-

Posts

692 -

Joined

-

Last visited

Content Type

Forums

Downloads

Events

Gallery

Posts posted by rxsumo

-

-

You might struggle to get the 15 x 8 Kyushas under stockish RX3 guards.

Heres what they look like on my Coupe

The guards have been massaged fairly heavily under the flares - as the car used to run 8 or 9 inch slicks on back in the day

-

1

1

-

-

New PB at Manfeild at 1:20:33

Heres some incar from the day

-

2

2

-

-

Nearly all ready to go for tomorrow - new boots are on.....

Got the correct rear panel badge on now as well

-

5

5

-

-

But is there a certain ratio or is it simply a matter of rough guesstimate and add before fuel?

A stock/street engine doesnt need additional two stroke oil being added - as there is already oil being added via the oil metering system.

In race motors the oil metering system is removed - I assume to get a more constant oil mixture and to prevent the sump eventually emptying while racing at large durations of wide open throttle. It was done to counteract a potential metering pump failure in endurance racing motors.

According to the Jim Downing book on modifying RX7s - the stock metering pump runs between 250:1 and 150:1

For race motors they recommend a pre mix of between 100:1 and 160:1

The 100:1 ratio is for long distance endurance racing

In the RX3 - we run Amsoil Two Stroke oil at ratio of 160:1

-

2

2

-

-

+1 for the R888 Toyos

We use them as road tyres on the RX3 - and they work okay - and they are at least 6 years old.

I had some Dunlop Formula R's of a similar age - and they are shocking cold - need 2-3+ kms on them to get any grip.

The RX3 isnt generally driven on the road - except for road testing and runs through to my engine builder in Palmerston North.

As mentioned - they track shockingly on the road - and will follow any rut or camber change.

If these are going to be put on a daily driver - or only driver - I would recommend 2 sets of rims and tyres - road and track

-

1

1

-

-

Alex - you mentioned a concern about oils in the V6

Mazda are now recommending their golden oil - in their motors in NZ (as you would expect them to do

)

)However the local parts guys were saying that through Aussie and NZ - they have seen a huge reduction in the number of warranty related issues - by going to the oil - from the locally branded "Mazda" oil - which I think may have been a Castrol/BP brew.

Perhaps something to think about.....

We are running this in the MX5

-

Had a stunning outing last time out with getting the RX3 into the low 1:21s at Manfeild

Had a couple of issues - with a sticky starter solenoid - on a brand new starter motor!, and a plastic bush on the ball end of the shifter breaking - resulting on the gearbox overshifting and jamming in 3rd gear.

Hopefully the times might come down again now that the new tyres have finally got in the country

-

8

8

-

-

Try Ultimate Mazda in Tauranga - they are one few dealers I've come across that the guys know Rotarys - the Wellington Dealers dont have the knowledge in my experience anymore

-

electronic distributors dont use ballast resistors or ballast coils, only points distributors use ballast resistors and ballast coils

yes ballast resistors are for the increased cranking voltage etc, but the ignition coils are different,

you have 2 coil types, ballast ignition coils and non ballast ignition coils, as the ohms etc are different

you need to check what coils you have, you should be using non ballast with electronic distributor

pretty sure gt40's are non ballast coil, but check the specifications

also wiring, you can not run the same power to the leading and trailing power wires,

as the leading and trailing timing will not be separate and you wont be able to set the timing up correctly and car will not run correctly

you need to use a diode in between the power going from leading to trailing, this is a must

I'm not too sure on your story here....

Why cant you run the power to both coils from the same feeder - its effectively the earth that is switching and triggering the coils - via the igniters or points. So having both power sources common is what the factory do in run mode (not start)

The factory setup - for the RX3 - and points ignition - separates the feeders - and this appears to be to allow the leading to bypass the ballast resistor on cranking - no doubt to give a fatter spark.

We have run the RX3 in both "factory" and direct common cable and it makes no real difference.

