-

Posts

6756 -

Joined

-

Last visited

-

Days Won

32

Everything posted by Roman

-

Man I hate bending up lines. Although, I think I dread the thought of it more than actually doing it. Good to get that off the list! Are you going to run an NA setup to start, with EFI setup? Will be interesting to see how different it'll drive and powerband etc.

-

You know what to do

-

14s will fit on the back okay, as I've had 13s on there! It's only on the front where it's real tight. But long term plan is to downsize brakes so I've got more wheel options. Cool thanks, will keep that in mind if I ever get this damn thing going haha. My graphs are a screen grab from this absolutely excellent website. https://www.blocklayer.com/rpm-gear

-

Ahhh just realized another problem, if I use a crazy diff ratio then the speed of the driveshaft and bearings in the gearbox ends up going fucken crazy. I actually am super keen to participate at the land speed trials one year. I was thinking about taking the echo for lolz but that ship has sailed. EDIT: I had an ask around, and a US company makes a 5.7 ratio and it's about $600 NZD + shipping. Not bad! Good to know there's an option if needed. https://www.yukongear.com/shop/yg-t75-571

-

Haha yeah, iterative improvements once the car is running, (by which I obviously mean graphs) is the fun part. Just gotta get it over that finish line first! It's getting close. In some spectacularly good news in terms of project progress, have got a signed up deal to sell my house. So hopefully come early March I can get back into things decently.

-

I guess I need to see if it actually makes any power before getting too carried away...

