-

Posts

1511 -

Joined

-

Last visited

Everything posted by ~Slideways~

-

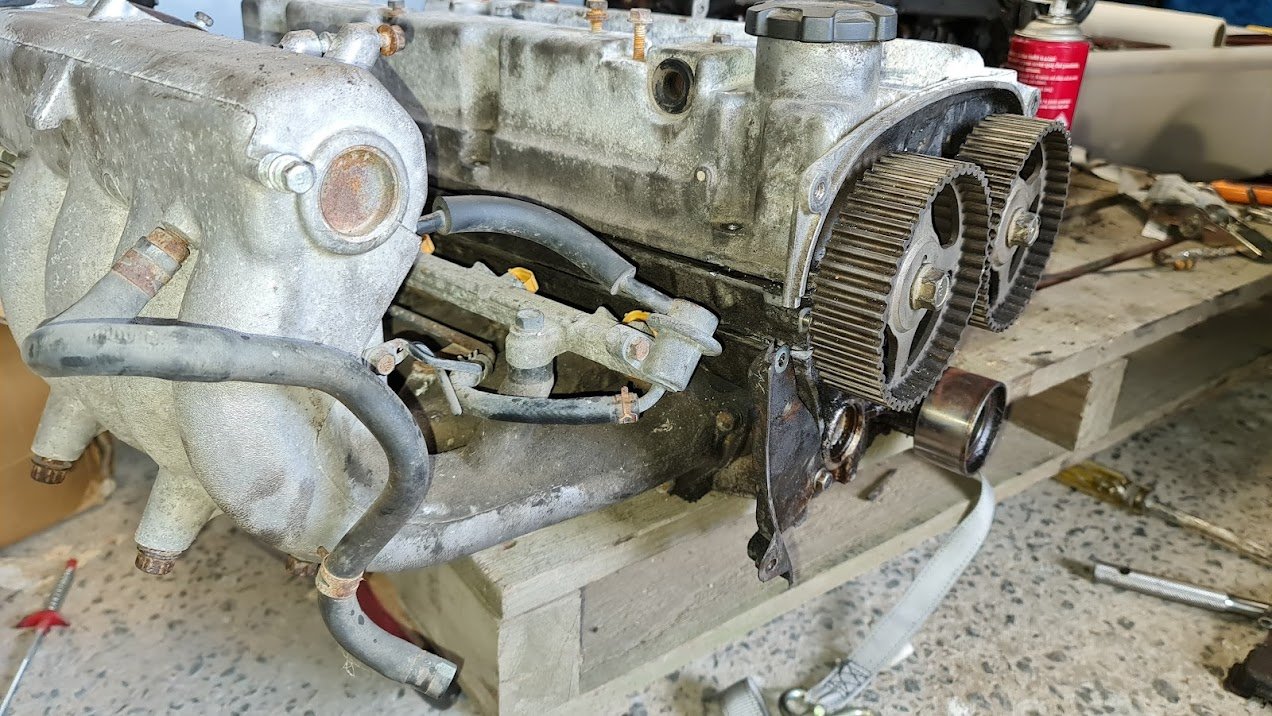

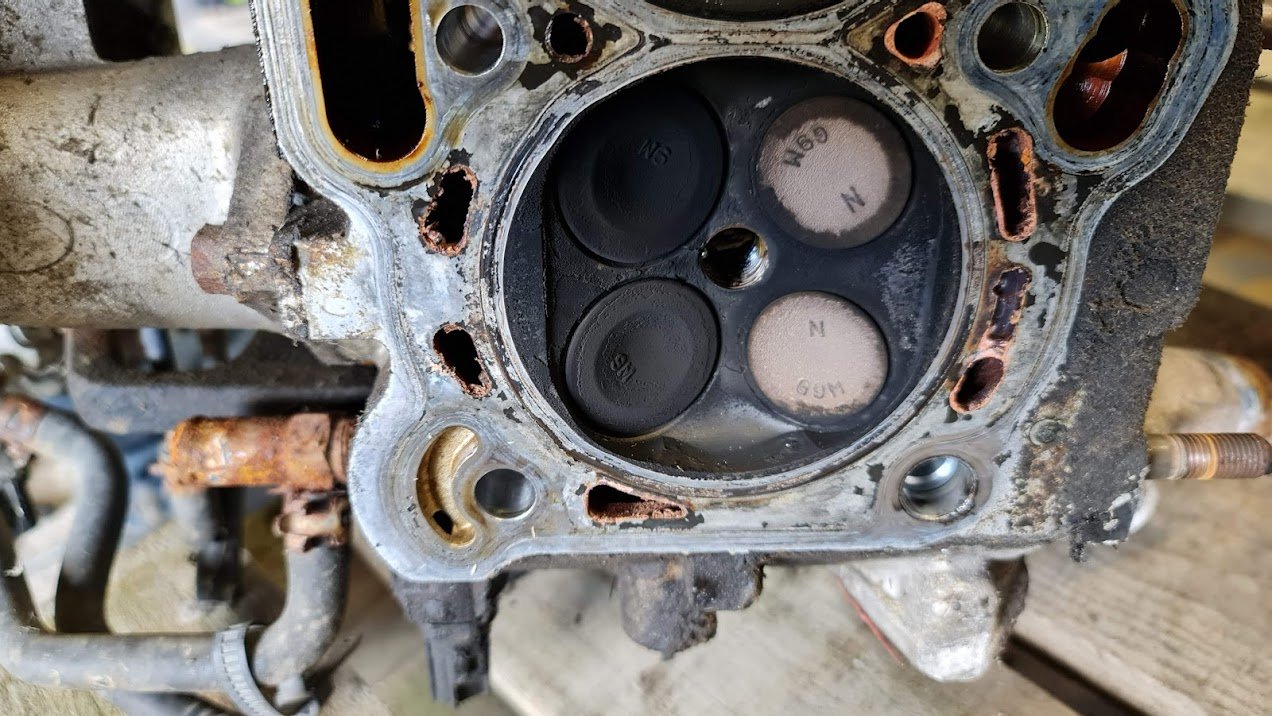

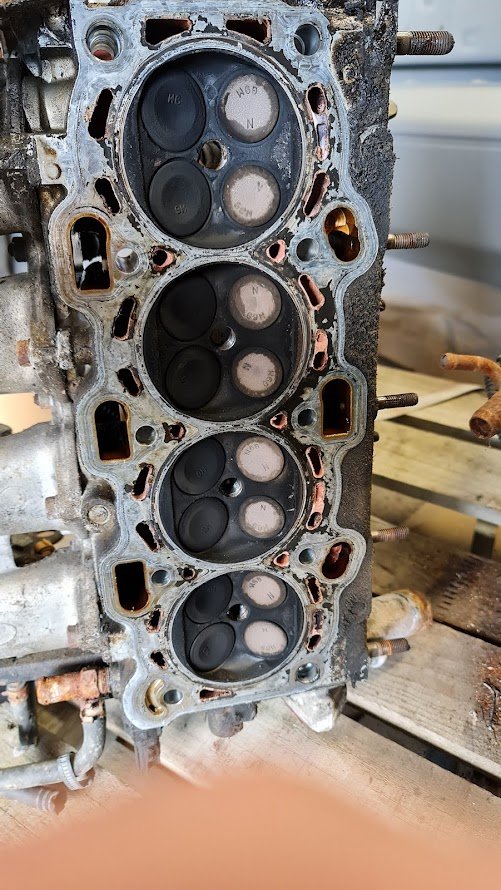

Put this back on the dyno last week to redo the boost table since last time, which was about a year ago, it was found that the little filter thing on the solenoid is quite restrictive. So it wouldn't allow enough air to be bled for more than 16psi. On the street it goes great on wastegate pressure which is 10psi. Got the call that after 20 runs it started running on 5. Big puff of blue smoke (think there might have been a noise...can't remember the exact description). Compression test showed zero compression on number 4. Leak down test is pushing air back into the intake manifold so it has to be an intake valve problem. Nothing excessive out of the oil filler hole. The spark plug does not show signs of running lean. No knocking or metallic noises. Obviously not what I'd hoped for but that's where we are. Had a big think about it and am wondering if there has been an issue with one of the intake valves since day one. It could explain the intermittent misfire which the long list of things I've tried has not resolved. i.e. something making that valve not seal sometimes and is now worse. Got it home on the trailer a few days later. It runs on 5 with no bad noises except sounding like a Subaru. So I decided to compression test number 4, and from stone cold it immediately made a decent amount of compression? Not zero. I didn't take note of how high it went but it shot up and held it after just the first few turns. OK, so I put it back together and start it up thinking maybe the theory of an intermittently sealing intake valve makes some sense now. It still ran on five, I double checked the injector/coil plugs etc. So I compression tested number 4 again and now it makes zero compression like had been reported at the dyno. The needle barely moves. OK. Interesting. So while this has all been quite disappointing to say the least, I am looking on the bright side, getting angry at it won't fix it. The bottom end is hopefully undamaged (hoping a piece of valve hasn't dropped into the bore, because it was able to make some compression at first). No bad noises. Could it be the spring is bad? The valve spring seat/keepers are loose? Worst case, something melted causing damage to both the head and bore. Middle case, damaged valve. Head comes off and rebuild it. Best case, a replacement valve spring/keepers/seat solves it without taking the head off. It'll be a while before I have time to look at it now but am keeping my fingers crossed. Still looks cool though right?

