Leaderboard

Popular Content

Showing content with the highest reputation since 04/19/23 in Posts

-

Bench testing continued. The sump was now holding oil. Phew. I fitted the old smiths mechanical oil pressure gauge that was originally fitted in the imp race car. I mounted the gauge to the temporary coil stand. With the engine cranking over it was seeing about 20 psi. The oil level would drop in the sight glass and after a minute or two it would be back to the old level. I was happy with this. Next on the list was to check the idle control valve was working. Its a 2 wire Bosch style pwm type unit. Very common, simple, reliable and hence used often in megasquirt installs. Its basically a rotary valve that is opened against spring pressure by a solenoid windings when current passes through them. The ecu earths its ground wire in a series of pulses, the quicker the pulses the more it stays 'open'. Simple as I thought.. but.. this is where I discovered that I had bought one of the units that is actually 'closed' at about 30% duty cycle. A failsafe on cars that use these for closed loop idle control (aircon/powersteering/epic sound systems etc etc) If the valve fails then spring pressure actually takes it to a slightly open state so the car cant stall. But I'm only using the valve for open loop at start up. So when its closed I want it to be closed. Luckily I was able to pick out/burn/pick out/burn/pick out the tough as epoxy that was holding the valve stop adjustment screw in place. I wound the screw in until the valve was closed with no power. It still passes a tiny amount of air but its much better. I'll manually adjust the idle bleed screw on the throttle body to get the fully warmed up idle where I want it when that time comes. Which was going to be soon I thought! Next thing to check was that the crank angle trigger wheel VR sensor and the camshaft half moon hall sensor were both putting out satisfactory signals. Opened up the composite logger on tunerstudio expecting to see nice clean signals. But there was nothing. My heart sank. Oh here we go.. I took off the cover on the main board plug and checked the connections there. I then popped the volt meter, set at AC volts, onto pin 1 and 24, wound the engine over and got about 2.0 volts. I don't have an osillioscope and only have an old megastim 2.2 testing unit which won't create the required rpm signals I needed for testing. I wasn't quite sure what to check next so I started a thread on the megasquirt forum. Got some bits of advice but in the end I rang a mate in Richmond who has a lot more knowledge with megasquirts and has helped me out in the past. Organised to go see him the foloowing day. In the meantime I checked the hall sensor. I had never been able to find confirmative details on the polarity of the hall sensor even though it was a really commonly used unit among many a citreon/fiat/renault etc. I finally found a factory service manual online for Fiat ducatos which had a pin out of the sensor. Turns out I'd got my polarity wrong and after swapping the wires around at the hall sensor plug I now had a strong clean cam signal. I also made a mandrel to hold the old honda 12-1 trigger wheel in the lathe. Then I made two jigs. One for the spare goldwing VR sensor, like the one I'd fitted to the engine. The other jig was to hold a Mazda V6 VR crank sensor of which I had a few kicking about and had used them with no issues on the Viva. I spun the trigger wheel up in the lathe at various speeds and took voltage readings of both sensors. The readings were very similar but I still couldn't tell what the actual signals are like. The next morning I drove out to mates place and he set to work on my ECU. He compared the board to his spare Ms3x. looking for any differences. Remember I had bought this ECU secondhand from someone on trademe and was told it was working. I had swap some of the circuitry jumper wires to suit my application. Once he was happy there was nothing major missing on my board he got another spare ecu he had and ran up my sensors in his test bed to confirm they were putting out a good signal. Then we (well - mainly him, I just stood about and learned) systematically went through the VR circuit looking at the signals on his osiloscope. Discovered that transistor U7 was faulty so he kindly swapped out the known good item from his MS1 which I'll find a replacement for him. After that he found a loose, terribly soldered resistor in the circuit- when it was wiggled the signal would appear.... re-soldered that and hey presto - clean signal. Lots of other pins got re-soldered too. The Goldwing pulse generator/VR sensor puts out a much weaker signal that the Mazda crank vr sensor. we double checked them against each other and the Goldwing item struggles at slow speeds (cranking type speeds) so I'll swap over to the Mazda item. When I got home I quickly tried the repaired ecu out and now there's a good rpm signal but it drops out of sync but I took a log anyway. Then started making a new bracket to suit the Mazda sensor. New vr sensor in place and wired up. I then had to remove one cambelt, which is so easy to do on these engines, remove the trigger wheel, file off the old key and weld a new one in place to suit the mazda vr sensor position which was now bolted in the other set of holes Honda used for the original 'pulse generators' as they call them. New trigger wheel key peg.. Finishing that lot got me to this point when trying it out that evening... The red spikes indicate an out of sync situation and no rpm reading but at least the log was clean, consistant and rythmic. Something wrong in the settings, not interference. I tried changing various trigger settings but no luck I was tired so off to bed. Following morning I discovered that when I was changing the trigger settings I didn't spot the prompts to power cycle the engine because I was still on the diagnostics page. So none of those changes took place until the very end when I had actually set it back to the typical default settings. This time a power cycle after changing the capture to falling edge and I got this lovely log... Yay!!! Now I was ready to check the ignition coils and then the base timing. What else could possibly go wrong? Coils all tested fine and the sparks were nice and clean looking. I then marked the timing mark on my custom crank pulley and tested the base timing. I was out by 4 degrees. Pretty happy that I had got my trigger wheel so close. Simply changing the trigger wheel offset value in the settings by 4 degrees had the timing marks line up bang on. Engine start up time was here! I went to bed happy, excited and somewhat nervous about what could happen, or not... So this morning it was time to roll the engine out on the table to the front of the workshop, throw some fuel into the mix and see what happens. I set up the garden hose just in case, taped my phone to a light stand, started recording, tentatively went for a start and this is what happened... Wow!!! Faaaaaaaaaaaarking awesome! What an occasion. What a milestone. Such relief and much giggling with joy. I couldn't believe it. First start on my own custom built engine and it sounds bloody amazing! That was starting on a basic universal base map loaded onto the ecu so I was really expecting a lot more mucking about with the starting settings to get a clean start. I was stoked! I tweaked the cranking settings slightly and now it would start on the button after a few cycles... I can only run it for a few seconds as there is not a drop of coolant in the engine. So my next job is to set up a makeshift coolant circuit using a spare Nissan micra radiator and setup the Davies Craig electric water pump. I can test for leaks and then I can really have a good crack at setting up a nice clean starting and idling tune. I'm so happy! Alex.114 points

