Taistorm

Members-

Posts

2056 -

Joined

-

Last visited

-

Days Won

1

Everything posted by Taistorm

-

I'm pretty sure the box that's in this is out of an early l200. Will just run it for now until it goes bang then look for a km132 5 speed (I know a guy in the wops that reckons he's got a couple, but probably wants decent money for them as they're rather hard to come by here in Perth). Most of the boxes available here are wideblock so no dice. Don't really want to go down the route of a custom bellhousing or adaptor plate to try keep this on the cheap for now. Good to know about the engine mounts though, is that the complete mounts or just the rubber or block mount? And yes the factory ecu is there. The wiring and most of the various plugs to the sensors are broken or brittle as so I'd rather pin out new plugs and wiring than patch up what's there.

-

Tai's 1976 Chrysler/Mitsubishi Galant Goon

Taistorm replied to Taistorm's topic in Projects and Build Ups

Couldn't help myself.. The mounts off the 4g52 were pretty close so figured I'd just mock them up and and hoist it in to see how far off everything is. Mounts need to come up slightly to drop the engine a little and also shift about 20-30mm back. I'll probably chop up and modify the block mounts (or make new ones). And clearance at the firewall. Will need to reroute the brake line as it's too close to the cas and will need more clearance. Sump clearance. May need to trim the crossmember a little but might get away with it. I'll try get engine mounts sorted in the next couple weeks then there probably won't be any progress as our daughter is due in Feb. See how we go anyway. Chur- 7 replies

-

- 10

-

-

Yeah that's what I had thought. To my understanding it had more aggressive cams, 510cc injectors,bigger turbo and a better mapped ecu. Not a worry though as it was a bit of a gamble when I brought the engine haha. I'm not doing anything wild with it though so it should be all good for the build.

-

Any advice on the conversion please let me know. Cheers.

-

Tai's 1976 Chrysler/Mitsubishi Galant Goon

Taistorm replied to Taistorm's topic in Projects and Build Ups

Decided to do some more work on this on new years day. Wasn't sure on what spec the vr4 engine was so decided to see what we were dealing with. Was hoping it was a evo 0 engine so was looking for the tell tales nut unfortunately it fell short, no biggy though. ECI Multi on the intake didn't quite look right, turns out someone had just stuck a plate over the 'cyclone' lettering. Also the turbo is a td05h 14b, as opposed to the bigger 16g. Going off the ecu part number it looks to be from a 1988 vr4. Stripped off the bolt ons and had a look down the ports, no bad signs so far. Timing belt and idlers look to have been done but the water pump is pretty crusty on the inside. Decided to mock up the turbo flipped around for a laugh - Will probably just make up a basic log style manifold for this to keep costs down. Then ripped it off and put on some alloy tape to seal it up for now. Check out the repairs on this old manifold from previous cracks... Later on in the evening I decided to rip the 4g52 out from the bay. Got her all setup and on stands in the front so the engine crane would clear the lcas. Check out the inside of the bellhousing.. The bloke who swapped the 4g52 didn't sort out the right size clutch/flywheel setup and the outside of the clutch pressure plate has been wearing on the inside of the bellhousing - it hasn't driven really at all but when I brought it and test drove it around the parking lot I knew something wasn't right but didn't expect this haha. And here's where we're at. Does anyone know where I can source original plugs/connectors for the engine wiring loom, most of what's on here is old and brittle or broken and I'm keen to repair most of it or even maybe make a new loom entirely. Also if anyone has any suggestions for easy ways to go about the rwd swap please let me know. I have been reading up on project zero g and also a lot of online forums so far. I'll probably be looking at a top thermostat housing delete (to get better clearance at the rear) and run an inline thermostat housing. Have someone modify the inlet manifold to swap the tb to the opposite side. https://oldschool.co.nz/index.php?/topic/88881-tais-1976-galant-goon-discussion/ Chur. -