-

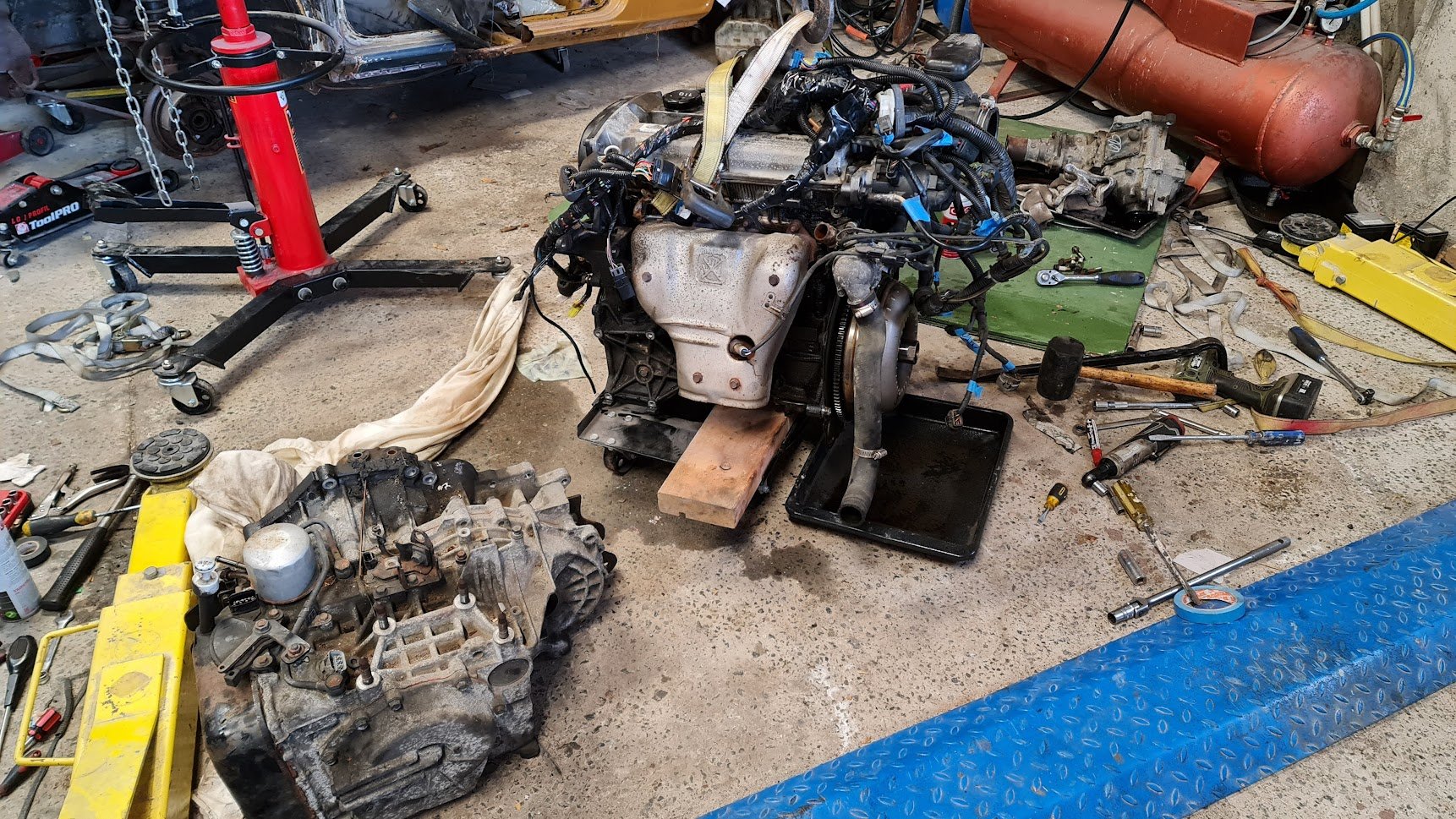

My 200sx 1jz car lost compression on the dyno last week so needed to get the 'parts lancer' off the hoist, so put the 4g15 in and got it rolling again. This combination of transmission jack (500kg rated) to position and lift the engine up in stages plus the hoist to lower the car over it works pretty well. It's in: Wiring is a bit different but have got it turning over at least and confirmed the clutch is all working. Will look at the rest later. Found some amazing twist and tape wiring in a few places: Also here is the fuel filter cut open, this is the one which I suspected might be causing fuel starvation on the mivec/parts car. Doesn't look great but not really as bad as I was expecting. Could still be blocked with tiny particles. Have now moved it out of the garage since the wiring doesn't require it to be on the hoist.

-

Took the manual fwd gbox off of the mivec engine. Cleaned it up, didn't take a photo so just imagine it has less dirt. Put the gbox onto on the 4g15 and confirmed that the bellhousing bolt pattern is the same which is good. Also welded up a crack in the lower radiator support, just looks like someone positioned a jack in the wrong spot. Fixed now and painted. Think there might be a difference in the power steering pumps because the crank pulleys are different between the engines. Hopefully I can mix and match something to work. Mainly an issue because the mivec engine has a non-A/C type bracket for the P/S pump, which includes a idler pulley to tension the belt where the A/C would be. But the crank pulley on the 4g15 might stick out further. Guess I'll see.

-

- 79 replies

-

- 14

-

-

-

Oh and before putting it on the hoist I checked the ign timing, I couldn't find anything about having to bridge any pins or anything in order to check the base timing. But checked it anyway and it's consistently in the same spot on the timing cover mark but didn't go any further than that. It's all coming out and changing anyway. It idled fine but when I went to move it, it would almost die under a little bit of throttle. Like it was running out of fuel (it did the night before I bought it, so I'd put in 4-5L to test drive it at the time). So I put in some more fuel but it made no difference. Coughing and spluttering. Maybe the fuel filter is clogged? I'll check it when I take it all out.