-

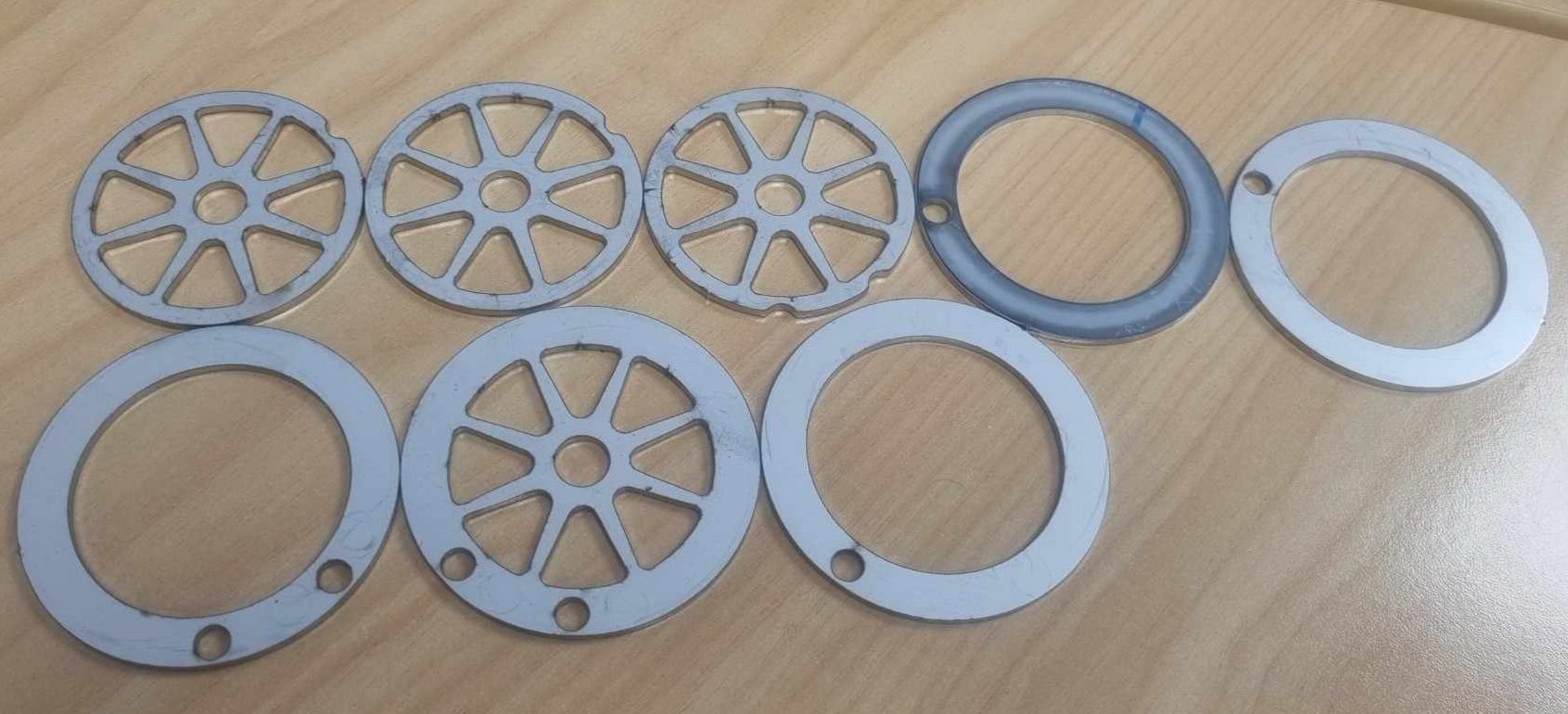

So where I left off last time was the oil filler pipe and sight window ideas. I don't really need a separate flange now I have decided to run the pipe shorter in height. So I dug out another old bit of alloy, gave a it a clean in the lathe and welded up a new pipe.. While in Nelson city a week or so ago I popped into a plastic place that told me on the phone they had 25mm thick walled acrylic tube. Turned out they didn't and instead I left with some thin walled lexan (polycarbonate) tube, closer to 25.4 in size. It was cheap so I thought it gives me something to play with. I picked up some thin 25mm O-rings on the way home and started to suss out a way I could make it work. The plastic was way too thin to machine Oring grooves into so instead I machined some alloy ends with grooves. Cut a short length of plastic tube to suit.. Which was pressed onto the end caps.. I milled a window into the side of the filler pipe. Now I had some bits to assemble.. Fitted in place.. The bottom of the stub which the filler cap screws onto is pretty much at 100mm oil height. Bottom of the sight is 80mm. So if I aim for a 90mm height I'm smack in the middle. Some led keychain trinkets turned up in the mail from China and I have a metal 'momentarily on' switch from Jaycar electronics. I'll have a play about and see if I can make a neat enough attempt fitting it within the filler cap so it does something like this (using a bike light)... Back to proper jobs now. Painting and finish assembly. First though I wanted to check the TDC marks are correct and make some timing marks to suit on my alternator pulley. I set a DTI up and found TDC. Luckily it seems the factory marks are bang on. Paint time. I had bought some paint for the engine a while ago. I gave the block and heads one last clean and masked them up. Primer first.. Then top coat. I decided on alloy finish, similar to the original colour. Really just too tidy it up and stop the alloy getting that annoying light corrosion. Then that fun job of removing masking tape to reveal a neat finish.. I masked over the original hand painted OK checks - just because I like them. Engine painted I dug out the brand new head gaskets Id bought very early on... Torqued the heads in place and then moved onto the camshafts/camshaft and follower housings.. In place... Now I needed to finish the trigger wheels which meant getting them phased in the correct position. I laid out all the bits that go with the cam covers and pulleys. This alloy bit was damaged from when the original Goldwing bike must have been dropped (I think the engine must have come from a low mileage bike that had been involved in an accident many moons ago) It wasn't sitting flat and needed a bit of a straighten.. Simple I thought. I'll use the press. I carefully set it up on the press with various bit of metal so I could bend it back straight. I got it pretty good - but it needed just a little bit more... Bang! Whoops. * Pic is taken after I'd already started prepping it to weld. I preheated it in the oven and then carefully sticthed it back together. Not the nicest casting to weld but it turned out ok and luckily the repairs are not on display.. Welded both sides.. Trigger wheel time. First off I wanted to work out the wire polarity on the oem goldwing VR sensors.. Now I knew the timing marks are good I set up the main crank position trigger wheel in place and marked it. Then welded a stub of steel in place which was cut down to form a key that locates in the cranks keyway. I doubled checked the megasquirt MS extra build manual and removed the appropriate tooth so creating a 36 - 1 trigger wheel with a 50 degree offset. Then I fitted the brand new Gates cambelts I had also bought ages ago. Sadly I discovered they are English made which means they'll probably leak.. Now I could setup the camshaft position sensor trigger wheel - needed so I can run the injection mode as fully sequential. I had made this wheel a while back but had not yet removed the half moon of material. Annoyingly I forgot to weigh the wheel before I removed material. I now had no real accurate way of working out what to mill off the opposite side to balance the wheel out. Balancing it is probably not super critical but considering that at 6000rpm this wheel will be doing 3000 rpm I really wanted to avoid any extra throw out stress on the pulley or camshaft/camshaft bearings. The final nail in the coffin for this wheel was it slipping in my makeshift rotary table (actually just the mill vice which can be rotated to mill the concentric slot - which I did by hand) It slipped, the end mill grabbed and became two pieces with a loud bang. So I made a new wheel. This time I weighed it before removing the halfmoon. Then I was able to mill the exact right amount off to balance it as best I could. Weighing it before milling out the final weight reduction slots.. Setup in place.. All that sorted I could move on to a fun little job I was looking forward to. Painting the cam covers and sorting out replacements for the old badges. After a really good clean and some light sanding of the covers, which have been through the wars and have extensive welding repairs due to the same crash I guess, I laid down some primer. See one repair here... Due to the fairly rough finish I decided on wrinkle finish paint because it can hide sins and blemishes. I've used this same product to good success on that Mazda V6 I had plonked into my Viva HB so I was pretty confident on getting an OK finish. Covers were warmed up in the sunshine and 3 thick coats were laid down, 5 minutes between each coat. Once the paint did its magic thing they came up ok. I'm happy. Now the badges. I was going to try a couple of mates about getting something with the word HONDA 3d printed or machined in alloy but I really wanted to do it all myself and thought about some nice machined ribs to insert. they turned out neat.. Carefully fixed in place as per original badges with double sided foam tape... Covers bolted up in place. I'm really happy with the look80 points