Tai's 1976 Chrysler/Mitsubishi Galant Goon

Taistorm replied to Taistorm's topic in Projects and Build Ups

Ordered an engine from a local importer months ago, was supposed to arrive late October but the importer had huge delays due to cyclones and customs and only finally had the parts ready for delivery earlier this week. Had a call yesterday saying the truck was on its way! What do we have here? It's a 6 bolt vr4 4g63. Imported over from Thailand with little to no information on it besides that it has done around 140,000kms and it drove about 400km to the place where the importer stripped the car down, also a short running video of it sounding OK. Looks like it has been sitting for a long time, signs of grey silicone all over it, wiring cracking in many places and pretty rough around the edges. Hoisted it into the shed and started stripping off the unnecessary shit today and have a look over it. Definitely lools like the head has been off at some stage and it's pretty clean under the rocker cover. I'm still unsure whether I'll keep this car and carry out the conversion but this arriving before Xmas has given me some motivation. Would be a weapon however if I pull it off.- 7 replies

-

- 12

-

-

Tai's 1976 Chrysler/Mitsubishi Galant Goon

Taistorm replied to Taistorm's topic in Projects and Build Ups

Then after pulling off the wiper motor and having a look under the scuttle panel I found this! Was not happy at all... tbh I felt pretty defeated at this point. Was not keen at all to be needing to remove the windscreen and unpicking the scuttle panel to access this point. Thought about it for a moment then decided to start pulling the dash apart to see if I could access it from the inside. Still a prick to get to but I think I'll persevere with it.- 7 replies

-

- 14

-

-

Tai's 1976 Chrysler/Mitsubishi Galant Goon

Taistorm replied to Taistorm's topic in Projects and Build Ups

After going to a local car meet Orient express yesterday (which was awesome with a huge turnout!) I decided to throw the exhaust manifold back on, hook up the battery and fire it up after sitting for a few months. Then today we had a public holiday so I decided to start pulling it apart and start the prep work for the new donk and assess the rust situation. I was gonna rip the engine out but it didn't have a front lifting eye and I didn't have anything to adapt to suit today so we'll leave it for now. However here's what I uncovered with the rust. Front of the lh sill. Battery box and where the inner tub meets the chassis rail. Rear corner infront of the firewall by the lh guard. Lh strut tower. The front of the chassis rails by the lower radiator support panel. Worse than I was hoping for but still manageable. Also had a few snapped bolts which was a pain in the ass. -

