-

Posts

2188 -

Joined

-

Last visited

Posts posted by Adoom

-

-

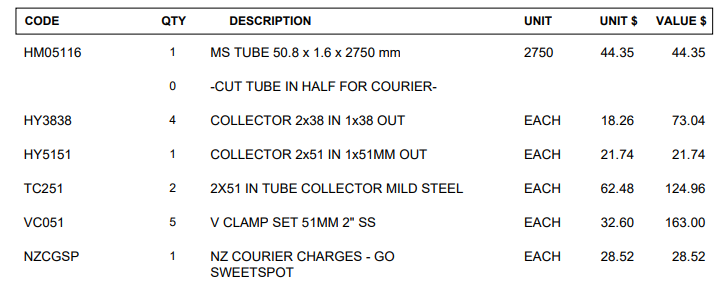

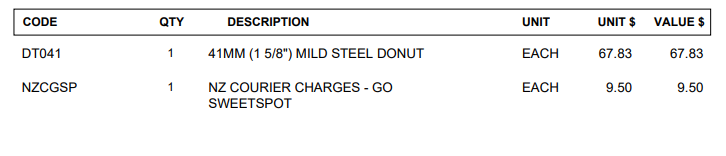

Never bought any 90deg. But here are some old quotes to give you an idea. They are kinda old, 2020 and 2019.

Just email them and be all "how much is?"

-

1

1

-

-

I've used Autobend a few times for exhaust bits. They do deal with the pooblik. They have the catalogs online, but you need to email them for prices, then they email you an invoice and your bits turn up with the courier.

-

3

3

-

-

- Popular Post

- Popular Post

Working out how to machine the steering arm with some aluminium I had. Much easier to machine than a big block of steel, that I don't have.

I used the bandsaw to cut out that corner, much faster than turning it all to swarf.

I had plans to machine the balljoint taper(the hole on the left) using the lathe. As it is now, I should be able to fit it in the big 4 jaw to center the hole.

But I just tried a practice taper in some scrap and it seems real close, but the finish is not as smooth as the oem hole which I don't think is good enough.

I'd buy a taper reamer, but OMFG they are expensive. Also, as far as I can accurately measure, the taper is 4 degrees(per side) and I cannot find anything that size.

I think for the steel version, I'll get it profile cut as a rectangle, so I have my reference surfaces, but also cut out most of the material I need to remove. So I don't have to spend hours at the bandsaw cutting the outline, I would just need to cut some tabs.

-

13

13

-

I used a bad word yesterday when I broke my last 12mm carbide endmill by trying to take too deep of a cut climb milling into aluminium with the quill extended waaaaay out.

-

1

1

-

1

1

-

-

2 minutes ago, sr2 said:

I've only got one piece of tooling, it's a fly cutter that looks like it's never been used.

I have the same fly cutter. It must be the standard tool that comes with a RF30 clone.

Mine is MT3. I assume your's might be too. I made a drawbar out of std 20mm threaded rod. Something high tensile would have been better, it's a bit bendy when I hit it with the hammer to break loose.

I get my tooling from Ali or BangGood if some youtuber machinist says it's not shit. I cannot afford legit brand name tools.

I got a 19 piece ER32 collett set to hold my endmills. It's okay, not great... just okay. The holder was not usable out of the box, there was a 'lip' inside the retaining nut that prevented it from clamping the collett?! I chucked it in the lathe and removed the lip, now it works good. The accuracy is good enough for what I do. But the only other option is to spend big money on a brand name collett set.

My mill came with boxes of endmills, but most of them are blunt/broken. I looked into getting them sharpened and it's just not economical.

I'm sure I made some posts about my mill ages ago...

-

1

1

-

-

- Popular Post

- Popular Post

I ended up replacing my sacrificial anode with a sheet of steel. More surface area and easier to wipe the scum off.

Pretty much all the rust is gone, except for the bit in the middle due to the size of my container.

A lot of the paint came off too. I did no scrubbing, just shot it with the water blaster.

Most of the grease came off(it turned white) but probably due to soaking for days in the washing soda that's used to make the electrolyte solution.

I got mine from Mitre10 ages ago but I can't find it anymore, it's this stuff.

-

13

13

-

- Popular Post

- Popular Post

The subframe has a bit of surface rust. And some oily greasy stuff that the water blaster didn't shift.

This is a bit of a no-effort experiment. I know the electrolysis will remove the rust and after a few days it may lift some of the paint(from previous experience). But I want to see if it will lift any of the oily stuff.