-

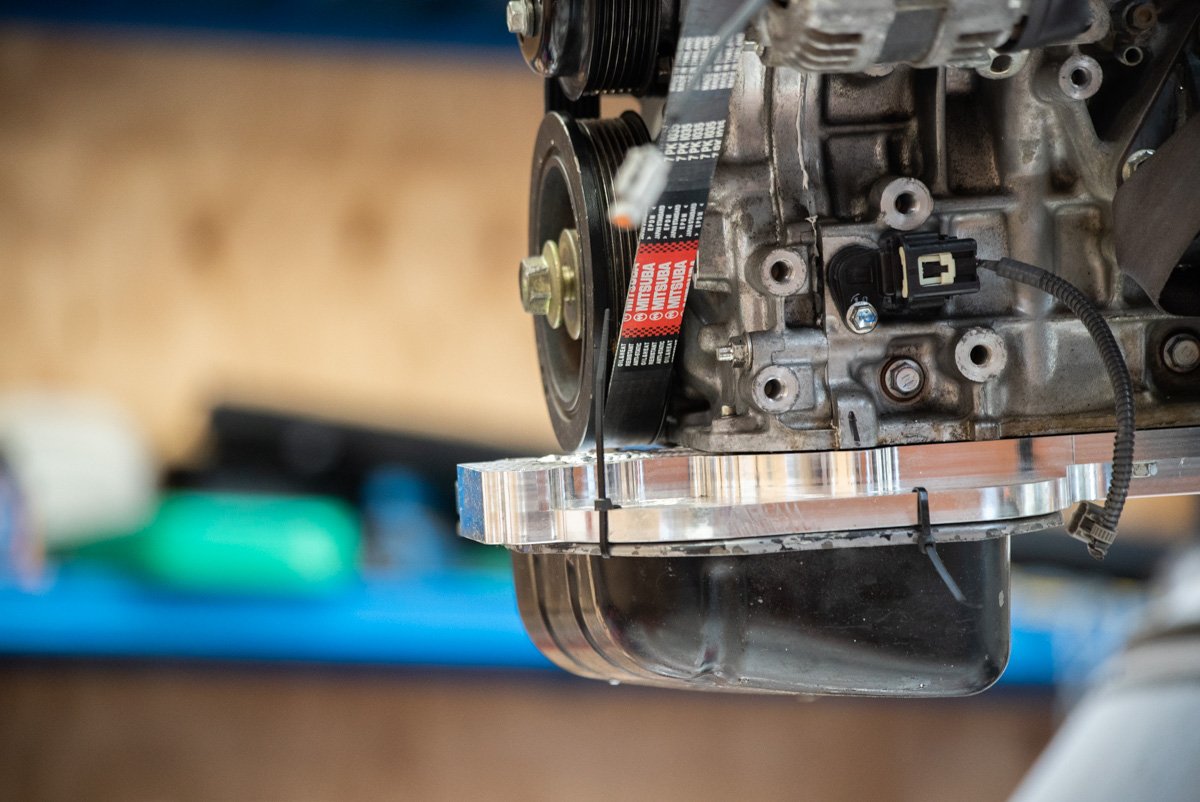

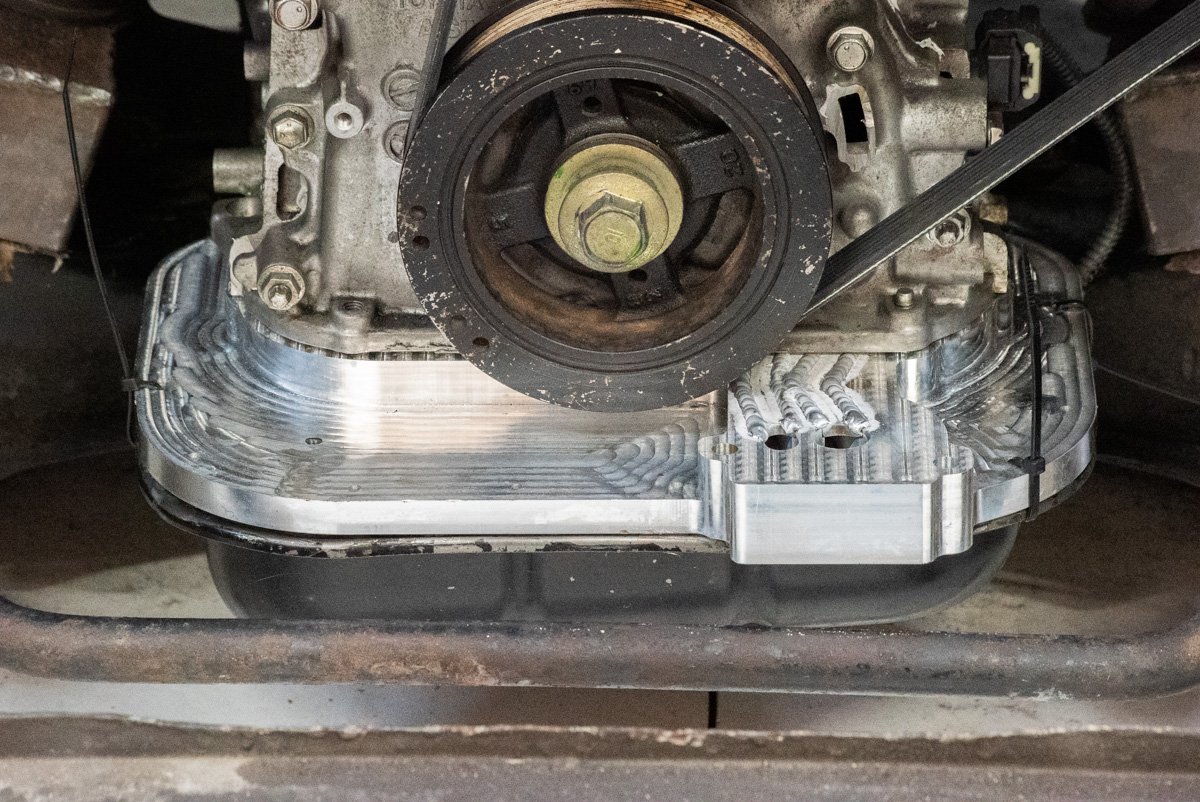

Part 2... catching up now. I finished what I needed to on the loom to enable testing of the injectors. I had made a simple little alloy jig that I could bolt the two rails onto and it sat high enough that 6 matching jam jars could sit below. We set this lot up on the big mobile steel bench and rolled it down to the front of the workshop near the entrance just in case it all goes a bit wrong. Set the ecu up along with a little 'ignition' switch and starter button for later testing of various engine sensors/ test running. The tuning software that megasquirt uses, Tunerstudio, has a good set of testing programs built in including injector testing. Started using that and as soon as the injectors primed and started squirting we found a tiny leak. Poos. My home made rails were brazed together and there was one teeny bit the bronze hadn't flowed into leaving a tiny pin hole that let out a comical jet of fuel. Glad I tested them now. Here under that lovely layer of carefully applied epoxy black... was a tiny hole.. So out with the oxycet and I brazed it up. Then re-tested the setup. No more leaks We ran through a few tests and made notes on fill rates at different opening times/frequencies etc etc to work out the injector dead times. Not a crucial thing to do but since it was setup as such it seemed rude not to. The battery I had was a bit tired and my charger couldn't keep up so I installed a larger wheeled type of Nissan charger at the front of the workshop. This also meant the testing was being done at a realistic voltage you'd expect to see. Happy the injectors were all matched and meeting the factory Nissan specs I packed all the stuff away. Then I fitted the inlet manifold gaskets and bolted the inlet in place on the engine, followed by the rails, with the repaired bit hand painted with epoxy as best I could to match. Next job to finish was the Bosch style idle air control valve. It had far too big in and out bosses so I machine up some stepdown parts to suit a more sensible sized tubing. I needed to mount it somewhere out of the way, safe and not on view because its not very pretty. I spotted a handy bracket on the bottom of the starter motor that has a threaded hole. Perfect! I made a little P clip to suit mounting the iacv. which bolts here.. Like so... I did some more plumbing to suit and after a few last little bits of wiring the engine was about complete. I fitted the pod filter I'd bought a while back directly onto the throttle body but it will actually end up remotely mounted in a cooler spot. I was just waiting on some posh ventilation hose to arrive. The Imp got a fresh wof and we took some pics of it when down at a local swimming spot near Motueka. It looked neat on the river stone so I took some pics.. Went hooning up a local valley to get wild plums.. Got home and snapped some pics of the engine next to car. The perspective makes the engine look huge... Next stage was to bolt the exhaust headers in place properly with the new gaskets and special nuts I'd bought. But before playing with exhausts always be aware of the potential dangers, as so carefully pointed out in the workshop manual !... Manifolds bolted up fine but a few of the nuts are awkward to get started as its tight on space around the header pipes. Next parts in the exhaust chain was the flexible joints. My welding was improved a bit by wearing some reading glasses. I guess I just have to accept that aging thing and embrace the power of +1.5 because now I could actually see what I was welding. Its still not instagram weld porn but it'll do for this project Bolted the cross member in place and with a bit of alloy I was able to check the heights to weld the next sections at. Unfortunately I must have fabricated the LH manifold out of line and I have ended up having to weld the secondary pipe at an angle to make sure the outlet heights match. It wont be easy to spot when its on the car, with a exhaust box hiding them. But I know its there... Or maybe I don't bother with a single large tranversely mounted silencer and just run a couple of old dumpy mufflers... I was now at the point I could fill the engine with oil and test the oil system. Quite a while back I bought some quality oil when on sale.. I filled the filter up first and then carefully filled the engine. Up until this point I had no real idea of exactly how much my resized sump would take before it got to height I wanted it at. I'd done some basic sketches and napkin formula and I knew it would be more than 3 litres. Hopefully more than 4. It almost took 5 litres to get to the halfway point on the sight glass and that will drop once the oil pump primed up and filled the oilways. Cool. Great news then. I'm really happy it'll have a decent amount of oil in there. Now remember back to around the end of December 2021 when I wrote this... "Lastly I needed to bolt the sump cover in place. I had to think carefully about bolt placement for sealing purposes and get the bolts square. This sump plate is going to have to be sealed well because there is no usual high sided sump like most cars. Hence I built it rigid to help against flex. Good quality sealant will be the order of the day* *It will leak. Its a British car. Its destined to leak." Well then. Guess what. It leaked! Ha. Just after patting myself on the back at having a great sump capacity the level started to drop and was leaving a good puddle on the engine stand top. So Hannah helped me move the engine so I could drain the sump and then I mounted the engine/box assembly into the spare imp. On a positive note I was chuffed with how quick and easy it was to bolt up in place by myself - all of about 5 or 10 minutes. Engine in place and with the car up in the air I took that above photo. I had a good idea where it was coming from and wasn't feeling to glum (not even a single toy was lifted from my cot) I unbolted the sump plate and found the hole... Back when I was machining the sump plate and milling the slots it wasn't initially clamped down tight enough and it shifted out of line without me spotting it. By the time I noticed it had moved it was too late. I had to weld up the resulting mess and re-machine that area. I thought it was all fine but I'd obviously missed a tiny pinhole, maybe exposed when I machined the inside of the plate out to take some weight off it. The plate got a good clean (that threebond sealant is tenacious stuff! ) and I fixed the hole with a dollop of JB weld. Took some pics of engine from below with its innards exposed.. Little pistons... Bolted the sump plate back up, waited till the following day and refilled it. This time no puddles. Yay. While the engine was bolted into the spare imp I took the chance to double check measurements and clearances. It was all looking good and I was very happy that I had placed things ideally, especially as most measurements were taken in awkward areas by all sorts of various ruler/tape measure/level balancing acts. The ignition coils for example, just mounted on their makeshift bracket I'd made for bench testing, are actually almost bang on in the right place and only sitting a touch too high. The filter hose will just clear the underside of the parcel shelf and there's heaps of room for the remote filter.. Hose (turned up the day before) .. Hannah's hand holding filter roughly where it will be mounted to the bulkhead... Lots of room out back between engine and where the removable rear valance bolts in place.. and lastly, the 'Mandalorian spaceship' will not at all be hidden by the rear parcel shelf .. Engine is now out and back on the bench for more 'bench testing'...79 points

-

Finally (finely?) got it across the line yesterday afternoon!!! Repair certifier got back to me, said he would drop in a dealer plate on Monday if I’d bring the car in Tuesday. It has laid-up insurance cover with Classic Insurance (great to deal with!) which means it’s not covered if it’s driving. I was able to change up to fully comprehensive and they only charged me a difference of $54 that gets me through to February which is when the laid up cover was due for review! Went to start it Tuesday morning and the battery was too lame to crank it.. jumped started off the falcon and all was well again. Only thing I could think of was me finally tightening the clamps and found a bad patch of contact. Jiggled, sanded, no real benefit. Charged it at work while I was waiting to get the word to bring it to the shop.. Didn’t get word. The next day he said come over about 3, I text to say I’m on my way. Car started fine, turned off and on when I got there to test, nice! waited 20 mins for him to appear and had a chat, he was impressed and said it should be pretty straightforward from here. Went to move it over the hoist and it wouldn’t start. Good look. Jumper-pack and parked, lime-scooter back to work just before close. It sat at the structural repairer certifiers panel shop for almost 2 weeks, the Compliance guy was asking me how it went daily but I’d heard nothing and wasn’t getting replies. He started pestering him on my behalf. Get a call on Sunday nite saying as far as he was aware it was done and just needed to shore up the paperwork. I didn’t hear shit till Thursday morning, he says he’s aiming to have it finished and round to compliance today. Fuck yeah some excited nerves, still stressed out but on the edge ever since dropping off, no word. Friday morning I get an email of a Read Recipt from a message I sent him 2 months ago so I figure he’s looking though my files and everything and today might be the day, but the compliance guy had openings early week and was alone at the end of the week, not to mention it’s a long weekend. 8:20am ‘it’s good to go’. Now were short staffed at work but everyone knows the situation so I lime-scootered over, it’s all covered in panel shop dust but I grabbed it (wouldn’t start) dropped to Vince at i4Checkpoint. He was stoked to see it but said it’s gonna be here all weekend,sorry..but it’s nice and safe. 3pm he calls and asks me to bring a handful of cash a over and I can take the car to get some plates. Well that’s a surprise! Emptied the till and added to my walking cash so had enough, caught a ride with a sprint courier heading in that direction and paid the man, got the forms and jumper-packed me out the door with a WOF and a 17 digit vin plate attached!! Few points to fix but I’d figured out some of them on the maiden voyage the other week. Now I didn’t want to risk that battery bullshit again so went straight back to work, grabbed the Datsun and ripped round to the local AA, filled in the last bits on the forms and waited patiently (impatiently) for my spot at the counter. One of the cheaper transactions from the Gubbmint and I was reg’d for a year and had some big gay white plates! Rip back to work, and across the street to the battery place which had nothing under $300. Remembered the Mrs has a battery stand at work so pinned down and grabbed a big Koba for much less, back to work in 5pm long weekend traffic, stabbed it in the hole and she’s been a honey ever since. Took it out to get dinner as well, all dusty and shit. It was a fucking slog, absolute emotional roller coaster and doesn’t come recommended if your like me, but there was a hell of a relief driving it home completely legit and insured against the rest of the world. .phew. Today I remedied the issues, fitted the swaybar, flared the top of the front guard where the arch meets the inner stay a little, repositioned one exhaust that was tapping the rail from time to time, fitted the front spoiler, washed and dried it, changed to mopar bonnet pin escutcheons and took some pics for you fine folk. We’re by no means finished, I’m a serial tinkerer so I’ve left some jobs for later. Have a scotch, I fucking am!78 points

-

Hey, looks like a great day for Pickapart! Time to get a bellhousing. So I using some fairly crappy tools I brought, after smashing a few knuckles and many swear words I got a gearbox separated from an engine. Luckily I didnt have to undo the torque converter, it just slid off. As that was looking like a whole other nightmare. I couldnt get the bellhousing off the box, and it's same price for a full box. So I decided I'll just grab the whole thing. However, my next problem. I'm down near the back of Mangere Pickapart and there are no wheel barrows or carts or anything. This transmisison is bloody heavy. I can carry J160s okay, but this thing is beefy. So, I made a little sled out of an engine heat shield and a seat belt. Instagram vs real life: Then I dragged it to the car on a piece of carpet. What a mission haha. The auto bellhousing is very short, but hopefully the idea of a cut and shut onto J161 front will work okay. That's enough punishment for one morning though.75 points

