-

Posts

3263 -

Joined

-

Last visited

-

Days Won

2

Everything posted by kpr

-

I havent done any v8 stuff. but on 4 cylinder 1.6L making around 175hp at engine. this is close to ideal setup , after the collector its 2" then tapers up after the vband to 3" into a glass pack. after that you can get away with more sins. So yeah if you want to get fancy with it, carry on tapering down your collector to 2", run 2" for for a bit, then chuck in a 2" - 2.5" exducer cone with 2.5 inch reso's directly after that, bigger they are the better. some of the small ones dont really do much. think of the reso as the exhaust ending. after that do what you like really. merge into a single 2.5 or 3" and add mufflers till its quiet enough. you might grab a little bit of power off the bottom and in the middle doing it that way. otherwise your original plan will probably work fine

-

reso's /glass packs after headers can actually help power wise, and smooth things out. esp in bottom end.

-

I use this stuff now. is a whole lot cheaper than buying from motorbike shop etc.. https://nzfg.co.nz/product/muffler-packing/ sometimes use a bit of chop as well

-

well it will run like it has a carb at least

-

Have you tired changing the edge they trigger on? Does the toyota setup use a 5v supply? The cherry/zf sensors say they will run off 5v, but they case the odd trigger errot on link, when run on 5v? Are the sensors for the vvti? its not seeing them in the f12 menu?

-

soon as you go cams, most cases its to much for the factory ecu to deal with. unless its an ecu that can be tuned. really need an aftermarket ecu and a good tune to get it all running nice.

-

Some years later, seems i have a solution. if it doesn't break; I ended up making the gearbox better replacing a lot of parts, but was never amazing at high rpm. had to shift pretty slow so didn't grind. recently tried some thinner mt-lv redline oil, in an attempt to get the syncro's to grip some more. Yeah it made it worse over the castrol vmx. After sifting through the internet and finding not much other than the old grind some teeth off the synchro. Found a comment saying something along the lines of; "putting double springs in the selector may help with high rpm changes" The spring being what red arrow is pointing at below. Yeah you cant put 2 in there, but some have a coil spring the sits in the middle of the hub so maybe that's what they meant. After looking how it actually works, rather than just replacing parts. The spring presses up against the little keys in green. they have a raised section that sits in a recess in the selector hub(outer part) Now when you go to change gears the selector hub pushes the 3 keys up against synchro ring, which pushes the synchro ring onto the cone, slowing the gearbox down. Until you put enough pressure on the shifter/selector hub, the selector hub cams over the keys and selects the gear. So having a stronger spring on the keys will put more force on the synchro ring before it trys to select the gear. which means it should slow the gearbox down more before it tries to change gears, cool. Will it work who knows. sifting though my pile of gearbox parts I found some bearing retainer spring clips that would work for 1/2 gears. 3rd/4th found some that would work out of some hilux front hubs I dont have any pictures of what it looked like once i modified it them. but ground them down to similar shape as the factor ones as above, just thicker, so more spring pressure. I ground a few teeth off some of the synchro rings also, but i dont this would have changed things much. All this went into my spare t50, with the best selection of 2nd hand junk i could find. So worse base than the one in the car. Result. It amazingly works, can throw it through the gears at 10k easy, haven't been super rough with it yet, but changing pretty fast no crunches, changes nice. only side effect, is its a bit more notchy selecting gears, but not terrible at all. I even used the same oil that come out of the gearbox in the car, for a fair test.

- 25 replies

-

- 15

-

-

-

from memory it helps with rollsteer

-

na stuff doesnt need that much cooling, especially since your engine is a giant aluminum thing to start with. Also half the time peoples cooling problems, is all the stuff jammed up behind the radiator. if air cant get out, its not going to go through

-

That honda one may work if its steel like it says. is 6 rib but can zing the side off and weld it back on. fd rx7 is actually smaller, 120mm so aftermarket under drive probably wont get me there, if its a thing.

-

My accessories don't agree with 10,000rpm's, trying to track down a big pulley for my p/s pump. needs to be bigger than 150mm diameter. If anyone have a spare moment, to do some measuring on what you got, would be choice. Ideally something with a 4 rib belt. Beams 3sge looks to be 4 rib and big ish looking, but cant find any measurements.

-

my max china rods haven't flown out at 10k rpm yet. probably made in the same factory as all the other cheap rods out there, and some of the not so cheap that are making bank. Like anything from china, roll the dice. some stuff is decent some not so much. Have heard their coilovers are junk.

