-

Posts

255 -

Joined

-

Last visited

-

Days Won

1

Everything posted by vk327

-

standard rubber lined braid with an fitting on the reservoir and these on the maser cylinder end ? https://nzkw.com/shop/hose-finisher/

-

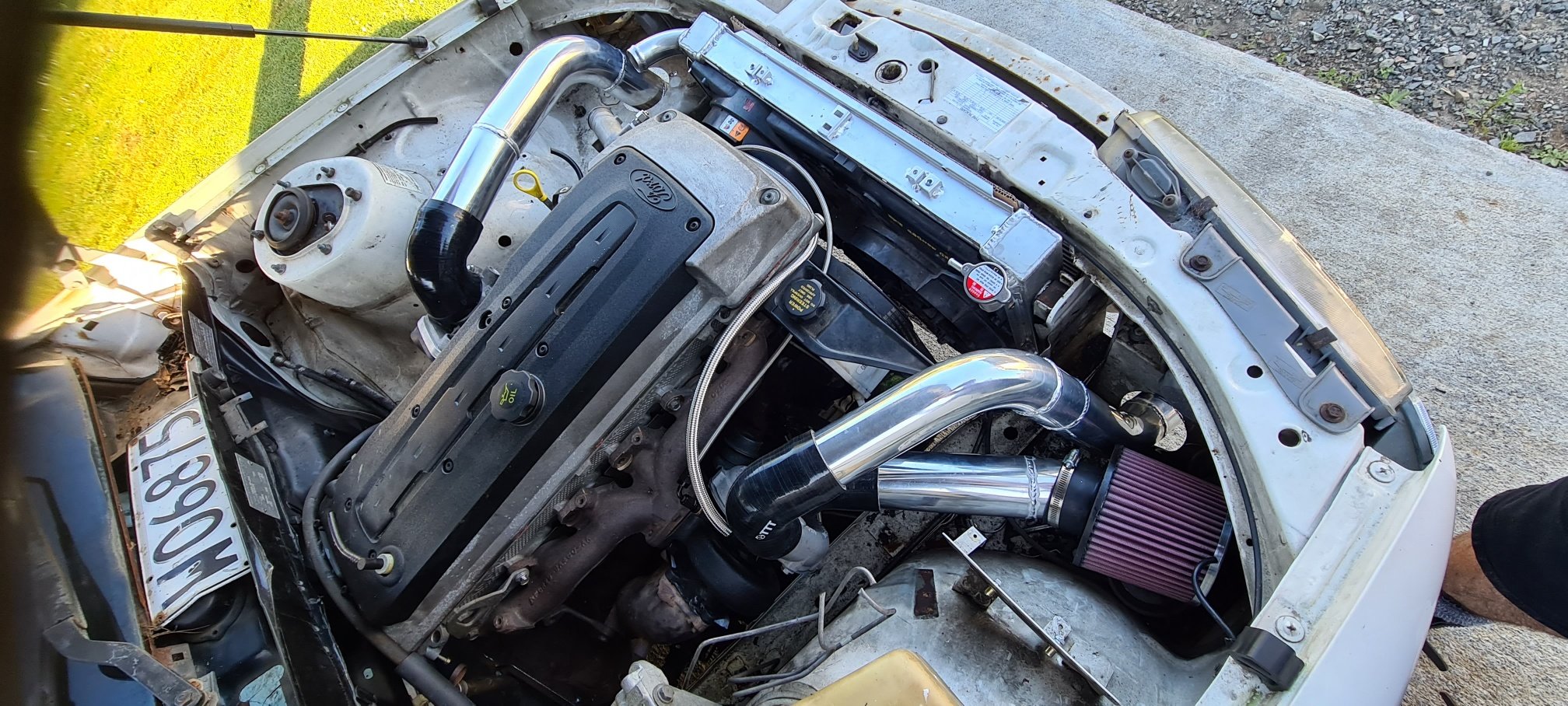

making good progress now, decided to buy mounts instead of build them since my lack of spare time factor, took a while for the tuffmounts kit to arrive but a nice bit of gear including the custom swaybar to clear the sump. proceeded cut up a brand new ali radiator to suit barra outlets and fitted up a set of 2002 mondeo fans(have these on the turbo vk and they work mint) got the intercooler mounted and hot and cold side pipes done, really making progress now a bit of plumbing a driveshaft and throw in the wiring and should be pretty close to running