-

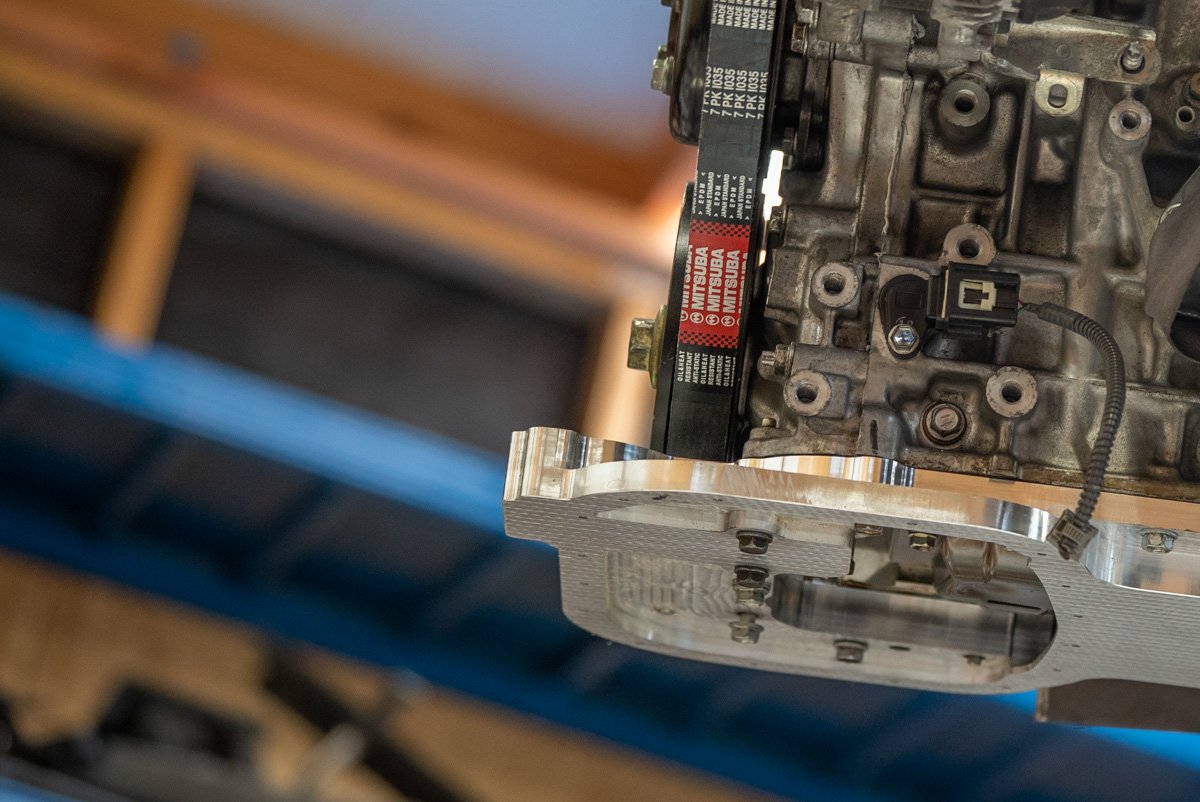

I glooped the two halves together, bolted them up, bolted the tailhousing on and let it set. Following morning it was bolted onto the engine, unsurprisingly a bit heftier with all the gubbins placed back within the box. Its about 9kg heavier than the standard imp box. I then started to fit the first part of the gearshift linkage. The first of those snazzy universal joints, handily available in a diameter to suit the shifter shaft on the Subaru box. I just needed to add a small locating hole for the grub screw... Universal in place.. Engine and box were then bolted back into the car. This bit is so quick and easy when using the 'engine stand 2000'. It takes about 10 mins and I'm getting quicker. It'll be slower when there's shift linkage to undo and driveshafts to slip out of the way. But at least the main heavy awkward part is actually easy. That lot in place I took some pics. Its neat to be able to look out from the one of the lounge room windows down onto the workshop floor and see this... With that lot in place I was able to suss out the angles I could get away with, as shallow as possible and allowing for the handbrake mechanism. I had this old imp gearstick assembly that @dmulally kindly posted over to me. Some previous owner of the car he got it from liked painting things. Everything. Multiple times... I scraped all the layers off, took it apart and cleaned off the dirty old grease. Discovered it had been cobbled together from two old shifter bases. It was originally a very early Imp unit when the very first cars had an automatic choke, which often proved problematic. Hillman then changed the cars over to a manual choke with a nifty little lever in front of the shifter. This mount had been added to the early base. Which means they must have chopped up a later baseplate to get the choke mount. Why they didn't just fit the entire newer base plate I don't know. But what I had in front of me was a frankenstein of base plates with barry spec welding and fixes, but also including a not too badly made bronze bush on the lever where there is normally a (wornout) plastic bush. I had a couple of shift rods to choose from. I chose the least worn. Moving back to the gearbox end I machined up some shaft ends from stainless bar to suit the universal joints. I had some stainless tube and welded the ends in place on the first shaft that runs from the gearbox universal down to the tunnel. Now I needed a sturdy, slippery support to mount in place of the second universal joint. This will not only take back and forth movement on the shaft but also a bit of thrust loading created by the angle on the connecting shaft. I had already bought a lump of slippery hard engineering plastic with this application in mind when I had ordered the plastic for the flywheel thrust bearing a while back. It was bright yellow. Luckily not seen under the car as it would clash with the blue paint. I put a hole in it and machined the outside down. Which also created a pile of pretty swarf.. Then reamed it out to 1" Still a bit tight so out with the adjustable reamers.. until it was just right... Then made a stainless cradle .. The cradle got some wings welded in place and I dug the rivnut tool out.. Mount now bolted in place in the tunnel I had to chop the last tube to the right length, weld on the end and bolt the universal in place.. The front end below the shifter was was standard imp stuff and this is where problems popped up to throw a medium sized spanner in my workings. The side to side gearstick movement across the gate was minimal. Ridiculously so. Like about 1". Or 25mm in new money. Yet the fore and aft movement was about right. But quite stiff. I was contemplating why this was so and what I could do to remedy this when I also noted that 1st gear was where 3rd was and 3rd was where 1st was. Poos. Four years ago when I had compared the Subaru gearshift pattern at the box to the imp unit I thought they were exactly the same. But I had not accounted for the reverse rotation taking place under the imp gearstick. Also I never really thought much about how little of rotation the Subaru box needed on its shifter shaft to shift the internal selector across the 3 rods. Its a tiny amount, like 3 degrees say. Whereas the Imp box has a shorter internal selector and requires more rotation at the shaft. Hence the Imps gearstick knob only moves a teeny bit when coupled to the Subaru box. But the Subaru box has a standard/similar amount of rod movement within (ie 1-2 and 3-4th) which was going to make things trickier to fix. Simple linkage/leverage multiplications that is easier to see than explain. Sorry if your brain hurts. I had to hurt my brain a little bit to suss out a solution but there was only a little bit of smoke. The reason the scooby box is different becomes obvious when you see the scooby shifter setup. Which luckily I can show you because last week thanks to @Leone I was put onto a local fella to me who happens to have many old Leones and Brats kicking about his property and he had a spare leone front wheel drive box that I wanted (always handy just in case...) His property is amazing!!! Long 4wd only driveway up to a ridgetop house with stunning views out over Tasman Bay. Old leones just kicking about... Luckily we have our trusty old 4wd Hiace and that became the days gearbox transporter... Box on bench. Look at that shifter mechanism... The shifter rod attached to the gearstick only rotates a tiny amount when the stick is moved sideways across the gate. But the rod moves 10mm in each direction when shifting for and aft. Simple. Robust. Very Subaru. I can't copy it though because I have turned my box 180 degrees. No matter where I put my pivot point (below or above) I'll have one of the planes working backwards. So I decided to build a new shifter base setup. The most important thing was to reverse the rotation so the gearstick pattern is correct. The imp pivot point needed raising to allow the offset shaft end to be rotated to above rather than below the centre line, so reversing the across gate movement. I would add the ability to adjust both rotation and lineal movement. Started with a new pivot cup because I was not happy with the worn and Barried pressed steel item.. I dug out a large lump of steel bar... Chopped out a square and cleaned it up in the mill.. Big drill = big hole.. Rough machined out a cup shape. Cut a form in cardboard to suit the brass ball and used a die grinder bit to finish the shape... Grinding paste time... Slots for pivot pin.. Lightened the lump down.. Built the shaft up with weld and machined it down so I could add a lower pivot point. Milled some steel like so.. Welded a boss on.. New socket for shift lever ball end... Cut out Barrys previous workmanship... Machined up some spacers and a base plate.. Welded up a little tower (my stainless and steel tig welding is definitely improving, helped muchly by realising that not being able to see what I'm doing does not help much and finally admitting to my age and buying some reading glasses....) Welded tower to base.. Now all together please... Bolted together. You can spot the adjustable rotation, which the spacers allow for, along with adjustable pivot point. In place... Yay- it works! The shift pattern is correct and the action is much smoother. The spring loaded indents on the internal gearbox shift rods are quite stiff, which I noted was the same on the other box with its stock shifter. Its a bit baulky to push past the synchro baulk rings into gear but I think will feel better when the gears are actually rotating. There's certainly no slop in the system and it feels very mechanical - not rubbery. I now note how much flex there is around the shifter base in the imps tunnel (granted a very rusty shell..) Its something I might just try to stiffen up on my blue Imp when fitting this lot in. Phew. That was a little mini engineering mission I was not expecting but that's this project in general74 points