-

Doing more work on the parts car than the 4wd one! Had a good clutch and the correct flywheel for the 4g15 so cleaned those up and installed. Put the parts car up on the hoist and started removing bits. It's a bit rough but it'll be a good car when done. Here is my temporary way of shutting up the exhaust leak for the test drive of the engine that is coming out of this lancer. Fibreglass sheet, aluminium tape and some hose clamps. Worked pretty well lol. Have drained the gearbox, engine oil and radiator. Removed front wheels, found a snapped stud, loosened driveshaft nuts. Quite like the colour too. Don't like the wheels though.

-

Tested the resistance of the water temp sensors from the mivec parts car and compared it to the one of the spare head I bought earlier in the thread. Both react to hot and cold water the same, both have the same resistance at room temp. So I think they are ok. This water temp sensor is in the back of the head rather than the one that is in the thermostat housing, which is definitely for the water temp gauge. So I assume this other one has to be for the ECU water temp. It was worth a try though, could still be related. Maybe the wiring is damaged etc.

-

-

Got the gaskets and rear main seal, they only had upside down ones. Inside looks pretty good: Cleaned up the cover and fitted seals: Even replaced the oil cap seal, old one was hard and brittle: New: New rear main seal installed: Not all that exciting but this'll get the engine ready to go back in the parts car, to then be sold and fund more interesting things.

- 79 replies

-

- 12

-

-

Yeah good idea could be that. It was up to temp on the gauge, although it probably has a separate temp sensor for the ecu.

-

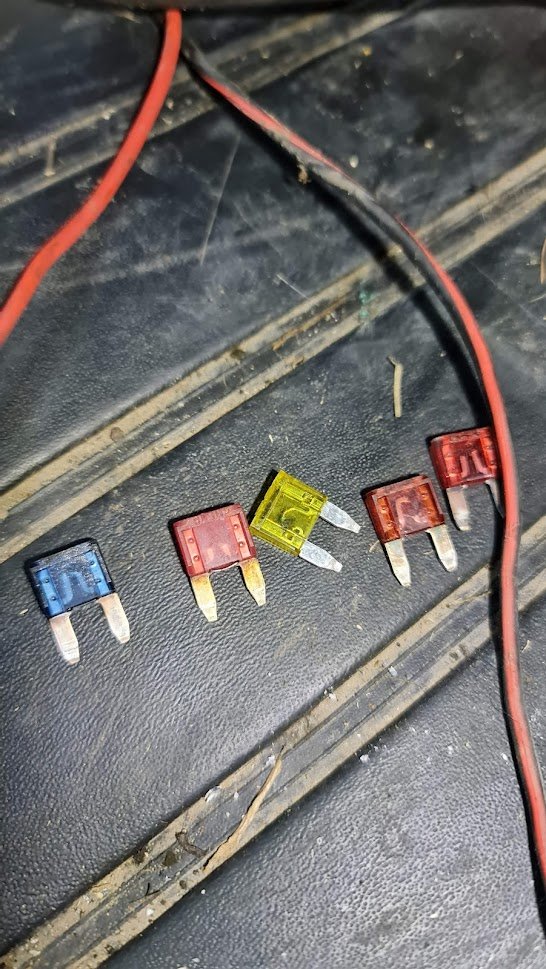

Also tried to do a compression test last night, number 1 went up to about 200psi, but I think the one way valve in my tester is stuffed because it just drops to zero again. Didn't have this problem a week or two ago. Then tested number 3, because 2 and 4 have the coils in the way and it was raining by then. Same story, about 200psi and drops to zero as soon as I stop cranking. Annoying, wonder if I can fix the tester... Thought maybe there was a check engine light that I didn't notice that could explain the sluggishness. Nope, light comes on then goes off after it is started. Seems to idle and rev perfectly smoothly. Check if knock sensor wire was still attached, it is, would think there would be a constant check engine light if something like that was wrong. i.e. limp mode type thing. Another guess would be that there is ECU damage from what ever caused 5 fuses to blow. But the fact it seems to start and drive fine with no check engine light it doesn't really fit. Maybe the timing is out? Also the ECU is hanging down in the passenger foot well. As if it has recently been worked on. There is also another ECU that was just in the glovebox, it looks to be for a non-mivec Mitsi (plugs simply not compatible). I THINK the engine swap was done in 2010 because that matches with the Mivec cluster on carjam. i.e. the km's drop significantly to match what this cluster would have had on it back then. It looks to have done 40,000km's since then too so surely it didn't have the ECU just floating around like that. Car jam history shows it changed owners a bunch of times in the last year. It didn't worry me when I bought it because I wanted it for parts. So I think a lot of people gave up on fixing what ever the problem is. It would be nice to know what is wrong with it, but I guess I am not going to be using this ECU or even short block. So I will probably stop trying to diagnose it and just get the engine out in order to swap in the 'correct' 4g15 from the 4wd lancer. That way I can tidy it up, hopefully wof it without too much issue then sell it. I'll grab some clean trim from Pick a Part and that'll make the interior nice, it's actually pretty good apart from the crappy silver spray paint. I wish I had more time to get through these projects, I really enjoy diving into each one and making them good again...just not enough time to do it all.