-

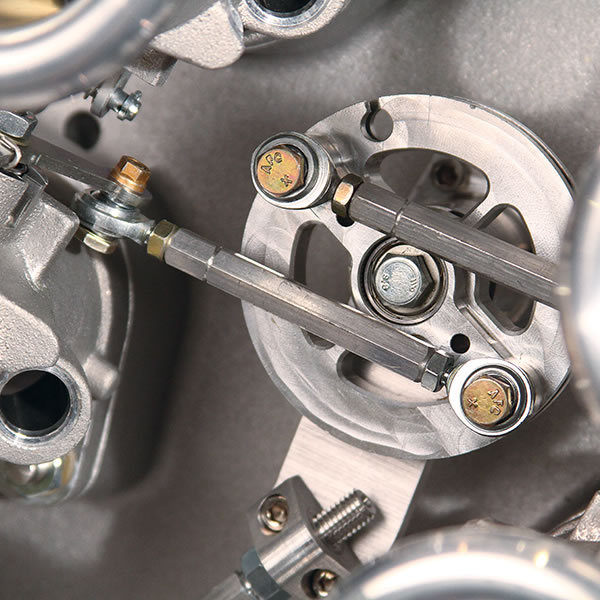

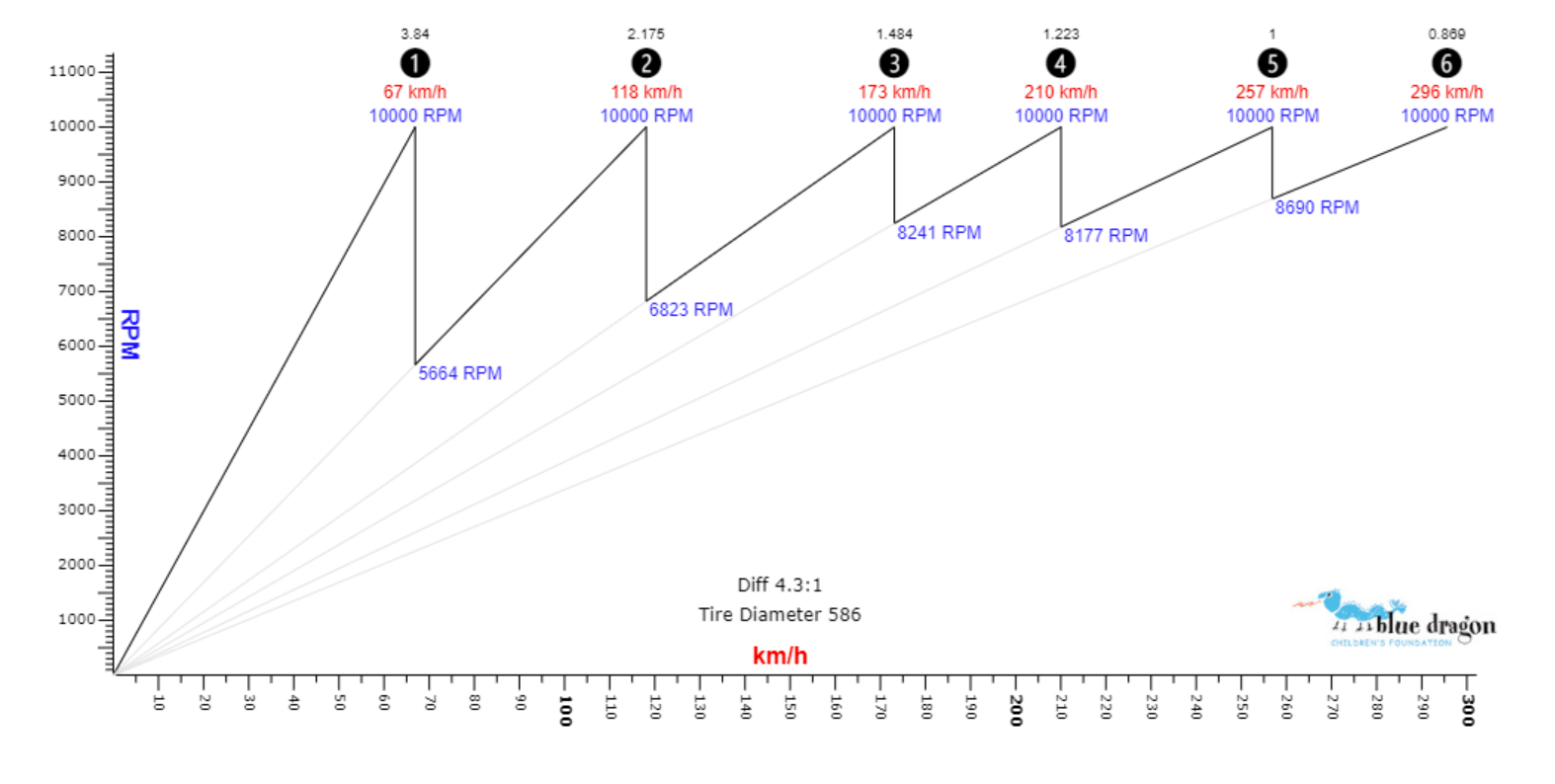

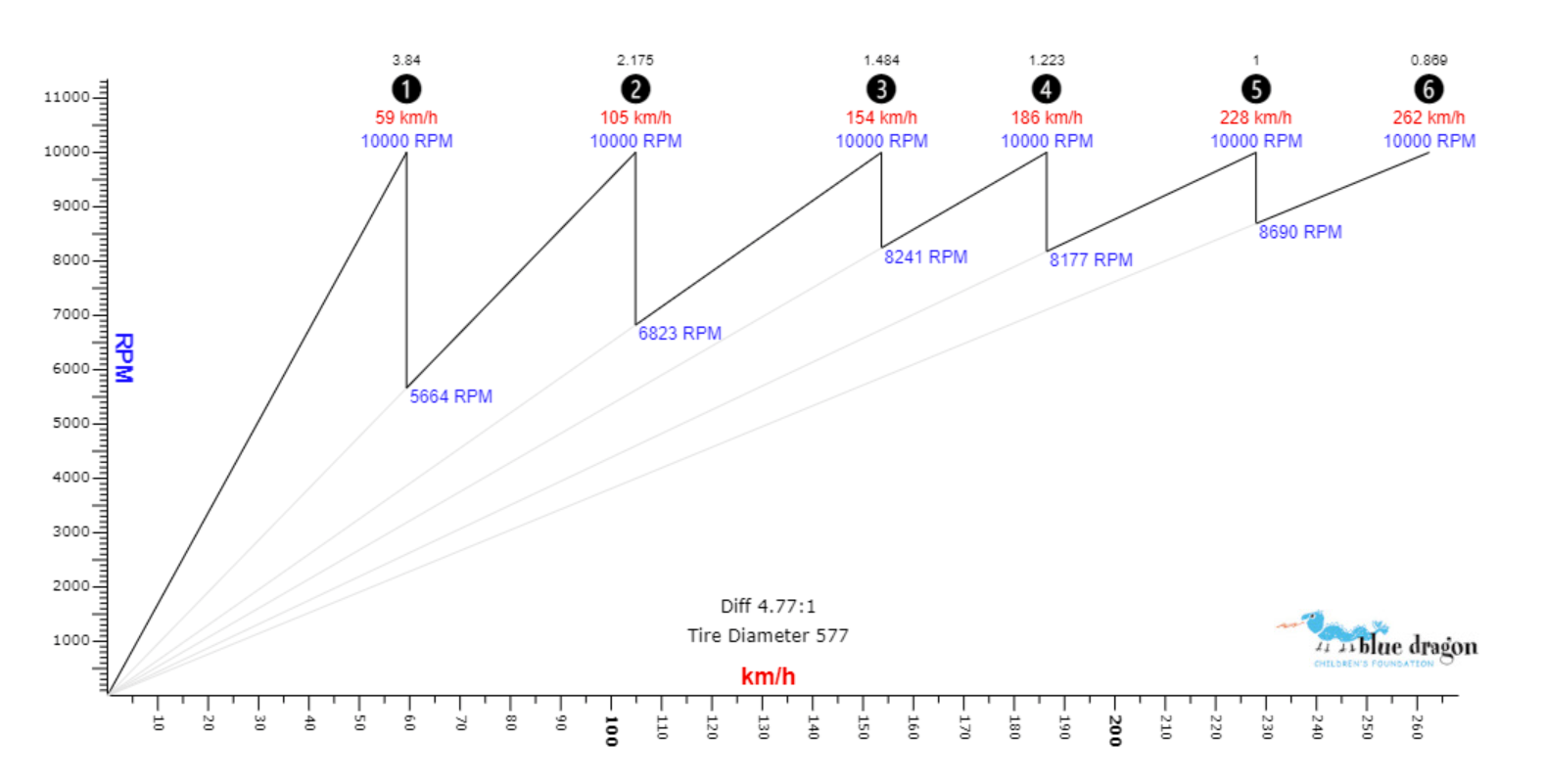

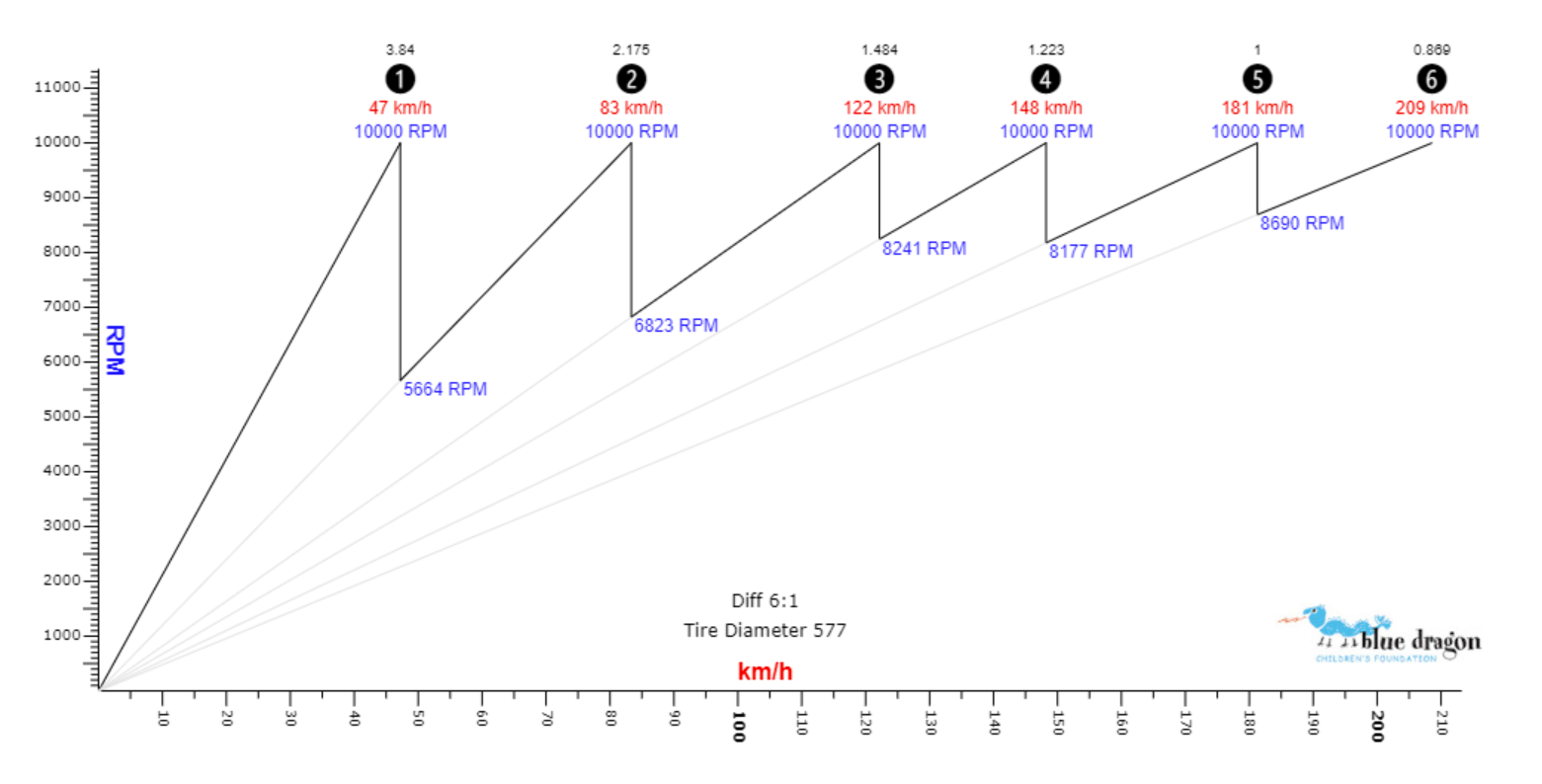

Throttle bank balancing I've had covid this week, which has sucked. But while my brain juice has been boiling like a stuck kettle, I had a major revelation for how to balance the two banks of throttles together. Most setups that I see use a pair of push/pull rods, mounted on a round disc (like my previous setup) However the problem with this, is you get a non linear angle vs distance pulled. Not necessarily in a good way either, like you could have a random patch of acceleration at half way throttle or where ever. Depending on how it's setup. This in itself isnt the problem, it's that if any of your geometry is slightly out, even if you match them at 10% throttle or 1% or 100% the rest of the range wont match. However, I saw a picture where someone used a cable to link the banks, and thought "The hell would you do that for" Then realized it's a brilliant solution. Because you end up with an angle vs pull amount that is 100% linear through the whole range. So the only thing that is really important is to get the tension of the cable set correctly, so both sides are open the same amount. Can do this by having an adjustable tensioner