-

Posts

4662 -

Joined

-

Last visited

Everything posted by zep

-

Is it worth buying this? What is this brand like? https://www.savageperformanceandspares.com/products/holden-commodore-vt-vz-5-7l-gen-3-ls1-v8-140a-alternator?_pos=19&_sid=6343e4a29&_ss=r

-

Ideally I can find this unit at Pick-a-part or from a TM wreck.

-

Serpentine, although I suppose you can change the pulley...

-

As the title says, I'm looking for an OEM car that has a big alternator - preferably a car that is common. Any ideas? Cheers

-

The car is back home now. The brackets and tunnel are done. Next bit to do is buy some coilovers for the rear and mount them up nice and neat. I've decided to swap the upper rear mounts from single stud to and eye, for ease of buying the coilovers as well as strength.

- 73 replies

-

- 24

-

-

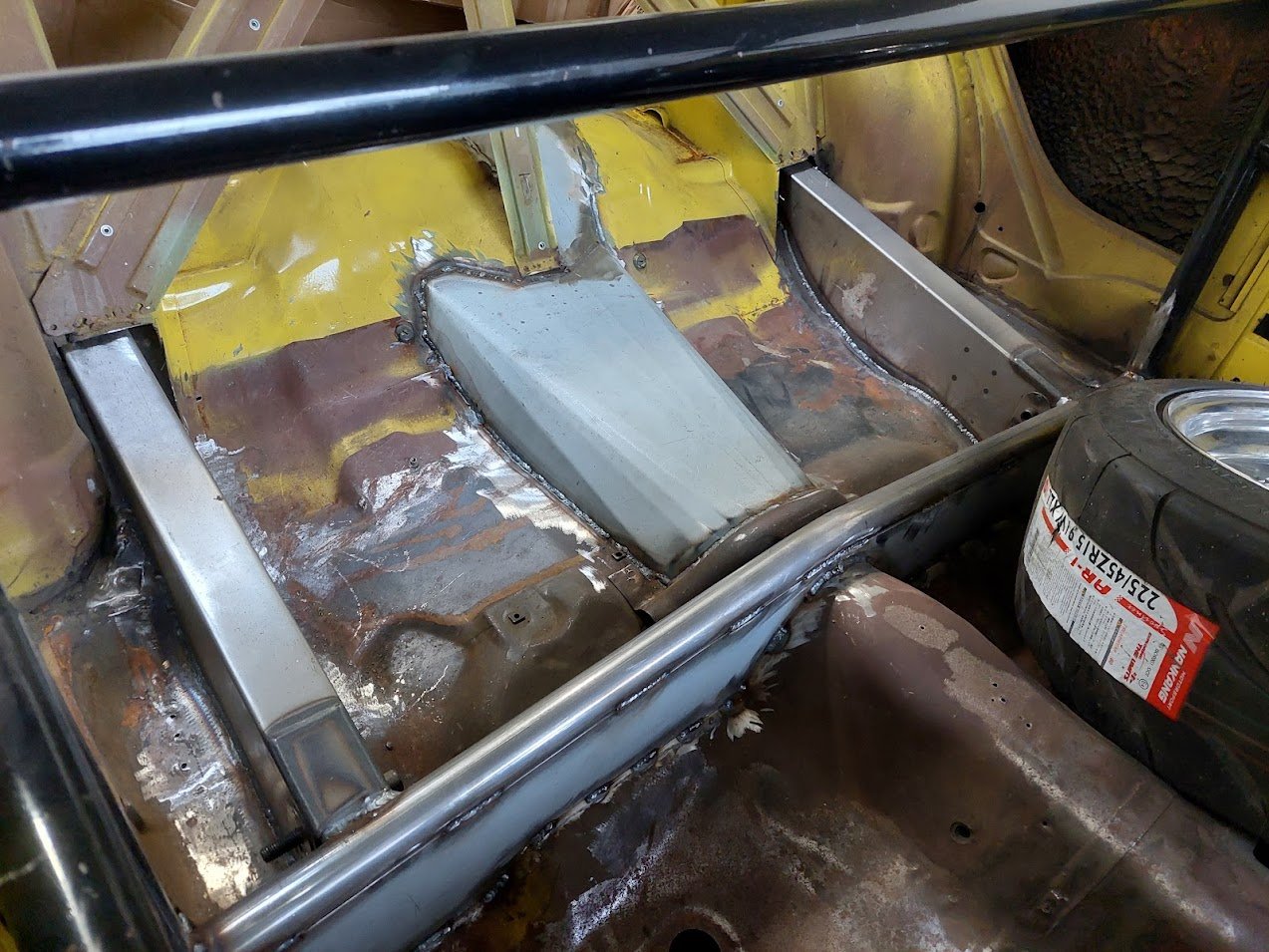

Almost done with the 4-linking. Tim has opened up the tunnel so nothing can hit at full bump, and closed up the channel that was cut for the old ladder bar.

- 73 replies

-

- 24

-

-

They were like $100 each to be cut, welded up (due to the dip in the axle after the spines), resplined and heat treated. Ridiculous!

-

Things taking a little longer than I had hoped, but yesterday I got some good news. The 4-link boxes are in and I'll go and have look on Friday and figure out what the next steps are. I also heard from Skeleton Welding that my core has arrived, so should be getting that sorted to soon too! Pretty happy with the progress.

