-

Posts

2338 -

Joined

-

Days Won

2

Posts posted by kempy

-

-

On 09/06/2023 at 09:32, Ned said:

Just plug the car in and it can be setup to charge on how much energy is being produced.

So with solar plug car in during the day, with hydro or whatever that has a power dump, just dump it into car.Or charge your batteries as normal, and charge off of them when needed?

Most EVSEs have dynamic load balancing and also 'solar' integration where you can make it charge only of the solar is producing (but you can put the CT onto any old in feed)

Or charge it at work, plug it in and run the home off the car at night ….

-

1

1

-

-

-

-

Updating pics after iforce going the way of the dodo

-

Yea sad to see that happening, Would jump on it if it was 50t

-

On 12/07/2022 at 20:02, Nominal said:

Where did you find the tooling/ wheels, I haven’t found a source in NZ with plenty of googling so far

-

-

That's a shame, it had it's own crop circle included in the price

Barfoots list it as being sold March 22 for $4,675,000 so Im guessing the Trademe link isn't pointing to the right place and just showing a suggestion, which i wouldnt mind TBH

https://www.barfoot.co.nz/property/residential/papakura-district/ardmore/rural-property/818993

-

On 09/06/2022 at 13:01, NickJ said:

Fancy pants rental car I had could read speed signs and adjusted the speed warnings to suit, do any radars have that ability?

Some dash cams do a similar thing , I have a HikVision dash cam that reads speed signs out audibly which is pretty handy in Akl traffic, it also has so other analytics like detecting if the car is moving away from you if you are stationary it says "Keep up with the car" but I turned that one off as its a little over zealous

It can also warn you when the traffic lights go green..Kinda, Often Ive been parked and a voice speaks "Traffic light gone green", not a green light in sight, especially in my driveway.

-

1

1

-

1

1

-

-

I’m not saying that I would t really like to have one

-

1

1

-

-

Noticed that too with auction sites on TM, stupid stuff like cheap Ozito tools going for much more than retail :/

English wheels seem to be quite expensive for what they are, to the casual observer

-

2

2

-

-

49 minutes ago, datlow said:

Will it start if you spin it?

Try both directions

Yep, sure did.

I forgot to mention... Before embarking on totally dismantling the motor, it's advisable to check that both sets of windings are OK, by memory the start winding was approx 8 ohms and the start winding approx 17 ohms. ( you'll need to take the terminal end of motor off to get to the winding side of the contacts to check this)

If either winding is open then you're screwed without a rewind.,

-

1

1

-

-

All reassembled, a quick check with the Multimeter and Fluke tester to check the windings, wiring of the reverse switch and earth leakage etc. and it's away.

It starts instantly in either direction, the only thing that really need some attention is the black plastic or Bakelite clutch plate has a crack and in time could possibly fly apart. it also make a ticking noise when the clutch disengages and presses the black plate against the contacts as the motor comes to a stop or is starting up.

Unsure if that's a part I will ever find so I'll cross that bridge when I come to it.

-

6

6

-

-

The weights when spun, extend outwards and pull the clutch in (indicated by the direction of the Blue outlined arrow) and the contacts open, which disconnects the START winding.

The issue here (as you may have already guessed) is that the Centrifugal Switch was jammed up by a little bit of corrosion and very old grease which had gone hard and by result permanently keeps the START winding open.

Picture of a dirty shaft...

Gave the motor windings and rotor a quick clean and blew out decades of old dust.

Said shaft cleaned , lubricated, and reinstated clutch, points lightly filed to remove pitting and fitted, bearings were mint so were pressed back on and wiring reinstated to the correct terminals this time.

-

2

2

-

-

This picture shows the clutch disengaged and the contacts closed, which would engage the START winding.

The Start winding gives the motor an boosted magnetic field and kicks the motor in a direction determined by whether the phase/neutral are wired in forward or reversed.

Here you can clearly see the two windings, The Red wires connect to the RUN windings, the black wires connect to the START windings. This of course may differ between motors, revisions. manufacturers etc. so don't trust this solely just by colour.

-

2

2

-

-

As you can see from the picture above, it's an old Brooks 1/3 HP single phase motor.

There's no starter capacitor on these, instead they have a centrifugal clutch which opens or closes a set of points/contacts.

This motor has two sets of windings, one set is the RUN winding that stays powered when ever the motor is running, the second winding is a START winding, this winding is energised when the motor

is first powered on and disconnects shortly after the motor reaches speed by means of a centrifugal clutch

You can see from the L/H side arrow that the contact is open and sitting against a rest, it should be firmly against the contact which is shown by the R/H side arrow when the centrifugal clutch isn't engaged

-

2

2

-

-

I haven't posted anything much apart from Random pictures for a long time, However realising that I'm in the company of other Myford Barry's and recently becoming a member of this exclusive sect, I thought I'd post up a few pictures for those that may come across this problem in future.

I recently picked up a sweet little Myford ML7 lathe in really good condition, the previous owner has stripped it down and replaced guides, bearings, bushes etc. and apart from one or

two things it's almost ready to go

One of those things that needed attention was that the motor doesn't start by itself, instead it just meditates and hums.

-

22 hours ago, SOHC said:

If kempy dosnt want it its available, Its too small for my Atlas lathe witch has one of those stirrup tool holder holders

Keen! 'll send you a pm

The fella I bought the Myford from replaced it with one of those Chinese lathes, he seemed pretty happy with the replacement (approx $1200).

I think he was making small model railway stuff with it.

-

1

1

-

-

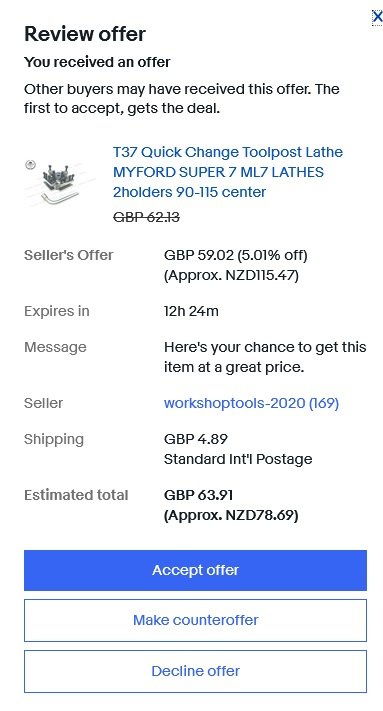

Sweet, thanks for the replies, I think I'll go for one. ( unless @SOHC finds one first?)

Ebay's calculations are a bit off...

-

1

1

-

-

-

1 hour ago, SOHC said:

Do you have the lead screw?

Yep, it's still wrapped up in brown wax paper

-

1

1

-

-

- Popular Post

- Popular Post

-

This thread reminds me that I must get my shit together and try this.

-

Tech Spam thread - because 1/4" BSP gets 5 hand spans to the jiggawatt

in Tech Talk

Posted

@h4nd Cheers, I have a couple of others already as well, knock yourself out @Ned