-

Posts

236 -

Joined

-

Last visited

-

Days Won

7

Posts posted by Not-a-number

-

-

Awesome project. going to be keeping an eye on this. The company I work for built a couple of 4 1/2 liter Bentley engines from scratch before i started there. Its interesting to see the process of recreating the parts. You want to be sure the grade of cast iron is up to scratch as you'll run into valve recession problems if its a little soft.

Whats the company you work for?

Do you know what grade of cast iron they used?

-

Did rookie dave suggest your username?

Not a chance!

-

What kind of crank bearings will go in this? Original (roller bearings?) Or is there room for improvement?

Luckily these wernt roller bearing crank. They are babbitt/white metal bearings. So I will just use shell bearings.

The T35 is the one with the roller bearing crank. And yeah they last 10000miles and cost 10s of thousands to rebuild so ive heard.They were roller, bearings alone are like $20k and don't last long so many convert to conventional plain bearing if they are used often.

Whats the plan with the valvetrain? Planning finger followers like the original? Also are you planning to run the original firing order or run the more modern inline 8 firing order? I believe the Pursang cars run the modern firing order which is apparently a lot smoother.

Can't wait to see how you tackle that front axle...!

The T57 is the saloon car. Lots a variants and would be the most common bugatti engine/car. Ralph Laurens $40m Atlantic has this engine.Crank is 2-4-2 with 1, 6, 2, 5, 8, 3, 7, 4 firing order.

The T59 is the GP car which essentially took the 57 engine and hotted it up.

3.3L fixedhead, twin cam, supercharged, drysump, straight 8. 230Hp (i find it strangely satisfying saying that sentence!)

Big difference was the crank was 4-4 with a different firing order. These ran really rough, didnt rev very high, broke cranks and didnt make any more power.So im going for a T57 engine since there is a lot more info on it. More likely to get hold of genuine parts (which ive got now) and a higher chance of someone wanting to buy some parts.-

7

7

-

-

How do you press in the hardened valve seats?

Even cutting them in?

How did they do it way back in the day?

Its cast iron so dont really need hardened seats. Your crossflow lasts 100,000+ miles without them. So thats like 100 years bugatti driving! Crank would break before the seats woreout anyway!

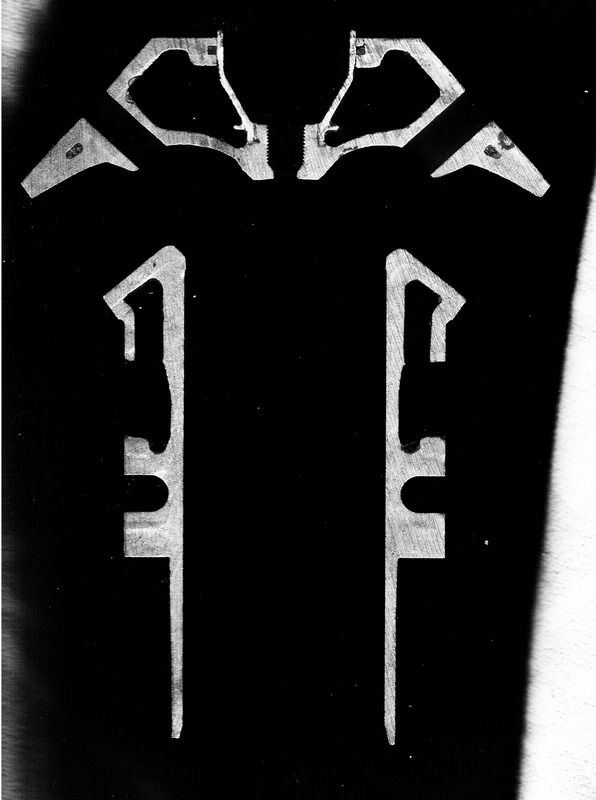

You use a reverse seat cutter. Valve guides are really big diameter, so you feed the cutter in through the bore, push the guide in from the outside and then cut back with a spacer to the base of the guide.

If that makes sense

. Assemble the valves like that too and the valve springs hold the guide in.

. Assemble the valves like that too and the valve springs hold the guide in.This gives you a better idea. A lot of plane engines are like this.

-

2

2

-

-

Fuuuuuuu this is beyond any skill level I could ever dream of having.

Are you going to make your own gearbox and diff to go with it?

Plan is to use as many parts from other engines/cars as I can. So would use internals from another gearbox and cast a housing to suit to make it look legit. Diff is a bit harder because its not like a regular diff. Havnt really looked too hard into that side of it. Many years away!

