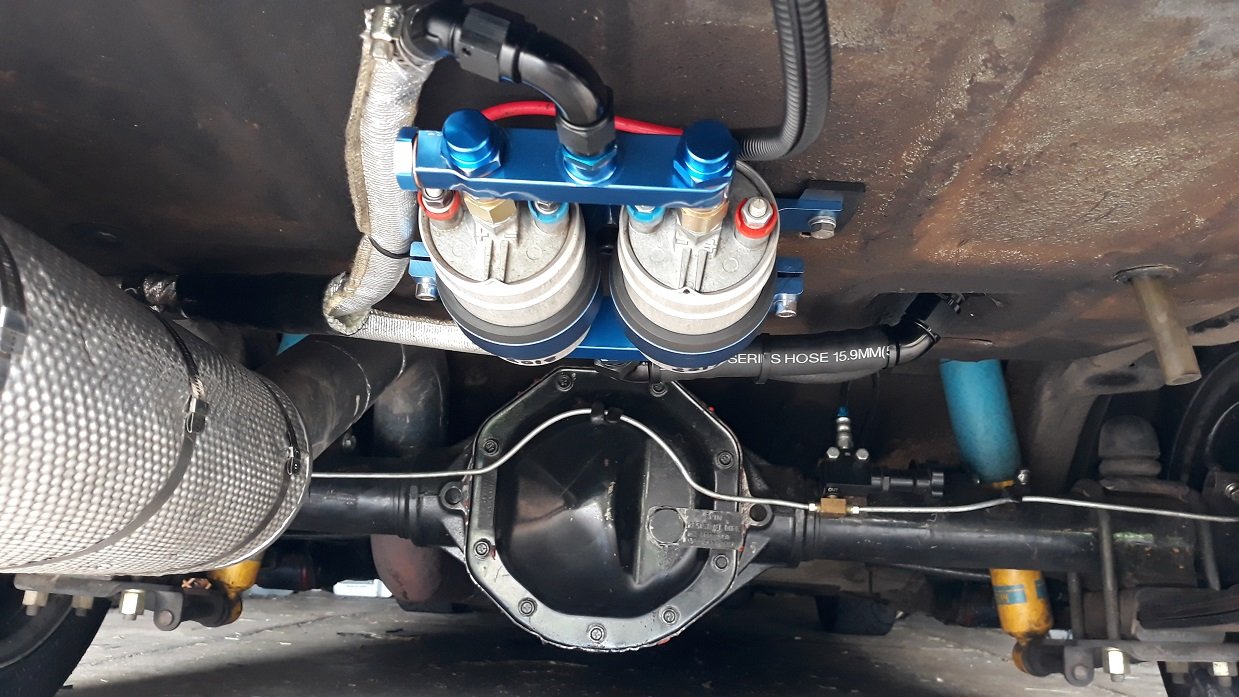

Hi crew. It's been a while since posting. I sold my 355whp turbo pinto Escort after many years of good times. Living 10mins from a popular race track (Lakeside, Kurwongbah) that hosts everything from circuit racing to show and shines/ cruise days it was just a matter of time before I became miserable not having a project to tinker with. I want to go much faster this time and thanks to Castlemaine Rod Shop the process is simple. Engine mounts , T400 transmission crossmember, VT brake upgrade hubs from them and front swaybar (to clear the front sump) from Muscle Garage. It's a 1993 Holden Commodore Executive. 92,000 genuine km country car from Roma, Qld. No rust! The reason for choosing this car well there's a few. My favourite series of Commodore and lovely Marine Aqua paint. Ford's from the same era are heavier and uglier (no hate just my opinion!). The weight, only 1275kg. 1250kg with the barra. No firewall modifications other than massaging the tunnel for bellhousing where starter motor sits. Power goals 650whp 1300nm but it might increase to 800whp depending on the transmission spec. Motor will get forged rods, stock turbo BF pistons, ARP bolts, crow springs, girdle, stock timing chain, stock BF cams, torrington bearing. Fuel system Aeroflow 76L anodized cell with triple pump hanger, 2x Walbro 525 pumps. Diff has been built with 31 spline axles and Chinese Trutrac. T400 is going in for build on 3rd July. Torque Power bellhousing, billet input shaft and possibly a billet intermediate shaft too. 36 element sprag etc. Link to dicussion

- 1 reply

-

- 32

-

-

-

- 32 replies

-

- 17

-

-

-

-

Drags again last Saturday. 11.7 @ 121mph. The photographer captured some great shots of the tyre wrinkle. I'm making some cosmetic changes to the engine. Rocker cover painted in 2K same colour as the body, Olympic blue. The inlet manifold, turbo inlet pipe & bov pipe are getting powder coated satin black, I will have them back next week. Really happy with how the rocker cover turned out.