-

I run the same setup, just link's version of it, on my itb turbo setup. has an afr lookup table to tell the fuel model how much extra fuel with the map. assume haltech does similar. works on na stuff as well, but isnt the go to on more aggressive stuff

-

I'm just saying you can tune perfectly fine without the map sensor, no need to complicate things.

-

The video they done on that itb honda was kinda pointless, as the throttles were too small for it, = vacuum. so they kinda just tuned as normal. does haltech not have a built in baro sensor? In most cases with Itb's, just throw away your map sensor and tune in tps vs rpm.

-

Its pretty hard to tell by those logs. but yeah run it at say 70% throttle. then 100% and see what the difference is. if 70% is same map reading as 100%, means you have no way to tune the last 30% throttle. so will have a rich/lean situation at 70/100 throttle. As above its pretty easy to tune around with tps when you have it setup right.

-

unsure what you are asking. but if its what mode to tune in; If you run out of vacuum before you get close to 100% throttle just tune fuel map in tps. If you have good vac all the way up to 100% throttle can use map. but likely means your throttles are too small also i dunno how haltech does it. but when tuning fuel map in tps, should be able to set the fuel model to baro correction or map. and the actual fuel map in tps. if its an aggressive setup with cams etc, use baro. if mild you can usually get away with map, which will make any idle speed stuff or the likes work easier

-

Hyperblade's KP61 Racecar "KP61R" Discussion

kpr replied to Hyperblade's topic in Project Discussion

100 looks fine to me most things like all the advance through the middle. the point at high rpm where the cam wants to retard , can vary quite a bit depending on intake and exhaust tuning. -

Hyperblade's KP61 Racecar "KP61R" Discussion

kpr replied to Hyperblade's topic in Project Discussion

Also just looking back at your vct/vvti map. seems a bit low. yours should have the 50degree vct pulley. All the ones Ive done like more advance through the middle, pretty much max it out to 50. -