- 7 replies

-

- 18

-

-

try the guys at HCB batteries, on arthur porter drive, will prob wanna sell you a whole battery thru an account holder

-

be wary of chinese terminals on anything critical, have seen it several times after a couple cycles plugging in they lose tension and end up with bad contact as they are made of way thinner material than genuine ones, can really notice the difference with the Chinese LS looms from VPW and aeroflow vs OEM even the connector bodies are made of sub par plastic and cant handle the heat of an engine bay and go real brittle, the old saying you get what you pay for, common terminals are pretty easy to ID, GM its all generally Delphi/Aptiv metripack 150/150.2 or GT150, most japanese stuff is sumitomo, can generally figure out parts crossover to RS from ballenger, waytek, eficonnection or nzefi listings

-

Finally had a bit of time to work on this thing got the Castlemaine rod shop adaptor kit bolted up and mated the TH400 to the engine and got it slotted in the hole Decided to drop the money on the tuffmount barra conversion kit so that will be on the way here soon, tracked down a manual steering rack to pickup after lockdown to give me clearance for a 3.5" dump pipe. still lots to do but looks like progress

- 7 replies

-

- 22

-

-

-

highly recommend these if your ordering connectors from ballenger motorsports get a couple, they work well for depinning most connectors https://www.bmotorsports.com/shop/product_info.php/cPath/111_113/products_id/366 the key ring ones work well too just wear out quickly

-

got a list of a few places I frequent msel.co.nz techflex.co.nz bmotorsports.com eficonnection.com racespeconline.com efihardware.com having accounts with local auto electrical wholesalers means I can access a lot locally, but not easy to get in the door there. also check out on facebook motorsport wiring alliance for tips and ideas, best advise practise on small thing like bikes and sub harnesses that are easy to redo before diving had first into a whole engine loom Braid sleeving always looks good and is quiet cost effective and easy to work with

-

split corrogate can look good, when its wrapped in tesa or hellerman loom tapes or just straight wrap in the cloth tape, would be worth investing in tooling to use Deutsch connectors (basic ones are about $60) and a decent open barrel crimper for OEM stuff Hozan p706/ p707 and a delphi weatherpack/metripack crimper work well , you can get every commodore v6 loom connector and pins new from EFI connection. com (except the ones that connect to the body). its pretty easy to blow $$ on tooling iv got a few drawers full of differernt crimp tools but can get by with decent basics, have a look at my facebook page or my website for ideas of what looms can look like re sleeved or remade also check out techflex.co.nz for braided sleeving the even have a wrap type braid that can look good, would suggest looking at depinning tools for various pins can depin and slip sleeving on

-

havnt played too far with the v6 ecus myself but that looks like it should give you enough headroom on the maf table, could possibly use the AC pressure sensor input as a way to input a wideband 0-5v and be able to log it if you can define your own parameters and calc like im able to with HP tuners for LS

-

memcal based L67 ecu has the proper table resolution setup for boost and the control for the s/c bypass valve later L36 flash ecu can run it but will run out of map table with the boost cranked up

-

iv played with keeping the delco controlling the trans only, and results in average trans control (also need the factory ecu to keep the ABS and dash happy), the way the triggering/ignition work on the v6 makes it a bit of a pain to do piggyback with an aftermarket ecu, would suggest looking into using an vy supercharged ecu convert to an nvram board to realtime tune with it, dunno why your having so many issues with crank triggers they are normally ok once replaced with a decent sensor unless the balancer is wonky and eating sensors or other wiring issue going on

