-

Posts

17055 -

Joined

-

Last visited

-

Days Won

91

Everything posted by 63Ragtop

-

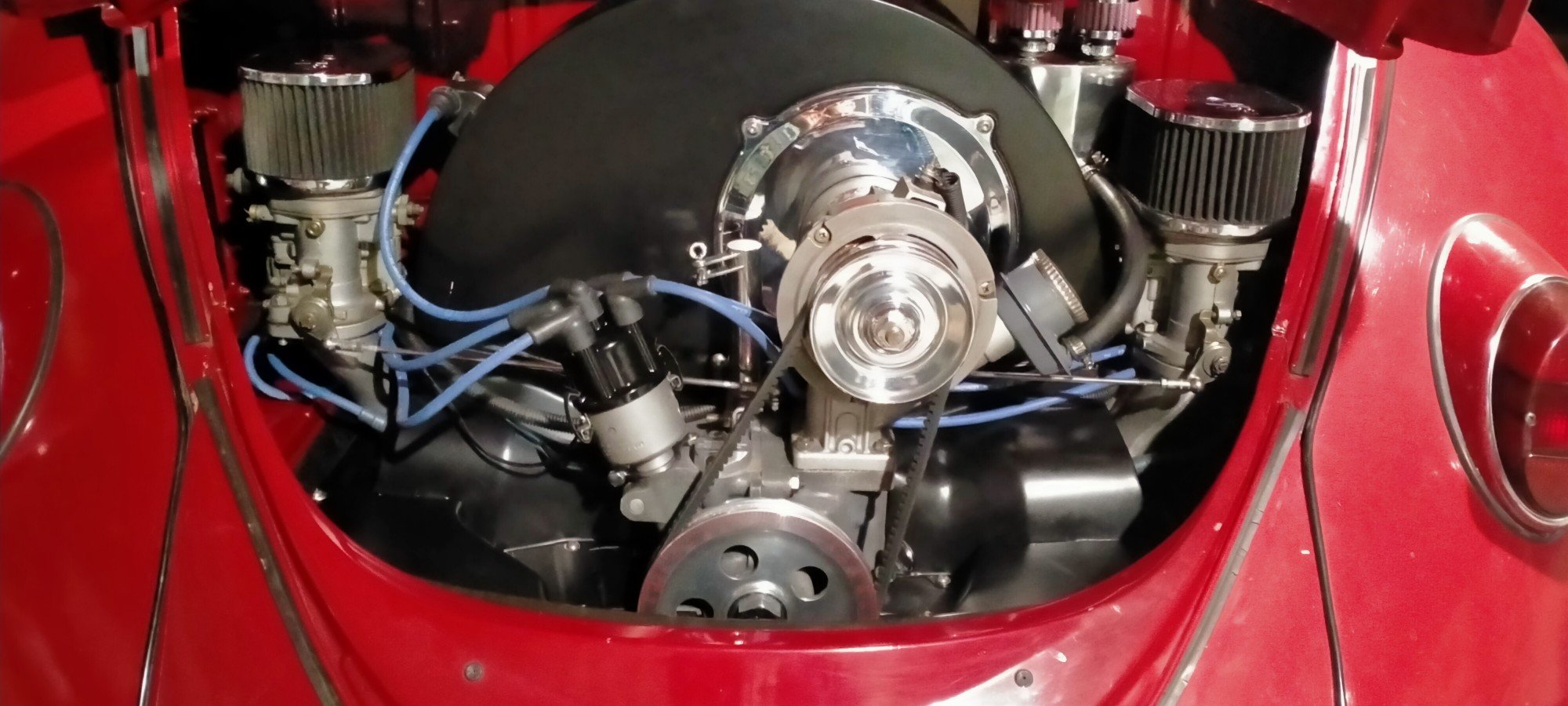

Minor maintenance tasks update. Thought I'd give the air filters a birthday day to protect my newly rebuilt Dells. Cleaning kit is only 40 bucks from ripco/supacrap autos. Stage 1, clean all the nasty. Once dry, stage 2, re-oil and done! Colour match filters. Other thing I've been chasing is this very annoying oil drop from the filler/breather. I wasn't sure exactly were it was getting out from. Pretty sure now it's from the breather hose connection as it's the factory fitting is slightly smaller and doesn't have a barb like the ones I put on the catch can. I had hoped just hooning on the hose clamp would work but no so I'll ad that to the list.

- 254 replies

-

- 10

-

-

Discuss here about Yoeddynz's little Imp project...

