Monsta01

-

Posts

79 -

Joined

-

Last visited

Posts posted by Monsta01

-

-

Cheers for the luck mate, it's a long term sort of thing I'm only on a budget because of saving for a wedding so every now and again I can sneak the cash my way instead of to the wedding and plead ignorance haha after the wedding I will have more to play with so I can set myself up with parts even until such time and then go from there

-

Yeah stil an l16 with 9.3:1 static compression to me fine for a few psi only, I just like the idea of twin carb supercharger, I'm not fussed that it may take time or whatever I am driving this as it is at the moment everyone always says go with the tried and true but if everyone always did that we would never learn how to do new things, I am a mechanic by trade, I have access to welders and all the tooling so I can make things as I need to I understand the tried and true is easiest but I would like to look into this, if I can't do it well then I won't but no harm in looking at it, cheers for everyone's answers

-

So I understand about a draw through being a lot easier I do but I am running twin carbs at the moment, a supercharger on this would be really sweet running low boost no intercooler or anything like that, as far as I can see running low boost the carbs should be okay, you need as in the BMW link I posted a different float bowl top which is connected to the inlet and this gives you equal pressure in the float bowl so it doesn't blow fuel out, then u need a rising rate fuel pressure Reg that will keep the fuel at 2.5 or 3 psi above boost pressure then they should work but I wanted to know if anyone had done it or seen it done for the purposes of jetting and stuff like that as when you read boosting through these carbs people say to run modulator rings and other says to use a turbo emulsion tube and all this jazz I would hate to spend the money and then not be able to get it to run well as I'm on a tight budget for this

-

Im seeking help here brfore i decide to do anything, has one done or seen done in person nd know the ins and outs of supercharging using twin dellorto carbs? I have searched the net for sources of info but nothing really more turboing and thats mostly on vws, just want some ideas here are some images of one i have seen

https://www.bmw2002faq.com/gallery/album/493-twin-carb-supercharger-conversion/

-

Hey mate nah it was algood just went and went was 2 or so years old then judt while driving went bang,mine was out of warranty hence buying the cheaper option haha

-

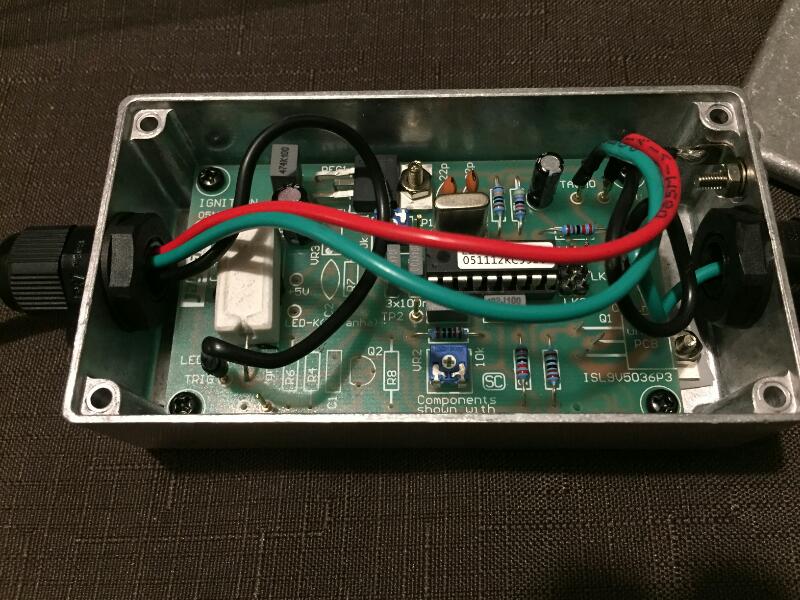

Because the msd had a built in adjustable rev limiter i decided it would be fun to try and make my own since the msd was gone now, i got a frequency relay module from jaycar yet again and it has the ability to shift a relay when its either going up to or coming down from a certain point which you can adjust using any sort of input ie a wheel speed sensor to have a speed related something happen or to trigger a shift light etc so i decided to use it and wire it so that when it got to the rev limit point i wanted it switched the relay and essentially earthed the wire from the points meaning the coil doesnt fire until the revs drop back down thus making a rev limiter,if anybody wants to know how i can help in my discussion thread

