-

Posts

3118 -

Joined

-

Last visited

Everything posted by d.p.n.s

-

yeah... think I'm going to take some time with the head ... port match the exhaust side to manifold.. and clean uo the flow and a bigger value. the intake needs a bit of work. port match the opening (properly...rushed it last time as it was just to see if it worked). to adapter plate and manifold.. knife endge the valve area .. remove that sharp turn at the valve end on the floor and clean up that flow straight down the throat to the bigger valve... it's only a evo 4/5 td05 on there ..but u would like to see if I can use it all....then look at sizing up.

-

I was thinking about it mate as everyone keeps telling me it's not to essential being forced induction...but I just keep thinking it it makes NA breath so much better then ut must work as welk for turbo

-

so things have slowed down a bit now. was trying to get it all drivable for end of October but I was also hoping the motor I was using to set it all up ......would last .. so wasn't factoring in a motor build . I could have found another running motor but I would have had swap the head over anyway (this one is matched to adapter plate for inlet).. and it would probably need a gasket set ... so I may as well build one....... and then I thought if I'm building one I may aswell build the one I want.. I wanted one with standard bore to start with.. and out of the other 3 motors I have I have 1x 2.1 bottom end 1x .50 over bottom end and 1 that will need crank ground as run bearing had fucked it .... so the last motor was the one in the car ......out it came pulled it apart and pulled the head off...so far so good .. original size SOHC pistons . (what a great sight). so at the moment I'm just doing a whole bunch of waiting ...for funds and parts. but in the mean time I have stripped and cleaned the block and it looks good (gave it a paint ) but all in all damage was only to big end bearings. gave the block a quick hone and it looks good ..will give it a better one once the postions arrive and I can put a rod and piston together and see if I need the block decked. I'm also going to have a go at porting a head myself ... I have a few heads and it turns out the best casting and condition is the head off that motor .. so I stripped it and bolted it to a mates stand (just waiting on some carbide burrs and I'll get into it). so the plan is standard bore and stroke bottom end ,forged rods,YB cosworth pistions ,under pistion oil squiters (still researching that).higher pressure oil pump, cosworth 1.3mm head gasket , ported polished head ,bigger valves, and I'll have a talk to mate PK at kennelly cams to see if he can work some magic for me... so just waiting on parts , money and researching

-

hi everybody. just to let you know where I'm at... I've looked at the motors I have here.. and I have a plan so cunning...you could put a tail on it and call it a weasel . just waiting on part

-

yeah I love that... caught fire in first burnout comp.... from pics I've seen

-

can't see it mate

-

well that might be the end of that ... for a weee while . put new filter and oil in today... topped up the coolant..... fired her up and she is KNOCKING her poor brains out..... I can continue putting things together ... and maybe see what the other motors are like under the bench..... but I don't really have the funds to build a motor at this point....

-

git a few bits done while engine was out... new rocker cover gasket .. some P clips to hold oil feed for turbo out the way small heat sheld to help keep the heat away from the coolant temp sensor I moved to the black. made a small sheld to keep heater hoses out the way and tucked back on the firewall has a small vibration in the steering system.. turnout being the Bush that sit in the fire wall and the column slides through it.. ended up being a ass of a job. got the motor all back in.. nice to know she comes out and in ....with little hassle extended the temp sensor wires moved the mountings on the heat sheld... gave me a wee bit more room around the manifold hoses tucked out the way back on the wheels.. now. I also removed the oilcooler setup as the oil light would flicker so I wonder if it was low on pressure because of the cooler.. I'll grab some new oil and filter this week and then hopefully get back to tuning on Saturday....if the motor holds up. .I dug the drivers door out and ut seems in bloody good condition.. just missing chrome surrounds (think I have a set ). and missing door handle ..found the one from the rusty old wagon but uts broke.. (might have ti steel it from the white mk3 for now) on a side note ... about 5 months ago I ordered some LS1 coil boots and terminals.... but actually gave up on them ever getting here.. and just made them out of the ones I had .. but they arrived today.. so may about better terminals.