wheel pushing against the cable half way between, will be able to fine tune it really easily. It seems like a minor detail to have solved but this is actually a huge problem if you cant get the banks to balance nicely. Stoked about that! So I've ordered a cable repair kit for a motorbike (or something) that comes with one cable end premade, and the other is a screw together end for making it a custom length. I also had the fuel rails drilled on the CNC machine, which was fun to watch! I need to get some fittings welded onto the end of the rails, I'm glad I didnt do that before having the "aha" moment about using the cables. Because my fuel rails would have bonked into this space that I need to make this work at the back of the motor. Gearbox stuff I've realized I've got a bit of an issue that might be annoying, if this motor actually revs out as well as I hope. It's fairly well known that the closely stacked gears on a J160 box are 3,4,5,6. So you want to have your powerband/ speed band operating in this range. However, if you are doing 30% more RPM then all of your gears get 30% taller. With a 4.3 ratio, I've effectively only got only a 3 speed gearbox for most activities... and using all of the wrong gears! Look at the RPM drop from first to 2nd... 10,000rpm right down to 5600. That is NOT going to be a quick gear shift when needing to drop by that much. Gross. It's not too bad from 2nd to third, but you can see how nice the 3-4-5-6 is by comparison. Now if I change to a 4.77 final drive (I've got a 4.77 ready to go in) and swap to a 195/50/15 for a smaller rolling diameter. Then things are a bit better. At least managing to use 4th gear now under 200kph. But 5th or 6th gear are still in fairly unusable territory for full throttle in a car made out of bean cans. To make the 3-4-5-6 gear stack as useful as I'd hope it would be, I need to have something around a 6:1 final drive ratio. Yikes! So another option is to disregard the idea of trying to use the 3-4-5-6 stack and try improve the early gears. TRD made a gear kit that changed the ratios of 1-2-3 so they are more evenly spaced. However it's discontinued, and cost a fortune as well. So one improvement could be to fit the S15 Silvia first gear, change it from 3.874 to 3.626. However this means instead of dropping to ~5600rpm you drop to 6000rpm. Hardly a life changing difference. If I could find the NISMO 1st gear for the S15 box then it would only drop to 7500rpm which would actually be awesome. However, I suspect these are also NLA or hideously expensive. Maybe one day need to spent 10x my cars value on a sequential box...