63Ragtop replied to yoeddynz's topic in Project Discussion

-

Thanks @Lord Gruntfuttock I don't drive it as much as I use to, but it's just a VW, the corolla of its day and should be used. Future plans include, renew sound system, some kind of headlining which means some work on the sunroof mechanism, new running boards, and I just lost one of my wee hubcap things off my mags. Also a narrow beam, drop spindles and disc brakes would be nice!

-

Always looks better after a wash. And from my favourite angle. Finally got around to changing the oil, really should have been done sooner, there was so much crap in the sump, all that lifter paste. VW's don't really have a sump, or a filter, just a sump plate with a tea strainer around the pick up. Ignore the big square sump in the picture, that's aftermarket and my car is probably to low for such things All was going well until I went to reinstall the tea strainer plate arrangement. The gaskets in the oil change kit have recently gotten at least three times thicker, so now the six little studs are getting very short. Only had just enough engagement, one but had to go sans crush washer. Have continued tuning the carbs, @sluggy suggested cranking the accelerator pumps, so I've been doing a little at a time, everytime it's gets a little better and nicer to drive, idle is very low but very smooth and doesn't stall, just seems weird not having it shake the car at the lights. Mrs even commented on it.

- 254 replies

-

- 22

-

-

-

Fuck that's a sweet set up. Nice work Matty.

-

And a permanent roof tent. Nice work on the interior, huge improvement.