-

1

1

-

-

- Popular Post

- Popular Post

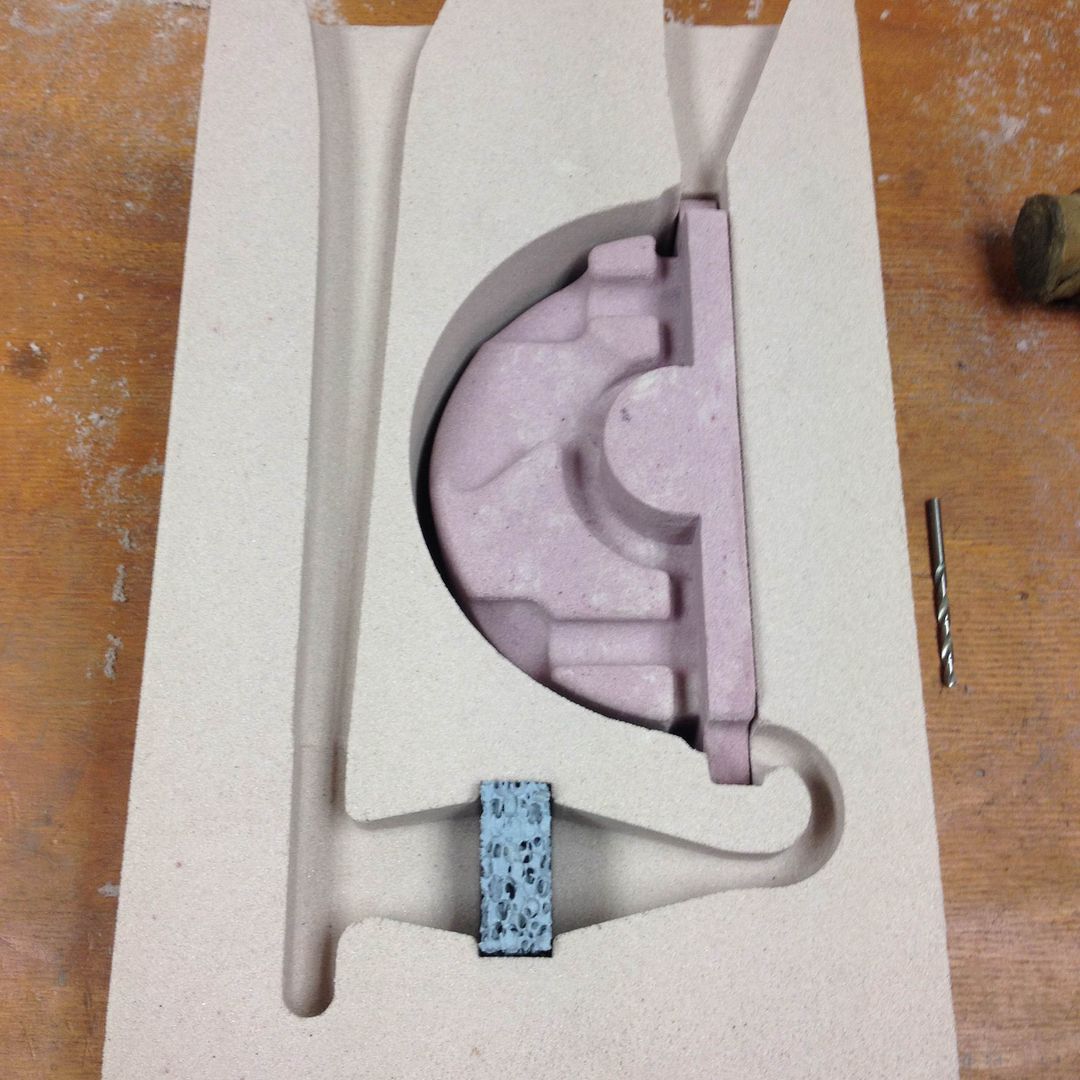

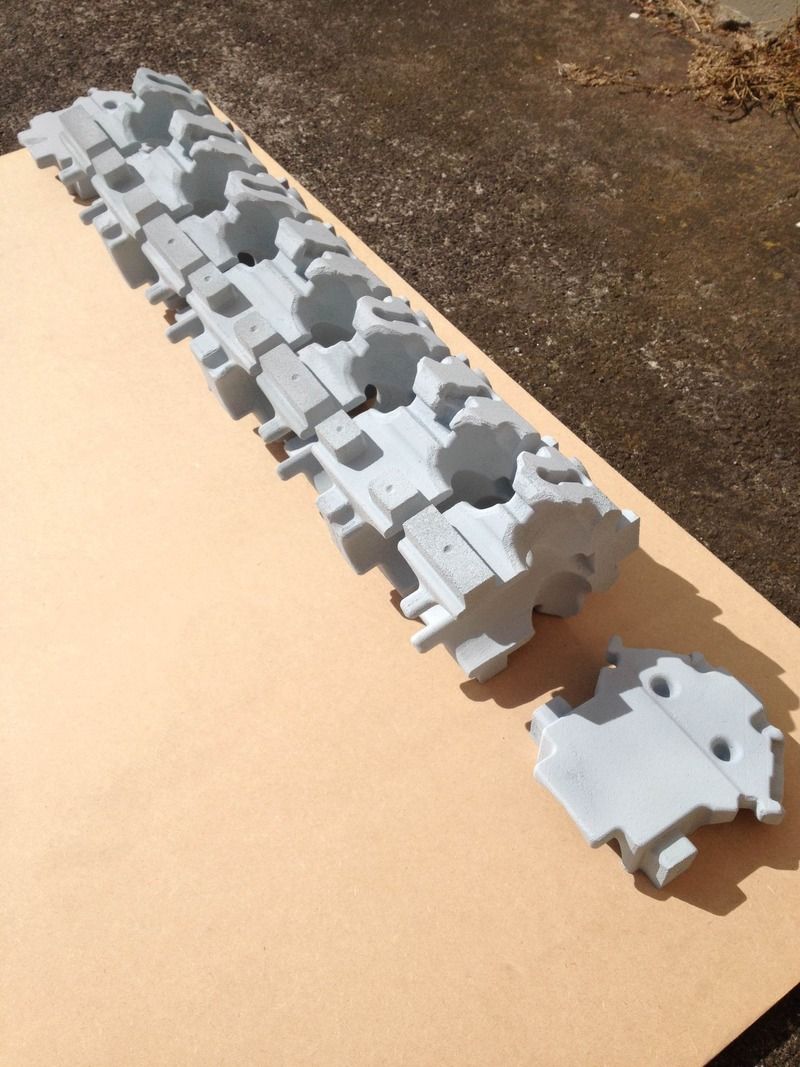

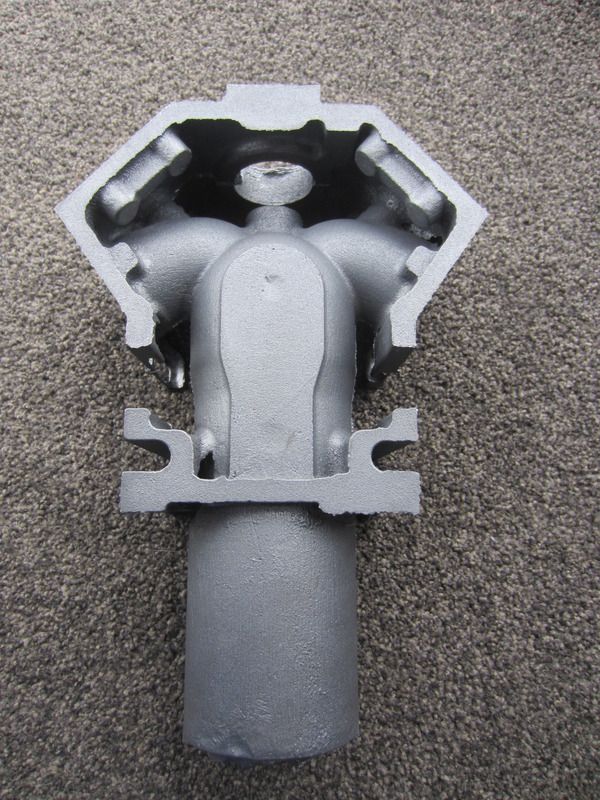

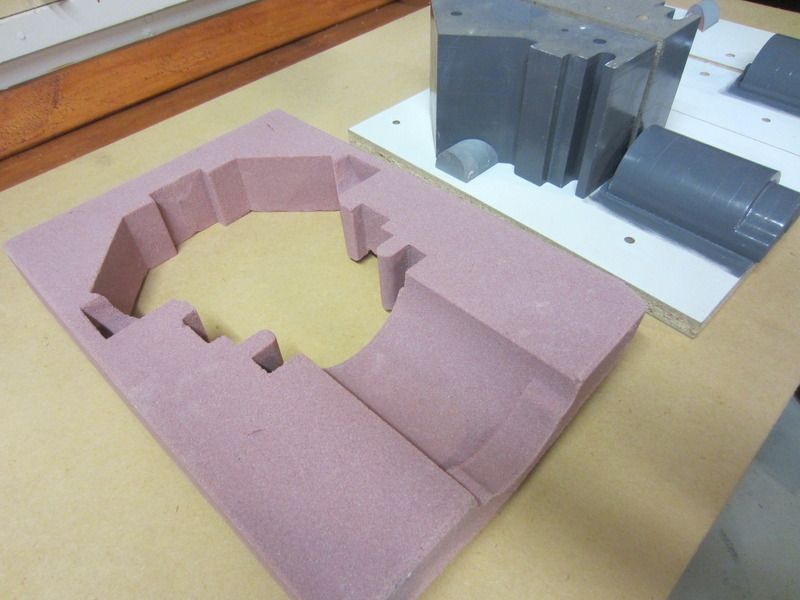

Dropped the moulds off in the morning and had the parts by lunch time! Thats service.