Tai's 1976 Chrysler/Mitsubishi Galant Goon

Taistorm replied to Taistorm's topic in Projects and Build Ups

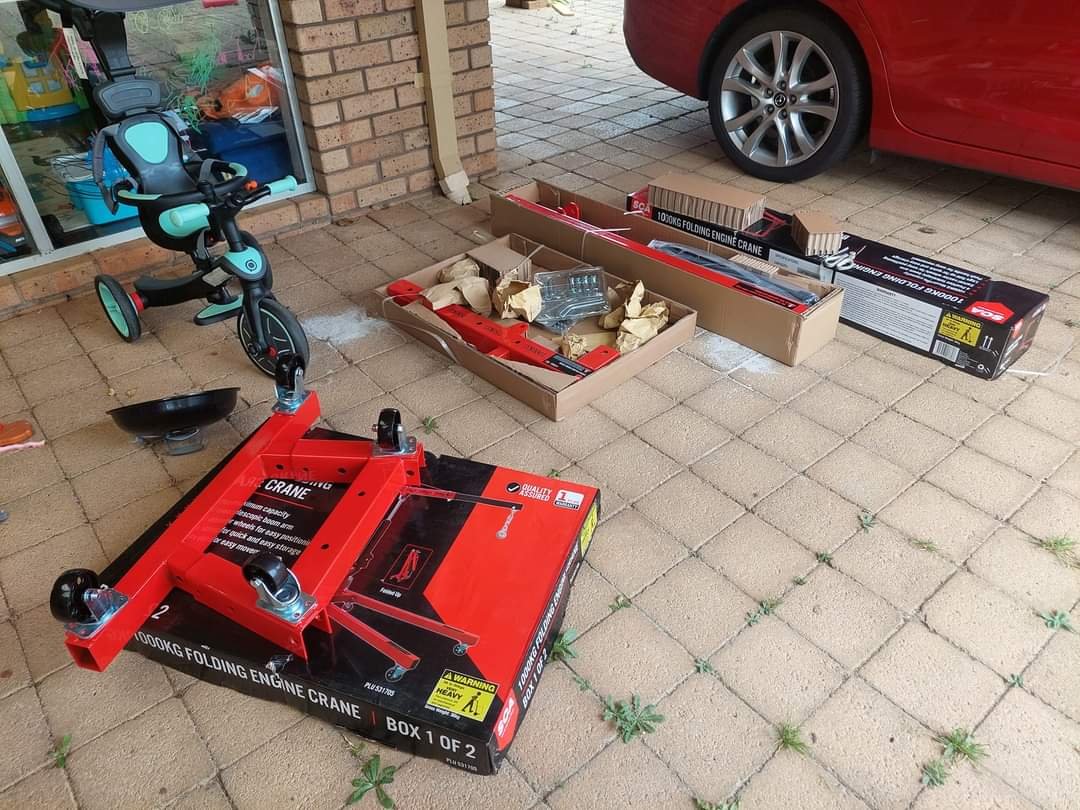

Not a proper update as I haven't been up to much with this yet, have had a lot on and not much spare time. Have been trying to sort parts but really have no luck so far. A couple months ago I got a local exhaust shop to bend a bit of pipe and make a slip join to try marry the 1.6 exhaust to the 2.0 down pipe. The slip join cracked when stretching it out but it wasn't a problem to weld up. Pretty rough for now but should be ok. The exhaust gasket wasn't right and too small and I've had issues trying to find the right size. Also the first muffler was rusted out so I was gonna cut it out and just straight pipe it but I didn't have enough pipe at that stage. However I've since picked this up as it came up on sale... The boy wanted to sort out his bike first though. Must mean the engines coming out soon. Wonder what will be replacing it.... -

Tai's 1976 Chrysler/Mitsubishi Galant Goon

Taistorm replied to Taistorm's topic in Projects and Build Ups

Not a proper update but I have been trying to organise the shed a bit better and picked up some more tools to make my life working on this a bit easier. I'm in the process of changing jobs and my roll cab won't fit in the new work vehicle so now it will be staying at home. I've also picked up a Lincoln 191c multi process welder and a cheap jack and some axle stands (had to fix the family wagon a few weeks ago so got them then). I plan to weld up a solid steel work bench to take up half the back wall, setup a vice etc in the near future. More to do with mitsi, I've put some feelers out for parts and may have some better taillights and some interior bits sorted. Looking to get the front indicator lenses 3d printed as well. If I get time this week I'll take the welder for its maiden voyage and weld up the 2 piece exhaust. Cheers, Tai- 7 replies

-

- 12

-

-

Hey guys, fully forgot about this and didn't end up buying the datsun. Cheers for all the info and pics/vids though. A series definitely can be little weapons! Have picked up a 76 Galant wagon anyway so have thrown up a build thread. Cheers