-

Well there goes 5 months. Ha. I've been too busy doing the summer things, entertaining guests, lots of cycling, loads of swimming and some hiking. But I have still been whittling away on this engine. I'd love to have done more but like I think I said in a previous post - I only really want to do it when I can properly relax and enjoy the process. Plus summer has continued on quite nicely here - it's really only just become late summer However there has been a few chilly evenings and some decent rain had recently which makes for perfect tinkering time. So where I left off was some water pipe work. I needed to build some pipes to get the cold water into the heads. The original goldwing water pump used to reside about the middle of the engine at the front (now the back..) and feed straight out into a rubber hose that split the flow equally up into the heads. But I'm now bringing the water from the front mounted radiator, via the electric pump, along the side of the engine and up into the heads. I'm going to use the original steel pipes that go into the heads. I chopped the bends off the ends of the old hose, fitted them onto some stainless tube like this.. Now I needed to feed that pipe evenly. I cut a hole in it and squeezed the end of a stainless elbow to suit.. Mitred the end to suit.. Welded it in place.. Then continued the pipe work so it made its way around the block. I've kept it tucked away so its not out on view too much when looking into the engine bay- for a cleaner look. I'll continue the rest of the pipework later on and brace it off a mount further back. Possibly add a little heat shield where it runs close to the exhaust headers although I don't really think the water will absorb up much heat from them. But just in case.. While I was doing the summer things I had some bits turn up from China. Some nice connectors for the engine loom. My hope is to have a setup that really easily connects with just a couple of main plugs. Time will tell on that but these will certainly help. Another parcel - more goodies.. Yay. I can continue on with the exhaust work. I need to form some 3 into 1 collectors to suit. But I need a press. Then a customers job that was in also needed a press. A Hiace van in which I was rebuilding the front suspension and new bushes had to be pressed into place. So I built a press. We had plenty of steel in the rack left over from customers jobs and an old 12 ton bottle jack so the only thing I had to buy was a pair of springs. I made the press nice and tall to suit my height and allow for long jobs in the future. Press in action on hiace arms.. I painted it a nice grey. I machined up a stub and a couple of different ends to suit. Over time I'll be sure to accumulate many different bits to use. Now I've been using it I wish I'd built one ages ago!!! So back to the exhaust. I made a form with some pipe offcuts. 3 into 1. It worked but I just felt the angle was to sharp a transition. Version two, on the right, next to version one... Worked well but getting near the end of the forming it started to collapse... This surprised me. I was expecting the stainless tube to split. The form deformed so much that I couldn't get the last bit of flare I needed. Roll on version three... This one I reinforced.. It worked a treat. Much better.. Back into the press and I applied some heat and hit it with a hammer... Which created this... Now to fuse these collectors onto the headers. I filled in the middle hole between the tubes with a teeny little triangle of stainless. Then with more little triangles I filled up the gaps where I couldnt get the collectors formed close enough. That's where I'm at now. I added the filling triangles to both headers and will carefully flap disc them neatly so they match the collectors as well as I can so making for an easier time welding. I know the welding wont be flash. Functional - not artisan.. but I'll just be happy to get to that point because its like a big part of the build to check off. I promise I shall do my best to get more time in on this build from now on. however - I do have this shiny Scott CR1 road frame that I've just painted to build up and ride before winter turns up... Alex68 points

-

I drained all the coolant out, took the radiator and pipework off and flushed the whole lot through until only clean water flowed. Let it sit in the sun while I did other jobs and gave the engine a couple of short 30 second runs to help dry it right out. I left it at that and decided to sort out the idle control valve that wont shut completely. I started by removing it and putting it somewhere it'll probably just collect dust for a few months and then maybe get sold/thrown in a bin. I then took Hannah on another exciting date to the local wreckers where we looked under many bonnets to find a suitable replacement. 'Automotive foraging' I like to call it. Here I am in the wilds of the wreckers... I took home a couple of throttle bodies with valves attached. One from a Mazda 3 and the other from a Mazda 626. They had almost identical iacvs but one had an adjustment. I cut a section of alloy out of a big block.. Milled it flat and square.. Throttle bodies.. tested them with some pipe and the earlier 626 item has a similar fail safe to my now removed Bosch item, whereby it still lets air through when 'off'. So that just wont do and I have decided the keeper... Mazda 3 unit wins this competition and gets to stay in the workshop while the 626 item went in the bin. I did some more machining of the block so turning it into a ported hub the iacv bolts to, with an in and out pipe pressed in place. I made a bracket to suit the starter motor through bolts to which the aicv block bolts onto. In pictures.. Bolts onto starter like so... Ended up being not only more compact and better mounted than the old Bosch unit but with better pipe routing too. I ran the valve through some tests on tuner studio and it works really well, shuts properly and is also much much quieter , partly due to it running at a much higher frequency than the Bosch unit. The next thing I thought I'd check was the headbolts out of curiosity to see if they were still torqued up fine. I first laid out some neat material that was absorbent, but waterproof. My sister, a surgery nurse at Wellington hospital, gave it to me and said its handy stuff to have about. Certainly is!... Bolts were all fine and I saw no point in giving them anything extra beyond what Mr Honda specifies, so possibly risking deformation of the heads etc. Next thing was to sort out the electric water pump placement. Where I had mounted it turned out to make it a pig to bleed of air due to the outlet pointing downhill and I knew it could be better. See here... I removed the mounting bracket I'd made for it... Unplugged the ecu etc etc and slid the whole engine/transmission onto the the 'engine stand 2000'. This process is super easy as it can be adjusted to the same height as the big table or workshop bench and the engine slides really nicely on the ribbed sump. Then I slung it into the spare imp and tried out the water pump for size in the new location I had in mind... Cooling pipework serving the Datsun engine exit the bodyshell roughly about here... Much better position. Not only will the pump almost self bleed, being at about the lowest point in the cooling system, but I will also clear up the area of uglyness where it used to be. It also gives me full easy access to the transmission filler/dipstick. I removed the engine, put it back on the table and set to work marking out for a mounting bracket... Then fabricated this bracket.. Which mounts the pump here... New improved temporary cooling setup which filled up sweet and bleed of air easily.. Quality touches.. With the cooling system now filled with just water I ran the engine up to temp. The new iacv was working well and I was more confident in running the engine for as long as my lunchbox fuel can would allow. I kept checking for any leaks and found nothing. The cooling system was working well, the fan kicking on and off, the temp staying around the 95- 97 degrees range I had set on the water pump controller (which also controls the fan relay) and I was finally able to set the idle properly with the idle bleed screw on the throttle body - something I was not able to do with the Bosch iacv which was letting in too much air. Still no leaks. I ran it several times, let it cool down, checked it the following morning and the level was spot on. Touch wood but I think the extra heat and lack of slippery coolant has allowed the head gaskets to 'set'. Either that or maybe there wasn't a leak at all and it was just residue coolant from spillage when I had removed the top pipes to pressure test them. Anyway.. I was a farking happy bloke! (Hannah was super happy for me too) Now with the coolant system working and it idling nicely etc I had the confidence to finally give the engine a decent rev up and see what it sounds like at 6000 rpm. Hannah took a vid... I just love that sound. The overrun rasp that flat sixes make. It revs up so quick and clean (and there's no acceleration enrichment setup on the tune yet until I sort the main fuel table later on so it can bog if you snap the throttle open too quickly) Another vid I took showing the hand throttle... So far the little Mandalorians have managed to keep all their limbs in place. In fact the plenum chamber stays quite cool with the constant stream of cool air flowing into it. Their spaceship has aircon? Anyway. I was happy. The only issue was that the whole time I have been running it without any alternator so meaning the ecu is having to use the voltage compensation tables and its not really an ideal situation having everything running at 2-3 volts less than it should. I took my alternator apart again and ran through as many checks I could, following a very handy NZ auto electrical school tutor video about alternator testing online. I suspect the rectifier is kaput and I couldn't locate a cheap replacement. I managed to locate a second hand alternator, pretty much the same unit and have bought it - now just waiting on the seller to sort their sh1t out. In the meantime I got another similar alternator, this time a nippon denso unit from a Honda prelude that actually has a bit more clearance out back, but with an ugly grey painted steel cover. I ran some pigtail connections and bolted it up, started the engine and now have charging! Yay. With things running at full voltage I tweaked the engines idle tune and cold start settings and am much happier with where I'm at there. In case the other alternator turns out to not arrive/be a dud etc I decided to give this working unit I do have a bit of a polish and paint. In pics, finishing it off with wrinkle finish paint on the tin end cover. Much better looking. I bolted it back in place and did one final run up to temp with a bit more tuning of the fuel table idle zone. I now have the engine able to idle at 650 and I could almost get a 50cent coin to balance on the plenum lid. The engine is still only sitting on the table, not bolted in place so I cant really expect it to be perfectly smooth. I think it idles a bit nicer at around 750- 800, a zone where its also running leaner at close to 14.7. Lots of time in the future to play with settings. Confident its all a good starter and idler, plus realising I'm stalling on the next stage, I have now started to take the pump controller, cooling system and temporary wiring apart. The next time it will be started will hopefully be in the Imp. Next job is to reassemble the transmission, bolt the lot into the spare shell and sort out the gear shift linkage.67 points