-

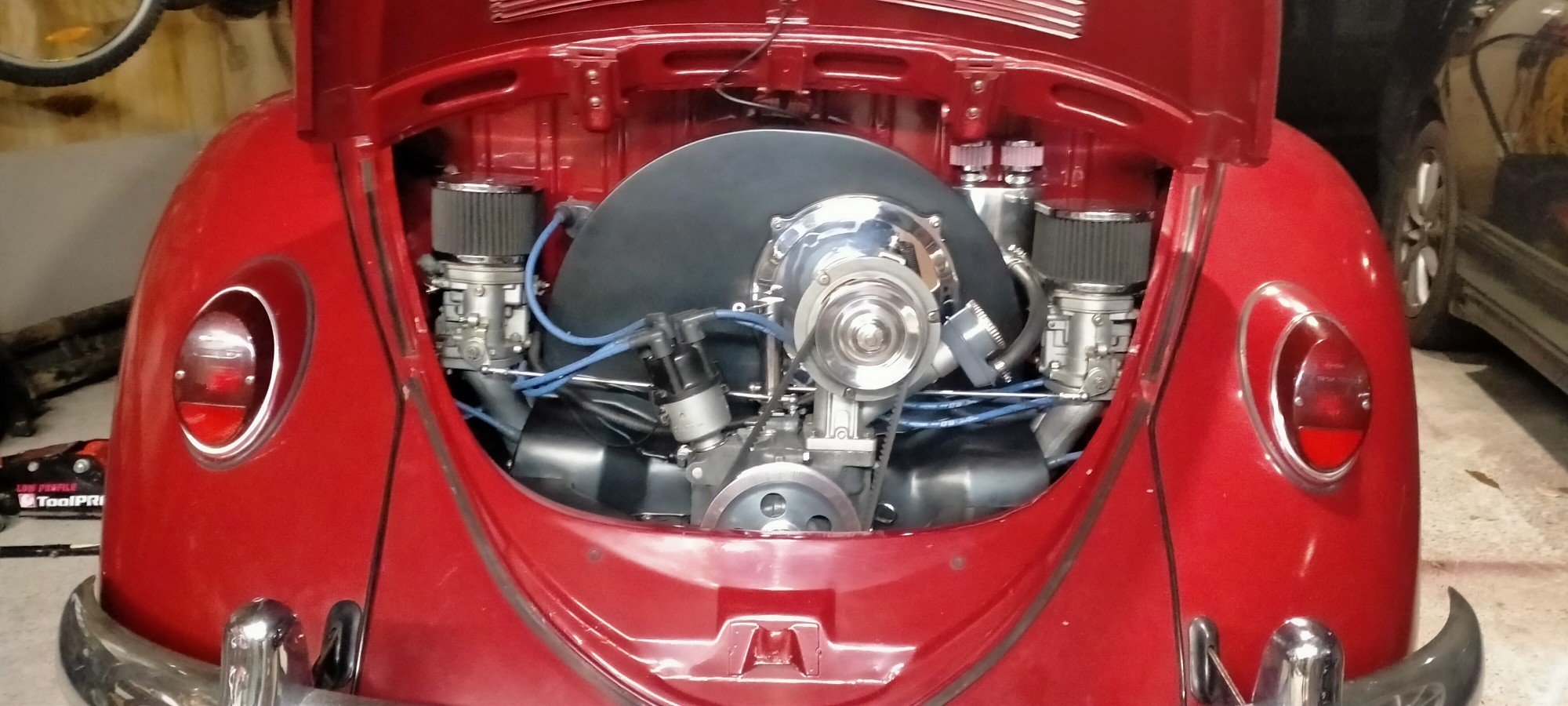

Gentlemen, after a good six months of neglect, general wear and tear I finally had time to service the VW. Living outside had not been kind to some of the so called stainless steel. Was to embarrassed to pop the hoop open at Kumeu. It been driving okay, it runs hard but it's that traffic speed, just puttering along off idle, it just didn't sound right, but fine when accelerating, something was a miss. One of the projects at work is up Silverdale so popped in the see the carb Barrys at Weber specialist, got a complete rebuild kit for the Dells. Alfa Romeo, very fancy, much racing cars. Having been through everything else the carbs are the last thing needing sorted, I don't think sitting for nearly two years on a shelf whilst I built the motor and various other life admin got in the way, helped. Borrowed the ultrasonic cleaner from work and cracked into it about 8:30, Friday night. Fuck there are a lot of very small parts in a 36mm DRLA Dellorto, and I've got two. many hours later and into the early morning I was nearly finished, didn't want to stop half way and forget where something went or lose a tiny jet. Had to stop drinking so I could concentrate! In a very rare occurrence I got to spend nearly all weekend just working on the car and not the house or the yard or visit relatives or anyone. After forgetting to tighten half the screws on the right hand carb, it started and ran pretty good. So took the time to sand back all the rust and polished it all back to a mirror finish, cleaned and wiped everything. No excuse for a ugly engine bay. Carried on adjusting the brakes, always amazes me how much a badly adjusted handbrake affects the overall performance of the old drums, seems to take up a lot of slack in the system. Popped the valve covers and set the rockers and checked the headstuds were tight still. Just need to grease and adjust the front end and actually change the engine oil and the maintenance will be up to date. Continued playing with the carbs, the access windows I put in the rear wheel wells make this easy and actually possible. I'm pretty happy with how's it's running now, so much nicer to drive, smoother, quieter better performance, more responsive. Maybe the tiniest flat spot just off idle, but nothing like the spluttering bullshit I've been driving around. Much nicer at motorway speed, just cruises.

- 254 replies

-

- 30

-

-

- 254 replies

-

- 25

-

-

-

MMMINI'S NEW MINI PROJECT 64 MORRIS MINI MINOR

63Ragtop replied to mmmini's topic in Project Discussion

Congrats on the wof, always fun in a old car. I love the ratty og paint, it's only original once! -

Random slightly cool stuff you built but not worth its own thread, thread

63Ragtop replied to h4nd's topic in Other Projects

Was doing some yard work a couple weeks ago and my cheap tree saws plastic handle feel apart. Whittled this out of a old piece of the house, on Saturday the neighbour who is into his woodworking helped finished it. Came out nice, looks great, fits your hand mean. Could have just bought a new one but this was heaps better.- 1289 replies

-

- 35

-

-

Me brother has a Grange, hsv number. Huge boat of a thing but so gangsta!

-

Kp60nick's D21 kingcab Soon to be Bagged on Cadillac Escalade rims

63Ragtop replied to kp60nick's topic in Other Projects

Awesome bro, no reason needed. Looks like you've been busy indeed! We are starting our Reno at the moment so I feel your pain. -

Have been chipping away at the Dells, turns out several things were a miss. There isn't a lot of adjustment on the DRLAs. I don't have any other jets so it is what it is. One thing I can adjust is the wee nut on the accelerator pump that, this is why is been popping, have wound it and it loads up the little spring and has nearly completely stopped the carbs farts. The other issue was the stumble. It was better but still randomly there, usually after giving it beans. I thought it might have been a kink in the fuel line restricting flow, as above. Picked up some 8mm pipe and wouldn't you know it the tank was full! Better but still fucking about. Spent most of today trying to tune the bastard things, then it would start running like a bag of shit, this is a bit of corrosion behind the acc pump cover. Then I realized what I'd done, the fricking choke was randomly coming on! Once it was behaving itself, I had a go at adjusting the air correction valves, I think they are called, spend ages going back and forwards, using the temperature gun from work it I got the exhausts without 20⁰ of each other. And balancing the left and right carbs. It's idling so nicely now I can hear the camgears and tappets all rattling around. Which has completely transformed it's road manners, it so much smoother and doesn't pop and fart about, hopefully that's all the gremlins sorted, wife says it needs a exorcism!