The first one had a bit of shrinkage going on in the thicker parts so they dropped the temp a bit on this pore and it worked mint!

This is only the right hand side. Left hand side is pretty much the same just doesnt have the cutout.

-

31

31

-

Nah looks sweet.

-

1

1

-

-

Awesome thread matey, I've split the thread so the project is in one thread and the discussion in another - also I'll go back in later on and edit the thread to spread the pictures out.

At the moment the first post is MASSIVE and once it gets 20 posts down the page, it'll start crashing peoples browsers. Try and keep it to 4 or 5 pics per post if you can. Ta.

Cheers for that. You split it up well.

-

1

1

-

-

- Popular Post

- Popular Post

Cheers for the comments. Hours and hours of work there! A lot more to go!

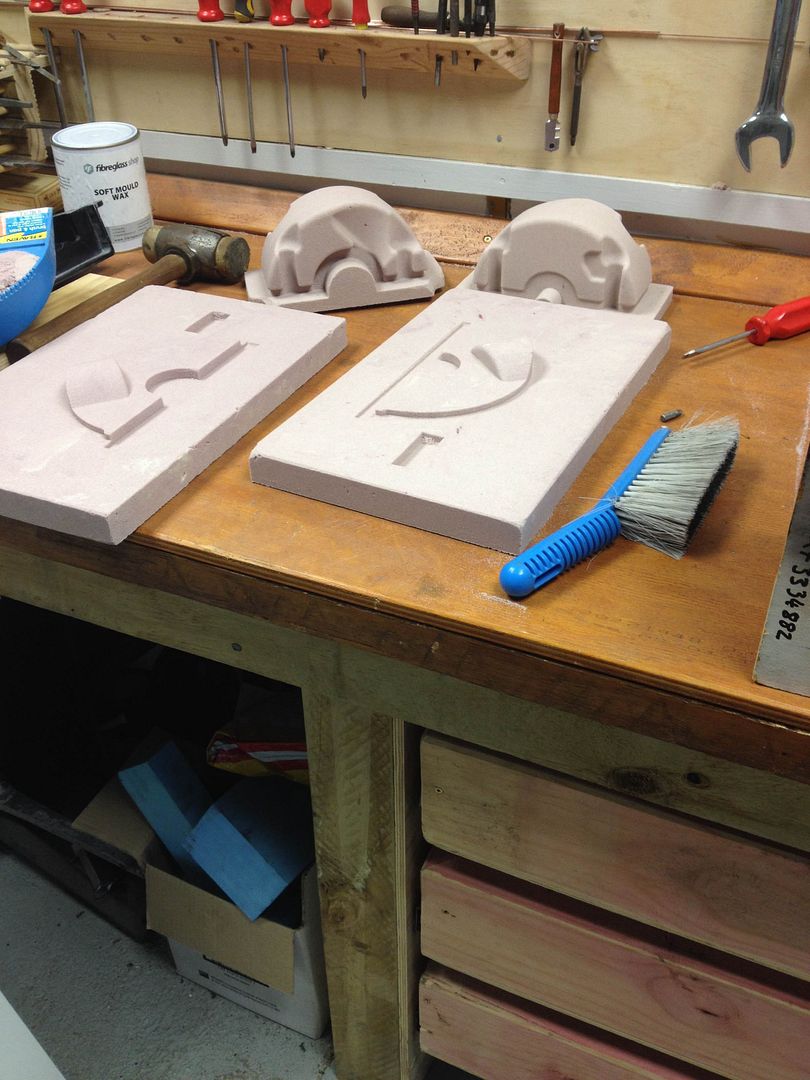

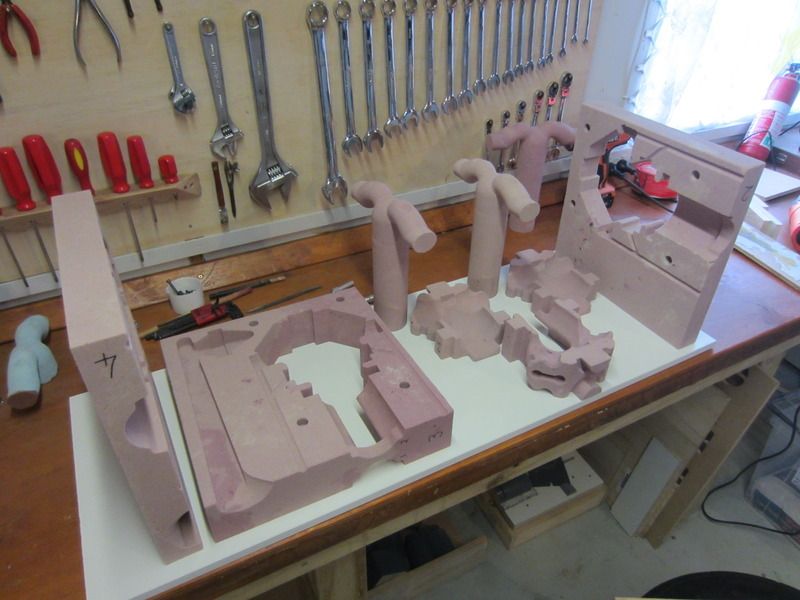

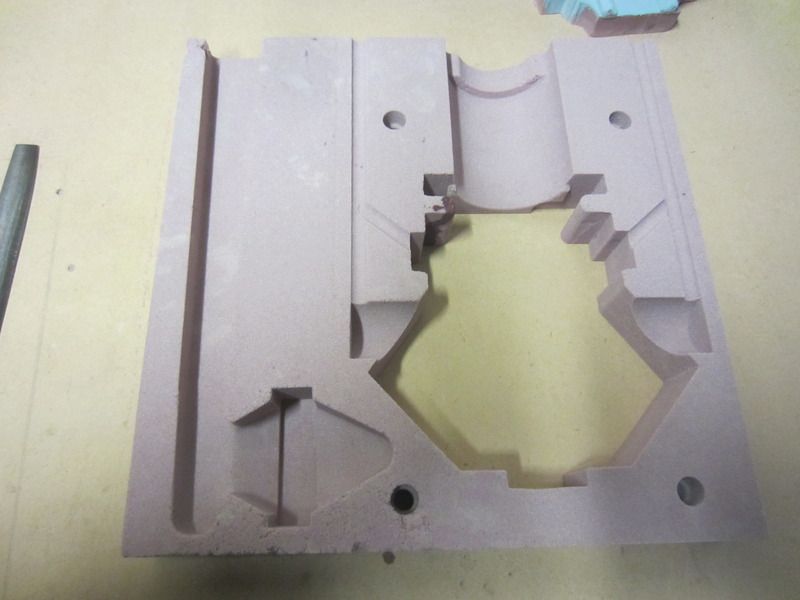

Yesterdays work. Two more cam gear covers, off to the foundry tomorrow.