-

Got the torque converter off and had a look at the rear main seal. It was practically falling out, this is how it was, already half out. I didn't even need to pry it out just touched it with my finger tip and it flopped out... It can just be slid back in with zero effort. Something about a hallway and a hotdog. Do these seals shrink? Waiting on BNT for some seals but Covid has done a number on them.

-

Got the engine off of the trans jack and removed the transfer case and then the auto. Waiting on prices for a rear main seal and cam cover gaskets. In the mean time I had a look over the 'parts Lancer' the one with the Mivec 4g92. Which isn't running right. When I test drove it before bringing it home it felt very sluggish. I wasn't too concerned since I didn't plan on using the whole engine. The heater fan controls and clock didn't work at all, I knew that the indicators didn't work as well. Found FIVE blown fuses. That's a great sign... Replaced them and everything seems to work again. But why did they blow? I did find that the stereo loom has been cut and is exposed, but would think that would only blow one fuse. Exhaust is leaking, found gasket very buggered, kind of looks like it was installed wrong too, like it was jammed in since the sides are bent up. Yes those floor mats are amazing. As a temporary measure to shut it up I put on some exhaust gasket goo and left it overnight. Started it the next day and found it was another loud leak from the flexi. I want to drive it around the block to test it a bit, so wrapped it in some fiberglass matting and held it on with some hose clamps Sounded a lot quieter so got it to operating temp and took it around the block. VERY sluggish. Like the timing is retarded? No misfires and revs fine, just very very sluggish. In first gear up I got it into the MIVEC engagement point which is something around 5000rpm. It really opens up and sounds really cool. But still super slow. So at least I know the Mivec solenoid is working and it must have enough oil pressure to engage it. I got it home and pulled a spark plug, looks real old. Was about to do a compression test but then my wife got a bloody migraine. So dropped it all and will get back to it another day. I am semi considering putting the 1.6 mivec into the awd Lancer. Since this parts car Lancer appears to have been driving around for 12 years with this conversion... it's a lot of effort though when the end goal is to build it with a 1.8 block and turbo it. But then again the first wof could tell me to go away and cert it.

-

Me too

-

This is awesome.

-

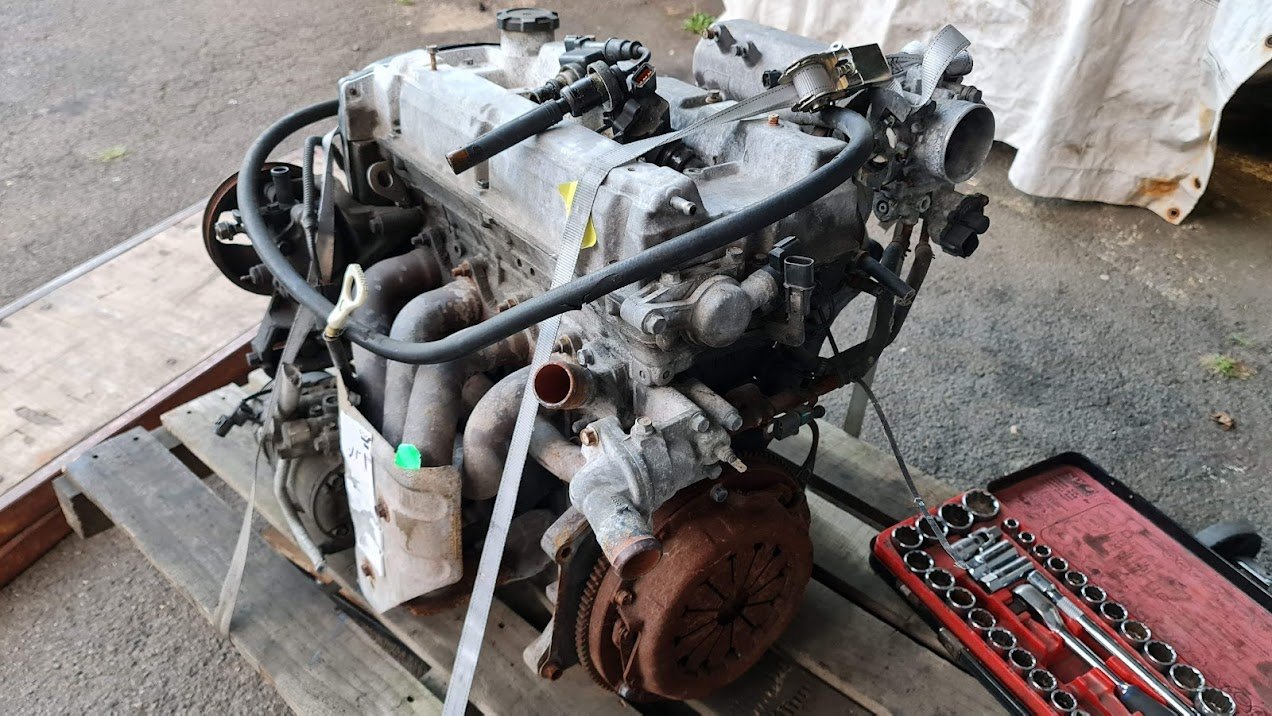

Got it out last night, didn't need to remove the alternator in the end. I thought it would get in the way but was able to move the engine forwards enough. Used my transmission jack, its rated to 500kg but I was a bit worried about balancing it. I guessed where the centre of the weight would be and didn't quite get it right so it leaned over a bit... Reminds me of a 16v smallport 4age.