-

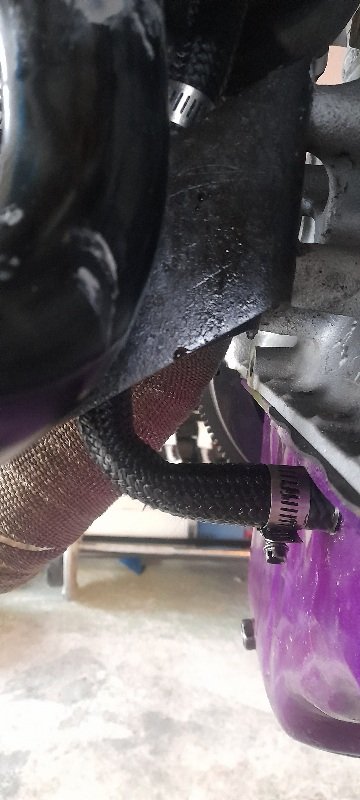

few .ore bits done.. *battary box mounted ,factory jack and a wheel brace and boot cleaned. *passenger door on , door card cleaned and also put on door (need to find a set of oldschool-ish speaker covers to cover the holes). *sump back on motor with new gasket.. *new oil Drain from turbo done. *tightened all the bolts around the turbo I struggling get up with motor in the car. *made the block breather fit better and now it sealed *put a bracket on for the dipstick tube. *pulled the coolant temp sensor out of the ba k of the head and put a new frost plug in... it was a good idea but a pain in the arse ti get to and when I pulled it out you could see it was starting to weep any way.... Could find anywhere to put the temp sensore other than where tha bung is at the rear of the exhaust side of the block..(will need a small heat shel).. I no its not ideal to have ut in the ocean and head is best ... but it's not really doing much ..the electric water pump has its own temp sensor in the top rad hose and that controls pump and fan (takes care of all the cooling ).

-

pulled the sump off ...found *gasket was fucked .. *sump was full of crap (petrol must have cleaned the motor as I cleaned the sump last time I had it apart). *motor is clean...oil pick up is clean . *sump.must have been full as there was what looks like airated oil up the front of the sump (not bowl) from where it was churned up by the crank... 4x800cc injectors may have filled the bores on a few occasions. *pulled a main cap (didn't get a pic ) pulled a couple of big end caps and they seem ok. also found oil in the bellhousing and you can see a stain on the steering shaft and oil on that side ... so I'm going to say 90% of it came from seal letting go at the rear and oil coming out the turbo drain. so on conclusion.....slap a new sump gasket in ,, a new rocker cover gasket and go again... lol got a few other things to do while it's out ..

-

took a couple of hours ...but the motor ame out.. not all that hard and mostly complete. there are a few things...leaking. *both sump and rocker gaskets are weeping ..(rear of the sump seems pretty bad)( left rear of the rocker cover is pretty bad.)...may be another reason for the sump gasket ....get to that later. I did put a full gasket set through it in October 2020 but it's sat dry till about a month ago. *the clamp on the oil return had had slipped down and so had the hose and kinked it a bit (not sure if it's enough to stop oil flowing..maybe another reason for that ...) also might need a restrictor in the oil feed line *oil on the block from the crank breather (may be another issue causing that ) .. * the main thing is I lost about a litre + on the floor..the oil cool and lines were full... and I only put 4l in.... and drained 5 out...that smelt a lot like fuel... so I think the 1st few days of fucking around with ecu setup ..it pumped so much fuel into it that it filled the sump... enough for the gasket to leak....the turbo drain to be blocked .. so replace a few gaskets and try again... there are a few things I wanted to do anyway and would have been easier the motor out... so 2 birds 1 stone.