- 73 replies

-

- 30

-

-

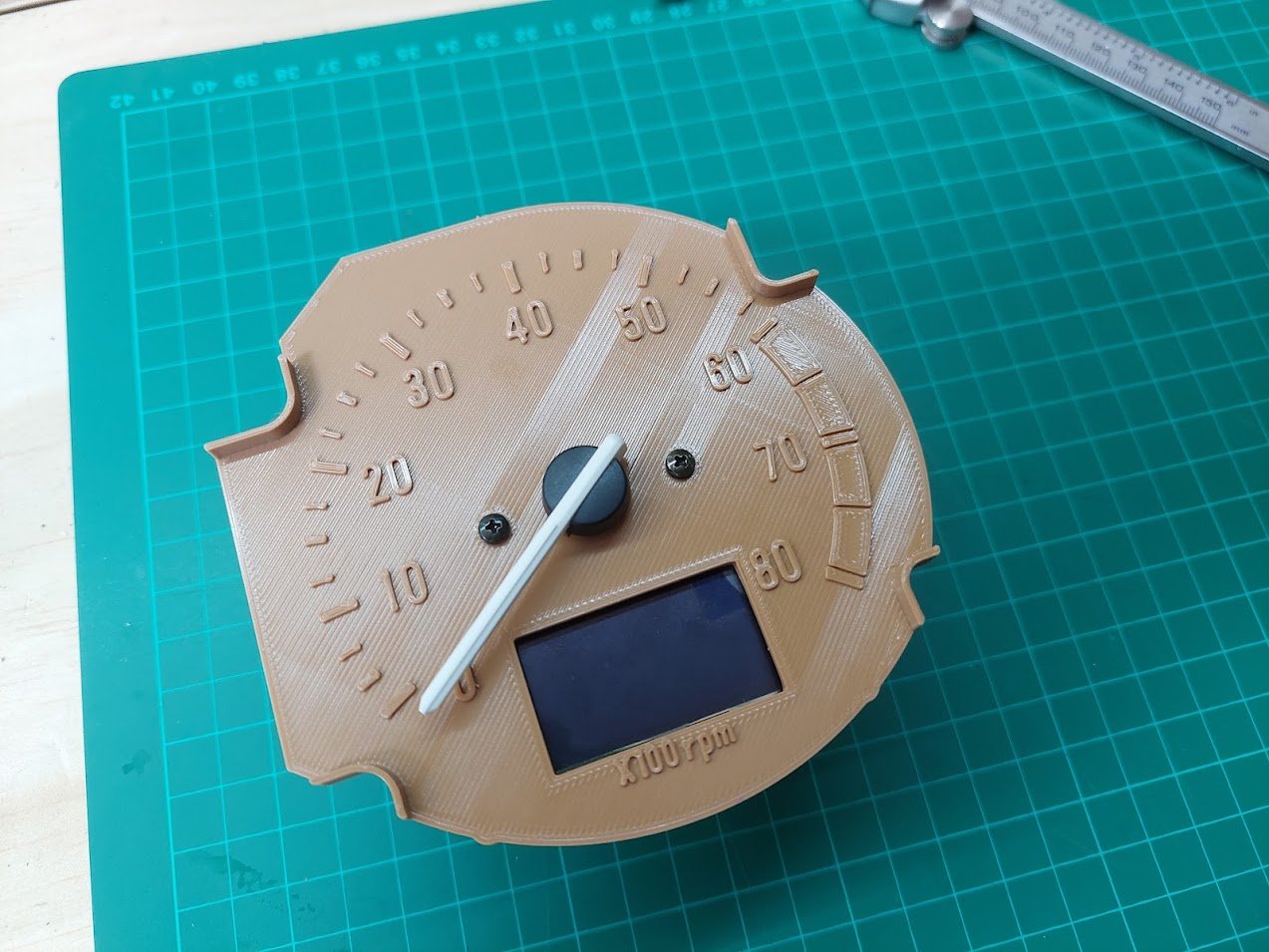

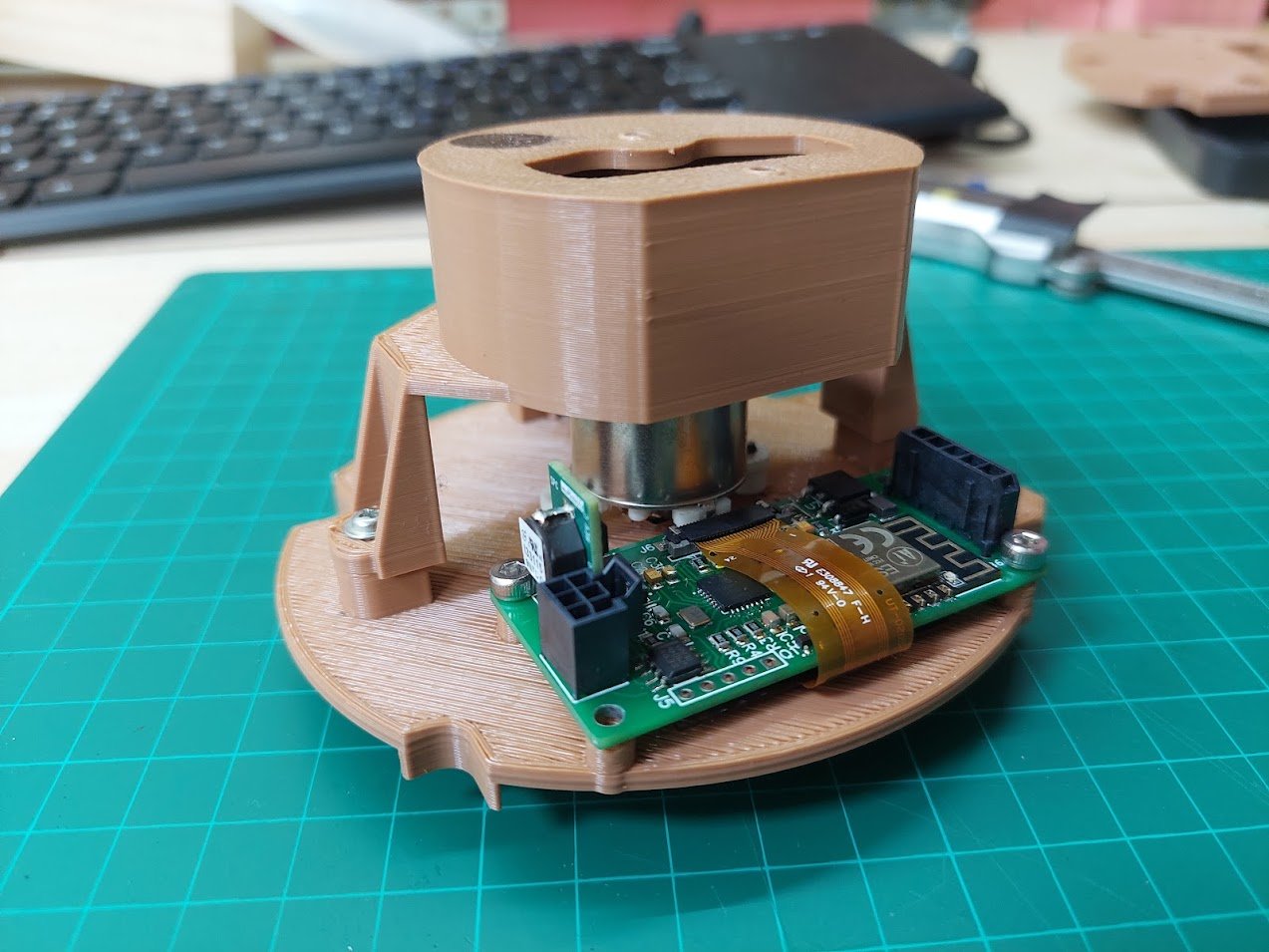

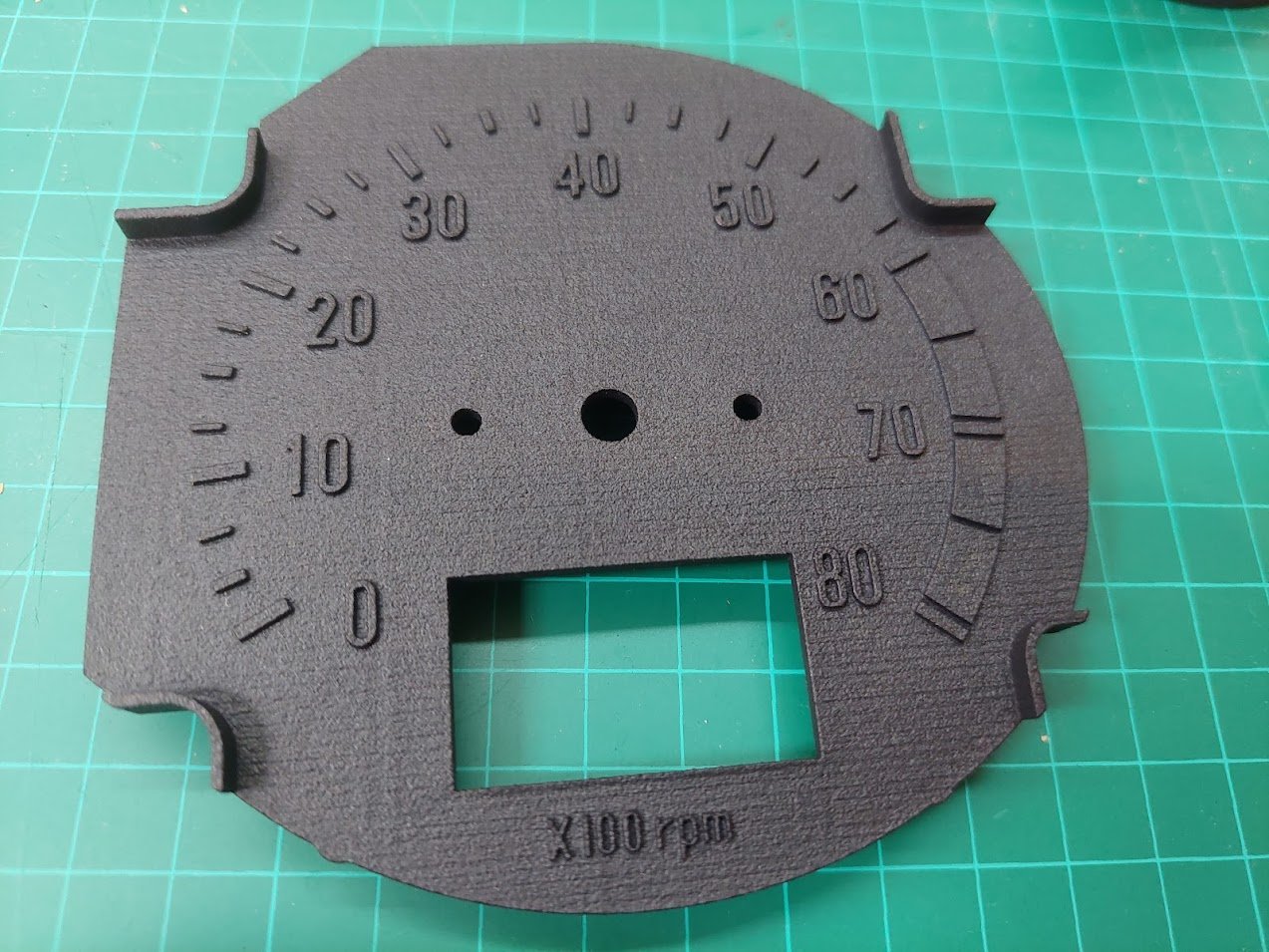

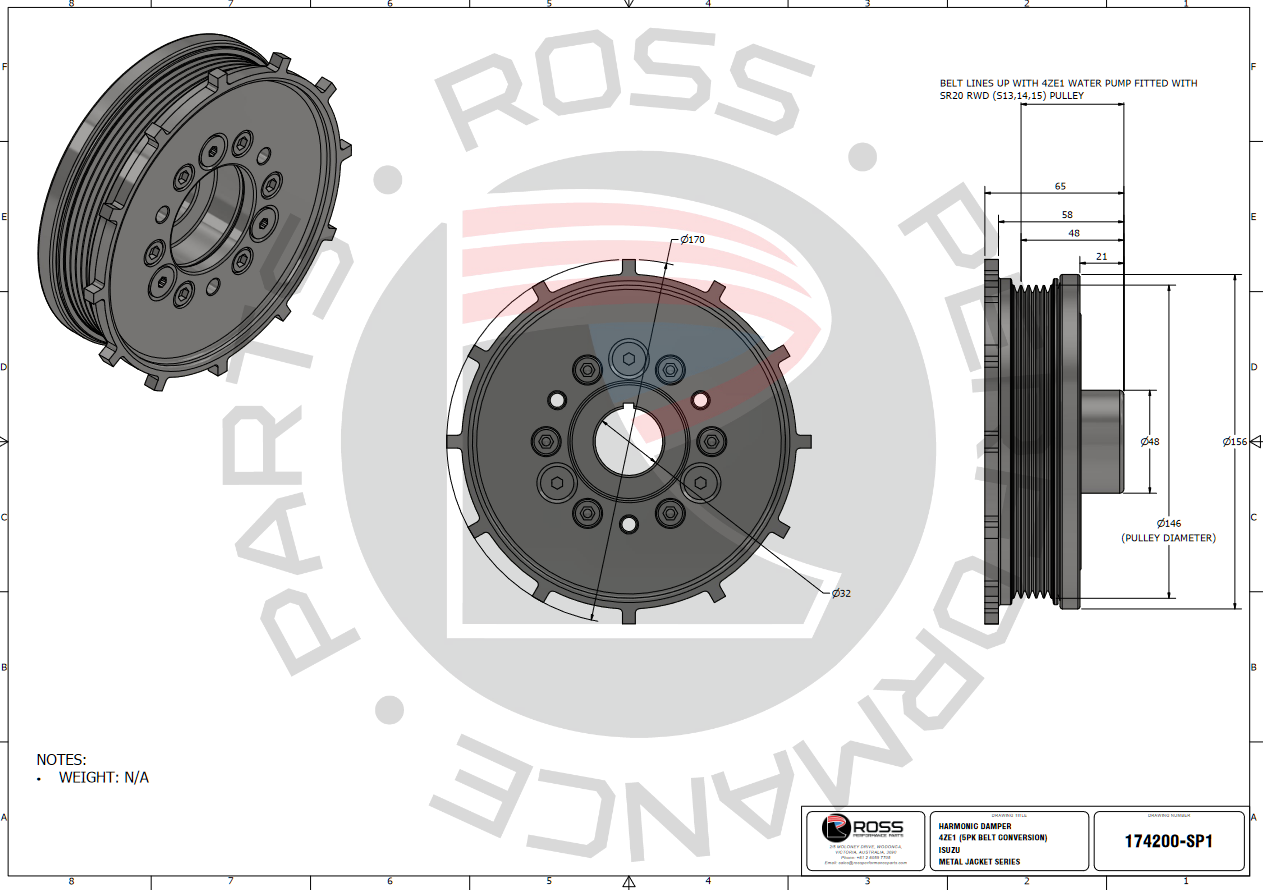

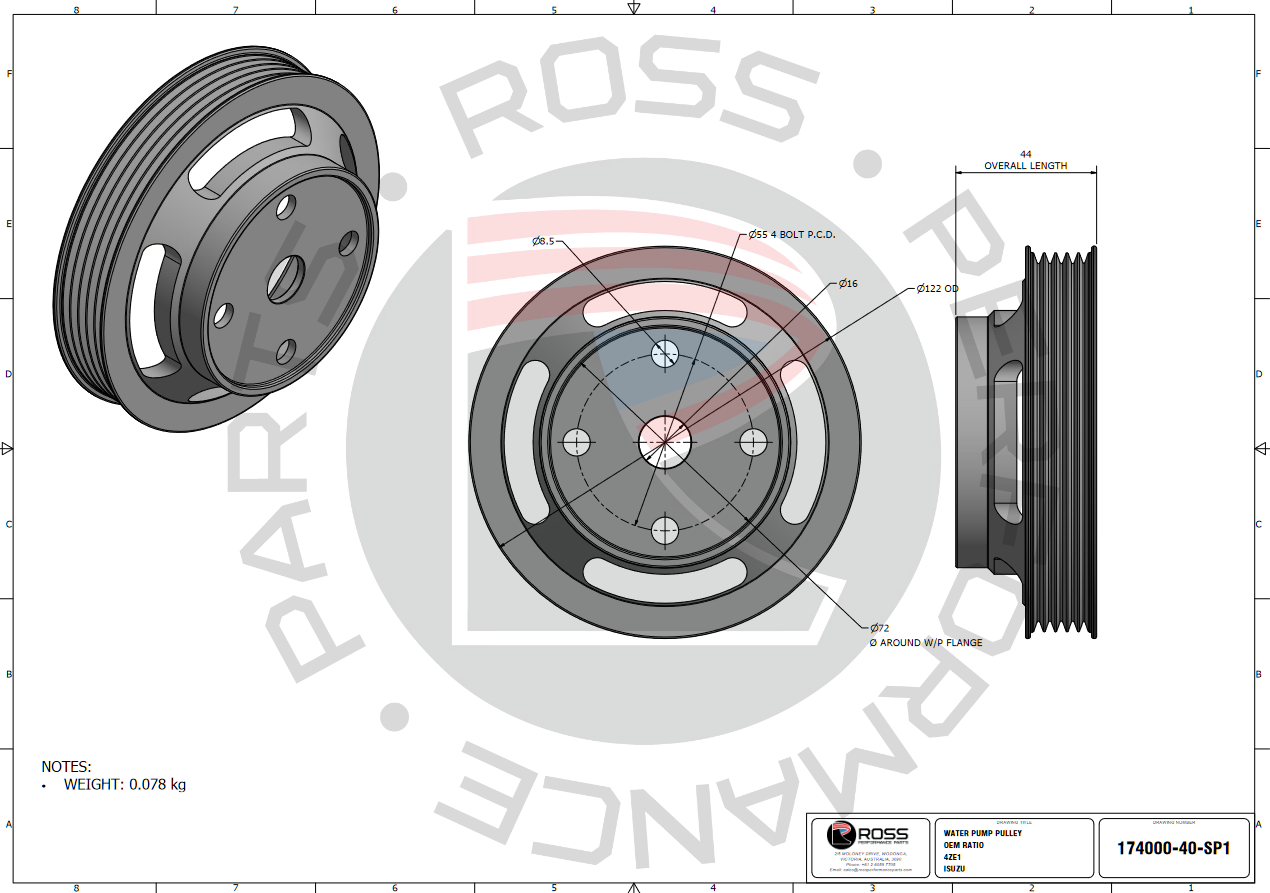

Wow! I really haven't updated this in a while. There's been a bit of progress in the last 7 months, but not a heck of a lot. I've been mucking around with brakes, dashes, diffs and cooling. In the end, I decided that shortening my axles the "build up and machine down" way was going to be okay, so I sent them to Howat Engineering and had 35mm lopped off and the splines cut back on. I then took the housing to Tin Tricks where it had the Gemini mounts cut off, was shortened and had the 4-link brackets slid on. I left the ladder bar mounts on so it still had a way to mount to the car when I had to move it. Turns out I was spot on with my measurements. The wheels just sit inside the arches - will need some work done to get unobstructed bump - and I have