-

22

22

-

- Popular Post

- Popular Post

Been talking a bit with the guy that owns the Hamilton car museum. He bought the T57 from the Baillon collection in France. His engine is essentially the same as what im building. Hes given me access to any parts I want when hes got it in bits. To copy and 3D scan etc.

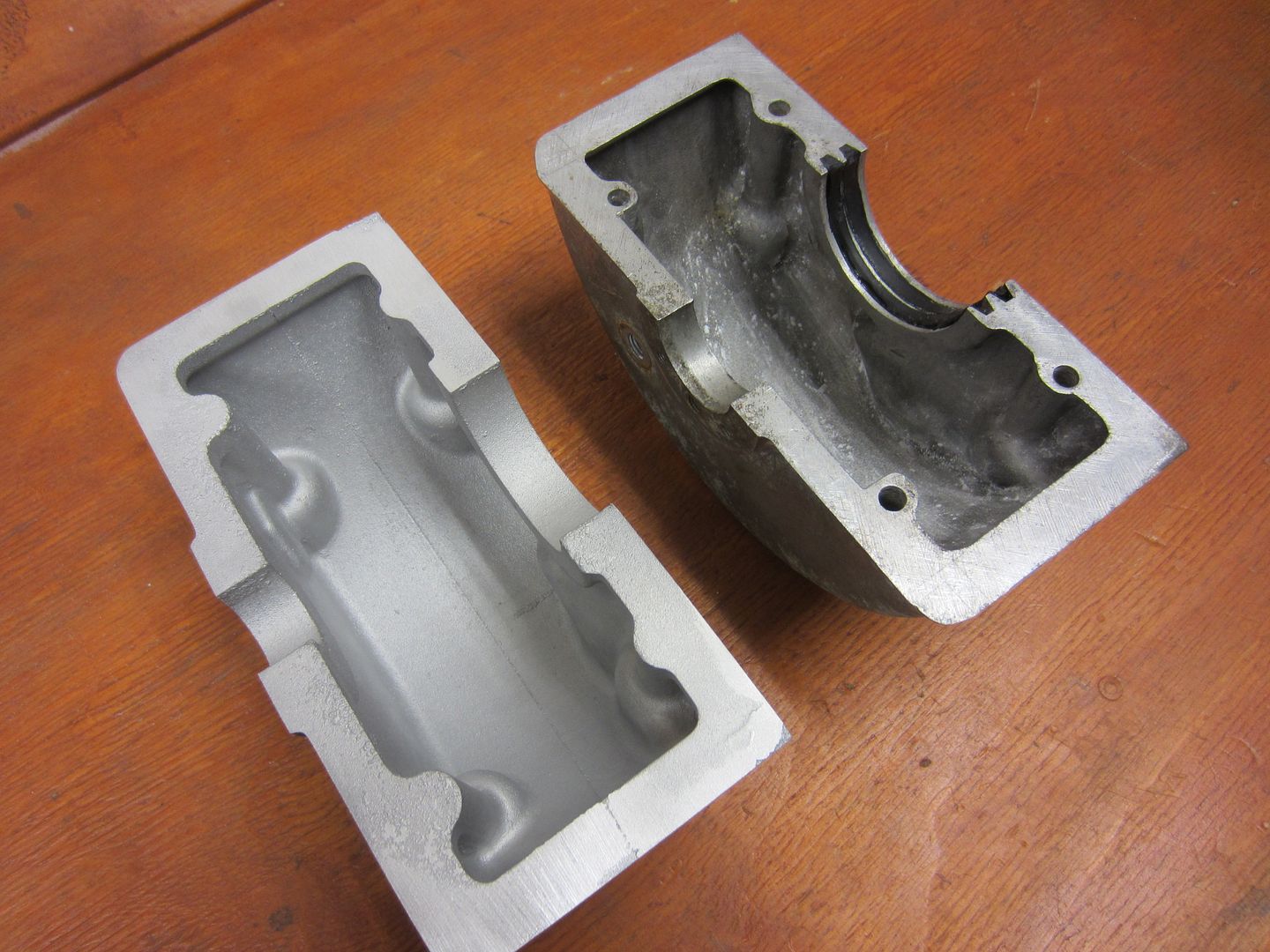

So Ive got some pretty cool parts sitting around the living room now. The sump is a beast

First ali bit cast! Right hand cam gear cover.

Using a David 3D light scanner. Sort of useful to help with drawing in CAD

More 3D printed moulds. Perfect for part this big with this detail. Would of taken me days to machine it. Still have to do a lot of sanding and paint to get a good finish.

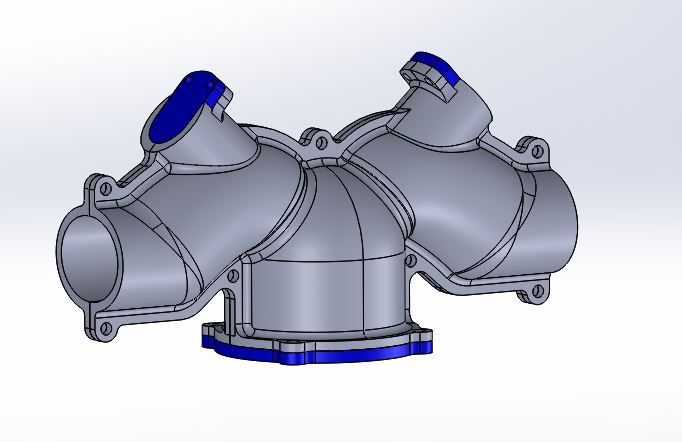

Playing with different filter runner designs. Think im getting a better idea of how to do it.

2016 on the left and 1938 on the right!

70hours from start to finish. But only bout 3 hours to make another one. So I plan to make atleast 3 of each part.