-

So I've been dormant for a little while with the old Mazda locked up at my parents place in NZ whilst we decided to shift back over to Perth to try and get ahead in life. Picked up an 08 wrx and ran around in that for a bit, sold it about 6 months ago and have been on the hunt for something old again for a bit of a project. Everything seems to get snapped up within hours over here and had missed out on an old TX Gemini, B310 Datsun, AE70 Corolla (amongst a few others) by a hair. Finally stumbled across this for a score from a Mitsi nutter looking to cull his fleet. It's a 1976 Chrysler-Mitsubishi Galant wagon. Believe it was a GL spec 1600 however it has had a 4g62 2000cc and 4 speed out of an l200 swapped into it. It's rough, needs work. Has rust (most of which is pretty minor bar the lower front guards and rear quarters) needs some leaks sorted out and the clutch looked, some electrical gremlins sorted out and then it should be ready for running over the pits to get licenced. Pretty stoked to say the least being in something oldschool again. Plans at this stage is to get it licenced and on the road properly, then thinking about engine swapping and cleaning it up a bit but we'll see what happens (we're trying to renovate our house at the same time and have 1.5yr old so it's just a matter of time and money freeing up). Here's some pics anyway. The arriving home off the tow truck. The boss definitely approves. Chur, Tai

- 7 replies

-

- 42

-

-

-

I meant the hikoki corded grinder! Have had a couple which haven't failed from about 3-5years abuse. Definitely wouldn't use battery powered grinders for heavy use.

-

The milwaukee grinder is pretty handy but I find that you burn through batteries far too quick. Works well for small jobs or on site but if I have access to a power lead, I'd rather use a cord grinder. The Hikoki 125s are pretty sweet and can handle long days of grinding disc abuse.

-

Have used hitachi/hikoki, bosch amd milwaukee 18v. For heavy abuse drilling through thick steel on the daily I wouldn't bother with anything but the milwaukee one. Ugga dugga impact guns go well, the only issue I have sometimes is if they are accidentally out in direct sunlight, the batteries can overheat pretty quickly (obviously be mindful of where you leave them). My 2c.

-

That's pretty awesome bro, reminds of my mates old 1200 coupe which had a similar setup. He ended up switching to efi and running itbs! Initially wanted to try go for an a15 swap but it looks like they're alot harder to get now than when I was last over here. Even the 5 speeds for a series are as rare as hens teeth (there was a local company over east that produced toyota t50 conversion kits as they were easier to get a hold of but even those are costly now). The main reason why I'm considering the parts car is that it had all the bits to manual convert (albeit the trans and hydro clutch setup to suit the L series engine box) and also has the h165 diff and spares to suit with extra displacement. Not really interested in going SR or CA route as it would take far more effort and time (which I don't have with a toddler running around haha) but definitely set on doing a turbo build for fun, not too concerned on how messy it can look. Will probably end up just running log manifolds and a J pipe for ease and see how we go.

-

Hey everyone. Been a bit dormant on here since shifting to Aus but looking to pick up a new project in the coming weeks and seeking a bit of advice from Datsun and Turbo gurus. Looking to pick up a 1979 b310 Datsun Sedan running an a12 and 3 speed auto. The car itself is relatively tidy with minimal rust, had an average paint job years ago and Barry (the old boy who owned it) gave the engine a top end rebuild and replaced most of the ignition bits. Goes pretty well but slow as shit. I've been reading up online and going down the rabbit hole and have been thinking of doing a cheap efi turbo build for a bit better power and hopefully line up bits to manual convert it. Looks like the stock a12 can handle around 120hp pretty comfortably running a bit of boost. However I've also seen a non reg 1979 Stanza (same as the b310 but different spec) come up for a couple grand which has the L16 engine with a 4 speed manual behind it and I'm pretty sure most of the suspension and steering components are a bit beefier and possibly stronger diff and everything is more or less a straight swap. These look to be around 96ish bhp at 113kg as opposed to the 69bhp on the a12 weighing 87kg and would be a bit more torquey. Is there any preference from you guys and whether the A series would be fit enough for a weekend warrior or should I shell out and grab the parts car and swap over the engine and other bits and use that as a base to start with? I'd still want to carry out a basic turbo build but unsure if the l16 is as susceptible to boost (not looking for big numbers or anything if I can achieve around 150bhp without opening up the heart that would be awesome but the L16 in the Stanza is a bit of gamble so i may need to give it a refresh anyway). I'll be attempting to fab up my own manifolds and run a megasquirt or cheap haltech or lower end link to manage the system. Will do some more research into the likes of turbo sizing and such but just getting some ideas on what direction to head in at this stage. I figured as well that I can cruise with the a12 while I mock up and build the setup on the stanza, then when I'm ready crash out the swap. Any advice would be much appreciated. Chur

-

Yeah first thing to look at is blocked fins on the radiator. Unsure what that hose is for/goes to though. Running coolant temp is probably around 90deg. Is it only running hot when loaded up or even at idle?