The only place we have run an additional diode - is on the alternator wiring - as the RX3 was converted to a late model alternator - and a diode is required to drop the voltage on the sense wire to trigger the alternator.

I think this was to ensure that there is sufficient voltage drop to trigger the charging circuit - due to the battery being in the boot more than anything else.

Same for ballast resistor coils versus non ballast resistor - on the RX3 we run MSD Blaster coils - which have to run ballast resistors (PITA as the MSD Ballasts are a unique resistance) - with a electronic dissy.

The engine will quite happily fire to 10000+RPM - so unsure why you cant run either. Only thing to be sure is that you dont overheat the coils by not running a ballast on a ballast coil - or be prepared to change them once every now and then.

-

1

1

-

-

Not too sure about the High Pressure pump - driving into a low pressure regulator.

When the previous owner of my Bronco ditched the stock EFI - and swapped to a carbie setup - this is what they did - left the EFI system intact - just regulated and with a return line back to the tank.

The Bosch EFI pump died in my opinion prematurely because of this.

If you wanted the flow - and are using a hi pressure pump to deliver volume - I'd be looking for a better hi-flow low pressure pump

-

Holley red may not need a regulator for a standard Mazda Nikki - but you do want an accurately controlled fuel pressure with an IDA - hence why Holley Red with external regulator.

Only issue we have had with the Holley - is like most pumps they dont like sitting with Avgas in them - the Avgas absorbs water - and causes the Holley pump vanes to rust - and then sieze.

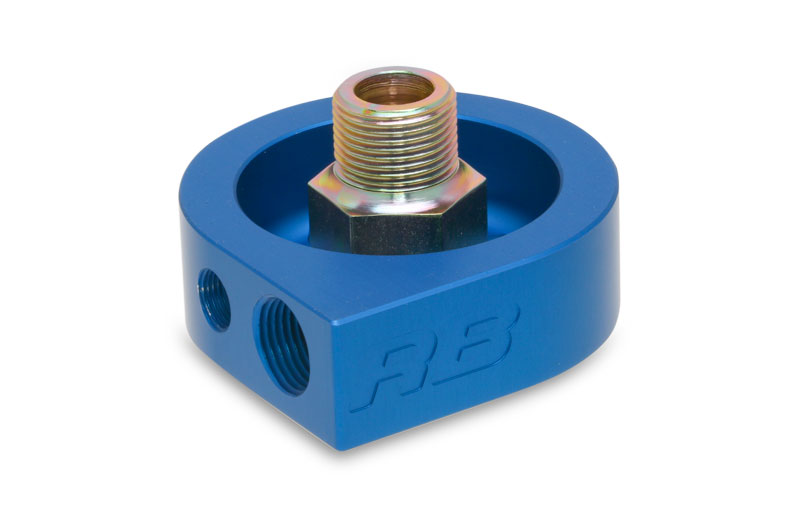

I havent had an issue with sandwich plates - either in terms of leaking or accuracy - on the PP we use the original oil sender position for the pressure light sender - and sandwich block for the pressure and temp senders.

-

There was some discussion regarding Holley fuel pumps - and not to use them.....

The "standard" setup for a carbie fed performance engine is a Holley Red pump - and a Holley Blue regulator - its been that way since I got into rotarys.

Its what is quite happily feeding my 12APP

Racing Beat also recommend the Facet pumps - and we have used these in stock and street ported engines.

The Facet is similar in size to the stock fuel pumps - so is a good fit in the stock fuel pump location - where the physical size of the holley means relocating fuel lines

So I'd recommend staying with a Holley setup - if you have the room.

Only thing to watch out for - the regulators DONT like being fed from a right angled T piece - so I would recommend always feeding straight off the fuel line

-

1: I think the gasket set should have o-rings to seal these

2: As mentioned above there are 2 threaded holes on the back plate - one is water - one is oil. The usual way to tidy this up - and leave a hole for an oil pressure light is to use a sandwich plate between the back plate and the oil filter pedestal.