-

27

27

-

- Popular Post

- Popular Post

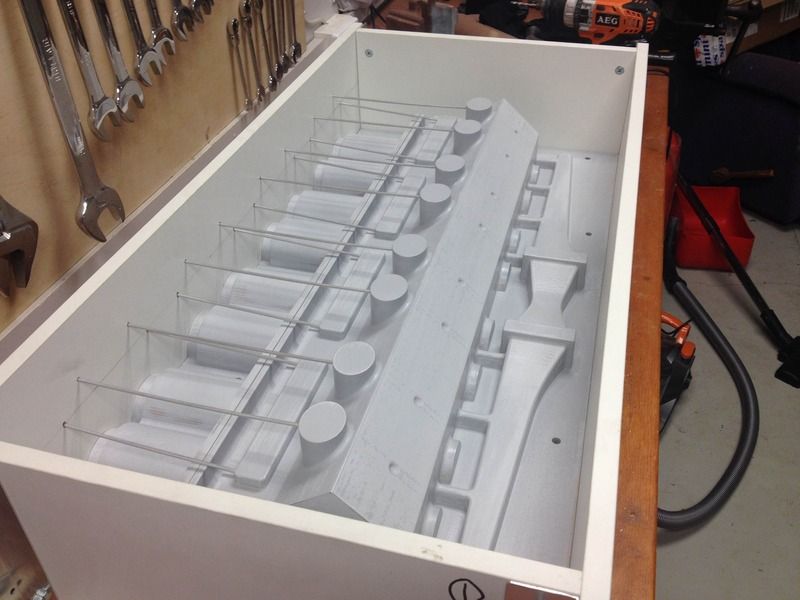

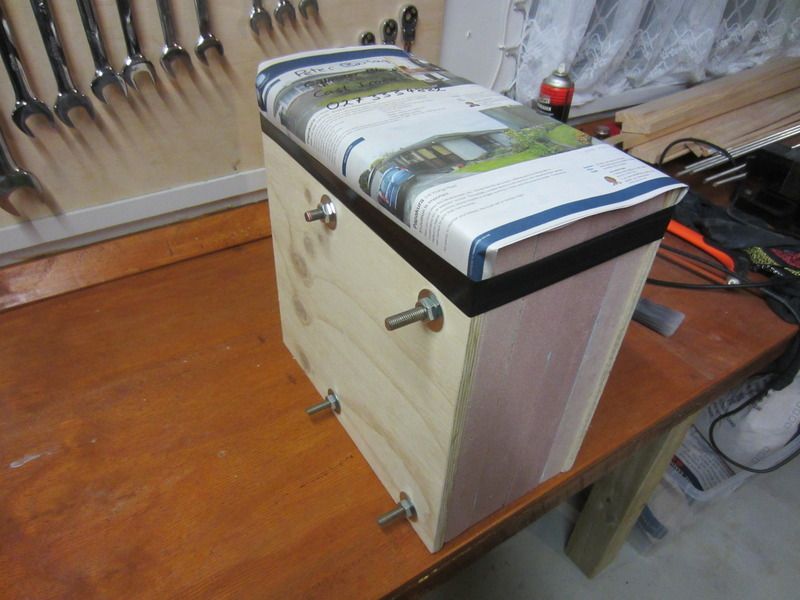

Dropped the second half on with no drama. So its all bolted up now and ready to go to the foundry at the end of the week.

Nailed it

Thats like 1000hrs work right there!

-

48

48

-

- Popular Post

- Popular Post

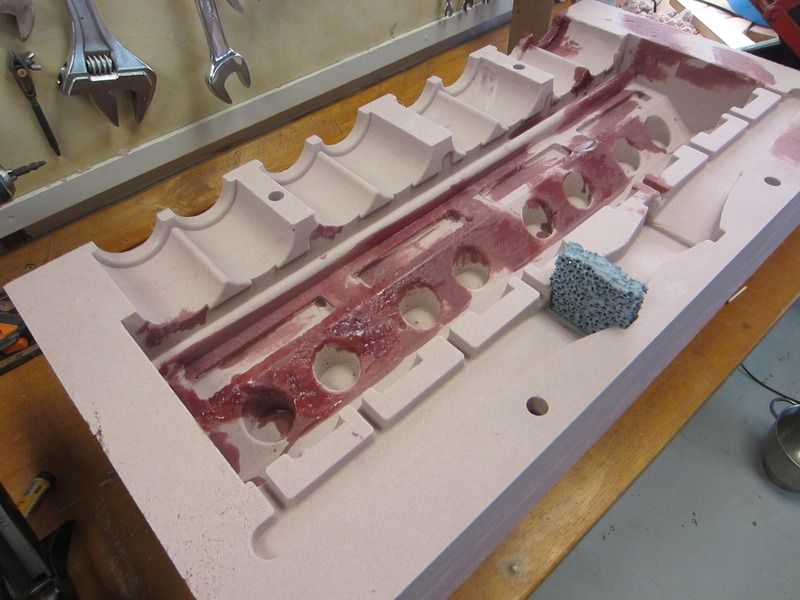

The first mould didn’t work out! Mixing the sand in small batches didn’t work out. I couldn’t mix the sand fast enough to get an even mix so ended up with layers that didn’t go hard. 70kg of sand for the garden.

Employed an apprentice/the mrs to run the mixer and had another go. Second attempt worked pretty well. Sand started going off too quickly again so there are a few dodgy patches. Can seal up the dodgy bits with resin.

This didnt really work that well. Adding that red resin was a bad idea apparently. It would gass off and cause problems. So went to the foundry and filled the patterns there.

Time to fill it up with water and cylinder cores now. Theres 165kg of sand all up!

Not easy to work with!

Not easy to work with!

-

16

16

-

- Popular Post

- Popular Post

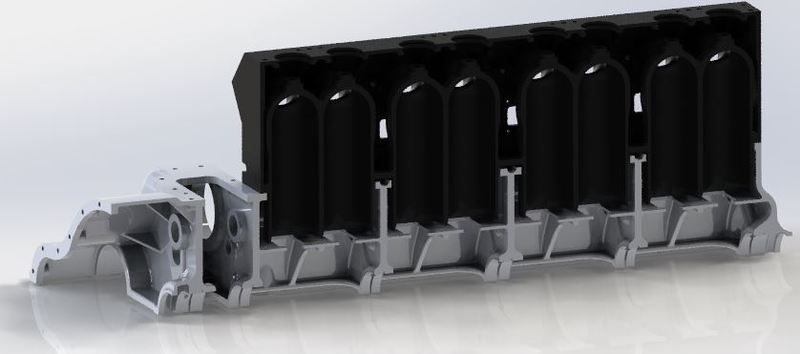

Great success!

I have a twin cylinder block and I'm pretty stoked!

I have a twin cylinder block and I'm pretty stoked!

Been working on this thing flatout. Along with everything else though so not as much done as I had hoped!

