Vertigo

-

Posts

58 -

Joined

-

Last visited

Content Type

Forums

Downloads

Events

Gallery

Posts posted by Vertigo

-

-

Im wondering if the power wiring has intermittent resistance, causing the sense wire to see a voltage drop and tell the alternator to work harder. Running a new wire to the terminal would help the problem, but not solve the actual cause, if this were the case. There are a few spots which Id like to redo anyway with proper crimping, such as large gauge splices.

-

Im on my third alternator trying to fix this issue. Randomly my alternator will begin putting out 16-17V, the sudden spike of which will reset my Megasquirt CPU, killing the engine until key is cycled. There isnt anything special about my wiring, though it is custom so of course I could have cocked something up here. The main +ve cable goes straight to the battery terminal, and the sense wire goes to the starter motor +ve cable, to take advantage of its low resistance. Standard SLIG connector. The only thing I can think of is that the IG wire is fed from the main relay, so constantly energized.

Any ideas?

-

On 27/04/2020 at 02:27, Yowzer said:

10-20psi hot, is that at idle? Coz that seems pretty low already.

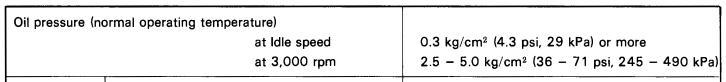

Yea, at idle. With revs it goes up to 40's or so. Heard its fine for a 4AGE. Also, running a turbo on it with no restricter, and Im reading the pressure at the oil filter after a relocation. I should move it to the stock location on the side of the block, tbh.

Heres what the service manual states.

-

Id prefer it to be an ignition cut, as its more immediate. Its more about preventing as much engine damage a possible, than anything else.

-

Hiya. Thinking about doing this. Seems like a relay triggered by an aftermarket oil pressure switch would work, but then I realized that there is no oil pressure when the engine isnt running. But there should be at least some during cranking - would it be enough? This is a 4AGZE that produces about 30-50psi when running cold, about 10-20psi when running hot. Id like it set to cut out when pressure drops below 5psi.

-

Lol found the cause of my low boost!

-

2

2

-

-

Yea thats what I figure too. Ill be searching for exhaust leaks for the time being. Pretty sure the turbo is A-ok.

-

Unsure, but looks factory EVO to me.

-

Hey, dredging this up again.

Ive totally sealed the intake now, convinced theres no more problem there. The idle control valve blockoff plate needed sealing, and a few other minor leaks. This has raised my boost up to a max of about 6.5psi. Still getting bubbling through the turbo oil drain when static testing, but only sometimes, which is odd, and when it does, I hear air escaping through the PCV outlet, or when that is capped off, the dip stick tube. Perhaps a turbo tear down is in order...

Its either that, or the turbine not spinning up enough. Ive had issues with the internal wastegate not closing quite enough. I tightened the actuator rod up as much as I could, and that solved low boost issues last time. Ill try that again, but Im wondering if the exhaust housing is cracked and leaking pressure. Or possibly other pre-turbo exhaust leaks. All things to consider, I guess. Is cracking around the wastegate port common on TD05's?

-

1

1

-

-

On 30/03/2019 at 15:49, Yowzer said:

Unless you're running something crazy high powered, your oil pressure should be quite significantly higher than your boost pressure anyway so there shouldn't be air leakage into the oil supply while running

Not the high pressure supply - the drain passages.

-

After some reading around, Im pretty convinced that the amount of leakage Im witnessing is normal, and in fact helps prevent oil leakage into the housings.

-

Yo. Im sorting out a few boost leaks, and one of them is between the compressor housing and the turbos internal oil passages. With a tester attached to the turbo inlet and the rest of the intake piping capped off (disconnected from the engine), I can see oil being pushed through the turbo drain into the sump (I have a transparent hose, so can easily see this). This is a TD05HR.

Is this normal? Or do I have a problem?