- 75 replies

-

- 30

-

-

-

Discuss here about Yoeddynz's little Imp project...

Roman replied to yoeddynz's topic in Project Discussion

ACHEIVEMENT UNLOCKED: Saying Nipple 300 times in one post -

bonkas tired old Lancer EX - Engine Swap/Build Thread

Roman replied to bonkas's topic in Project Discussion

Hello @bonkas, I'm curious if there were any further updates on this car? -

Discuss here about Yoeddynz's little Imp project...

Roman replied to yoeddynz's topic in Project Discussion

Sooooo cool! Also I'm blown away by how cool you've made that motor look. It's a work of art. That's not easy to do. -

Also its awesome how with VVT it just seems to absolutely nuke all of the downsides of a bigger cam.

-

Hi, no I dont. I dont really have a proven working design yet.

-

Oh awesome! Keen to see how this goes.

-

Unfortunately not, as I'm moving house and so I'll not have any space for something like this for quite a while. After I've built another shed and have the Carina running I'll get back to this.

-

@h4nd yeah ive thought similar, but using ethrottle to hold it to a minimum of say 1/4 throttle then use an ignition cut on decel. But transient conditions in and out of that would probably be... sub optimal. But another option is to just keep a crappy exhaust on it. Finally, an actual valid use for backpressure. Not making power, but holding piston tops on. Haha! Oh yeah, since this engine has exhaust side vvti, I might be able to do some weird fuckery with that to try get an egr effect on decel that helps.

-

Yeah shrouding could be an issue. However I think on a 4 valve motor shrouding isnt much of an issue anyway, compared to a big single intake or exhaust valve. I would have to check the CC of combustion chamber too, as the 3GR is only 10something to 1 compression. I'm not sure if thats entirely thanks to the piston, or the chamber is different. It makes the squish bands a little less than ideal as well. Either way, I'll run the tiny ports/valves first and see how it goes. I expect it'll want the bigger valves and exhaust ports though.