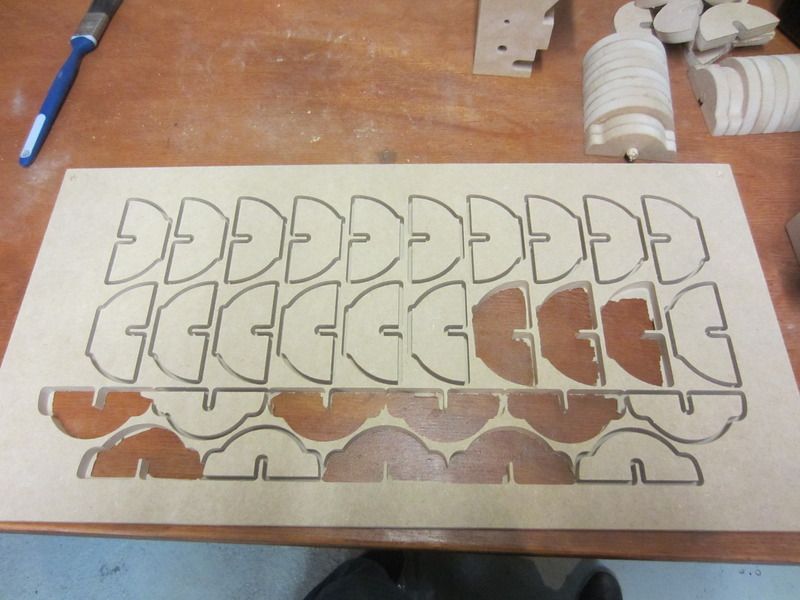

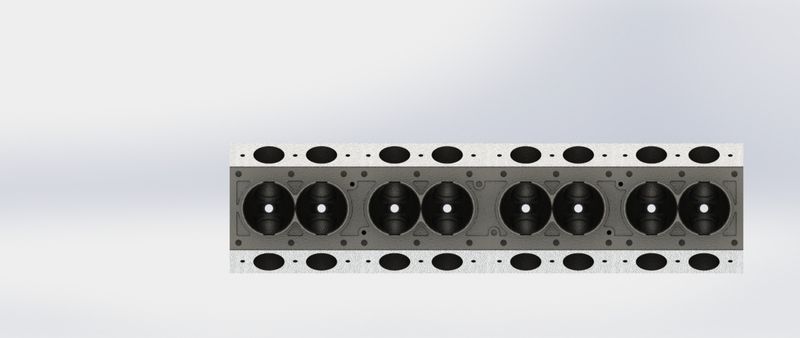

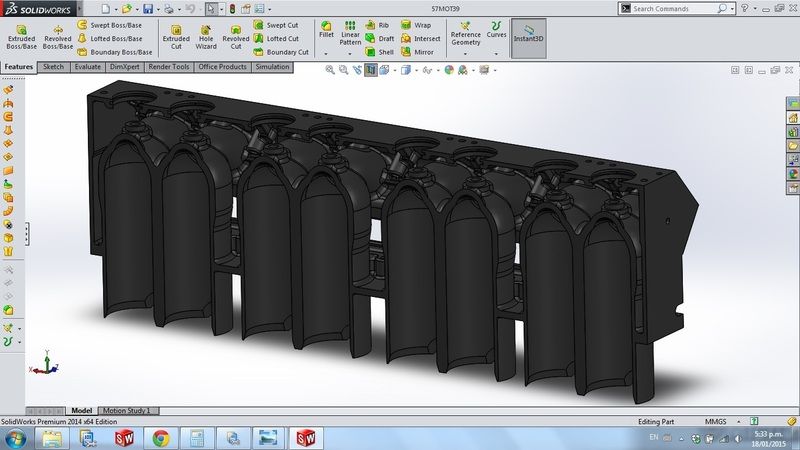

Made a full 8 cylinder pattern. Got this machined at Jacksons electrical who do a heap of patterns for us at work. Turns out Rookies mate works there so he did a real sweet deal. Did a good job too.

Guys at work Duratech coated it. Awesome stuff to sand down, smooths everything out.

-

16

16

-

- Popular Post

- Popular Post

Did a bit of machining and chopped it in half.

Added some valves to make a proper paperweight.

Finished off the moulds for an attempt on 2 cylinders. At the foundry now and theyre meant to pour it early next week. Fingers crossed it works

-

15

15

-

- Popular Post

- Popular Post

Ready for the first pore. The guy at the foundry likes classic cars and was really keen to help. Will charge $5 a kg for casting. Thats cheap!

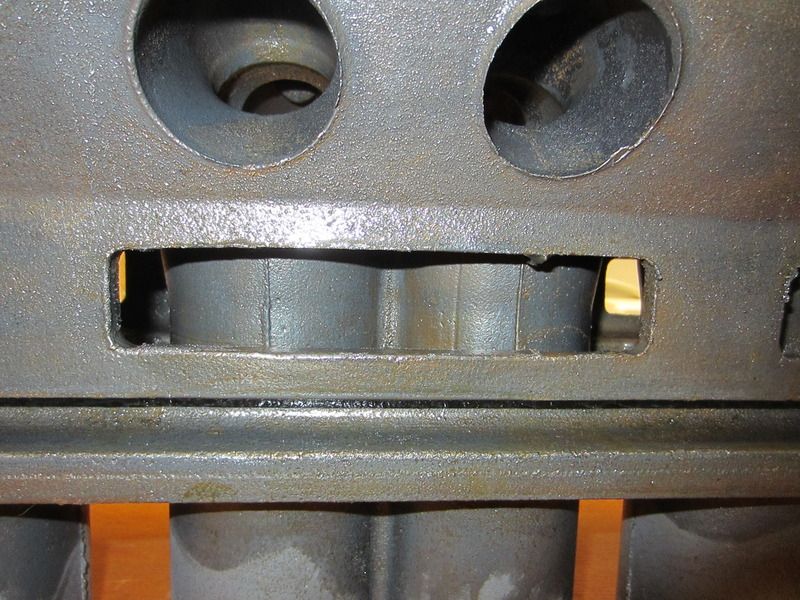

The filter area was too thin and failed after it filled up. So it filled properly and then just before it solidified it half drained out.

. I knew it was dodgy but thought I might get away with it.

. I knew it was dodgy but thought I might get away with it.

Even though this failed, this is a great success.

The cores worked perfectly, they didn’t shift or break, the surface finish is great and there are no cracks or porosity which is really common around the port and cylinder head areas.

The cores worked perfectly, they didn’t shift or break, the surface finish is great and there are no cracks or porosity which is really common around the port and cylinder head areas.This is definitely the coolest thing I have ever made!

Next step is to cast two cylinders.

-

15

15

-

- Popular Post

- Popular Post

Then time for the outer patterns.

Filter and sprue area added.

Then fit them all together.

Then stack them on top of each other to make a 40kg sand castle.