I could do with a deeper container... but where can I get one that's as cheap as a $18 warehouse paddling pool?

An IBC tank with the top cut off would be good, but I can't find anything nearby and I also don't want to spend ~$100

-

16

16

-

I use ISO 220... But my lathe is decades old and that is what is recommended.

It's super tacky and 'stringy', kinda like honey.

I got it here: https://www.trademe.co.nz/a/motors/car-parts-accessories/oil-additives/listing/3641562467

I need a lot, the carriage is the(large) reservoir and it automatically pumps onto the ways when you move the carriage.

-

The gaskets are interchangeable, I'm pretty sure the cam cover is the same, at least with the non-COP ones.

I guess I'll take a punt that it's okay. -

Sooo I'm looking at a cga3de engine at pick a part. It seems to have done ~150000km. I pulled off the cam cover and it looks nice and clean.

I suspect the cam cover gasket has been replaced because the screws have been butchered by someone using the wrong screwdriver and there is excessive silicone.

The front of the head looks nice and clean but the front of the block and transmission are real oily and filthy.

What might be the source of all the oil? Just a leaking cam cover gasket and they only cleaned the front of the head when they replaced it?

-

- Popular Post

- Popular Post

-

2 hours ago, kicker said:

Hey, not sure how many bits you still need but I met a guy this weekend who is clearing out a large amount of Mini parts, he's done a number of restorations over the years so has collected a lot, he's based in Whanganui

Imagine a mini. Now remove the front subframe with the engine and suspension. Also remove just the steering rack. Now remove the rear subframe and suspension. Also remove the exhaust. Take off the bonnet, but leave the hinges. Remove the wiper mechanism, but leave the bracket and wiper arms. Remove the front seats. Remove the boot lid. Remove the fuel tank but leave the strap and bolts. Remove the rear lights. Remove the front grill. Remove the doors, but leave the inside handles and door card.

All the stuff that's left, I need all of that, except the actual shell of course.

I may be interested, but I'd prefer to get a bulk lot with most of the bits I need. If I buy a bit here and a bit there, it will end up costing a shitload.-

1

1

-

2

2

-

-

Whittled the old front panel off.

Realised later I should have also removed those flanges on the front of the inner wings.... the new front panel already has them. But that will make it easier to flatten out the damage in the front of the drivers inner wing.

No photo, but I offered up the new panel. Bloody hell the edges are sharp. Cut my hand.

-

9

9

-

-

I'd use paint stripper. The stuff from super cheap that has dichloromethane in the ingredients is safe for aluminium. Stinks terribly, I think it has ammonia in it. Works great for removing carbon from pistons and valves and stuff without scratching too. Don't get it on your skin, even a tiny little bit will start to burn in a few seconds.

-

4

4

-

-

- Popular Post

- Popular Post

-

-

- Popular Post

- Popular Post

-

- Popular Post

- Popular Post

Other side. And same double plating over rusty metal.

I think the sill has been replaced before. That hole at the top looks like it was caused by a chisel. And the flange on the left has been partially cut off.

Clamping a bit of copper behind the holes so I can weld them without making bigger holes.

And fixed all the cuts and nicks. I also used the vacuum and compressed air to clean out the sill and the inside of the crossmember that goes across the car.

-

14

14

-

2 hours ago, yoeddynz said:

Yeah you can have it for that. It's a long block - no dizzy, alternator or inlet manifold etc (the dizzy/alt went straight onto our Cg13 and we've kept the inlet/tb for spares. It was bolted to an auto so no flywheel.

But it is a genuine low mileage, unopened engine.

Edit: pics of it in this thread when I was trying to convince @dmulally to see the light for his imp...

I think I'll pass. It would have been interesting to build an engine, but with the added cost of bearings and gaskets, I'll be better off just getting a good CGA3DE.

Thanks for the offer.

-

1

1

-

-

9 hours ago, fuzzy-hair-man said:

You'll need to take the head off, the blocks are the same so the difference in stroke is made up by the conrods on the cg10de being longer, you'd need to remove the cga3de pistons from thier rods and put the cg10de pistons on. Probably want to double check wrist pin to piston top height is the same as cg13de and cg10de pistons.

I put cg10de pistons in my new engine.

The cg13de bearings are graded so that makes bearings swapping over probably less likely...

Yeh, I did further thinking after going to bed. That all makes sense.