-

had bits turn up for the intercooler piping.. just had to male a flange and weld the piping where I needed it from the turbo outlet. so apart from the speedo cable and hose for overflow tank that's everything that needs to go in the engine bay......its bloody busy in there now. was doing a wee bit of tuning today and getting the motor upto temp .. then when I shut it off and had lunch.. come back in the garage and found this so it looks like the motor is coming before tuning now.. I'm not sure if it's anything major or just some leaks... the motor is an unknown and didn't cost me much $$$$$ it was only to get it all set up and tuned .. put I'll pull it and see what's what and go from there.

-

well I cut all the bar 1 tooth of the cam sensor..changed trigger 2 sync mode to CAM PULSE WINDOW and then just set that to 50° and she's now running both DRIECT SPARK and SEQUENTIAL INJECTION. she basically a modern engine now with classic pinto oil leeks.. haha not much else I can do till I make intercooler piping (and our postal service dictates when I get the stuff)... but even at idle the air coming out of the turbo is pretty significant. also set the water pump temp to 70° .. engine temp got up to 68° water pump kicked in...temp got to 71° fan kicked in and bought temp down to 65° in no time.... so I'm happy with the coolant system. RX2 70mm thick radiator, 14" fan in shroud ,electric waterpimp... on a side note ... heater was awesome within minutes. cheers

-

pulled the crank and cam triggers off.. from what I've read and other have confirmed the 36-1 trigger is really hard to sync with a 36-1 crank trigger... so the car runs and even if I unplug the cam sensor it still runs as the injectors are being group fired.. but I want sequential so the answer is to have just 1 tooth on the cam trigger .... so I'm just going to cut another 34 teeth of yhe wheel and go with that.. once I have the rigger sorted and the intercooler piping (ordered today) in place then I'll be able to start tuning it properly... but she runs.... huge weight of my shoulders.

-

had a wee play today.. moved the trigger 2 wheel around a bit so it's not to close to the crank trigger missing tooth. put some new plugs in gapped to 25tho. change a setting on the injector fuel main from sequential to batch fired...(after reading up a bit more the 36-1 on trigger 2 is a bad fay of doing it.. it just needs to be 1 tooth and that will help it sync better) ..so ill pull the pulley off and cut all the teeth off apart from one and put it all back together and try and get sequential injection to work..... but hay in the mean time this happened

-

another picture less update sorry.. we had another play with things on Saturday.. wasn't getting anywhere again... we stopped went through it all again and again.... and then Simon said ...what about the plugs ? I told him they were new last weekend..so we thought fuck it ... I grabbed a set of old shitty plugs (pretty sure they came out of the motor in the old rusty wagon).... we slapped them in and she fired up.... only for a few seconds but she fired up... I can't tell you the feelings I had when she started..... just gave me instant hope that I had done things right ....was like a massive weight of my shoulders.... still heaps to do but I know now it will work.. massive thanks to @Stufor the basic tune to make it run.... cheers.

-

no it was getting late by the time we pulled a few things off to get a clear sight of the timing marks... the battary needed charging and I need to replace the air temp sensor..... and my brain needed a break..last day of my holiday time off today so... get back to work and get back into it on Saturday.. and thank fully it didn't matter what way around I wired the injectors as long as they there all the same. cheers