Also gives you an additional take off for oil temperature

Racing Beats one.....

You can machine one out of ali bar - or talk to Jeff at Precision Engineering in Auckland - I would assume he will do one.

-

Manfeild 1:21.20

RX3 over the weekend

-

The FB is US only - I think its the S3 - LHD only - with the unique to the US Dash

To the the rest of the world the S1/S2/S3 RX7 is a SA22C

The displacement for the engines are:

10A - 60 cubic inches 982cc

12A - 70 cubic inches 1146cc

13B - 80 cubic inches 1308cc

In NZ - Motorsport apply a 1.8 multiplier to NA rotary engines so

10A = 1768cc

12A = 2062cc

13B = 2354cc

The FIA internationally apply a 1.5 multiplier to NZ rotary engines - however MNZ wont adapt this

Forced induction engines have an additional 1.7 multiplier applied

12A = 3505cc

13B = 4002cc

Yearly registration for these cars would be $287.75

-

1

1

-

-

The FB is US only - I think its the S3 - LHD only - with the unique to the US Dash

To the the rest of the world the S1/S2/S3 RX7 is a SA22C

The displacement for the engines are:

10A - 60 cubic inches 982cc

12A - 70 cubic inches 1146cc

13B - 80 cubic inches 1308cc

In NZ - Motorsport apply a 1.8 multiplier to NA rotary engines so

10A = 1768cc

-

In Wellington we have a sprints series that has been running for many years. The series classes are engine capacity based - and whether the car is modified or stock. The RX3 is in class M3 - modified between 1800cc and 2500cc. NA 12As and 13Bs fit in this class. The main competition is from other rotors and E30 M325i BMWs.

-

-

-

Its been a busy couple of weeks trying to get everything sorted on the front end.

The bumper is now shortened and sorted.

Sunny day - so time to get the car out of the shed.

The two things we were waiting to arrive in the country were these ally tube air intakes to replace the middle headlights - these are quite nice - and give a 4 inch diameter intake - which we need both middle headlights for the air box

The other was the correct fitting kit for the electric fan - and a fan controller

The old - small fan is at least now on the radiator - which my give us some additional cooling.

Next up is dyno time in a couple of weeks.

Still need to sort out the air box - and get the fan controller fitted

-

5

5

-

-

- Popular Post

- Popular Post

Well it got its first outing - but not without drama beforehand

Got the engine in - and running - and then we noticed a water leak from behind the water pump....

When I had shaved the waterpump housing - I didnt think about the waterpump plate itself - and it had causing the whole lot not to sit nicely - so back out with the pump - and apply more grinder - all sorted.

Road tested the car - and found it would idle afterwards - the needle valve had been that modified - it had fallen out in transit.

The day at the track was pretty uneventful - I wasnt as fast as I was hoping to get - I clocked a PB in the car at 1:22:34 - and got the class win by around 1 sec - so its wasnt all bad.

The clutch is a pig - and I yet to master getting the car off the line cleanly.

The engine temperatures were still too high - so we need to do so work with the aero into the radiator, and I suspect the car is running lean on wide open throttle - so the next outing will be to get it on a dyno.

Anyway photo time.