Hyperblade's KP61 Racecar "KP61R" Discussion

kpr replied to Hyperblade's topic in Project Discussion

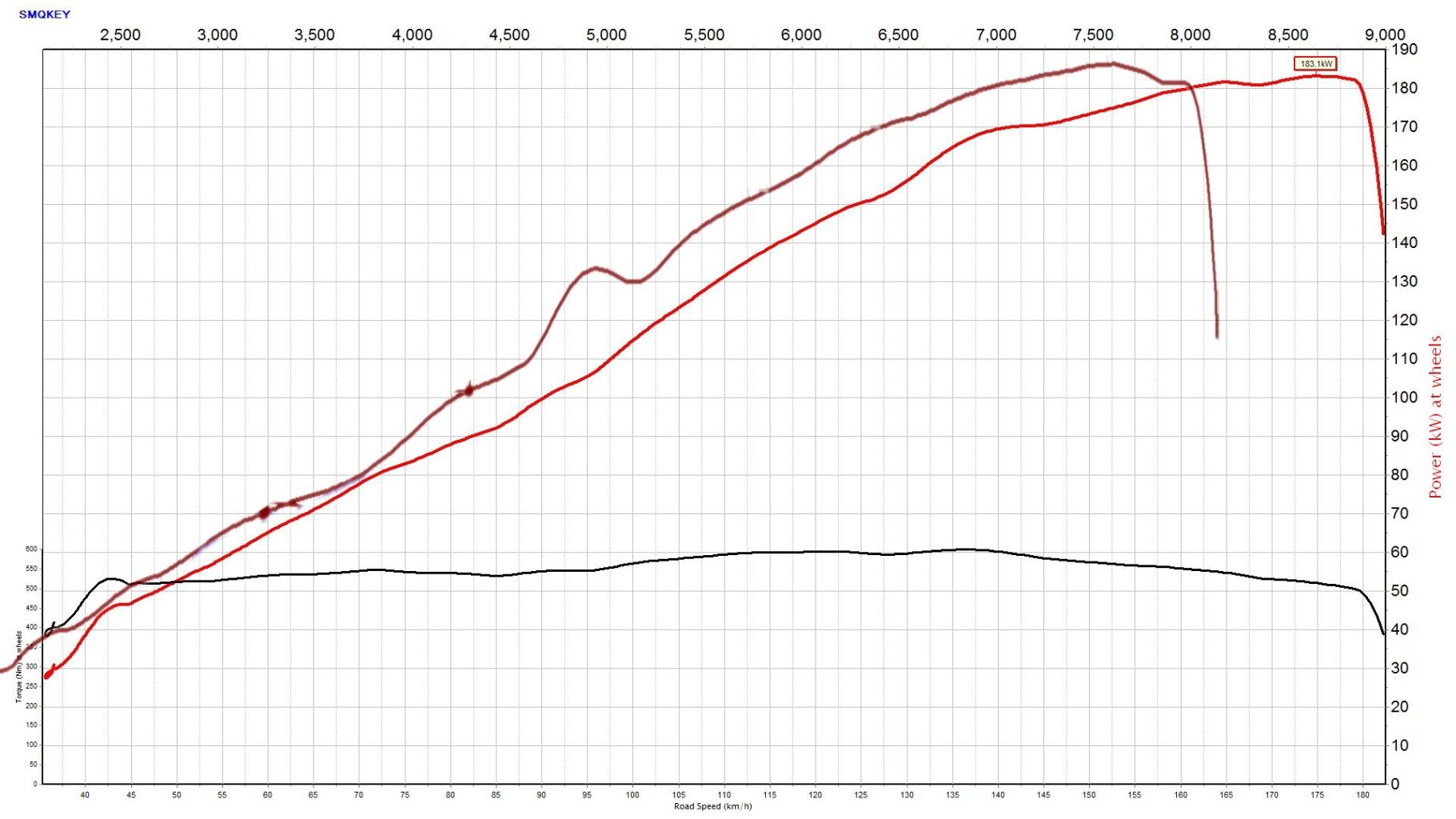

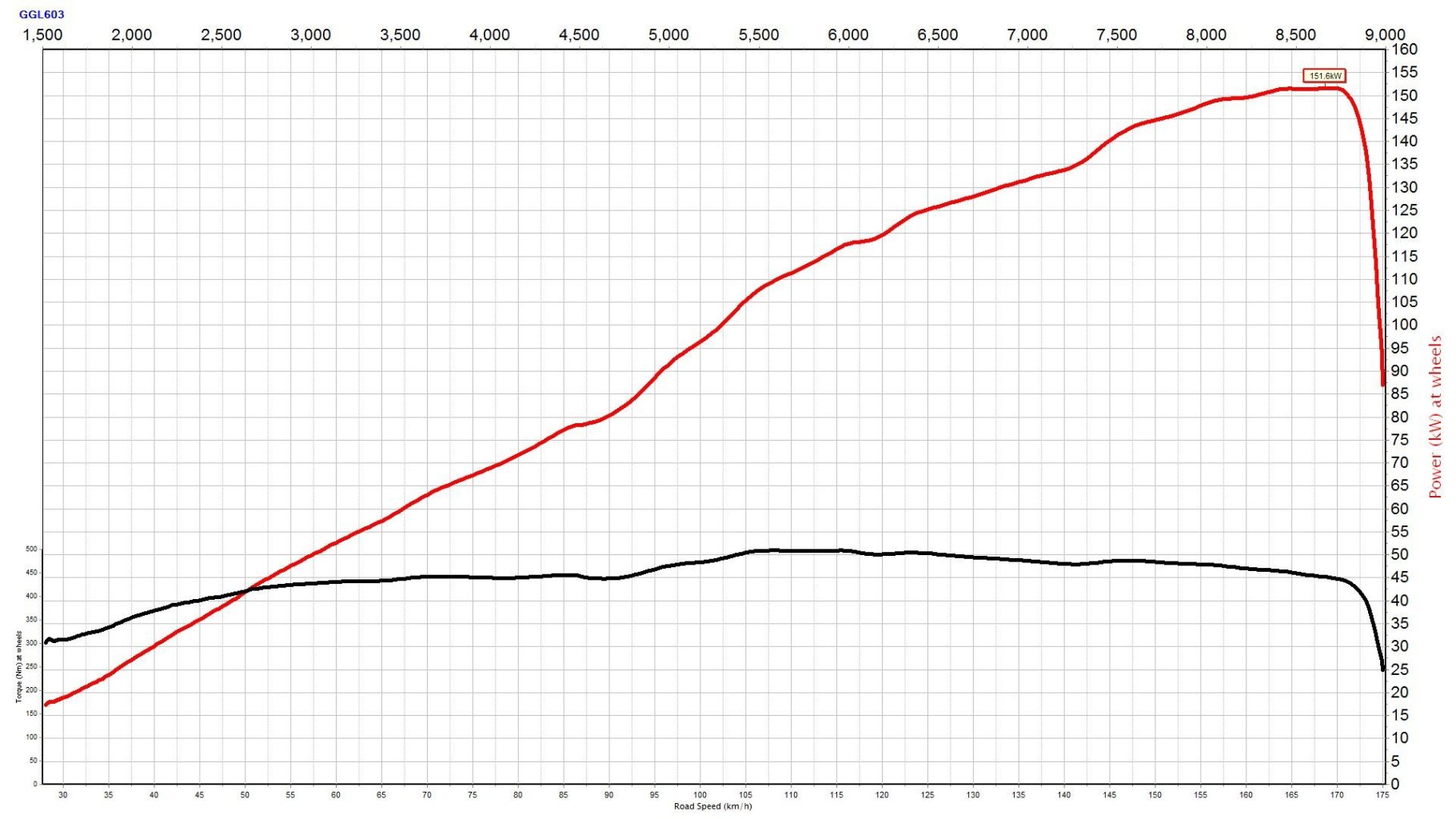

probably not, just come in for a tune. But i sold the intake off the ep3 , to another guy with a k24. k20 head and stage 3 cams, so better head and bigger cams. Done the initial tune on my dyno when it had a skunk2 ultra race? intake. which is the red below, and the ep3 k24 in brown. He lives quite far away, so remote tuned it to get the afr right when he swapped to my inlet manifold. had to add a lot of fuel through the middle and some up top. so probably pretty close to the ep3 power curve now. Don't see why the k20 wouldn't do the same thing. the heads flow good and have plenty of cam from factory, so good gains in getting the bolt ons right. this is the k20 -

Hyperblade's KP61 Racecar "KP61R" Discussion

kpr replied to Hyperblade's topic in Project Discussion

probably fine long as the bends arent super aggressive. assuming you are still using the 47mm throttles. probably best to have them on the shorter manifold, then can taper up in diameter sooner Interestingly i just tuned a k20 on my dyno. had really short intake with big plenum and big short headers. done as expected. made 202hp and weak through the middle. -

one cap cant keep up.

-

yup, I think it runs even better than the other engine on stock cams, which had the inlet advanced a little. its even fixed my weak starter motor. since the cam is pretty retarded at the zero position, it has less dynamic compression and turns over faster haha. from memory it has from 0 to almost 5mm lift at tdc. the recommended setting for that cam is 2.7mm at tdc

-

Yeah most "turbo" cams are pretty tame. It definitely starts to hurt the spool up when get to a certain point though. If i put the matching exhaust cam in this, turbo comes on about 1000rpm later. But they are na cams. would be on the big end of turbo cams. It really just has the same effect as an na engine. the bigger you go, the more sensitive engine gets to whats attached to the exhaust side of the engine. get it right and big cams will work down to lower rpm than most people would think. get it wrong and everythings going to come out the wrong end