-

17

17

-

- Popular Post

- Popular Post

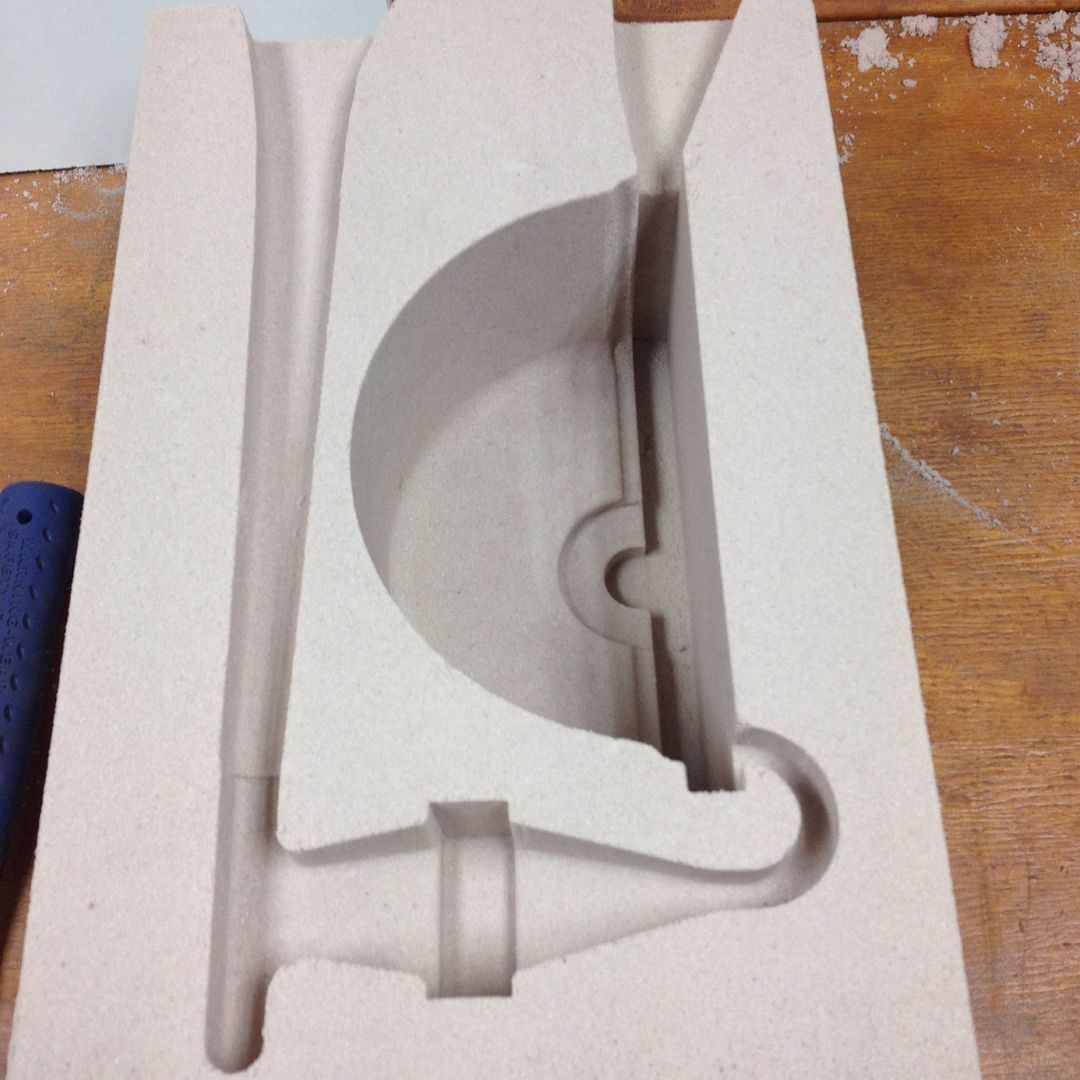

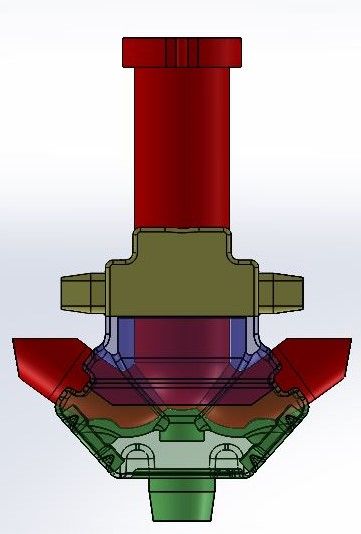

First sand core.

Cylinder and port core.