-

Ha. So pretty much the day after I had cleaned up that old alternator up and got it running on the engine the second hand replacement for my original unit turned up in the post. It came with a 3 month warranty so I'd better check it works before stripping the engine of its ecu etc. Started to fit it and oh.. Poos. It wont fit. So I took it apart, along with the original.. Discovered its just the front housing that's different and I can swap them across.. So while its apart it would be rude not to clean all the parts up and polish it all (tempting fate just a bit...) Fitted to the engine and started it up. Yay - it works and it looks great, which is really quite important given its right there, in the middle on display. I'll keep the other one in storage just in case I need it one day. Now I could strip the engine back down, removing all the cooling, wiring and fuel lines that I had installed just for bench testing. Then I removed the transmission and put the engine back onto the engine stand 2000, stashing it away because its gearbox tinkering time. This Leone transmission has a few little issues that need sorting out in order for it to run in reverse rotation and not potentially turn itself into an expensive insinkerator or coffee grinder. I could probably get away without doing these modifications because the box is overbuilt for the application but I wanted peace of mind. Remember I had acquired the two gearboxes, 1600 and 1800 items, before getting the engine. Ages ago, in fact 4 years ago I think!!! I had wanted to know if it was feasible to run these boxes in reverse. This pic I posted up way back then gives a good idea on what's going on inside... I had already worked out some of the issues back then and knew what I was up for. With more study I found a couple of other areas that need addressing. Here's another bit of wonderful scribbling I did this evening.. The pink arrows show the new axial forces that are being imparted onto the main (driver) shaft and pinion (driven) shaft. The circles are areas that I think needed attention to make sure it doesn't throw it toys from the cot. 1 : the blue circle. Under high torque loads this area could possibly create the sound of nashing teeth but with much messier consequences. The top left one being the third gear driver wants to move to the right and clip the teeth on the bottom right second gear. In normal rotation they would move apart. There's 1mm of clearance there which is probably enough tbh. But I wanted a bit more and had already worked out how I could get it with no other issues and just a bit of tool making. Which is fun. 2 : The yellow circle. This ring was no going to take thrust loading. It is a strong ring and has a deep groove but I wanted to make sure there was no way it could ever shift. 3 : the green circle. In this area there is a thrust bearing that also acts as a neat little oil pump and squeezes oil through the gear hubs/bushes. Under the new loading the thrust aspect is removed but I still wanted to it pump oil and it was going to be the wrong shape to do so in reverse rotation. So I set to work and checked off each job. I made a bolt holder for ease of reassembly - several different sizes and lengths. Once apart I started with the gear side clearance. First off I needed to split the mainshaft assembly down. 4 years ago I had out of interest tried using a puller on the spare 1600 box, which shares the same layout and design but with smaller parts in many cases. The puller didn't work. But this time round I have the rather handy workshop press I made. I just needed some extra tooling to do this job. Starting with some press plates... Allowing me to carefully press the shaft out... Because I'm not posh (or rich) enough to own a surface grinder I needed to make one. Yes its a bit basic but it will work. I made this... Which allowed me to do this.... I ended up with this gear having the 0.5mm more clearance I wanted. Super happy with the result. Now onto number 3 - the little oil pumpy thingee. I went to my friendly engineering workshop in town and got a big lump of 4140 steel. I drilled it out... Machined out a ring which had to be an exact width. Just in case it needed finishing after the hardening process I made an abor to take it.. I carefully machined it to the right profile, cut the sides down and filed the shapes in, just like the original but in reverse. Happy it was going to work I heat treated it. I have not done any heat treating for over 25 years since I spent a fair bit of time in the blacksmith department while doing my apprenticeship. But it wasn't a super loaded critical component and just had to have a durable hard surface. I didn't take any photos. Hannah was there helping as I carefully heated it up with the oxycet to the austenitic stage and agitated it in some lovely rice bran oil (because I can be posh sometimes) then slapped it in the oven to temper it... Following morning I polished it. It came up sweet and the old file test showed it to be as hard as the oem item. You can see the reversed design here... Here's a little vid I took showing it in action... While stripping the mainshaft down I was also pleasantly surprised to discover that this 1800 box has needle bearings in all of the gear hubs unlike the 1600 box which uses bushes on the mainshaft. So oil starvation would not have been as much of an issue but I'm still really happy I did this modification. Last issue to sort was number two - that ring on the bearing. It would hold fine I'm sure but if could make it bulletproof then why not - it's just a bit of extra machining. I started with another lump of high tensile steel and machined out a ring to suit... This fits over the other ring and then the main thrust plate that sits over the bearing was machined out to suit my reinforcement ring. Its all held in place by the end housing which I have yet to fit. All the potential issues covered I set to cleaning out the casing and then started reassembly. In doing so I discovered that the original axle seals are sided on these boxes. They have those helical lines on the lip surfaces which aid in pulling/pumping oil back into the oil side of the lip ( the lip does not actually touch the steel when the axle is moving and in fact runs on a tiny bed of oil) which I had not realised before I'd bought plain lip seals from an engineering supplies. This pumping capacity is shown to be twice as high in helixed seals. Subaru fit left and right handed items. But I'm running mine in reverse. Luckily the originals were in excellent condition anyway so I machined up a stepped tool, popped them out and swapped them to the other side. The diff axle seal surfaces came up good after a clean. Cute little diff.. I'm now about ready to put some 3 bond gloop on the case half and drop the other side in place. Its looking all very nice, clean and shiny in there...66 points

-

Oven cleaner. Just a tiny bit on a rag was perfect for removing the last stubborn bits of carbon staining on the pistons. Now for the what I fear is the trickiest part of the engine assembly which is assembling the two crankcase halves together, the last half over 3 pistons. Its the bit that's if not done correctly could at worse break a piston ring. Even the one of the manuals states this... So I started the process by giving the crank case halves a nice clean over and prep. Then I got the crank out from its hidy place under the table. Gave it a good clean and as per advice from @GregT double checked for any burrs in the oilway holes. They were spot on. Very nicely finished all over. Put the crank in the hole... Note the smallish crank thrust washers... (edit- this is just one of them - there's another on the flywheel side but I couldn't get a pic of that one because the flywheel adaptor hub is in the way) Rotation direction aside, this is probably the engines weakest spot in terms of being used as car engine, with a manual box that is. Good quality oil with snake oil ptfe treatments and don't sit at an intersection in gear with the clutch depressed etc etc will be the name of the game However all is not glum because after some extensive bedtime scheming and designing I have a good idea as an extra precaution I might do. Anyway- back to the build. Now I had to make some special Goldwing specific tools. Firstly are the piston ring compressors. Here's a pic of one of the Honda items ... Basic and gets the job done. But expensive, especially combined with the other bits and anyway - I like to make as much as I can. I got a bit drainpipe from a local plumpers supplies. It was actually a perfect fit over the piston. Like 10 thou smaller in ID and it wouldn't have gone on. Fluke. Lady couldn't be bothered to charge me anything either I chopped it into bits... To machine such flexy plastic rings I needed a support. Luckily I had a lump of thick alloy tube leftover from removing a customers lpg setup. I skimmed it down... Now I could turn a taper onto the rings and make lots of plastic mess... The taper locates the compressors into a tapered lead at the base of each cylinder liner on the LH case, so guiding the compressors and stopping the chance they might flex out as the case is lowered down over the pistons heads. I had to get the taper angle just right. Cut each rings in two. Now for some decent quality velcro. I found a meter pack of one side sticky, the other for sewing. Perfect! I then bolted the clean, shiny pistons in place. First to go in were the ones for the RH case that the crank is bolted into. Then the left hand pistons get bolted in place... More tools. This time some woodwork. I searched in my wood supplies and found a nice lump of Eucalyptus. Firstly two support blocks made to measure according to sizes specified in the manuals. They are used to space the cases at certain stages. Then a trickier bit which is used to hold the upper most piston straight and in the right location. In that last pic you will note two white plastic supports for the two lower pistons. Honda sell these as part of the kit. Not cheap either. So I cut up a bit of plastic chopping board to suit. The velcro strips needed wire pulls as like the Honda items. I have no fine wire, or a piano to steal some from. But I have a fishing rod, now with a shorter line. So it was all set up for the 'big lowering and clamshell manoeuvre' Oil the bores, the piston crowns, carefully lower lh case. The top compressor slid down the piston, rings were inside the bore and the case sat on the upturned blocks. Remove the wooden piston support and then slide compressor down and remove by pulling on the fishing line loops. Please excuse the lack of photos. I was a combination of being both nervous and satisfied and not thinking camera. Not until the block was over the next two remaining pistons and rings were in place. Then I took some pics... Plastic chopping board supports removed.. Final two compressors pulled out... Case faces cleaned one more time, dowels reinserted, 2 new O rings installed, lower surface gets a thin spread of 3 Bond sealant. Case is lowered then all these cleaned and pre-organised bolts go in and get torqued down. Job done. Phew !!! I had a cup of coffee and tidy up in preparation of the next stages. Its nice having a break from work and not having customers jobs cluttering up the space. Just a little spare Imp...66 points

-

66 points

-

Finally managed to pick up the fence rails from a mates yard. Got a whole packet in the end cos my boss gets a good rate directly from the mill down in Nelson. Was waiting for a while as my boss said I couldn’t pick it up due to the weight of the pack being near on 3 ton, so the initial talk was to split the pack so I could. Turned up expecting to get half the pack only to discover said mate has a she’ll be right attitude like me and said ahh that pack is only about 2.5 ton so should be fine.. hmm.. 50 PSi in the tyres and I was away. Got there in the end with a few more grey hairs on the head. Made a couple of jigs which proved to be a game changer when you’re doing it all yourself. Got the easy part done last weekend. Also had my free frames from work turn up that I’ll be building my shed out of. This weekend I finished up the front fence and I’m pretty rapt how it’s all turned out. I checked the rails into the gate posts. Ran the rails down the left side and trimmed all the long post tops down. This is my favourite pic of the day..63 points