-

-

The fuel pressure sensor has been connected for a while now but I had been putting off oil pressure until last weekend. I got stuck in and mounted this EFI hardware sensor block on the inner wing. Moved the fuel pressure sensor over and bought another for the oil. These are Variohm 0~150psi sensors. The lines are 3AN braided teflon and stainless hose ends. The loom wires were only long enough to reach the sensors if I mounted them pointing down.

-

Woohoo. Dipped into the 11's last Saturday. The bias ply slicks performed amazingly!! Chopped 0.3sec off my 60ft and 0.5sec off my ET. One of the runs at 121mph. I had read horror stories about mixing radials and bias ply so after making lots of calls and taking on advice I ended up with a set of used Avon ACB9 5x22x13 bias ply formula ford tyres up front. The car ran straight as an arrow on the strip, a lot more stable than previous runs on semi slick radials.

- 32 replies

-

- 10

-

-

I would not recommend this transmission mount, poor fit onto the gearbox extension housing (I needed to cut the tops off both mounts and weld the old top plate onto this one) and so much noise and vibration through the car so I put a standard mount back in, much better The ignition leads have been replaced after it was found they were causing a misfire on hi boost only. And I've finally sealed up some minor but annoying leaks from the thermostat housing and rocker cover using better products. Loctite 515 on the thermostat housing gasket and ThreeBond super sealer on the rocker gasket. It's a 2L rocker cover on a 1.6 head I don't know if that's why it's always leaked in the past?? The rebuilt gearbox is back in and the car shifts much nicer now especially with the Redline oil in it.

-

Another cruise session at Lakeside a few weeks ago and unfortunately the gearbox failed. It was not catastrophic so I was able to drive the car home 10 mins from the track. I used the dropped crossmember method to remove the gearbox which worked really well. It's been shipped interstate for a rebuild and I was told on Friday that the gears are all good but bearings are shot. Heavy duty needle roller bearings will be fitted as part of the rebuild. I'll be using Redline MT90 oil this time and have sourced a heavy duty transmission mount keep things supported a bit better. Thanks

-

- 32 replies

-

- 12

-

-

Back to the dyno today after sorting the fuel system. Made 355whp @26psi. It's safe to say an 11sec pass is coming up

-

-

From the very beginning my Bosch 044 pump suffered from cavitation. Sounds like glass beads getting smashed up inside the pump. Well when the fuel pressure fell over on the dyno and it was time to go twin pumps, I emailed GRP4, the tank manufacturer and asked them if the -8AN outlet would flow enough to support two pumps. He was good enough to be honest with me and explain the the pick up pipe inside the tank has a kink in it and would reduce flow. I had no idea it would be this bad! Needless to say this was causing massive flow issues and is a testament to the durability of the mighty Bosch 044 pump. After careful planning and acquiring all the parts to complete the job, I took the tank to Drew at ARE Cooling in Brendale where he cut side of tank open, welded on a -12AN outlet and 1" pick up pipe. -4AN fittings where the fuel sight gauge used to be and tidied up the welds where my fuel sender goes in. The car is back running and the pump is actually QUIET! I will get the second one wired up soon, the ECU will switch it based on manifold pressure, as a guess it will come on around 18psi.

- 32 replies

-

- 10

-

-

So I got the car out to the drags last week and was stoked to run a 12.4. The mph is the same as previous outings which is no surprise with hp being the same. But the better spool and take offs gained me 3 tenths of a second. Still pretty lazy 0-60ft so I'm thinking of getting some M&H 22" 8" 13" drag slicks and having a decent go after the next and final tune. I also ran in the Forced Ford Forum cruise last weekend at Lakeside All Aussie Day. Here's a link to a youtube vid from the guys in 51OBA. Enjoy