-

Plan is/was to take the engine and trans out the bottom, with the loom all still attached so I can swap it into the 'parts' lancer (with a manual box). Found the ecu location, which is under the dash on the tunnel. No real problems accessing it to unplug the loom. Nice work Mitsi. Loom is easy to disconnect under the carpet up to the firewall where it then goes behind the heater motor. Nice. Can't get to the engine side of the loom big rubber grommet thing since the ABS unit is in the way, tried anyway but could not. So had to disconnect the brake lines and the ABS unit. Not too bad I guess. Now I can pull the loom through a bit, but it doesn't seem like the plugs can fit behind the heater bits. Hmmm bugger, maybe it I undo the mounting points for the heater stuff? Undo the nuts at the bottom, can only see one above the blower unit. Can barely get a spanner on it, spent 20min on trying to undo this one nut. Maybe I have to remove part of the blower to get to it...realise its all one unit unlike most other stuff I've dealt with and there is no way I can get to the other top mounting nuts to remove the whole thing. Don't want to disconnect he AC lines... Not so great Mitsi... So I have another go at trying to get the plugs behind the Fan unit. Then I notice/can feel another part of the loom going to the A piller. Oh maybe that's what is stopping it. Found where that goes and disconnect. Nice...maybe now. Nope still can't get it out. OK fck it. NOW I CAN GET THE LOOM OUT. Quite like the way they've mounted the cluster plugs so it stays in place though. So... yay Mitsi? Not pictured: remove radiator, AC pump (tied off to the side), auto cooler lines, air box, loom connections to fuse box inside and in engine bay. That's as far as I got. But I think all I need to do now is remove the Alternator, shifter lines and two fuel lines then it should be ready to come out the bottom while still attached to the crossmember. Also, never seen one of these stickers. They would have had to remove the cluster to do this:

-

Made a start on getting the 4g15 out of the Lancer. Put it on the hoist, which involved moving 6 cars and a trailer Drained the auto trans fluid. Drained the engine oil. Looked real black but no flakes: The transmission magnetic drain plug itself had a bunch of crap on it. It doesn't really matter though since I am not using it. Unbolted the knuckles from the struts and that gave just enough room to pull the drive shafts out. Not in the photo but compared to the manual drive shafts I am pretty sure they are the same length. I was hoping that would be the case so I have spares. A photo of my oil collection as well as the 4wd'y bits. Rear 4wd bits, there is some surface rust to clean up but overall the underside is in good condition. Even the rails are pretty damn straight. Tiny exhaust is tiny: That's as far as I got and it was too late at night to cut the exhaust bolts off which were seized on. Plan is to drop it out the bottom with the loom still attached. I also purchase a whole other Lancer which has a Mivec 4g92 conversion, bit rough but it was a good price. No certor wof but has a 'covid reg'. Conversion looks to have been done in 2010. Originally it was a 4g15, so I plan to take the one out of the 4wd lancer, fix the seals etc and swap it into the 'parts' lancer to sell and get some money back. The parts Mivec lancer apparently isn't running right. I wasn't too worried since I will be rebuilding the engine anyway. But there are some parts I want to keep off of it, like the momo wheel (worn out), mivec engine, mivec ecu, white face cluster, side skirts and maybe the suspension. Looks like they are king springs but not sure if they are compatible with the 4wd suspension. I had taken it for a drive around the block a few times, it has blown exhaust manifold gasket at the bottom flange where it joins 2-1. And it had previously run out of fuel so I had to bring what I had which was only about 4L. But it started first pop etc and didn't look to overheat. Clutch feels worn but it shifted fine. Oh and it has THESE (never mind the silver painted plastic trim):

-

It is pretty tall yeah, but being aluminium it doesn't feel all that heavy, well compared to others I can remember. There is a quite a bit of empty space too. The 4g93 1.8 block is a taller block than the 1.6 so it will definitely be taller than a 4g93t like in a GSR. The hybrid 1.8 with this head has been done before so I'm sure it won't be too bad... maybe some bonnet ribs need removing... I guess I'll see!

