Stroker

-

Posts

14 -

Joined

-

Last visited

Posts posted by Stroker

-

-

- Popular Post

- Popular Post

-

12

12

-

-

On 15/09/2021 at 20:39, EpochNZ said:

Cripes! Will be interesting to see where that ends up.

On 15/09/2021 at 20:34, ThePog said:Interesting find for sure! I was lead to believe that the 2.8's were replaced with the 2.9 engine mid 1988, so technically it should have a 2.9 engine in it. Mind you, it could have been built in 1988 but first sold/reg 1989.

I probably have most of the mechanical spare parts you'll need to get it back on the road should you buy it.

Unfortunately I'm up in Auckland

Unfortunately I'm up in Auckland

-

My 2cents worth and just a thought.... Changing to a none factory engine is going to require a full VIN re-certification. Potentially can be expensive.

What about the 2.0 DOHC engine that the latter sierra's came out with? https://www.trademe.co.nz/a/motors/car-parts-accessories/ford/engines/listing/3237936053?bof=qjIgXifk

Has better potential than the pinto as they are available 16 valve heads and/or increase capacity to the 2.3L. Both would however require importing the parts.

Also the MT75 or the auto they come with should be cheaper than a type 9 box.

The big plus is they bolt straight in, no dicking around adapting parts and no re-cert required.

-

1

1

-

-

Just for reference, my vacuum unit uses 4 x 1200w vacuum motors that I have in parallel, wired in 2 x pairs. That way I only run the single pair when testing low valve lifts. With 4 going it's just enough on a hot day to achieve 28in vacuum on my 2.8 v6 heads at peak lift. Something else to be aware of is heat, the vacuum motors usually require airflow over them for cooling. So in vacuum they tend to get hot quite quickly. That's one reason I use a air bypass setup to adjust my test pressure, that way it increases the airflow for the vac motors.

Also my flowbench flows a max of 247cfm@10in.

-

2

2

-

1

1

-

-

53 minutes ago, ajg193 said:

Stm pro looks like a nice piece of kit. But again, if the firmware isn't great you could be in for a harder than ideal time

Probably the main issue with the firmware is some OEM trigger setups aren't supported yet. Apart from that it's regularly upgraded and evolving quite well. Works well for my N/A street needs, at 1/3 the cost of a Link Atom.

-

14 hours ago, gibbon said:

Fair enough, I'm looking at Speeduino stuff but holding off til I find an option with a suitable case for a start. Some of it is just a bit TOO bare-bones

There are a few options for a fully assembled Speeduino. You could try one of these https://www.everythingfuelinjection.com/store/

-

I'm keen to see how this turns out. I'd love to make my flowbench less manually dependent.