-

soooo one of our .embers STU offered to help with setting things up so I sent him the file and he sent it back with enough things in place to get the old girl to fire up...(once again thanks for that mate it is greatly appreciated). sooo a mate and my self had a play with things to see if we could get it to start on Saturday... The good news for me is the wiring is all good ( I did have all the relays running off switch 12v and the ecu was losing signal with laptop on hrad cranking .... so I had to run a wire from battary to ecu main power relay then turned on with key 12v). but we have been able to see things are working even managed to see that both triggers are doing as they should.. the bad news is I stuffed up the actual timing on the motor when I slapped the new cam belt on ..I wanted the motor to be at about 10° as ointos love to start there and I had put a nice clean whit mark on the pulley......but 2 things...I had then stupid set the crank timing mark to that white mark and not 0°.... now also as we found out (going through this last night ). I had also put that white mark on 12° and not 10° and that in turn had put the cam out about 6°... THAT IS ALL MY FUCK UP but when I set the base timing it seems I was bang on....its just the motor was way out...so that kinda had shit out of wack the basic tune a STU on old school had done for me is almost there... but there just seems to be something missing... it will cough and splutter .. so we are going to just start from scratch again and make sure it's all working and try again....(not sure when ..my brain needs a break) the old starter motor had to have a few smacks with the small heavy hammer.... the band new battles had a work out of turning a motor over for 2 days... so that the situation....... it is all new for me and I'm learning (and I want to ...to know how ut all works.....there's a reason why tuners charge so much to set shit up)... but the motor is 100% right (now lol ) and the ecu wiring is right (one back fire cased a fire in the inlet and caught the inlet temp sensor on fire lol).. cheers if you read all of that

-

link atom x. been in my shelf since may 2020 was going to use it on the 6 cylinder cortina...but this needs to be done 1st

-

small update .. *I have managed to set base timing.. and I belive also sync cam trigger. *I have fixed the TPS problem ( tried a few things in the pc link setup...but ended up just swapping 12v and sensore ground over). I think this may be my limit and were I'm going to need help setting up maps and trying to fire her up.... so ill have a chat to my mate tonight and see if he can talk me through it or even come and help me.. but she's closer than see was 3days ago. cheers

-

cheers Sam. I've git a few mates to ask questions to.

-

yeah this is a link ecu.. I just swapped 12v and signal ground over and then setup again and now it's perfect.. cheers tho

-

well my brain hurts.... got the unlock code and didn't do much yesterday as I got roped into the decorating that's going on in my daughter's bedroom... so that was annoying . I did watch a few more YouTube videos on setting up the ecu last night and had a go today for a few hours.. I down loaded the new updates and saved it there and then started a new setup and I'm saving that as testing.. (so if I fuck things up I can just go back and load the one saved after update.). So I have managed to .. *setup and test the coils (they work). *setup and test the injectors (they work. *set up and test boost controller..(it works but havnt set any figures in there yet). *setup and test shift light (same as above works but no extra figures added. *setup and test ISCV (works but havnt set any think els up with that). *set and and tested TPS and MAP sensors. tried to calibrate them but both came back with a fault code ... did some searching and most common answer with map sensor is its broken.... so I left it and had a look at TPS (throttle position) and when I was moving it the values on the MAP sensor where changing ..now the MAP and TPS where allready marked out in the loom with the 3 wires needed for them each and a tag at the end starting what ut was for and what wire was what... tours out they git the tags wrong so I just swapped them over on pc link and then ran and other calibration on the MAP and ut came as fine .. so cleared that fault code.. Then I tried the TPS and set that up but the values are the wrong way around for some reason ... wide open is low voltage and closed is hig voltage. .. (not sure if it will work that way around or not will look more into it tonight.). *set up fuel pump aswell and started looking at cutting up triggers... but thats where I left it.. think for tring to set base timing I might pull the plugs out as well so no compression so it should turn over easier as it's still old motor old starter motor hard cranking.. but yes my brain hurts..

-

-

so being Easter Monday yesterday and nothing being open I wasn't going to get an email with my link ecu unlock code so I did a few other things. finished making a set of HT leads out of a new set for a falcon I had sitting around .. knocked up a section of exhaust just to go from down pipe v band to about the rear doors of the car with 1 small muffler (just to make it a vital quieter). put the bonnet on for the first time since I've owned the car ....its in pretty good condition just was what looks like 80grit sand marks in it lol. added a geat sheld to it and also manage to lift the back of it a bit with the adjustment on the hingers...should help with removing heat from the engine bay. this just in ..... git and email with link unlock code...