-

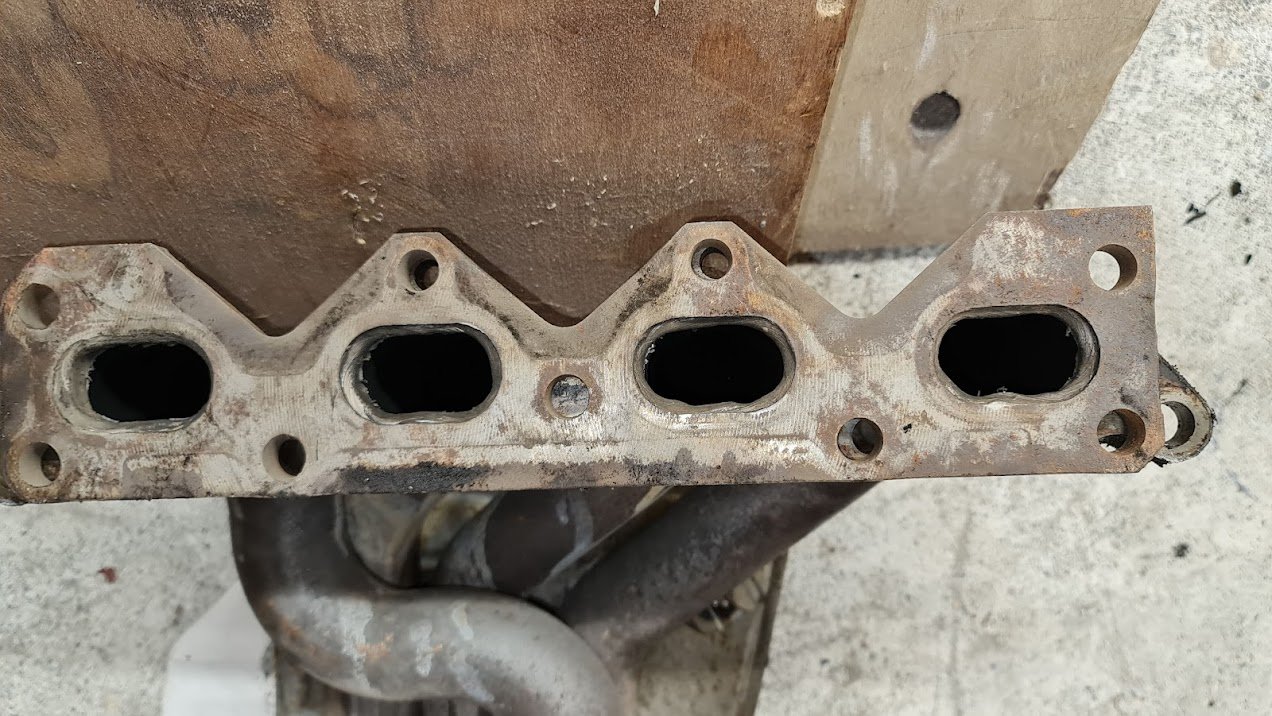

Have wet sanded about half of the car with 400 grit. Coming out good. Took a break from breaking my back to have a go at removing the weld in the exhaust manifold flange. Tried a few methods but a tungsten bit and a rotary tool ended up working best, still a bit of a slog. I really rate these cheap Ozito rotary tools, I've worked it hard and it is still good. I've had TWO dremels just stop working randomly, not even working them hard. Opened up port versus the one with the weld still blocking it:

- 154 replies

-

- 18

-

-

Not sure which project thread this belongs to but the 1.6 Mivec engine for my Lancer comes with quite nice extractors from factory. 4 into 2. I don't have the lower section, which must take it from 2 to 1. They don't look like press mends like the horrible Mazda one. I have the MX5 B6 exhaust flange cut off (still with factory weld bead inside the ports), comparing this to the Mivec manifold the spacing is very close! This is with the remains of the cut off mx5 tubes basically sitting inside mivec ports. Could possibly cut off the mitsi flange and weld on the mazda one. Will offer it up to the engine bay when I get a chance. The design is MUCH better than the Mazda one, maybe it'll be worth modifying it to fit?

-

Oh I wonder if maybe the oil pump gear is broken, I've read that can happen on 4G's. A place in Malaysia makes billet upgrades. Probably worth doing.

-

Out of interest I checked the bearings and they all look ok? Took a piston out and no damage to the ring lands etc. The rods are TINY! Also interesting that it has piston oil squirters built into the rods which is pretty cool. So I'm not sure why this engine had it's sump taken off and oil pick up removed and left off? Maybe one of the other rods is bent? Doesn't really matter though. Just interesting to see.

