-

Posts

991 -

Joined

-

Last visited

-

Days Won

3

Posts posted by dmulally

-

-

- Popular Post

- Popular Post

If anybody is going to call @yoeddynz a cunt then I'd appreciate it if you put the word rad in front of it.

His embarrassingly lame MS paint drawing dumbing it down to my level worked and I now have a proper shift pattern. Happy days.

-

16

16

-

2

2

-

Is scratch start TIG a thing? I know for my one I have to get super close but wouldn't scratch start fuck up the tip?

-

-

1 hour ago, Metalhead96 said:

Dunno if its come up before but i read on the lvv fb page that someone said that guard rolling is no longer legal in regards to wof? Reason being that it "structually affects the vehicle body" and thus is now a cert issue?

Mate doing his Commer was advised by the cert man to get his rear guards rolled a couple weeks ago.

-

1

1

-

-

-

9 hours ago, HumberSS said:

Always been curious of those standalone ECUs for the common rail Mercs, great to see someone using it for a conversion. @dmulally do this mate! There is one sitting at pickapart in np...

Would love to know how simple these setups are if you have more details

I wish I had that sort of talent!

There is a reason I'm going for a one wire hookup diesel and it's entirely skill based.-

1

1

-

-

I think you should use some 10mm thick angle iron and be done with it. Man up.

-

1

1

-

4

4

-

-

Gotcha ta.

I made a new list of what needs to be done before LVV and added it to the bottom. I'm going to try and book in over the next few days to give me a deadline.Right after I swap this perfectly serviceable ball joint for an inferior Chinese one which in my experience has a 25% failure rate during install.

-

2

2

-

-

On 26/03/2024 at 18:46, yoeddynz said:

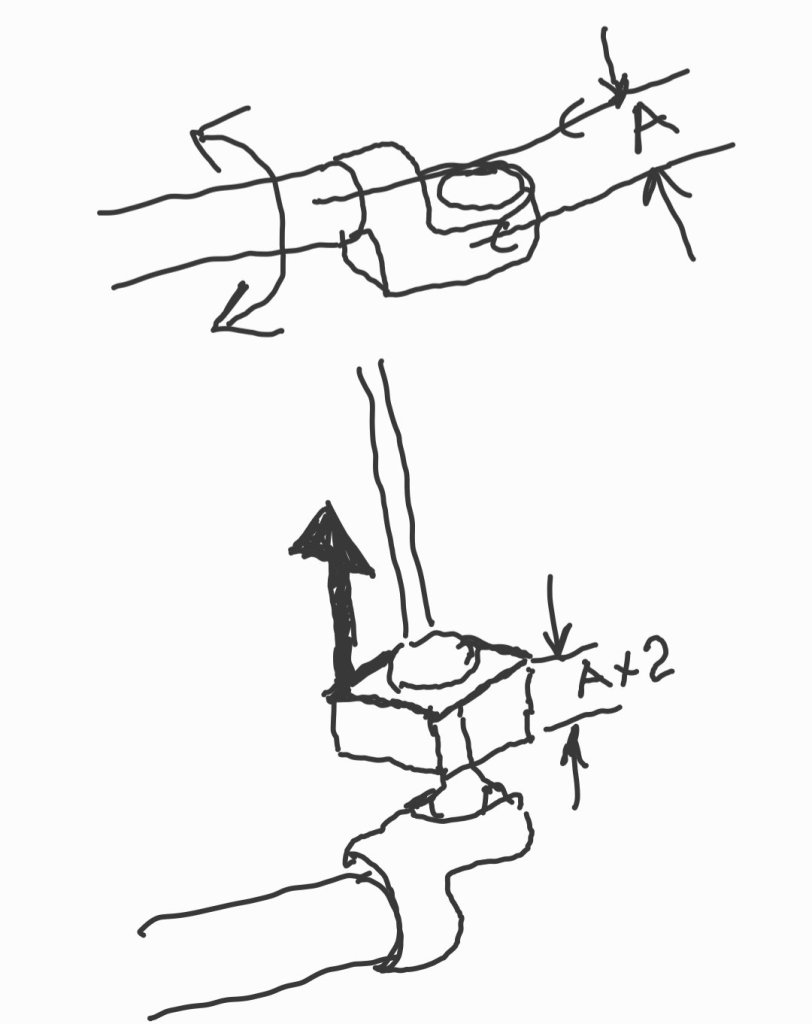

@dmulally like I said this morning on the reverse gearstick anonymous phone call, you don't have to make it as poncy as mine. Just rotate your under tunnel shaft 180 degrees so flipping the forged socket to the top and raise the gear stick fulcrum the required amount (30mm iirc), so reversing your across gate movement....

I had a look through the spares bin and found half a shaft (you have the front part) and most of a shaft setup. Ill have a bit of a play.

I'll still see if I could be bothered though. Anything I do make will be rough enough to make a David Brown owner blush.

What does A mean in your CAD drawing above?

-

- Popular Post

- Popular Post

Went for a decent blat into town tonight. A few things to note before I forget.

Cruises at 2200rpm at 100kph and has buckets of power upwards from that so the gearing is spot on. Maybe because Im used to a shitty old slow chevy but it feels like a rocket.