-

Thanks for that.

-

Hi guys. Do you absolutely have to go through NZTA to order registration plates? Just wondering if I can skip that and make my own (with legit registration matched to my car, of course). Would like something less tall and radiator restrictive. If it was made to look like the real thing, would there be any dramas?

-

Ended up solving it by ditching the vacuum bleeder and using the pedal to create pressure instead. No more air bubbles, now goes into gear. Still using the longer slave rod, though. I know the best solution will be to space out the pivot, but tbh I would rather avoid taking the gearbox off! Another day.

-

Thanks guys. I made various lengths of rod out of old head bolts - some improved the feel, and I actually got it into reverse, but I could feel the car wanting to roll backwards when letting off the brake, so it's almost there, but not quite. Doesn't want to go into any forward gear at all.

Going to have to adjust the pivot, space it out. That requires dropping the gearbox, which really sucks.

-

Hey. Ive installed a thin and lightweight flywheel in my MR2. Its definitely a 4AGE flywheel, but is about 10mm thinner than the factory unit. Ive bolted it up and throw the gearbox on my turbo engine and bolted the whole thing in, but upon bleeding my clutch lines I find that the slave cylinder actuator rod is not engaging the clutch at all. There is slop in the clutch fork - I can push it forward until it finally makes contact with the clutch, and at that point there is a 10mm gap between the fork and the rod.

Obviously I could take the engine/gearbox out again and throw on a factory flywheel, but there has to be a way to get this working.

Any ideas, gents?

-

Hi guys. Over the past 8 years Ive gotten progressively deeper into FI, to the point now where I have wired a complete custom system, run via Megasquirt, and learned a lot along the way. Any questions, ask away.

-

Im honestly running out of possible explanations, so Im willing to entertain that possibility! Everything looks like it should work.

Ill attempt it again, this time in the C56, when I swap engines. And Ill attempt to break it in a bit. Fingers crossed.

-

The clutch thickness is pretty much the same as the old one that did work. Hmm.

I mock fitted the clutch inside an old C50 I have lying around, and measured the distance from the bellhousing lip to the flywheel gear ring with the clutch fully disengaged (so, sitting on the release bearing), and came out to 16mm. If at all possible, can someone check this for me with a working clutch? Curious if its different.

-

Ill check that with an old clutch I have sitting around that definitely fits - thanks.

-

Could you elaborate on the offset to the fingers of the pressure plate, and how that could cause problems?

-

This happened a few years ago, and when it was apparent that it wasnt going to work, we took it off and put the original clutch back in.

It is a heavy duty clutch, sourced to go in the turbo project, but because the non-clutch parts came from a few different cars, and some werent known at all, there was some guess work involved.

The engine is a 4AGZE smallport from either an AE92 or AE101.

The gearbox is the C52 that came with the AW11.

The clutch is a 212mm unit, as is the flywheel. The shop asked what engine etc it was for, and so put the kit together with that in mind, including release bearing.

Toyota NZ tells me there are two sizes of bearing - 74.15mm and 83.8mm. Its possible the release bearing that was provided was not correct for the application.

-

Cool. And to make up the lines with fittings appropriate for an AW11 and pressure tested, Id contact ENZED or some similar shop? Recommendations?

Prosport oil pressure gauge damaged?

in Tech Talk

Posted

Hi all. Ive just redone the power side wiring of my car. New relay panel and all. All three of my pod gauges draw from the same power wires. When I tested, I had forgotten to pin the ground for the gauges, and they didnt function obviously. When I figure out the issue, the AFR and boost gauges began working again, and the oil pressure gauge turned on and did its sweep, but then ramped to 100psi and stays there, even with the car off. No touching of the sense wire to the sender unit terminal or battery ground seems to result in any change.

Whats the default behaviour of these? I would expect it should show zero psi with the sense wire disconnected, but could be wrong. I suspect the gauge may have failed. What could be wrong?