- 254 replies

-

- 25

-

-

Need to neutralise the acid, I've had the same thing just using vinegar, need to wash it in baking soda or something. I would imagine there is something similar for phosphoric acid?

-

Bubbles, fancy. Thanks.

-

Anyone know a good place to get hard fuel lines in Auk? Need about 6-7 foot for the vw.

-

Kp60nick's D21 kingcab Soon to be Bagged on Cadillac Escalade rims

63Ragtop replied to kp60nick's topic in Other Projects

Just start, enthusiasm will follow! -

Saw this a few years ago on thesamba, dude built the ultimate sleeper vw. Basically got rid of all the factory vw! https://youtu.be/axyN5zUulE4

-

Bought a new dizzy cap, they only seem to make these in shitty terracotta orange now. Gave it a wee paint and installed it with a new rotor. Was better but the stumble was still there when the revs got high, and then sometimes it would stumble all the time, I'd pull over and turn the engine off, and restart. It would be fine again, until you'd rev it to high and, back we go. Borrowed Darrells timing light and set the dizzy to about 30⁰ @ 3000rpm, but still the stumble. Did some deep diving in thesamba about 009 dizzys and the compufire ignition, someone mentioned lube oil for the advance mechanism. Shit I haven't touched it since I installed the compufire over twenty years ago. It's running the best it ever has now! I think that's it, the actual mechanism was getting stuck inside the distributor. I also lined up the engine lid alot better, sits so nice and flush now, on this side at least. Carbs are the next thing, it backfires thru the carbs really bad. It's not nice to drive, it's especially bad when it's cold, more research into 36mm drla dells is needed.

- 254 replies

-

- 20

-

-

Forgot to say, I had to buy this whacking great thing to tighten up the fan nut, hopefully I'll not have to use it again. Got the plug leads off, this fucker got stuck when I dropped the motor out, last time, I think. The old bakelite plugs screw into the leads and this one snapped inside. Darrell the Holden driving westy gave me old set to do some troubleshooting with, only issue is the vw plugs use a spring thing to grip the top of the actual sparkplug, so I had to reinstall the wee nipple thing onto them. Which necessitates removing the plugs as they are so deep in the bowels of the beast. What ballache. Chucked it all back together and did some late night testing (sorry bout dat!) Which seemed okay, but the misfire was back if I gave it Welly( again, sorry) so today I had a look at the distributor cap, also very old, the insides looked a bit corroded, so I gave it a scuff up and now it barely runs at all!! Guess I found the issue!

- 254 replies

-

- 23

-

-

-

So that lasted nearly a week? Was dropping the boy off at work in that's shitty weather Saturday evening, the harbor bridge was closed, the northwestern packed but moving. Luckily just after we got off at Westgate I thought I heard a rattle for a couple seconds. The unmistakable sound of a loose cooling fan. Which is the entire cooling system in a vw. Just as I was having a look at it, this guy and son walks up asks if I'm okay, do you need a ride? I owe that man a beer! You can remove the fan which is mounted to the back of the alternator, but this is easier. The sides are supposed to be flat, I had noticed it before but hoped it was okay. New fan installed. And back in she goes. Seems to run fine again, I did notice a little stumble like it was running low on gas. Bunged a new filter in as it the old one had been in since I finished the resto. Hopefully that is all the bugs out. Edit, it an't the fuel filter. Seems to be when under load. Need to check timing etc, might be the ancient spark plug wires. Not as old as the fan, but easily 20years old.

- 254 replies

-

- 23

-

-

-

Been driving to work the last couple days. It always hated slow traffic, carbs are spitting and hickuping, it wants to rev! No oil puddle! Made some changes to the radius on the bottom of the gauge pod. Should look rad. Been doing lots of reading about the sender end, a million opinions, should have tapped the case for them if I'd thought about it. Full flow, as it's called, allows for a actual oil filter and a good spot for senders. Maybe the new rebuild. Anyway, if it didn't explode sitting in this shit for two days, living the dream!

- 254 replies

-

- 22

-

-

- 254 replies

-

- 23

-

-

So, oil cooler replaced, old valves and springs installed, cleaned everything again, reinstall everything again. 3d printed gauge mount prototype. Plumbing in the other end is going to be fun. And after getting the number 1 and 2 sparkplugs wrong, again. Let's just say, so far, so good.

- 254 replies

-

- 20

-

.jpeg.3d2734e1be46c4b230b2cafddc6c95e6.jpeg)