-

16

16

-

- Popular Post

- Popular Post

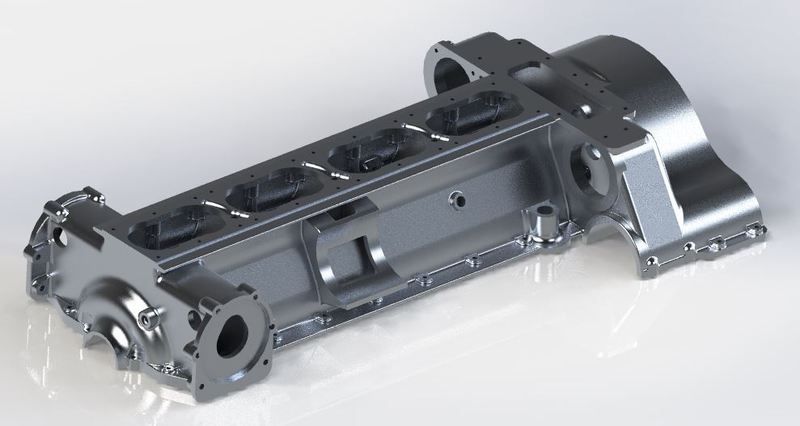

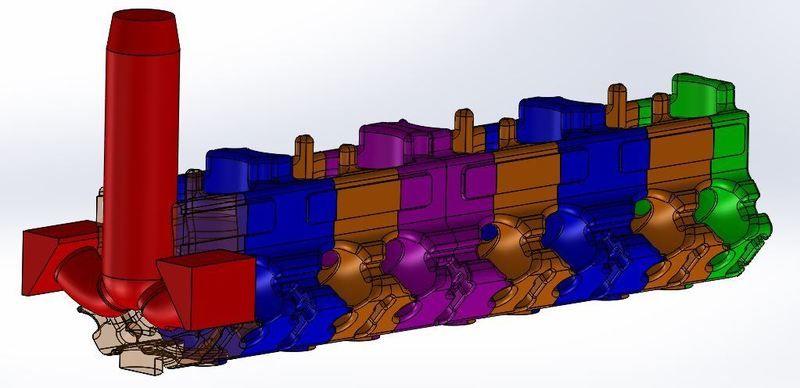

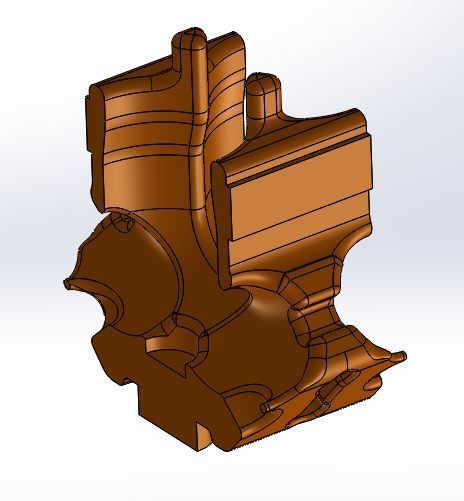

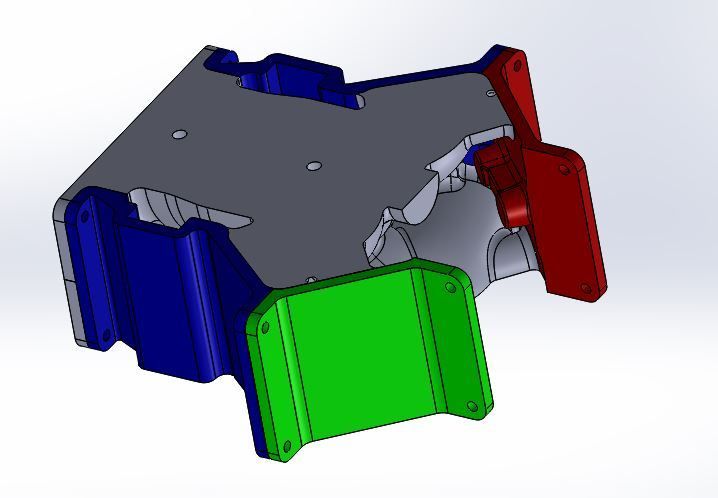

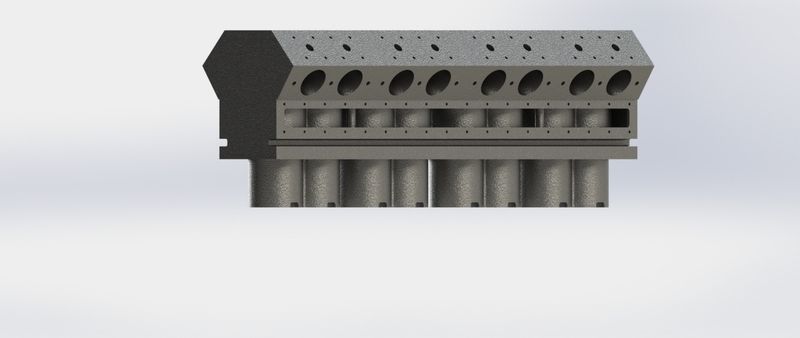

Crankcase.

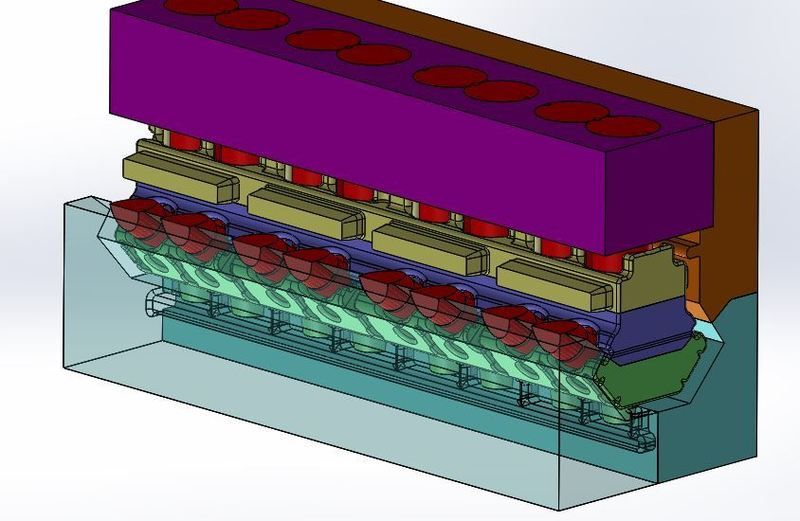

Then once I knew the CAD was right it was time to make the negative CAD for cores and pattern making.

Then take those parts and make patterns. Making just 1 of the 8 cylinders first. Just to get the casting right.

-

10

10

-

- Popular Post

- Popular Post

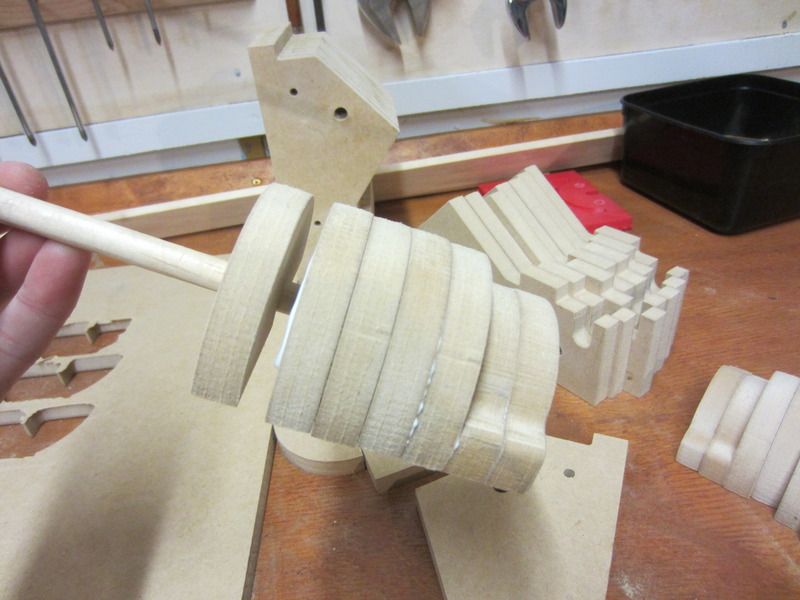

Fitting 3D printed patterns to get the CAD right.

-

21

21

-

I was in a Pattern makers shop not long ago, its obvious by your skills that you are an experienced tradesman.

Are you still pattern making for work?

Thanks. Im a design/development engineer but Ive spent my life making stuff. My job gives me some pretty cool toys like 3D scanners and 3D printing.

Havnt done patterns before but Google and a few books tell you a lot!

-

5

5

-

-

- Popular Post

- Popular Post

Decided to start with making the cylinder block first.

These are photos from a guy in Germany with a genuine engine and also an old sectioned one. He needs a new block himself so he is doing everything he can to help.

The Bugatti way of doing things was a bit different when it comes to the engine. The block is also the cylinder head so there is no headgasket!

-

13

13

-

- Popular Post

- Popular Post

Discussion Thread - //oldschool.co.nz/index.php?/topic/53921-bugatti-t5759-engine/

Embarking on an ambitious project to build a Bugatti T59 Replica.

Using modern manufacturing techniques, 3D scanning, 3D printing, CNC machining but keeping all visual details authentic to the original.

-

83

83

Bugatti T57/59 engine

in Project Discussion

Posted

I used Grade 150. Apparently this is generally what people use these days.

If I wanted Bugatti grade I'd have to go melt down some old park benches and frying pans!

Did they scratch build the whole engine? Cast the block?