-

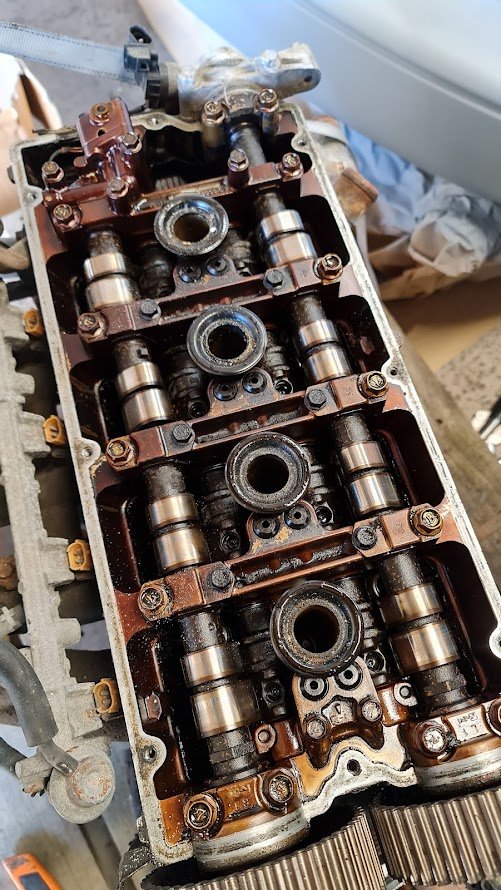

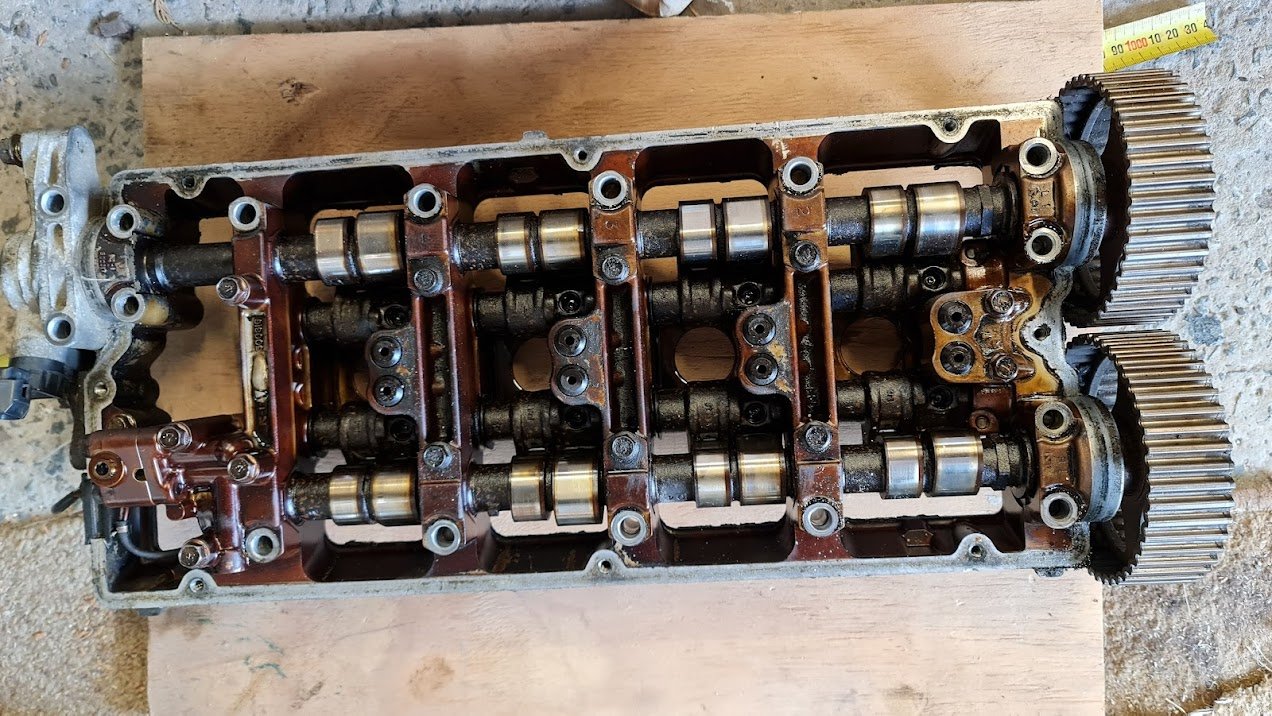

Found a 4g92 Mivec engine with apparent spun bearing. It doesn't even have the sump but the main caps are still there. Only want the head and intake so bought it and got it sent down to Wellington. It's missing the Mivec cam cover trim thing unfortunately. The cam design is really cool. I have recently learned that MIVEC is not MIVEC. The early stuff like this is basically VTEC where there is a 'race' cam lobe that is activated with oil pressure and a solenoid. I saw someone claiming they made 200kw atw on 12psi with a 4g93 with this head, don't know what turbo but it seems like it is easy to make power with a head that breaths well. The GSR 1.8 head apparently is not a good breathing head. The later Mivec like the Evo 9 is variable cam timing (I am pretty sure anyway), so less 'aggressive' I guess. Also the 4g69 etc I am pretty sure is just variable cam timing rather than vtec style cam lobs like this. So it looks like the 4g63 never had what I would call 'real' mivec, only variable cam timing. I'm hoping this 4g92 head will act like those Honda Vtec turbo's which make big power because they basically have a high lift cam profile in the higher rpms. Really interesting design. The cams sit in a separate cradle. and the head has two halves. Here it is removed: And the lower half of the head, it's actually quite clean, the photo's make it looks like it is all coked up but it's just a textured casting: It has super long spark plug tubes because the head is really tall due to the cam cradle design. Weirdly a normal spark plug socket won't fit, the tube is crimped about half way down (maybe due to assembly pushing in the tubes?), I had to grind down a spare one to be thinner walled. The head is REALLY tall, this is a big 550ml crc can next to it and the head is still taller: Valves a bit carboned up but otherwise look good: Not that it matters but the cylinder walls still have cross hatch markings: Really high compression factory pistons!

- 79 replies

-

- 15

-

-

Finished block sanding the high fill primer with guide coat. Now sprayed a few coats of primer surfacer. Came out looking awesome. Still need to wet sand the whole thing again with 400 grit.

- 154 replies

-

- 11

-