about 15-20mm clearance on the inside. So pretty happy. I've also spent a bunch of time prototyping up some parts with the 3D printer. Throttle body adapter: Brake caliper adapter: Master cylinder adapter: And for those of you who recall ages ago I was trying to make a new tacho face for my dash, I've gone in too deep. I've designed and printed up an adapter which uses all the stock mounting points and screws, as well as a new face which has the cutout for my CAN screen: I then had it MJF printed in PA20 nylon. Unfortunately it warped so I need to have another go and add some ribs in to strengthen it. I was planning to paint it myself using modelling paints, but I'm not sure that I have the ability. I spoke with Charlie's Pinstriping out west who said they could do it. When I get around to fixing up and printing a new version I'll take it up. Last thing that I've been doing for quite a while is working with Ross Performance in Australia to develop a harmonic damper and water pulley for the Isuzu 4Z engines. They have pretty much finished, I'm just waiting on one or two people to test some 3D printed templates to make sure everything lines up. And lastly I have been talking with Skeleton Welding down south to build me a new radiator. It's been a bit of a packaging saga to try and fit the radiator, intercooler and oil cooler up front. But I think with a bit of ingenuity I'll be able to make it work. Speaking of the oil cooler, I got this "cool" one from CSF: The car is now in at Shores NZ having the 4-link boxes welded in and the rear turrets strengthened for coilovers. So progress is happening!

- 73 replies

-

- 37

-

-

-

Awesome. Thanks Clint. I assume the same would apply if i was to incorporate the shock tower strengthening hoops into it?

-

Thanks Clint. Is there a limit to changing the cage? When the car is in for the 4-link work, I might ask if they have any suggestions about making it better. I was looking for half-cage rules, but couldn't find them specifically.