- 32 replies

-

- 11

-

-

Dyno happened just over a week ago. I lost around 8hp from the weight of the new tailshaft haha. So after optimising the E85 tune with the new GTX turbo we got it back up to 300whp with the same boost pressure 20psi. Pushing beyond that the car began to lose fuel pressure so the boost is fixed at 20psi until I fit another Bosch 044 to make a twin pump set up. But looking at the results from when we pushed past 20psi, I will be lucky to get another 20whp out of it. Any more than that will require a bigger turbine wheel from the likes of a GT3071R which is an option even with the limited space available. The compact T04B compressor cover from a GT2871R can be used on the GT3071R (they have the same compressor wheel) and there's a T2 flanged Mamba turbine housing with Vband outlet that suits the full size 60mm 84trim turbine. I'm trying to resist the urge to go bigger. There would be some down sides- Traction problems, I'd have to ditch my 13x7 miniltes and AO48 semi slicks, then change diff gears again to suit 15" tyres. Boost coming on 1000rpm later in the revs. And of course the cost of doing it all

-

- 32 replies

-

- 20

-

-

Another night at Test n Tune to try out my new 3.45 diff gears. Long story short, I geared it too tall by running 205 tyres. Couldn't get it off the line very well and being frustrated with ordinary times, gave it a bit too much on my 3rd attempt and got terrible tramp which snapped my universal joint on the tailshaft Everyone was so chilled about it but I felt terrible holding up the night for everyone racing. I can't say I wasn't warned about these uni's. They're hollow not solid. Hopefully the shaft can be balanced, it did sustain a bit of damage from the accident. My diff builder recommended getting a XR-XF falcon tailshaft which he can modify to suit so I've lined one up already from an XF sedan. Believe it or not I've had GRP4 tramp bar (radius rods) brackets tacked to the underside of my car since I've had it on the road. It's about time I finished the job and put the bars in. Next time at the track should be a winner with 185's, a strong tailshaft and tramp rods installed!

-

Turns out the turbo was in bad shape. Upon inspection it had noisy bearings and a chipped turbine fin so it was mailed back to the seller and I got a full refund (paid by paypal). On Saturday the diff gears were changed to 3.45 and I did a cruise session the following day. The new gears are an improvement. Speedo now accurate too

-

Hi guys. It's been a while since last post. The car has been performing great and I'm still getting out an about in it, mostly on weekends. There's always something on at the local track every couple of months. I really wanted to get back onto the forum after growing somewhat tired of facebook and all the crap it can add to this hobby. Anyway... as far as developing the car. I have learned that gearbox ratios are very important. The W58 I have is quite low in first and second gear and a bit of a gap to third. Typical of road ratios. Well, a 600hp XR6T i've not been able to beat at roll racing finally fell behind me the last time out because I rolled on in 3rd instead of 2nd. 3rd has much longer legs and I didn't lose the speed changing from 2nd to third. So I looked into close ratio gear sets for the W58 and turns out they are available. At a cost of around $4500. Needless to say, the CR gearbox can wait. But gee it would make a difference. Also, the temptation to add more power has gotten the better of me. I have bought a used HKS GT2835R-56T , it's a Garrett GT3071R with a back cut rear wheel so it fits in the T25 exhaust housing. Compressor wheel will go from 47mm-60mm 62 trim, to 53.1mm-71mm 56 trim and more importantly the turbine, from 54mm-47mm 76 trim to 56mm-53mm 90 trim. I'm aiming to add around 30 or 40hp so 330~340hp at the wheels. My current GT2860RS is pretty much out of puff @ 300whp. At first I was going to fit a 67mm GTX billet wheel, effectively turning it into a GTX 2867R. It could probably make that extra power but nowhere near as efficiently as the GT2835R-56T. The larger turbine is where the benefits will come from. A larger set of Siemens Deka injectors will also be fitted. Jumping from 60lb (630cc) to 80lb (840cc) I took it to the drags a few months ago and it went 12.75 @ 113 mph (2sec 60ft) . Hoping with the new turbo and tune to crack into high 11's. If not I will just live with it because any more power will result in problems like gearbox failure, clutch failure, cracked block etc etc. So here's a pic of the car launching when I ran the 12 with 205 60 13 rear tyres. I was only able to achieve low 13's with 185 60 13 tyres, as soon as the 205's went on it was into the 12's. I might put in some 3.45 diff gears with the 185 tyres which would work out about the same as 205's and 3.9. Cheers

- 32 replies

-

- 17

-

-(ZF-9942-13940-1-001).thumb.jpg.bc4b922cbc67ffb7fea82b1b683afcad.jpg)