-

Posts

573 -

Joined

-

Last visited

Posts posted by datto_610

-

-

Oh man thanks for the offers I'll find out which area. OS is truly a community of Gcs!

-

I have tentatively bought a diff and some struts from a fellow up in Auckland and was hoping one of the OS Gc's would be able to pick them up for me and possibly hold them for a small amount of time til I figure out the cheapest way to get them to chch. The diff is out of an R31 skyline and is IRS so it's not massive and the struts aren't that big either. Any help would be much appreciated. Cheers

-

Has to be within 150 of the UJ too I think?

Looks a bit far away in that pic?

It is about 150mm just the angle of the photo makes it look further back, Also after a but of searching the distance from the UJ has been increased to 250mm for driveshaft hoops

looks good to me. use a 100x50 washer on the top side of the floor, 4x 10mm bolts to attach to the floor, spring washers or nylocs on all fasteners, and take a photo before you put the carpet back in for your cert dude.

pro tip- tack the bolt heads to the washers on top of the floor and then its much easier to do up the nuts by yourself

Thanks Clint will do!!

-

1

1

-

-

-

yes, you can weld it, if done correctly as mentioned above

Cheers Clint, that was basically for test fitting purposes, don't have a hell of a lot room to play with down there so have already cut down the flat bar that I've tacked on quite a bit. Once it's all mocked up it will be getting welded properly by a good mate who has done a heaps of work to this car already.

-

-

Not sure your getting what I mean I'll post a pic soon once I've got it tacked up to explain better. But if yours was welded and you got cert then sounds like I've got nothing to worry about!

-

Hi Clint just a quick question about drive shaft hoops, Can they be welded at all?? I have the two 180 degree bent flat bars already from a kit but the not 90 degree flat bar that mounts to the floor pan and the hoop it self so was wondering if I am able to weld two pieces together to make a 90 degree piece (I wont be doing the welding myself just tacking it in place) Any help much appreciated!

-

1

1

-

-

Cold potato sald soup

-

-

Keen to catch up for a beer at Smash!

-

So I know of a place near that one on marshlands rd that has quite a few mk3 supras...

-

You can get them from, Appco, BNT etc but pricey!

-

-

-

It always seems a cunt to get them that last bit on. It probably is ever so slightly off, attach the front half (or complete length if you have no choice) of the driveshaft on to the rear (or if you've got a spare driveshaft, lop the yoke off and slam that) in the end it's helpful for keeping fluid in the box as well as twisting to get the spigot located in the clutch plate) Better living everyone.

All sorted! The spline was engaged, a bit of thread rod either side and my mate and I tightening the nuts up simultaneously did the trick!

-

Jesse from Saeco sorted me with the speedo drive seal thanks again man! Just need an O ring which my mate will get for me.Who needs a press when you have an angle grinder?? Got the old release bearing off and new one installed and fitted to gearbox!

Started fitting the gearbox to the engine, I'm about 80% sure that the spline is located but I can't seem to get box fully fitted :/ I need longer bolts for the bellhousing too as the manual housing is thicker than the auto, will got to Blacks tomorrow and get some longer ones will they need to be high tensile??????Shit Labour weekend is coming up fast, going to need to put in some big hours in the next few weeks! Will buy new shock inserts after work, order ali radiator and a few other things too.Made a start on fitting the JDM seat belts tonight as well gonna be so lush!

-

Almost forgot to mention that the spigot bush is also fitted! Went in with no issues, unlike the one in the CA :/

-

Ok so got stuck in again on saturday and got the clutch plate aligned and fitted, also while I had her jacked up I thought it was a good idea to commence weight reduction stage 1 haha and remove the LPG copper line that ran from the engine bay to just by the fuel tank. Maybe I can get a few bucks from it?? Fitted new seals to the front and rear of the gearbox, took a rather artistic shot of the rear seal if I don't say so myself. Also gave the box a good clean with some degreaser although it's still a little grubby but much better than it was. Picked up my brand new clutch fork boot from Scott at Nissan on friday, last one in the country stoked!!Got a speedo drive seal from Saeco but it's only slightly too small so will take that back tomorrow. So I'm pretty much ready to put the box in but can't put oil in til I get the speedo seal sorted but so much closer! I also have my eye on a few bits which I hope to acquire with the payout from leaving chch metal finishers