-

Wow- its been over two months since an update but this project has moved way down the list of what's important to me right now. However I am still working on it where I can because its a nice break from thinking about other things and still really fun to work on plus both Hannah and I really do want to get this engine in. I have accumulated quite a few photos so I think I might split the update into a couple to catch up as its too much to do in one hit. Wiring up the engine management has taken the most time because as usual I got carried away with doing my best to keep the engine loom hidden, the system as standalone from the rest of the cars wiring and make sure its easy to remove or service. I started the wiring off with the injectors but first I had to paint the fuel rails. I chose to paint them in epoxy black for a durable finish. Folding bike stand made for a handy hanging point.. unmasking.. The Nissan March k11 injectors, 3 from the 1.0 litre engine we have spare and 3 from a car at the wreckers. 1.0 and 1.3 k11s share the same sized injectors at circa 145cc/min which is ideal for this engine. Gave them a clean and fitted them in place. I didn't want the injectors to point out to the side as oem fitment in the k11s, so I very carefully shaved off the plastic tab on the injector bodies that locates in the retaining rings. I had to change out the screws for dome headed socket screws, which look much nicer and are stainless anyway, so I could use a ball ended allen key to tighten ones under the now rear facing injectors. Much neater. Bought a variety of this braided loom insulation stuff online. Never used it before. Took me a couple of practices to learn how far it shrinks when slipped over the loom and one has to think several steps ahead to make sure there's no backtracking later. Very satisfying to use though! I'd stripped down a heap of k11 injector plugs and had ordered a bag of the correct terminals, along with a very nice crimping pliers to suit a variety of terminal sizes. However the terminals were not a perfect pressing as per the original items and wouldn't click into the housings securely. So I machined a tiny jig that allowed me to mill out the pressings to suit.. I slowly and carefully wired up the injectors using my new braided sleeving. Such fun! Finished... Now I wanted to work out the electric water pump positioning so I could make sure it was allowed for in the loom build. I popped the imp up onto the hoist, did lots of measuring and scribble drawings.. I had to plan it ahead so the plumbing would be easy to route in to the existing radiator pipes that make their way to the front of the car. Because this flat six is still an unknown thing I really don't want to change anything much that would make it hard to re-fit the Datsun engine (which is still being a very well behaved little gem of an engine!!!) Pump will go about here... Happy with positioning I constructed an alloy mount, taking time to make sure the system is easy to work on, remove and not foul anything else. The pump kit came with an adaptor to fit the temp sensor into but I needed to fit another sensor for the ecu plus the imps water temp sender. The plastic one supplied only had room for the one sensor I rummaged through the alloy tube on the shelf and I cobbled together a suitable adaptor that also suited the hose size I wanted to use. Had to add some alloy flat to give it an area to drill and tap in the correct tapered threads. On the subject of hoses... I spent quite a laughable amount of time trying to find the perfect hose clips. They were all going to be on display and I was quite fussy about the look plus I have a hate for poorly designed clips that don't work smoothly. I don't like clips with the slots as they never work smoothly and tend to bind. I ended up going with JCS high grip stainless items with pressed worm ridges - made in the land of the long grey cloud. British quality! So they'll probably leak then. But they look plus my mate Matt at blacks sorted me out with a great price - which helps because I needed many! I was well sorted for neat little fuel hose clips thanks to many k11s Now back to the wiring loom. I carefully wired up new plugs for the crank VR and cam hall sensors and ran the wires back, hiding them as best I could. Did the same for the alternator and the throttle body tps. At this point I dug the megasquirt 3 ecu out, opened it up and did a fair few alterations to the circuitry to suit my setup. I think it had been setup to suit a Nissan sr20det engine. I added jumpers to allow me to connect the 14 point 7 wideband via CANbus while I was in there. I loaded the latest firmware onto the ecu and it all seems fine (so far) Another trip to my friendly local wreckers was now needed. I took this pic when I parked up.. I was on the hunt for a few little bits including some screw on ends for my spark plugs. I'd bought 6 shiny new NGK plugs to suit the goldwing engine but they, like many bike engines, just have the threaded end with a sparkplug cap to suit. I was changing my ignition leads over to modern silicone suppressed cable I'd bought off a roll along with crimp on car type sparkplug terminals. The screw on bits were not available from my local autosparkies and the prices online were priced at 'absurd plus post'. I found the bits I needed and fitted them.. I continued piecing together the loom and ecu setup. I mounted the ecu on some ply, cut to suit the space under the rear seat. I had a little helper at times.. I decided not to add an extra 26 pin plug into the engine loom to avoid an extra point of potential faults or resistance. I designed the loom to remove from the ecu with the main ecu plugs plus 3 nylon plugs. This way I can easily un-plug them, feed them back through the bulkhead and drop the entire engine out without having to unplug anything at the engine. It also allows me to easily set the engine up for bench testing. The fuses for the engine management, water pump and wideband controller are all located in the same unit, split into two sections separated by the tunnel. To sit in here tucked well out of harms way... end of part one62 points

-

Alright alright alright! So I pushed the car outside this afternoon so I could reach some wiring inside to try fire it up. I filled the car up with coolant, by which I mean water because I was expecting things to leak. Sure enough each head had a hole up the front where water started leaking out. I couldnt remember what these were for, then found out that they are like an air bleed channel that goes back to the thermostat housing. So, these seem to have gone AWOL when moving house so I'll need to pickapart some more. I must have removed them when taking the heads off to clean them. Easy fix. Then I got the fuel pump working and fixed a few fuel leaks. It turns out that AN fittings arent very good at sealing if you havent tightened them up? Crazy. Then I got my tune somewhat sorted, and tried cranking the motor over.... and the bloody battery died! Ugh. I mucked around to get another battery, it sort of spluttered a few times but not quite. I had a look through the tune settings. Engine size was still set to 1500cc from using this ECU in the Echo - woops. I needed to disable the fuel pressure sensor allocation. As since this isnt wired in yet, it took 0v to believe that the motor had zillions of psi worth of fuel pressure. Then when I cranked the motor it was registering the crank trigger, but not cam trigger. Checked the settings, had this wrong. Both were set to VR sensors, but the crank is VR and the cams are hall effect. So once that was fixed... Bam! We are running. It was absolutely awesome to reach this point. So whats next? Lots. Get the coolant system functioning properly. Make an exhaust for it. A lot of wiring work, get the fusebox setup all connected nicely and mount all of the wiring nicely. Need to put some gearbox oil in the box, will do this before running the engine any longer. Pull the fuel rails off, and do tests to work out the CC rating and deadtimes for the injectors. Calibrate all of the sensors Mount a radiator fan Check intake for leaks (I think all of the air bypass screws are currently all the way out) Install the wideband Finish wiring up the alternator And a bunch of other little similar jobs. Most of these I can peck away at over winter with limited space. Making an exhaust will be difficult when weather starts getting darker and wetter and I can only really work outside. Will push ahead as best I can. Super excited for first start though!61 points