According to the workshop manuals I have.......

CG10 rod is ~9mm longer. CGA3 and CG13 uses the same rod length.

All of the engines seem to have the same size valves.

CGA3 and CG13 share the same cam.

I'm assuming the combustion chamber volumes are the same for all engines and the pistons have more/less dish to get the compression ratio to 9.5:1

Assuming the CG10 pistons are flat top(google images seem to back this up), my rough mathculations for the longer stroke give me a compression ratio of 11.8:1

Which seems a bit high since I'd like to boost it.

Which seems a bit high since I'd like to boost it.

I suppose I could chuck the pistons in the lathe and dish them myself.

-

16 minutes ago, yoeddynz said:

@Adoom we still have the low mileage cg10de sitting ere that came out of Minky. I think it's done 140,000. It was a fine runner and well serived before we pulled it out. I was just going to throw it up on TM or marketplace and didn't think you might be interested in it as its a 1.0. But maybe it could be useful? I have no idea what they are worth either.

Problem being its here..quite far away.

Hmmm. Hypothetically I could put my CGA3DE crank in it and make a 1311cc engine. I think I should be able to do that without removing the head and costing myself a top end gasket set and head bolt set. But I might need different crank bearings unless I'm super lucky and they are the same.

If it was cheap, like $100 and @Nominal would be so kind as to pick it up and take it over the water with him for beers/booze/high fives. I'd be into it if you are. I can collect it from Nominal where ever he is in Wellington.

2 minutes ago, Nominal said:I'll be down in Brightwater next weekend, bring home a small truck....

-

My CGA3DE is from a Z10 cube. It's a dizzy version, so in theory I could use the cams in a CG13DE. But then, are the cams in a dizzy/non-dizzy CGA3 the same?

Looking at Trademe and PickAPart, for Z10 and K11's I've not actually come across any COP/non-dizzy models so far. I think I came across something saying all JDM CG engines were dizzy versions and the non-dizzy was a Euro market. Could be wrong though. Most of the ones in NZ will be JDM as far as I know. No idea what you guys got in 'straya.Most of the info I've come across on these engines seems to be people on forums who are guessing or repeating what another person has said... who may also have been guessing.

-

1

1

-

-

11 hours ago, fuzzy-hair-man said:

yoeddynz sent me to check out your thread...

The dizzy engines really aren't too bad in my experience, I've had no failures of dizzy or throttle body (touch wood) and depending how far you're going to push it the dizzy seems up to the task.

I also used to think the cg10de small gearbox would be nice but my cg13de box fits and frankly I think the ratios are pretty ideal except 1st is too short but the others are pretty good on 10 inch wheels 3,200rpm at 100km/hr and 3,500? at 110km/hr... I forget but it's perfectly happy sitting at 110km for hours on end and not loud or uncomfortable.

I've a sparse build thread here:

https://www.theminiforum.co.uk/forums/topic/253043-spot-the-micra-mini/#

Feel free to ask any questions or message etc.

BTW pretty sure you can use the cga3de crank in a cg13de to make a stroker then there's options for pistons out to 73.4mm to almost get a 1400cc

Thanks, I'll have a look at your thread.

I worked out, by counting revolutions, my gearbox is 3.915:1. So on paper... or excel, I came up with similar rpm at 100kph on 10" wheels to you. 3240rpm.

I suppose I could get a CG10DE, keep the original pistons, use the CGA crank to get a capacity somewhere between a CG13 and a CGA3, unless that makes the pistons come up above the deck. And the CGA cams...? I've been unable to find any information about differences between the cams in a CG10/CG13/CGA3.

Plans to build a franken engine is a bit scuppered when a full gasket set(from a local supplier) costs >$400!!! And a CGA3 or CG13 longblock assembly from the engine importers is <$400.

I did notice that AliExpress has full gasket sets for under $100.... but does that automatically make them shit...? It's about what I would expect to pay for a gasket set from RockAuto but the US never got the CG engine.

-

1

1

-

-

Oh, and the height adjusting rod is too short for some tools. I ran an m5 tap down the hole and replaced it with a locktited in long fully threaded machine screw with a nylock nut and the original knurled adjuster.

Ade Swash on youtube has some good ML7 videos.

(Custom)(Large).thumb.jpg.de70df1cb8757d8ad78f4e5474e3ead8.jpg)

Aubs minibike hotrod

in Two Wheels

Posted

Any idea what range you might get out of it?