Makes a weird noise for a second on startup.

The sump is too low. Either I have to put in stock springs or modify the sump. @cubastreet got any spare sump pans?

The oil filler pipe is now hitting the firewall so I have to modify that again.

Second is a bitch to find from 3rd but I'll get used to it. It has enough torque to take off in 4th but I'll leave the clutch alone.

I might make the aux water pump booster linked to the ignition as I forgot to turn it on.

It's criminal me having this car and living 10kms from a decent corner. It wants to corner.

-

19

19

-

Yeah nah. I'll just have a backwards shift pattern tyvm.

-

1

1

-

6

6

-

-

- Popular Post

- Popular Post

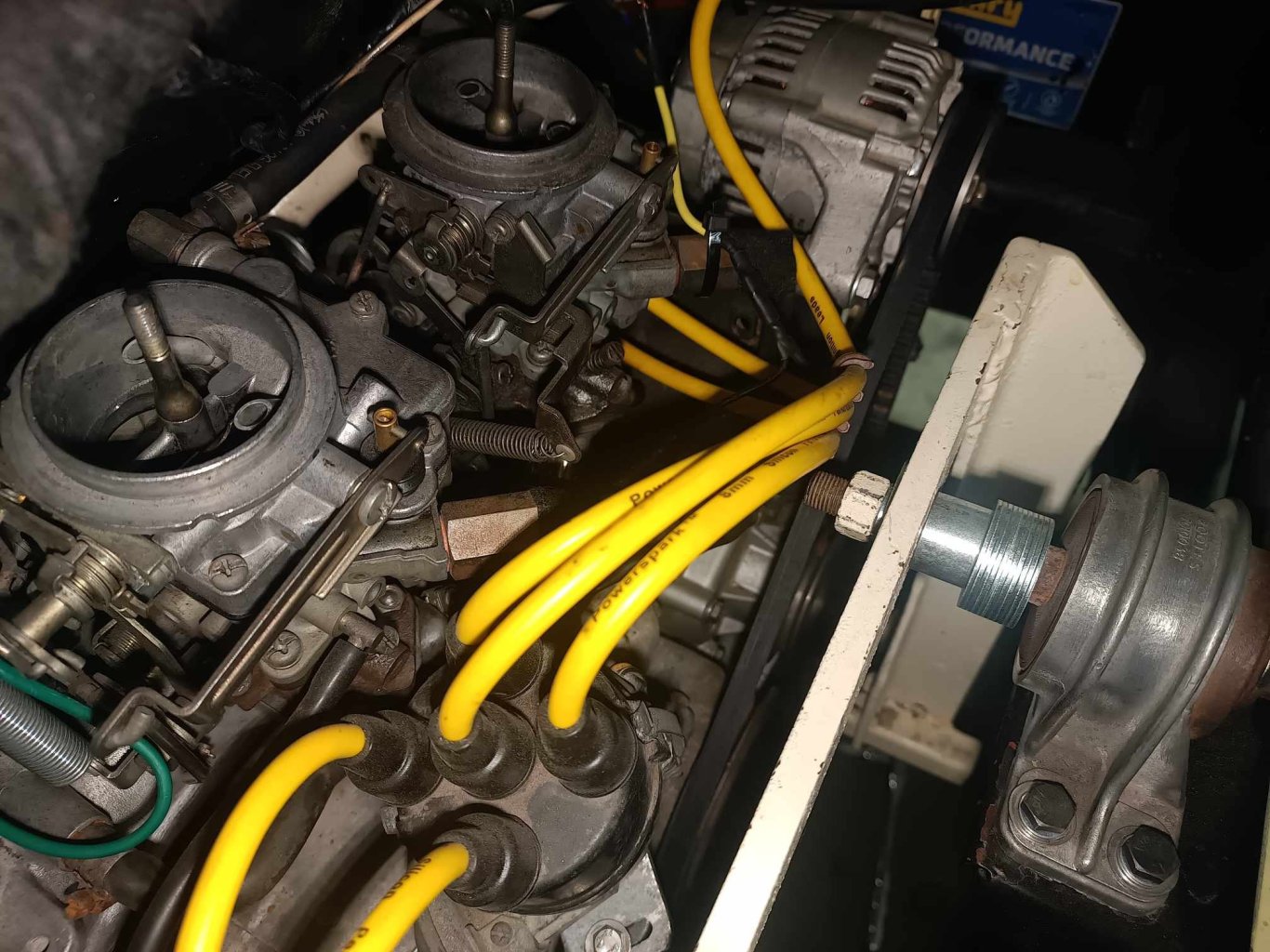

Reminder for myself next time I wonder why it is taking off so slowly.

-

5

5

-

11

11

-

-

- Popular Post

- Popular Post

After nearly three months my half shafts are done. Thankfully they fit really well and no binding with the full suspension travel. How he did it was to make a jig out of angle iron. The Imp end was a few mm smaller so he stepped the jig to compensate. Then notched a V into the ends of both and lots of welding to fill it up. He checked the balance and said they were fine.