-

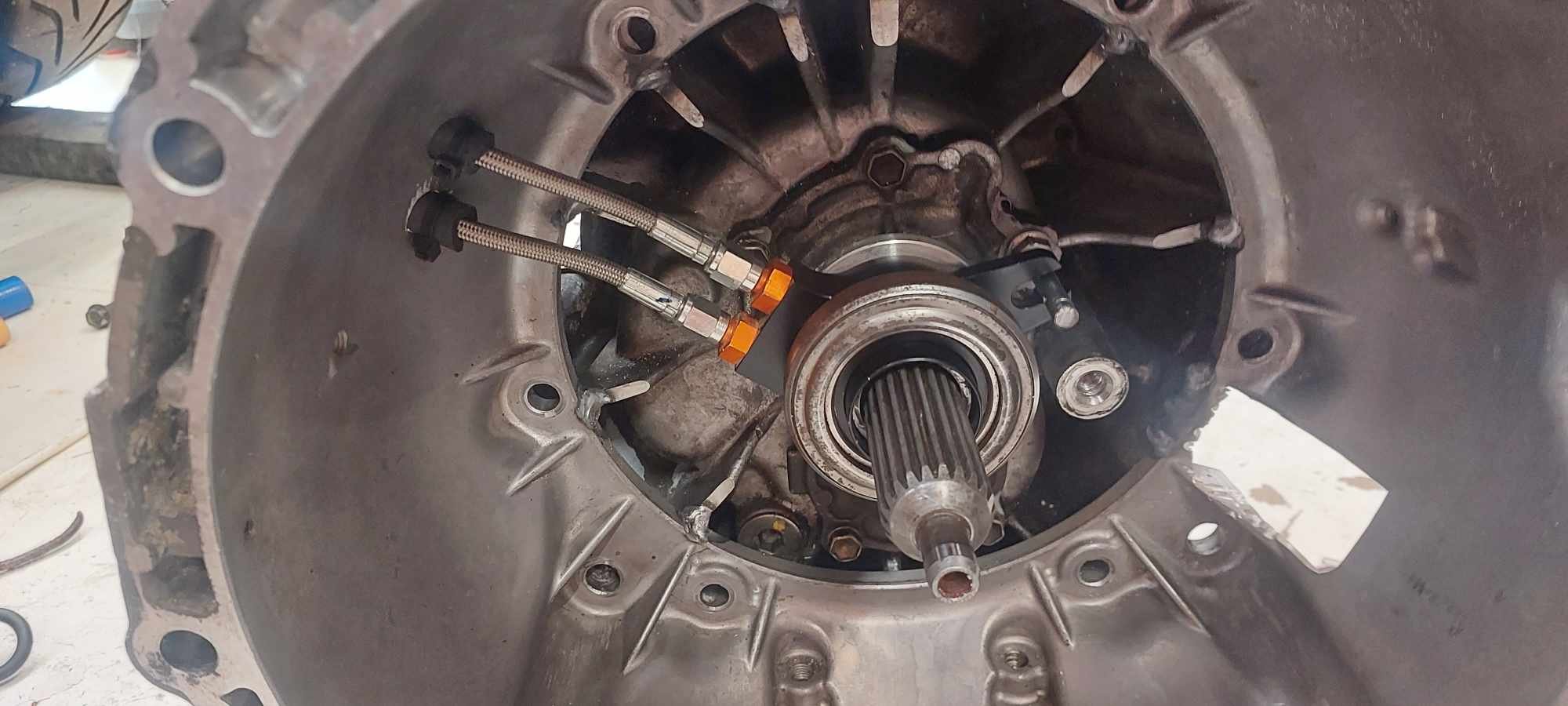

I put my timing cover back on, and then tried to crank over the motor while it's in gear with all of the drivetrain connected. So I can find the clutch point to put a stopper when the wheels stop turning. Overextending the concentric slave can mean it dumps its guts into your bellhousing. Do not want. I try turn over the motor - clunk. nothing. damnit what. I try cranking the motor via the front pulley, and it just goes super tight. hmm. Soooo I put the engine in neutral, and try turning the rear wheels. Thats fine. no noises. So I pull the motor and box back out, thinking there must be something jamming to do with the release bearing or clutch as that's all that's changed. Or maybe the lines were dragging on the cover plate or something. However, no obvious signs of issues. Just to eliminate it as a possibility I removed the starter motor - then sure enough the problem stops. Put it back in, then its a problem again. Which is very weird, considering it's worked fine literally just days before. So it looks as though the starter pinion thing either isnt going as far back into the housing as it used to, or... fuck knows. If I put some washers on the starter motor bolts to space it back slightly, then everythings fine again. But I'd prefer not to be point loading it when it's otherwise supported by the full housing. Damnit. It's only by the smallest amount, maybe 1mm. I'm tempted to just dremel back the pinion in the starter slightly. The clutch and release bearing all seemed fine though, which was good. Here's a trick for avoiding needing to bleed a concentric clutch when you pull a motor out - Just bring the MC along for the ride haha. Alsoooooooo something else interesting that I've just discovered. My understanding was that the 3GR and 4GR heads were the same. However I just stumbled across this pic. The top picture is the disgracefully weeny 4GR exhaust ports. Second pic down is the 3GR exhaust ports. Much bigger exhaust ports on the 3GR, and circular. Interesting. So finding some more pics, looks like the 3GR has bigger valves too. Look at the difference in the amount of space between the exhaust valves in particular. (3GR on the left, 4GR on the right) Checking on Toyodiy.com and it confirms that the 3GR has different part numbers for valves on both sides. The 4GR has a slightly smaller bore size (83mm vs 87.5mm) This pic below is how a 3GR head would fit onto a 4GR bore size. So the valves would fit without conking the bore. Based on my dubious scaling the valves are approx 33mm on intake side, 28mm exhaust side. Compared to from memory 31mm intake side, 25mm exhaust side. It would be interesting to see if the intake side geometry/port sizes are any different as well. I'm broke as shit currently, but if I see any more 3GRs come up at pickapart I'll go pull a head off and measure it up. Then I can decided if it's worth putting 3GR heads on. I'm sure as hell not looking forward to cleaning all of the shit out and porting some more heads though. What a mess! For the meantime though just carrying on down the critical path items towards getting the motor running. EDIT: There's a whole 3GR engine on Trademe for 300 bucks. Ha! Would buy if it was more local, and a few more months down the track. God bless these shitty unloved engines. https://www.trademe.co.nz/a/motors/car-parts-accessories/toyota/engines/listing/4519312323