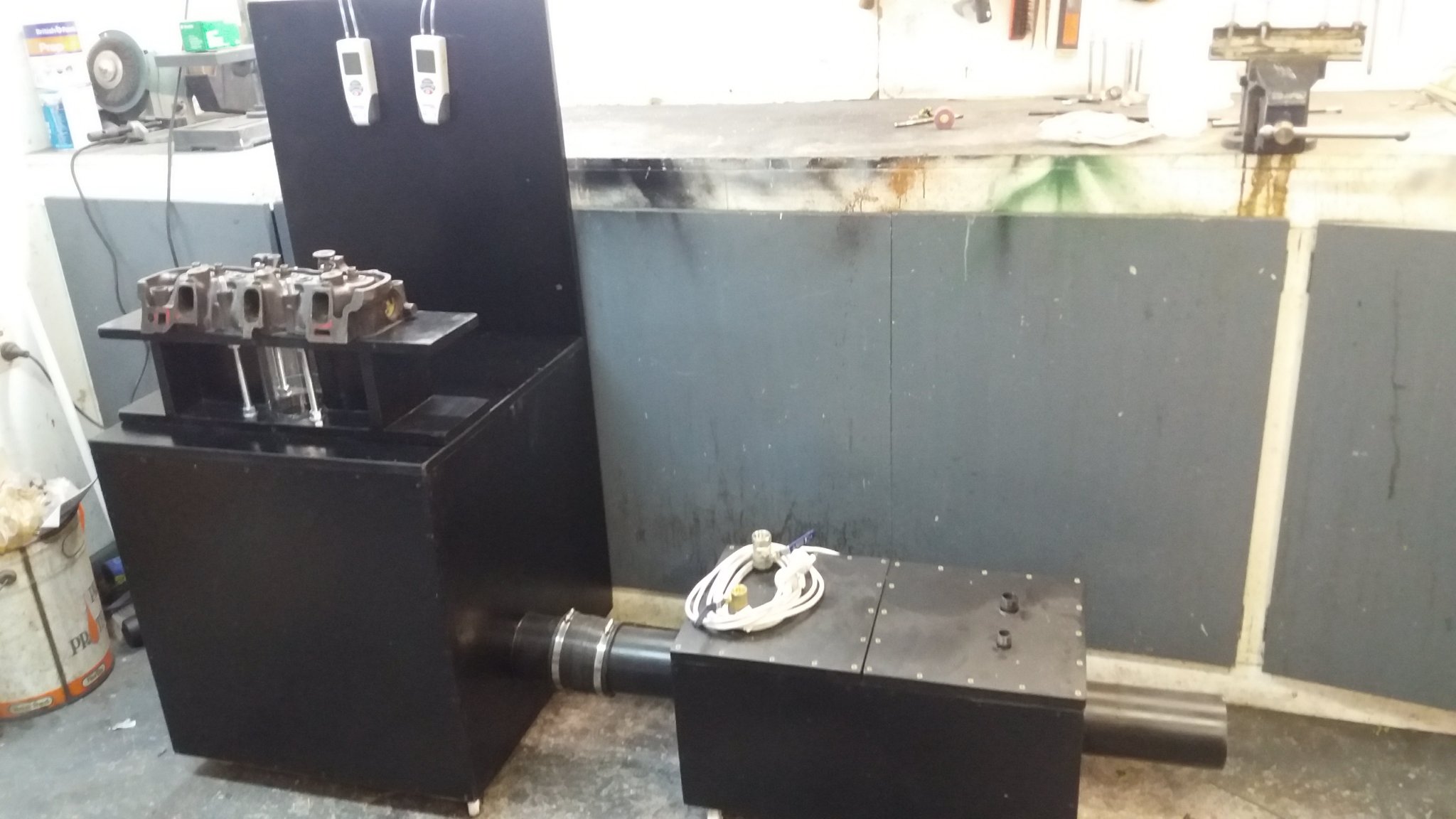

I built my flow bench a couple of years ago. I based mine on this design. http://dtec.net.au/Flowbench Design Guide.htm

But used a couple of cheap Ebay digital manometers for measuring pressures. I downloaded a spreadsheet that had all calculations done for head flowing. I just had to enter the pressures in manually and I could print a graph from that. Very low tech.

I use 4 vacuum motors in mine which is just enough to flow my Ford 2.8 heads at 28" so I suspect you'll need a lot more than a single vacuum motor for your 1NZFE head.

My flowbench is ugly but works and is repeatable. Great tool and fun to build and learn from.

8 hours ago, Roman said:

If your test shows that the head flows way better than your manifold does. Then there's hardly any point being a fuss pot over the state of the head.I've found that even with a low flowing inlet runner, improving the head flow usually gives an increase of flow at the valve with the manifold attached. It's just a smaller increase than the bare head. You will always get a decrease in flow to the valve with a inlet manifold attached, no matter how well the manifold flows.

-

1

1

-

1

1

-

-

8 hours ago, EpochNZ said:

-

1

1

-

-

- Popular Post

I thought I was the only clown in NZ with a liking for the Sierra Estates

Mines a Mk2 Sierra 2.8 4x4 Ghia Estate.

-

10

10

Looking for a K-Jetronic expert mechanic in Auckland

in General Car Chat

Posted

Being a digital WUR surely it'll be just a case of mapping the WUR to your engines needs. I looked at these digital WUR years ago when I was shagging around with the K-Jet on the 2.8 Sierra. They looked the dogs nuts at the time.

So yes you are going to need a pressure gauge and for the cost I would install a wideband O2sensor with gauge. With my Sierra I installed a Innovate O2 sensor with gauge and also the Innovate MTX-D gauge. That let me data log AFR/RPM/Vacuum. You then could tune from the data logs or on the fly with a laptop in your case.

I have a pressure gauge I used for the K-jet and I'm in Auckland if you're stuck.

Well I had no choose at the time because the standard K-jet was completely out of whack with my heavily modified engine. I got there in the end but it took a lot of research, time and effort.