-

injectronics are the specialists in aus repairing vz ecus , absolute garbage bosch ecu (they burn up the tracks inside the ecu not really a diy type job on multi layer pcbs) to go with equally as junk rattletec engine, my tuner/programming mate has replaced over 70 ecus in vz v6s in the last 2 years

-

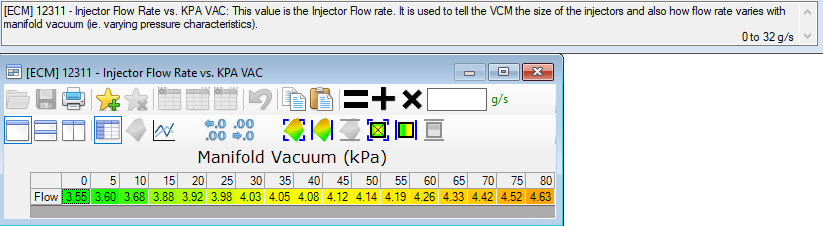

you'll probablly run into issues running the vy pcm on the l67, the vy pcm is pinned diffferently to the l67 pcm and the loom is different the l67 has the bypass valve control, as well as the l67 ecu has a larger maf table(and other boost related control), the NA vy pcm will likely max out its maf table (have had issues before with people running NA pcms on boosted v6s) if you can find one would be better off getting an NVRAM for the L67 pcm which enables live tuning on the memcal based ecu.

-

had to revin our kingswood due to dodgy plate/ tag mismatch from 97, we have owned the car for 5 years, VTAC were happy for me to do a declaration with a JP that i own the car, all proof/docs i had was relating to the plates that didnt match the cars chassis/vin number, VTAC had sighted the car 1st tho

-

complete prick of a thing to get out have to drop the whole pedal box ,column and brake booster plus half the lower dash, not the easiest to mount either recently pulled one out of a BF for my wagon build

-

Anything alloytec v6 onwards seems to be junk, the vz v6 ecus are total garbage, all the LS stuff is pretty reliable electronics wise

-

Yeah pedal will typically be 6 wire, 2 potentiometers to give failsafe signals to ecu, throttle body is similar setup, normally common up +5v and gnd, so 4 pins for position and 2 for motor, just need to go thru the e throttle setup in the link software to set the sensor slope, generally wired one upscale one downscale

-

-

Never had issues with the ve pedals, just looked now priced at $110+, depending on what space you have maybe look at some of the Nissan or Subaru pedals as they have metal stem which is easy to mod pedal angle/position if needed

-

check out these https://www.msel.co.nz/epages/motorsportelectronics.sf/en_NZ/?ObjectID=90387&ViewAction=FacetedSearchProducts&SearchString=throttle+body&SearchButton= https://www.msel.co.nz/epages/motorsportelectronics.sf/en_NZ/?ObjectPath=/Shops/motorsportelectronics/Products/SENBOSPED link will run damn near any combo just need to setup the calibration for the sensors, some subaru/ nissan pedal sensors are a lever arm type so can adapt a standard pedal if needed LS commodore stuff is pretty cheap too, I can get VE commodore pedal for about $90 new (similar mounting to the MSEL one) heaps of throttles available in various sizes

-

VK304's 1988 Nissan Vanette w/ added SR20DET

vk327 replied to Willdat?'s topic in Project Discussion

il chech the wiring info iv got for the vt cluster, fuel input should just be a hardwired input, does the level sender have its ground wired? I think they were 2 wire from memory -

brown is charge light white is sense on a stock ls plug should be marked on the alternator too

-

the commodore alternator vt-vy with the mitsi/hitachi large plug is the standard sense to battery and light terminal to ignition switched 12v via lamp or simulated resistor, vz ran a different ecu controlled regulator can probablly pull some injector data from an hp tuners file for a commo ls1 if that helps reverse lockout is simply a solenoid ign 12v to one side ground switched the other in factory application unlocks under 5kmh , common way is to hookup to brake light circuit so have to put foot on the brake to activate the solenoid switching +12v instead of ground

-

give me a call il flick you a pm with my number