In the meantime I have installed the slave and bled it with the trusted broomstick method. On the hoist the gears shift fine and no crunching and I can even find reverse which is novel in this thing. I presently have the coolant bleeding itself and have remade the radiator mount. The bolts welded into the side for mounting it were flimsy junk so I had to come up with a new solution which seems ok but may hinder my chances of putting on an electric puller fan.

I have a short list of works to finish before going to LVV but mostly bodywork and fine tuning. I'll see how it feels after the test drive which all being well should be this evening. Sadly I have to spend time sorting my C20 for the wof fails. I really need to find a new place. 3rd wof in a row I have failed on a ball joint that was fine the previous wof. The chances of three ball joints that are 60 years old failing one at a time every six months is a little disappointing for me. Especially as the replacement always feels worse to me but passes. Oh well. I have this year to get down to 2.5 wofs and I'm on a mission!

-

10

10

-

Does anybody know how GVM is dished out by VTNZ when getting a revin for a vintage truck? There is nothing on the truck noting GVM or tare weight and being from 1946 the rego is long since evaporated.

Do they go off sales brochures at the time? I really wouldn't mind getting it under 3500kgs to avoid rucs but not too concerned as it will be on farm rego if anything at all.

-

-

-

On 11/03/2024 at 09:06, Kiwibirdman said:

According to the google it had a 610 litre tank and had about 640km of range.

I wonder if having under 100l per 100km made the sales brochure at the time.

-

Still need to sort out the belt situation at the front. Needs a full redesign but one of those things where it still works so I keep driving it and I am resisting the urge to make it into a project before I absolutely have to. I should probably pick up a spare long block and take bits off it to swap it all over. Maybe when the Imp is on the road.

Anyway this weekend I managed to put 600kms on the clock driving all over the shop to the bush block for mowing and more trips than I would have liked to get gravel for an underground greenhouse I'm building presently. It can fit 1/4 cube of 20mm pebble in the tray so I just took the trailer which can take half a cube. As the fuel gauge is sketchy I took some figures down and it gets 13l/100kms pulling a load. I'm guessing it'll be much better with no load but already it's nearly twice as good as the chev.

-

8

8

-

-

I wonder what causes it to be that much heavier. Even accounting for 10kg difference in spool size.

Might go for the cheaper one. Cheers gents.

-

39 minutes ago, Bling said:

Might have just been bad luck? My inverter welder must be ~10 years old now, doesn't get thrashed but has always done a good job for me on MIG stuff.

Aren't both those inverter? Might have wrong link posted.

That has to be a typo on the heading surely. A 60kg inverter welder? Is that a thing?

Old mate in the shop said it was a transformer and it looks like one.

-

Finally got into my local welding supply shop today and was about to pull the trigger on an Xcel-Arc but thought I'd ask the brains trust first. My current mig is a transformer one. The two I have narrowed it down to are a 200amp transformer one for $2300 and an 180amp inverter variant for about $1200.

The last inverter mig I had shat the bed just after warranty ran out and it was unrepairable. Hence going back to a 30yo transformer mig which has served me well but is getting a little long in the tooth now.

Anybody got any opinions on either? I don't need to transport it so I don't care about weight. Just reliability and doing a good job.

-

On 04/03/2024 at 20:54, yoeddynz said:

Couple of questions that I need clearing up on. I have the lvvta manual and with regards to driveshafts I cant find any mention of halfshafts on IRS setups.

I plan on joining 2/3rds Subaru leone shaft to 1/3 Hillman imp shaft (both same diameter) I'd like to do the job myself because I feel confident enough as an engineer. I am happy to have them crack tested if that's needed. I will be visiting my hotrod builder mate in motueka (who's well known with most certifiers) and running a couple of ideas past him. Does this all seem fine?

Another thing I have spotted in the manual is this...

'Where a battery, and fuel system components, such as a fuel

tank or fuel pump, are located within the same compartment in a

low volume vehicle, the battery and the fuel system components

must be separated from each other by the enclosure of one or

both within a secured fuel-resistant non-conductive container'But at the start of the chapter on fuel systems it states this...

'Note that where a production vehicle is fitted with its original fuel tank or other fuel system

components in their original locations, the requirements in this chapter do not apply'I have my battery mounted very securely within an alloy box above the tank, the box is bolted to the firewall. The leads are secured within flexible conduit that's attached to the firewall before running into the interior.

I'll be using the original tank is but fitting the small nissan micra fuel injection pump within, through the top where I'll be making a sealed bolt down lid just large enough to get the pump in. (cant quite squeeze it through the hole the fuel level sender fits through) There's no room for a surge tank, nor do I want to go down the route of a noisy external pump again.

Does this seem all ok ?

My engineer (who might be your one too if initials are JC) said there were no real guidelines on it and I offered to have them fully welded by an engineering shop which he knows and was happy with that. So might be worth tacking it and having an engineer shop weld it up and provide a receipt stating exactly what they did.

-

1

1

-

-

I'd scrub it with a nail brush first and paint it with a couple of light dustings with no primer.

.jpg)

Discuss here about Yoeddynz's little Imp project...

in Project Discussion

Posted