-

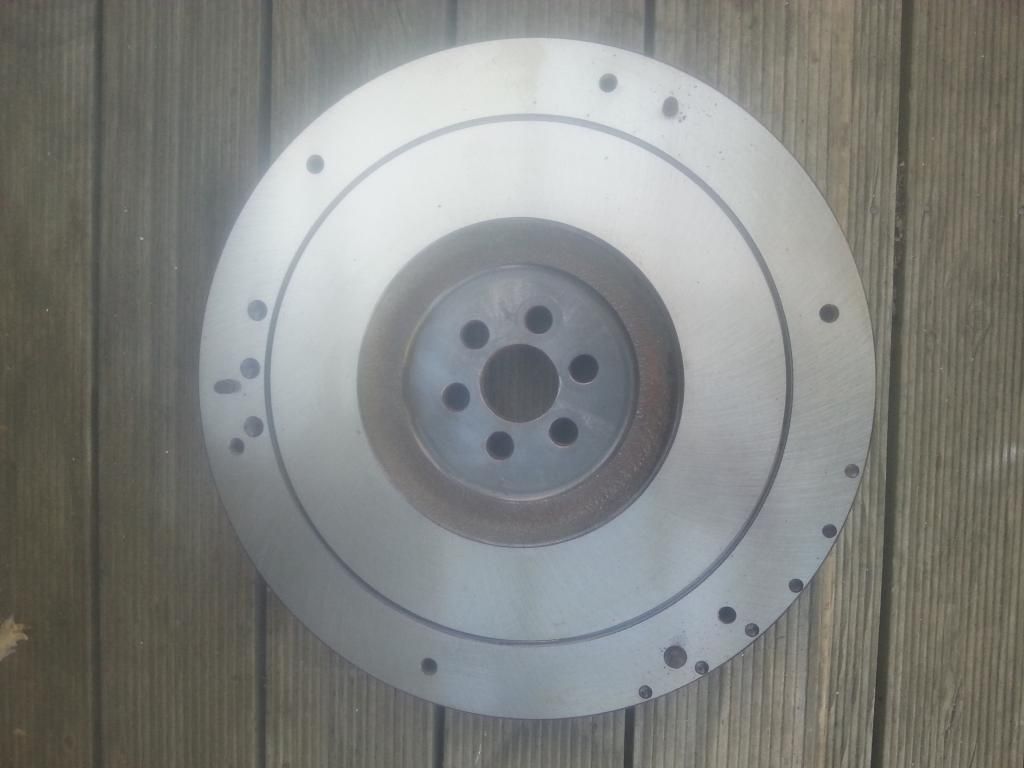

Woohoo!! My mate John came over this afternoon/evening and gave me a hand with getting the last bellhousing bolt. After fluffing about with spanners for a while we did up a couple of the bolts up around it and put heaps of extensions together which totalled about a metre and a half long we got it first crack!! So stoked to get that bolt out, so we kept going and got the slush box out, put the manual sandwhich plate on and torqued up the flywheel

I left the spigot bush at home so couldn't go much further but very happy with what got done tonight. So much closer to getting the 5 speed in ready for Datsun nationals

I left the spigot bush at home so couldn't go much further but very happy with what got done tonight. So much closer to getting the 5 speed in ready for Datsun nationals

-

3

3

-

-

Tidied up my gear stick as it looks like at some point the rod has been been bent a bit and the threaded part welded back on. Also re-chromed it because I could(although not for long)Saw Brock this afternoon and got a new clutch slave, spigot bush and front and rear gearbox seals. Will have to got to Saeco for the speedo drive o-ring and seal.One slight issue I've encountered though is the new slave doesn't come with a pin to engage the clutch fork, I thought that the one from the R30 I wrecked would have one but nope not even a boot so anyone got an old slave cylinder lying around I can pinch the pin off??

-

1

1

-

-

So been getting a few things sorted for the manwell conversion. Cleaned up the rust off my flywheel bolts and sprayed them with CRC in a snaplock bag, Bart also took my flywheel in to get machined(chur Bart!). Also on Bart's recommendations I have taken out the front and rear seals from my gearbox and the speedo drive o-ring to be replaced with new ones. Finally managed to get some 910 front springs from Skutaman to lower the front but they are a bigger diameter than the R30 springs :/ I may just cut the ones I have and reshape the end, depending on how much time and $$ I have left before the Akaroa cruise. So far I've dropped out the driveshaft and made a start on dropping the gearbox things are happening!

-

2

2

-

-

Some drums have threaded holes (not saying yours do), but something to keep an eye out for. Pop a bolt in and tighten it up, no hammer required.

^This!

-

1

1

-

-

Rad trip, can't wait to do it all again next year.

Uploaded the photos on to my FB, and made it public.

Will dredge up a link at some stage when I get some time at home.

Was good yarning with you on the drive there and back man. If I'm ever in your hood there will be alcohol consumed and more yarns!

Parts pick up in Auckland

in Upper North Island Region

Posted

Ok so he's in Epsom, if that is near any of you? May be a whole rear end now too hopefully won't be too much of a hassle...