-

Speedhut are pretty good and affordable. Customisable to however you like as well made in the US.

-

Our old mk5 used to use 1-2L in 10,000km.

-

Long time, no update.. 2 years later... Had a quick steering box heat deflector hammered up then got the car back home in the garage. Sold the recaro seats as they were still a little too wide and had fouling issues when trying to slide and had next to no clearance with the recliner adjuster. Picked up a pair of Daihatsu Mira TRXX seats which were a bit narrower and pretty supportive and some awesome chaps off OS helped me out getting them up from down south. This brings us to early 2021, had to move out of our flat and relocated to a small unit around the corner that had no garage so this went into storage at a family friend's shed up north to hibernate. Next we decided to have a kid so the car had been put on hold a bit longer as priorities changed up. We also were in the process of building a house so funneled our money into the drafting then after wasting thousands of dollars and a decent year the banks no longer wanted to lend us money to build which was lame, so also no spare coin for the car. Now on with early 2022. Due to the above we decided to plan to move back to Aus so we can buy a house and get on the big money to try get ahead. I decided to try sell this even though I knew I'd regret it, had a few people dead keen but no one ended up following through due to various reasons. In hindsight I'm glad it didn't sell even though I won't be around it for a long time. The family friend who had been storing could no longer keep it at theirs so I managed to convince the olds to let me convert part of their firewood shed to secure dry storage for this thing to slumber in. I'm no chippy, nor am I a concreter but gave it a crack. I used only reclaimed timber from around the property, a few lengths of timber that the old boy had milled years ago, old tin roofing iron that was left on the property and left over bits and pieces from odd jobs. Really only needed to buy some nails, screws, and materials for the concreting (which was all mixed in a mixer). None of the shed posts were square and I was truly limited with what I had haha so don't be too harsh on my shed bodge. We had a digger scrape out the bark and dirt and built up shit to reveal the compacted metal that was laid about 10years ago (awesome that it saved me a tonne of work). Filled in the holes with sand and metal to get it semi level. Boxed it up, and prepped it for pouring. Used a bowed piece of timber to try and screed it hahaha rough as guts. Next I build an inner wall to section it off from the wood storage. Rebuilt and added to the rear and side, framed up the front then screwed some iron to it. Made a door frame on some cheap hinges and hung a door that barely had enough clearance for the tiny mazda. Then earlier today we picked up the 50 year old mazda and threw it into its new home. This was all done across the last 1-2 months. It's locked away for the foreseeable future. I'm off to Perth on Tuesday and it looks like I'll probably accept a job in the mines and be starting in a few weeks. Fingers crossed when I'm back in NZ next April I'll be able to drop it off at a shop to continue with the build. We'll see how things go anyway. Thanks for looking. Tai

- 139 replies

-

- 27

-

-

-

Usually just swap them out bro. I've never replaced the bearings besides on a cat skidsteer that had this oddball setup that was grease one side and oil on the other.

-

Another short lived project. Was planning to keep this one as it didn't owe me much as I'm planning to move over to Aus shortly, however my Mazda hadn't sold (which is a good thing) so this was next on the firing line. Sold in a day so maybe I should have listed it for more ! Went off to a super chuffed buyer so that's a good thing. Chur

-

Contact chamberlain auto springs im Christchurch. They make cobra springs and can set them up however you like.

-

DABUZZ'Z 1971 MAZDA CAPELLA RE + New 74 RX4

Taistorm replied to dabuzz's topic in Project Discussion

Awesome progress bro! Looks so good.