-

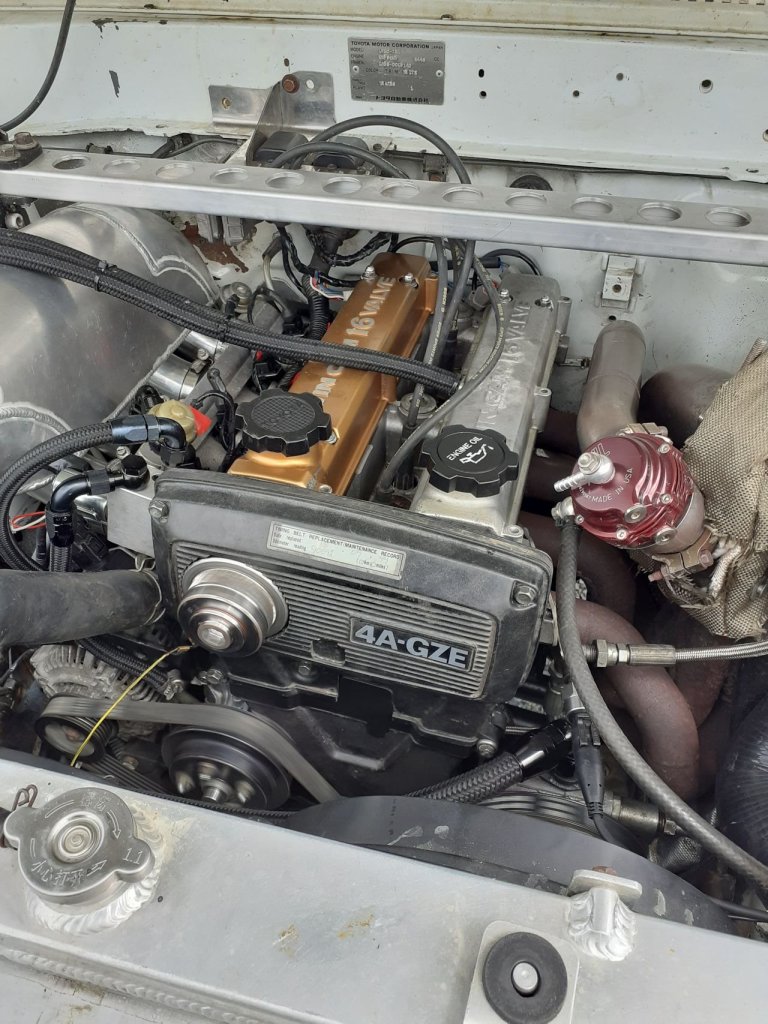

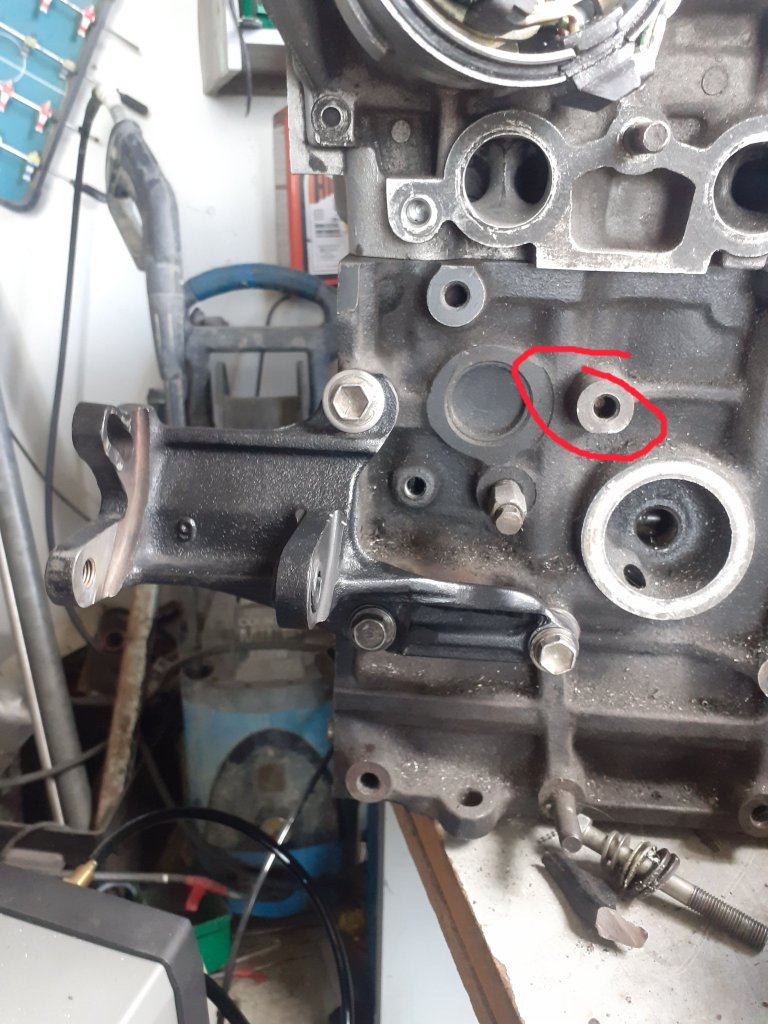

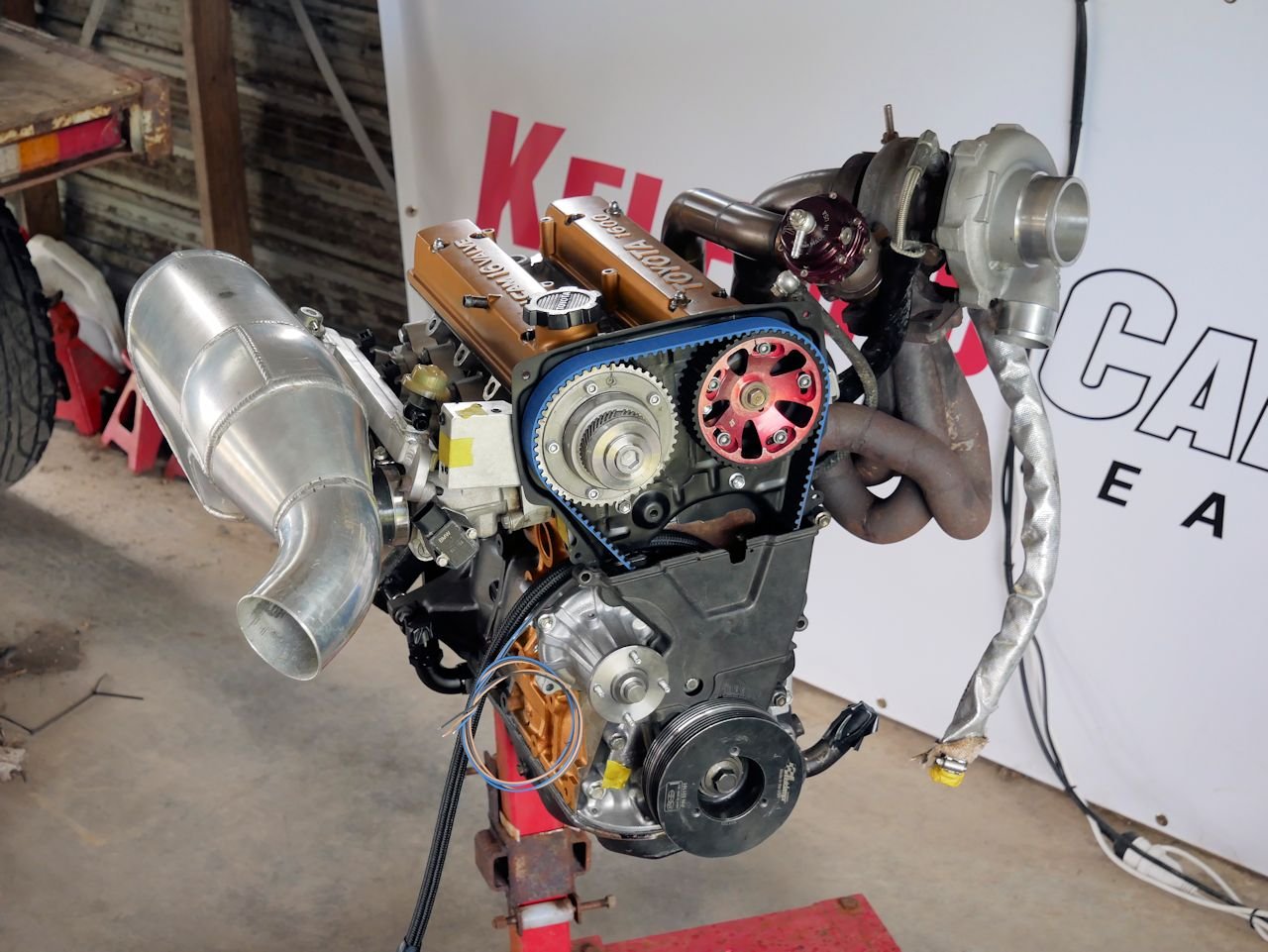

Still working through a few things. Also forgot to mention, the new engine still runs super nice with the big inlet cam and vvti. could daily drive it like a factory engine, smooth idle. doesnt stall out easy etc. would be pretty unsuspecting in a street car. Anyway since has to go in mud and stuff, been making the cambelt covers fit. which took some time, since has oversized pulleys and the 7a block is 15mm taller. made up a 3mm spacer between backing plate and the plastic covers plus a bit to fill the gap. had to nang a hole out for the vvti pulley to stick though. obviously covers arent going to seal off. but should keep most of the junk out some other stuff that had to do, that actually took pictures of. added an external oil drain to back head, between the to trigger sensors. since is bigport head. and this thing is mostly going up a hill when tapped out 7a block is missing a bolt hole which my butchered blacktop ps pump bracket bolts to. so did some illegal welding moves and made it attach to one of the lower bolt holes. also had some alignment issues making it spit the belt. which think i have solved cut 15mm out of the exhaust manifold, rather than modifying everything attached to the turbo. and yeah other stuff.

- 171 replies

-

- 28

-