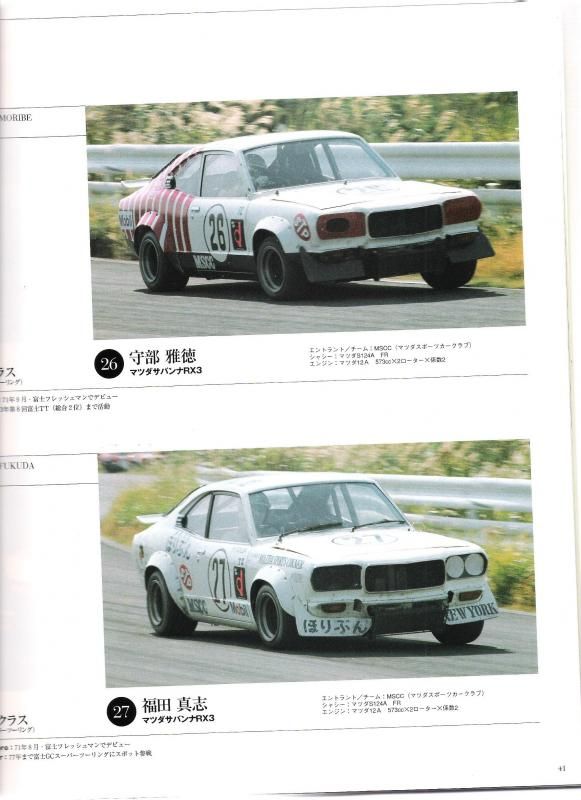

With the changes in radiator and oil cooler positions its time to take the car back to the future - and fit a 1972 style race front to the car.

I suspect for the early races in '72 the aerodynamic addons for the "new" Savanna were scavenged from the Capella (RX2), and the Rotary Coupe (R100), as for '73 the cars got a full width spoiler

Heres the look we looking for...

So heres what it looks like ....

Looks like I will need to modify a bumper - or use my fiberglass one, if I want to hang my front rego plate somewhere

-

12

12

-

Pick the car carefully - the biggest problem with old school cars is the underlying structure - on a 20+ year old car - what is actual state of the structural points of the car that you cant see - A pillars - Firewall etc.

Fit the newest seatbelts you can

Make sure the seats are structurally sound - some of the early reclining seats had locking mechanisms only on one side or non at all - get seats that have headrests - to ensure neck is supported

West German and Scandinavian manufacturers would be a better bet than most others

-

2

2

-

-

After a bit of a mission the engine is now sitting in position

As usual there were some challenges - the water pump neck is a S4 RX7 one - which normally are plastic - fortunately I brought an aluminum after market one - as it sat too tall - and needed cutting a welding to sort out.

We are racing in a couple of weekends - so its gonna be a bit of a marathon run once the new oil cooler lines are built.

-

1

1

-

-

Well its been a frustrating few weeks - after the drama with getting the right clutch - and the right sized flywheel - nothing much else could go wrong - right?

So we went to install the engine again - and the bell-housing was wrong - the single dizzy engines run a different stud pattern to the twin dizzy engines.

I tracked down a suitable bell housing - so we were all go - except as the bell housing was unknown - I thought it would be a good idea to replace the gearbox input shaft seal - so order a new one down.

The flywheel was still away getting balanced - so we took the opportunity to get the motor in the hole and rebuild the front part of the exhaust to match up with the 12A headers.

The seal arrived - went to fit it - groundhog day - the seal was too small for the bellhousing - WTF. It would seem that a previous owner had machined the seal to take a 44mm seal rather than the factory 38mm - and the shaft size was too big as well - so down to the seal shop to see what we could source - time to order a seal - as none in stock.

So last weekend was spent fabricating rather than getting the engine fully installed.....

So the 12A air cleaner has been modified for the RX3 - the carbie sits back further - so the air cleaner was hitting the brake fluid reservoir . We have to use the 12A assembly, as the Carbon Fibre one from the hits the bonnet - as the inlet manifold is taller.

The water pump housing was welded up - to remove the bypass around the thermostat - standard RX race modification - and a excess water line removed

The radiator had its heater feeder welded in - PWR had supplied an non heater unit - but shipped over the feeder pipe - top service from them.

The intake manifold needed a vacuum take off welded on for the brake booster.

Some Pictures...

Relocated Oil Cooler

Tea Cups fitted

So now we hurry up and wait for the flywheel to come back from the balancers, and the seal to arrive in.......

-

5

5

-

Rotary piner thread.

in General Car Chat

Posted

The old rims were 15 x 7 Performance wheels - which I think were around +10ish, and these sat inside the guards fine.

The car ran 10mm spacers at the front - and I'm not quite sure whether this was to stop rubbing on the strut/caliper or just to increase the front track.