-

3

3

-

-

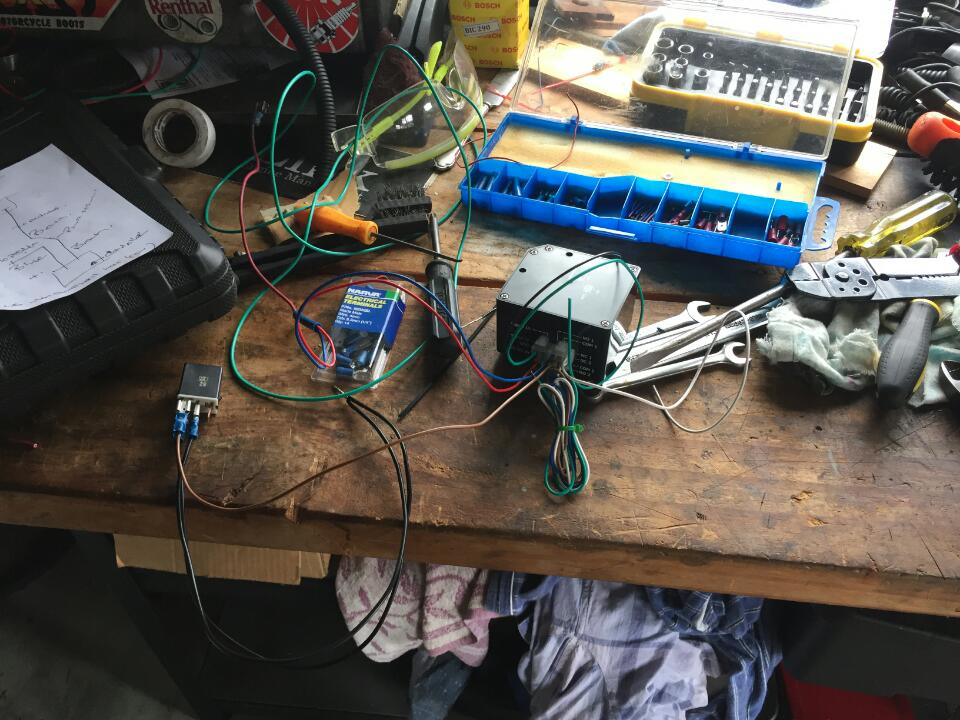

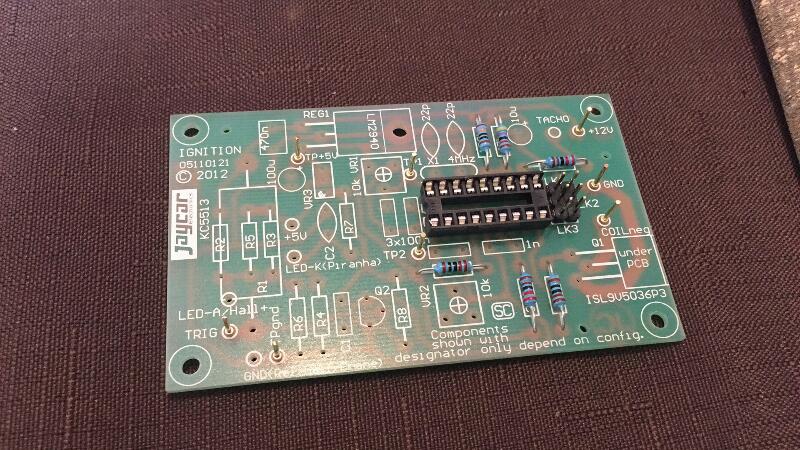

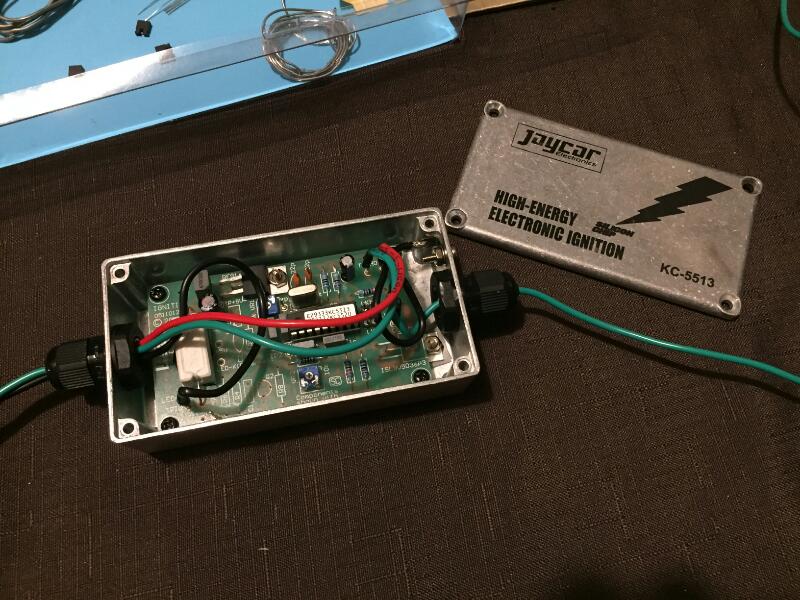

No updates for a while here just been trying to get out and drive and enjoy the car, a few weeks ago me and my brother and father all went for a drive in our own cars, we were on back country roads and speeding along, about 120 kms and my carlet out the biggest backfire ever,then nothing no power just nothing, luckily my dad hadsome small and i mean tiny wires in his car that we mwnaged to get me home, my 300 odd dollar msd had shit its pants and i had no spark. As you can imagine i was pretty pissed off about the msd so i looked into buying another but couldnt justify costs, so i went looking for alternative options, i found at jaycar an electronic ignition module, essentially doing the same as the msd but minus the capacitors, it was in kit form but was only 67 dollars so i decided to jump at it and have a go to build it myself.

It took me a few hours and a few coffees to keep me interested but it was done, i installedit the next weekend and the car started and ran awesome, once played with all the settings on it and adjusting the dwell and my timing the car was running better than it ever did on the msdso heres a fewpics.

-

Hey man can you pm some detailed pics of the carbs and the new tops etc? Seriously considering doing this to my L16 but dont want to waste money cheers mate this thing is so cool do ou know how much power you putting out? Or never got thst far? Wat about tuning of the carbs did you need anything special like ive heard of modulator rings and turbo emulsion tubes?

-

This engine as it is has been run for well over 2 years with absolutely no issues, i understand now after yesrs of research that is what you should do with these engines but as yet it hasnt proved necessary, if i was to get cam tower spacers now and fit them the lash pads would literally need to be about an inch thick so im trying to find a solution without needing to modify another head, i was thinking that if i got the correct lash caps it possibly could fix my problem as the cam would be pushing on the valves at a better angle and may give less lift at the valve than it currently is meaning that it may give me the clearance i need

-

did you alter cam timing to suit machined head ?

Most definitely yes played with it alot with degree wheel and dti set up and doing the maths alot so as to get the optimum timing

-

For start both cams are regrinds, the head was built with the original regrind from Franklin cams , the new regrind is from Auckland cams and has more lift but not much at all, yes they ground the head to bring the cam closer to the valve train to fix geometry but now with new regrind it's up the shit

-

Sorry for the spelling im on a tablet laying down and its hard to type lol uhm i dont have any pictures but tomorrow i can draw something up to exlain it better