-

Yeah, essentially everything in the car except the existing cage needs certing as it's all changing.

-

The old cert does not have any pictures, although Clint knows I'm asking this question I just don't want to end up in a situation where I have to rebuild the main hoop because adding the gussets effectively means the cage is no longer the same as how it was when originally certed. If that makes sense.

-

My current understanding that my because my car is currently certed for its half cage with the old diameter main hoop, I can keep it through the recert for all the other changes I am making to the car (brakes, engine, suspensions, etc.). Is this correct? And can I add some central gussets to the cage without having to recert it?

-

The other option is thread the outside of the master cylinder inlets. There is definitely enough meat, just need to measure to see if it's a common thread size.

-

An update on this. I just spoke with Brian and Howat Engineering and he said the best option is to weld up, chop and respline the axles I have - it's like $100 each - and if it goes south make something up later (around $400 per billet axle). His reckoning was that in a small car like the Gem it'll break traction way before it shreds the splines, and mentioned that they had drag cars with welded and resplined axles and that it was all good.

-

Ah yeah. That's a good idea. Could easily weld a dash fitting on the top as well. What's the deal with determining the OD of the push-fit in relation to the master cylinder inlet ID?

-

I can't quite visualise this idea in my mind

-

Cheers man. Might give him a call today then. I guess the main thing here is that I am a bit concerned about having to remove too much material off the back to get the 4x100 working nicely. Not sure if that would end up any different to something that is custom made though.

-

They are kinda gross but might have to do!

-

I emailed Howat a few weeks ago actually, but heard nothing. There is a place up this was called Precision Engineering that I hear can do them. But I'll look at those ones which you suggested too @Testament

-

Who makes them in NZ? I spoke with Altra9 (Aus) and they don't do Hilux axles.

-

Interesting. I assume that the gate powergrip clamps have some kind of adhesive in them. I wonder how that would react to the brake fluid if any managed to sneak around. It's not pressurised, though, so should be okay.

-

Yeah, it's more for looks than anything else.

-

I am keen to run my master cylinder to a remote reservoir with braided lines. The problem is that there are no threads in the master cylinder inlet, only these clamp on plastic things. What's the best way to adapt this to braided lines that I can thread in to the reservoir? My two thoughts have been using some kind of rubber bung and a push in adapter that is threaded on the other end, or welding on something threaded but was advised not to weld the master cylinder as it might warp.