- 75 replies

-

- 30

-

-

-

Hey what sort of cams and springs will this be running? Edit: nevermind i figured out how to read. ~280 deg, this is gonna be sweet! Im guessing the lift value is before accounting for rocker ratio

-

After a big bunch of mucking around trying to work out the right offset, I think I've got the concentric slave setup right. Thanks to @Sungai Sungai for the slave cyl and @flyingbrick for machining me a spacer on the lathe. Much appreciated! I'm just waiting on some 3AN line to arrive, and the adapter to connect to the master cyl. Then I can test it out. However now the motor and gearbox is hopefully bolted together "for good". Next problem is that the clutch MC wants to hit the back of the motor. This motor normally has the direct injection pump running off the back of one of the cams, and the pump would sit pretty much exactly where the MC lives. So I removed the pump as I'm not using it anyway - but this rear area of the cover that mounts the pump is still higher up than it would otherwise be, and reinforced. So it doesnt need to be strong here anymore. I chopped the back of the cover down, and smooshed some carbon over the top. I also got the brakes working, I had to remake a few of the lines that I cut when I decided I was going to run a reverse mount pedal box. My lines are ugly, and I might need to remake them when I finish the firewall. However this will let me move the car to my new place which is the main objective. Once I've got this cover back on, I think I'll be ready to weld the engine mounts in place finally. Fingers crossed I'll have my car moved to my current residence in the next couple of weeks, and it actually fits in the garage. I downloaded a program called Engine Analyzer pro, where you enter a big bunch of variables about your engine. This seems to think the motor should be able to make around 300hp with the big cams in it. Would be sweet! But probably not. I'm surprised it thought it would flow that well with what seem like tiny valves in this motor. Time will tell.

- 75 replies

-

- 35

-

-

Truenotch's 1997 Toyota GranV - Francis Jellybean

Roman replied to Truenotch's topic in Other Projects

Ahhh I've never considered a van for towing capabilities before.! That is actually a really good idea for what isnt just a single use vehicle (tow car) aaannnndddd if it's a camper you can sleep in the damn thing at the race track. You are a genius. What's the tow rating on a van like this? -