-

So guys i hope somrone can give me some idea here, datsun L16 engine were talking, when the engine was built the head builders skimmed 40 thou and then the cam got a grind from franklin cams, when thebuilder got it back they gad done 2mm oversized valves and 3 angle valve grind, they set up the cam and the clearances were rediculous so tgey skimmed 40 thou from the top side of the head to bring the cam closer to the valve essentially then it was ok, now since this i have a new slightly larger but more aggresive overlap and duration cam ground for the engine, i tried installing it and when setting the valve clearance they were way off or the adjustment screw was wound way out so the base circle is very undercut, when i tried turning the camshaft though i got coil bind on the inner valve Spring noe these are springs thst came with original cam good for alot more lift than i have and my spring installed height is correct, can anyone help me here? Just want to know if i can run this cam, on these engines you can change the lash pad thickness to make it so your clearances can be set but the machine shop didnt do this obviously, if inwere to change them now wouldni be able to grt the camshaft to work? I reslly want this cam in!

-

I understand it is getting hot in the float bowls also and getting a heat shield is something im working on, i kind of want to go electric fuel pump just so i can rid the mechanical pump from the engine bay but do you guys not think its worth it? Cheers

-

Meremere drag strip

16.78 at 80.1 mph, unsure 60ft, Monsta01, modified datsun 160j sss, street tyres

-

2

2

-

-

Hi guys looking for advice, at the drag day before xmas last year when it got really hot my car stalled after the runs, it has since done it to me once or twice sitting in traffic then going to take off, im thinking that it is vapour lock so want to go from my medhanical pump and fuel lines running close to engine to electric pump and braided fuel lines in the hope to keep heat away a bit, what is your guys edperience with stuff like this? The car and engine is a datsun 160j with an l16 so its twin dhla carbs with aftermarket extractors (not wrapped) non crossflow cheers for any help

-

Hey mate loving then build, sweet car and im a datsun man myself, as far as carb tuning goes i would say if you can get some cheap or free try a slightly richer emulsion tube even a .14 may solve your problem but if not try a.5 and see what works

-

1

1

-

-

Cool as look forward to hearing what he does and what hp it pulls

-

I would stick with 36 chokes aswell for more low down torque just try changing the mains and go from there

-

I would honestly say i think the main jet is too big air correcter sounds ok but smaller mainbwould be my try, not alot though, a big bore and high comp 1275 would run 38 chokes but if u havebchoked down to 36 you will get a better bottom end but mains i think are slightly too. Large

-

Firstly im not sure if they dyno themselves but talk to palmside auto they do jets and parts, secondky what size main jet are you running? I would expect somewhere in the range of a 145 or so? If youre running bigger than that i would say that may be your problem, the pump jet is just that for accelerating and the idle jet is purely for the progression phase so at cruise you are using the main jet, does it have any stutters or flat spots?

-

I will start with my Datsun , it's got an L16 engine, rebuilt bottom end to factory spec, the head is skimmed 40 thou and has 2mm oversized valves and a three angle valve cut, stage 3 Franklin camshaft, twin dellorto dhla 40 carbs on a port matched manifold, extractors and full 2 inch exhaust system, msd Cdi ignition system, makes about 70kw at the wheels and ran a 16.78 quarter mile at 80mph

-

2

2

-

-

Hey guys I'm always curious about this kind of thing I'd love to know what sort of engines you are running, what mods and then what sort of power or drag times or both that they make bcoz that interests me immensely

-

1

1

-

-

Hey guys just wondering what a pair of dellorto dhla 48s would be worth? With no jets just venturis and chokes? I have them btw i am selling but not sure how much worth

Twin carb supercharger

in General Car Chat

Posted

Het guys thanks for all your input i researched and researched about this setup and itnis still something i think i will look into in the future but for now since saving for a wedding means money is a bit tight for the car i have opted to just build myself another block for my engine a 1700 stroker, i have purchased all the parts to do so now and will give me a power and torque increase for now untill i can spare the money and time to do a Supercharger setup, so this is not goodbye to the idea jut for now its on hold! Thanks all though for input it is much appreciated.