-

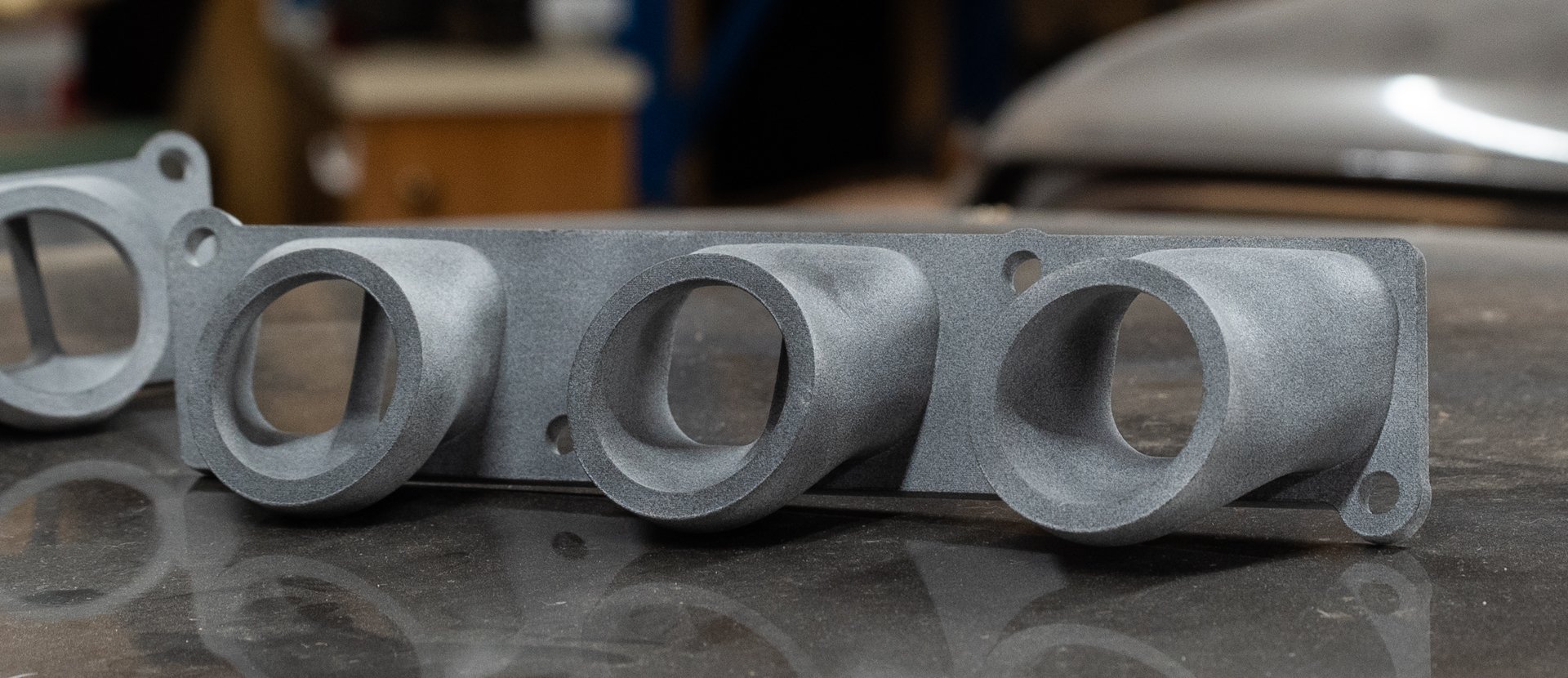

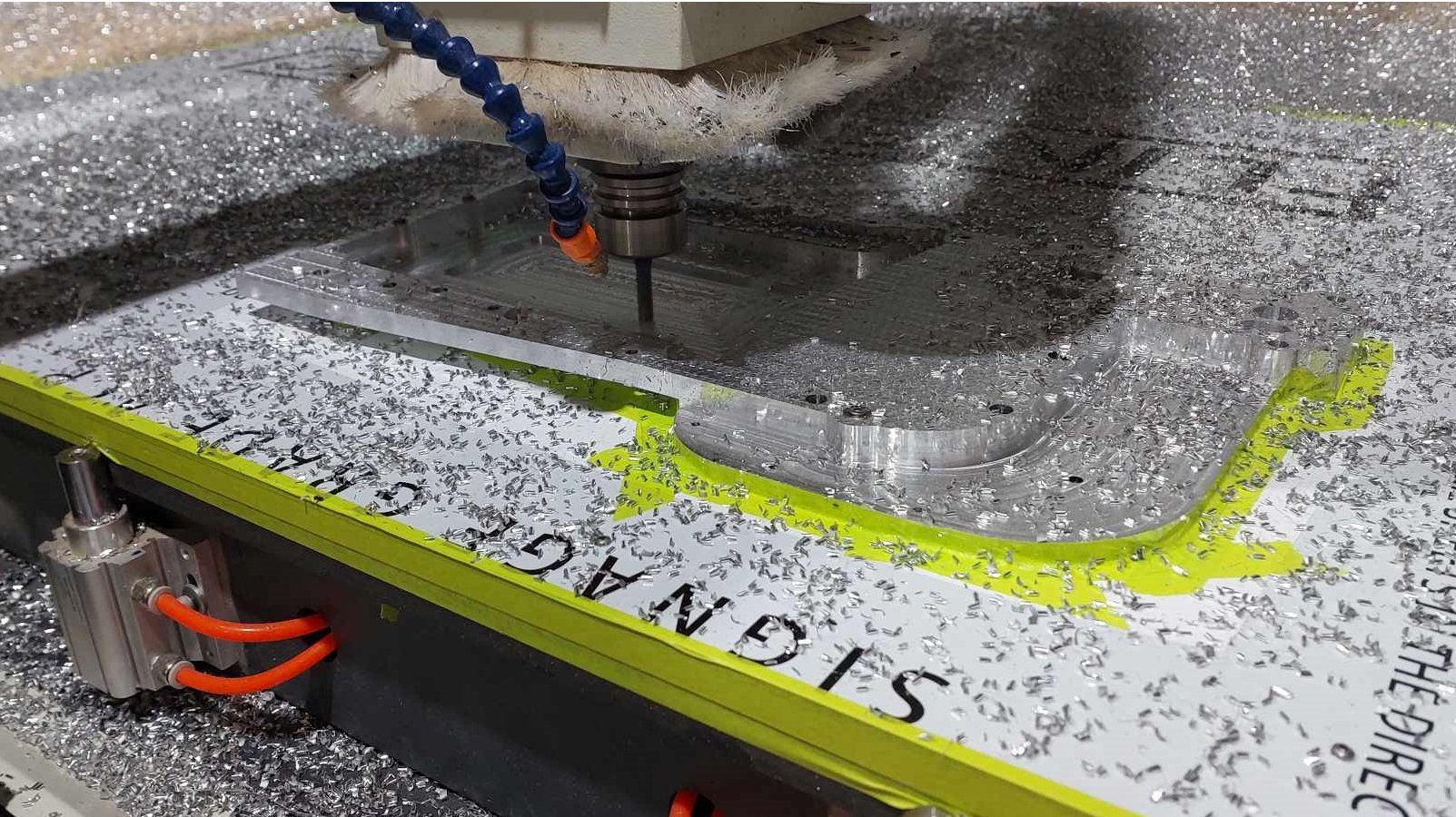

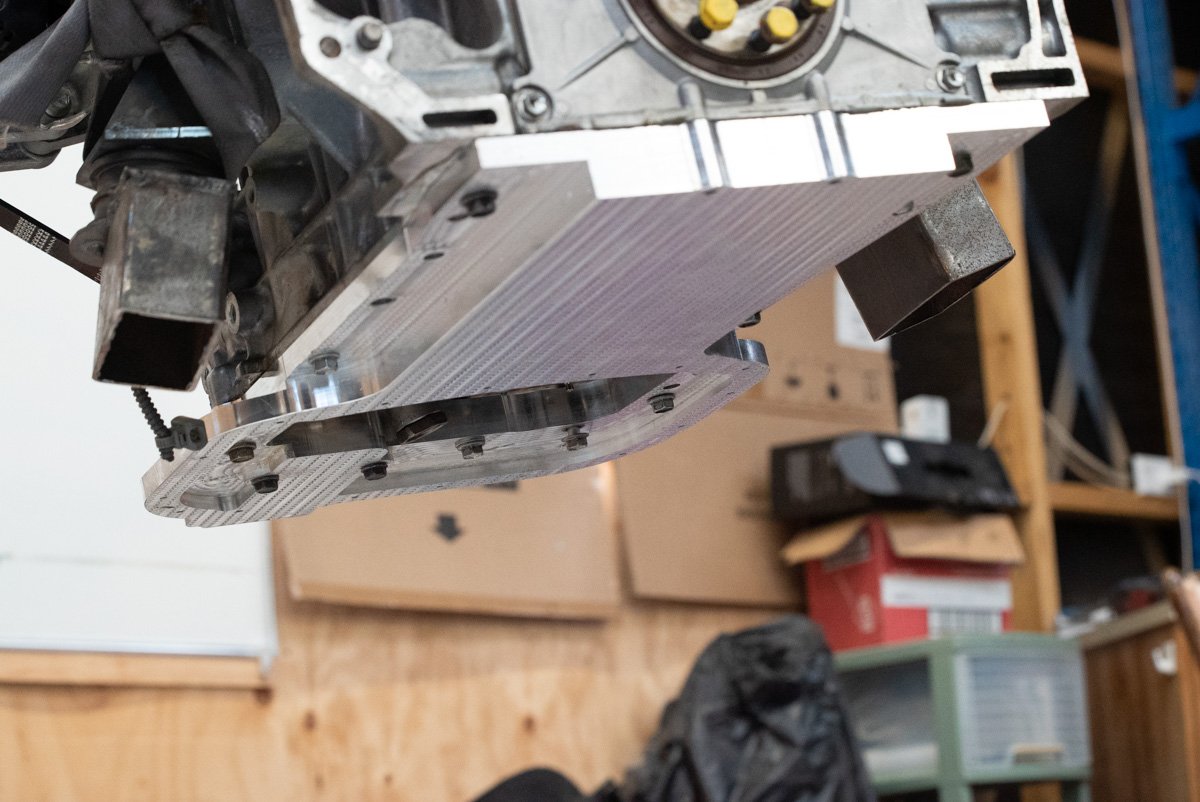

Oil pan activities! Absolute GCs @Stu and his workmate Sam found some time in their incredibly busy schedule. To spend a night programming some cutting paths and cutting a big slab of alloy down into an oil pan. I went along to watch and learn some things and it was awesome. Firstly, start out with a 22kg block of 32mm thick alloy plate. Then align this onto the bed of the router, and the it gets sorta vacuum sealed against the bed. Then one side was machined, making an absolutely hectic amount of mess. Then it was flipped over, and a a template was cut to align it onto the bed again. Making zillions of glitter carving out the other side. Then once it was all cut, we are down to around 1.8kg from 22. So there were plenty of chips for me to sweep up, haha. we needed to look at drilling the oil galleries for the filter, that I mentioned a few posts ago. Problem - the depth needed was too long for any available tooling and the height of the machines etc. So we decided to mill two slots in, and then weld a cover plate over the top. We made the slots do a bit of a zig zag, so that they would avoid one of the threaded holes for the oil filter housing. Which previously penetrated through into the oil gallery as there was no other way. Then Stu on the tig to zip it all back up: Then ready for a test fit. How good! (It still needs the welds flattened off and some threads tapped, havent done this yet) Much to my relief, it fits up great. Just zip tieing the oil pan on for now, until I can tap the holes. and back in the car... everything good! So that's one of the last remaining big tasks mostly sorted. And a big relief that it looks like everything is going to work as expected. Hugely grateful for the time spent by Stu and Sam to help get this done. I think its the most complex and coolest car related thing I've ever drawn up. Next steps are to thread a few holes for the oil pan and oil filter, flatten off the welds, and make an oil pickup. then I can fit it on for good, and fill the motor up with oil. Getting closer! Exciting.60 points

-

The 'hard' part of assembly completed I can now chip away at the rest of the engine. I'm taking my time, enjoying the process and tinkering with bits as I go along. The next stage is the oil pump and filter and connecting tubes. First thing to go in was the oil filter pedestal. I looked at the hole for the oil pressure switch/gauge sender and it just didn't look deep enough. I'd tapped it out with the appropriate 1/8" bsp tap and it fitted one switch I had but It just didn't look right for my Imps sender. Only one way to double check. Out to the 'garage' where little imp is safe and dry.. I removed the sender (luckily very easy access on the Datsun engine) and tested it in the hole. Sure enough it only barely started on the thread. Out with the bsp taps and I ran one in a lot further. Much better... Tested it in place. Easy access. I wanted to sort this out now as I could make sure the oil ways were completely clear of any swarf etc. Having to tap this hole out in place after fitment would have been a risky thing. That done I sealed up the filter mounting side with tape and fitted the unit in place.. Oh but not before taking this pic after assembling all the parts together in one place... I also weighed the block with crank/pistons in place before the oil system went in too. More about weights soon. But back to the oily stuff. I bolted it all in and set up the chains and sprockets. Some of the tinkering I mentioned as things went together included milling out as much as possible from all the various plates and mounting blocks. No point in extra weight and anyway- the bits looked nicer for it. Not that anyone will see them. But I know they are there in all their lighter machined goodness. You can sort of spot some of my Jenny Craig weight loss efforts going on in this pic on the idler gear mount.. That lot in place I moved on to another little job. For oil changes I needed a sump plug. This neat little stainless item arrived from China.. M12 x 1.25 and I didn't think I had a tap to suit. Luckily I remembered about a set of Chinesium taps my neighbour had given me a few years ago. Probably made of cheese but hard enough to tap the required thread I needed. Look at the spelling on the box ... Drain plug sorted... Cylinder heads will be next on the agenda. Give them a clean, strip them down, check and softly lap in the valves etc etc. I'll also be stripping, cleaning and bleeding the hydraulic lash adjusters. For that job I wanted a tray for all the little bits. I popped over to the neighbours farm as she has many many many chickens. Got some egg trays. She also gave me some sponge cake because she knew Id have run out of the cakes Hannah had made me. I like cake. Another job I am mid way through is creating a 'thrust' ring to go between the flywheel and the back plate. It's really just a belt and braces fitment in case because why not. As shown in the last post, I feel that the stock Goldwing crank thrust bearings are fairly minimal. This ring I'm building will only come into effect if the Goldwing item gets worn to much. There's about .0006 ~0007" clearance on the crank. Good oil and not sitting at the lights with the clutch pushed in should help things last. But just in case I will add this. I cut some 8mm alloy plate into a circle and then machined a ring up... Ordered some special Tecast Pa6c oil impregnated engineering nylon which arrived yesterday. I also got a bit of bar which will be used later on in my gear linkage. See my lovely shiny ring... More on this next time. I mentioned weighing the block earlier. I thought it best to weigh all the engine parts (because curious and couldn't wait actually). The block with crank/pistons was 36kg on the pretty accurate bathroom scales. Everything else I weighed with the digital scales. I wrote stuff down and took a pic.. Pretty happy with that really. It includes the clutch assembly and the engine side of the engine mounts. When I first started stripping this engine down many moons ago I had always hoped I might see a final weight of around 80kg - but unrealistic when the block and heads are 56kg alone. I'll wiegh the Datsun engine when its out but google sources claim my A12 is 87 kg so I'm stoked with a circa 10kg increase there. The Subaru leone transmission is about 9kg heavier than the Imp item. The big benefit is that the flat six is shorter in length and majority of its weight is down low in line with the crank - not up high like my current Datsun is. I'm super happy with how the current car handles so this will be a decent improvement on that. Plus I get the rear parcel shelf back for shopping bags! Since I had an empty workshop for a bit I thought I'd reunite Impy one with impy two for a few nights. Maybe I'll get baby imps?60 points

-