Looks more like goat or sheep legs I reckon. haha

-

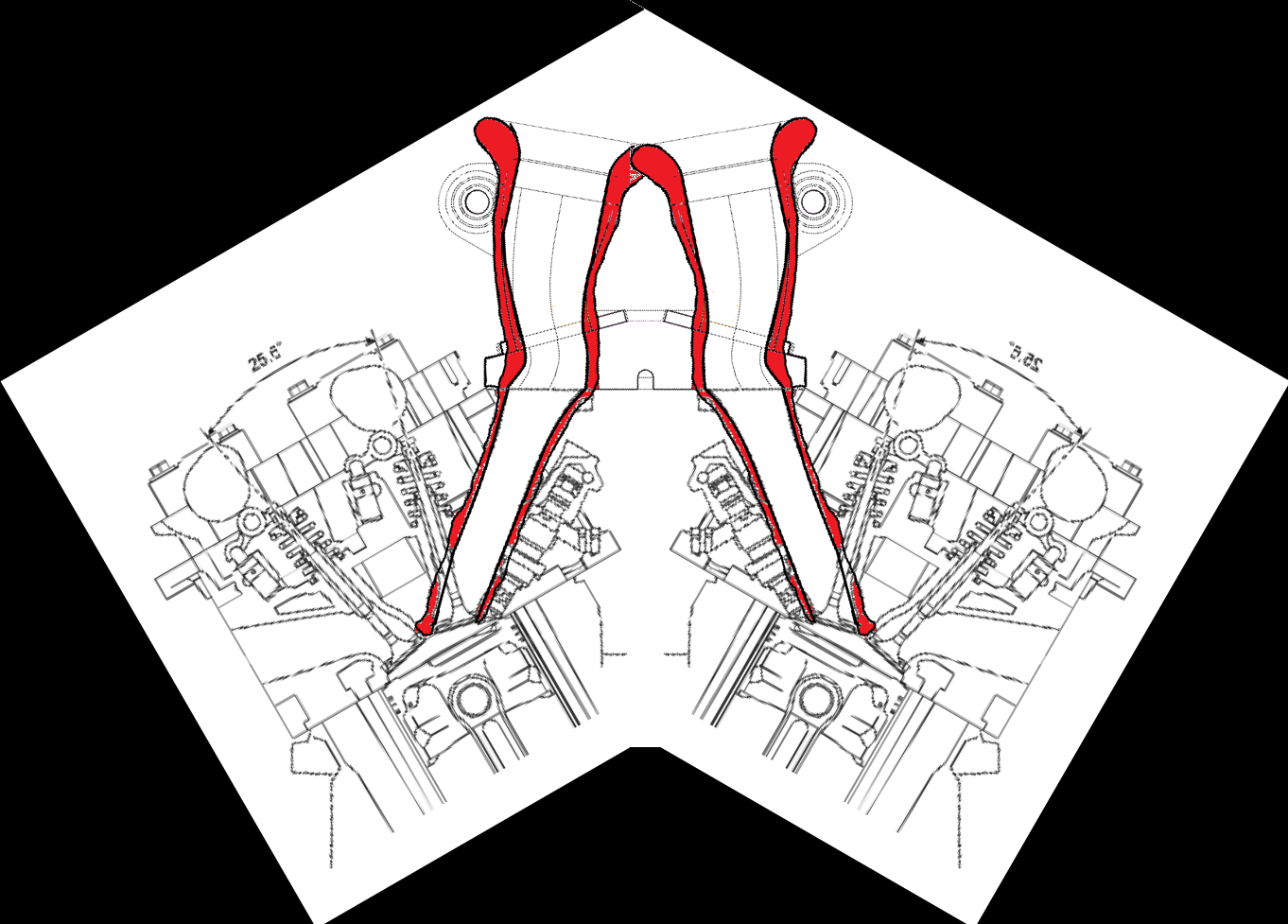

Intake looks really short? Surprisingly it isnt. Here is some mspaint magic showing overall runner length. The gumby looking part isnt as bad as it looks, it's just from where I've sliced the model slightly off center. As that's the point where it splits into a single runner per valve.

- 652 replies

-

- 12

-

-

-

Slowly getting there! Once the proper fuel rails are fitted I should be able to fire it up which is exciting. The clutch fork situation is not working out well so I'm borrowing a concentric slave from @Sungai Sungai to see if that will work. Looks like it should be good with the right sized spacer behind it. Most of the fuel lines are all finished. I've mounted the corvette fuel filter right down by the tank, so there's now only one main fuel line running to the engine. I finished printing some trumpets. Ordered some more AN fittings so I'll make it a straight tee at the back. Slowly getting there Still to do: -Drill throttle linkage rails -print carbon nylon version of manifold base -radiator mounts -remake firewall -finish exhaust -remake fuel lines -print housing for dash and fit dash -battery tray A few other things I've forgotten about. But just firing up the motor will be an exciting milestone. I've got no budget for exhaust parts etc for a while but I'm still making little bits of progress on the parts that dont cost anything.

- 652 replies

-

- 18

-

-

Good to see it out there again. Was meaning to come have a chat but I think you were too busy just racing the hell out of it. Awesome day!

-

Yeah I love what Doug does. And I just cant believe how damn fast his wagon is. So good!