Leaderboard

Popular Content

Showing content with the highest reputation on 06/28/22 in all areas

-

8 points

-

Put this back on the dyno last week to redo the boost table since last time, which was about a year ago, it was found that the little filter thing on the solenoid is quite restrictive. So it wouldn't allow enough air to be bled for more than 16psi. On the street it goes great on wastegate pressure which is 10psi. Got the call that after 20 runs it started running on 5. Big puff of blue smoke (think there might have been a noise...can't remember the exact description). Compression test showed zero compression on number 4. Leak down test is pushing air back into the intake manifold so it has to be an intake valve problem. Nothing excessive out of the oil filler hole. The spark plug does not show signs of running lean. No knocking or metallic noises. Obviously not what I'd hoped for but that's where we are. Had a big think about it and am wondering if there has been an issue with one of the intake valves since day one. It could explain the intermittent misfire which the long list of things I've tried has not resolved. i.e. something making that valve not seal sometimes and is now worse. Got it home on the trailer a few days later. It runs on 5 with no bad noises except sounding like a Subaru. So I decided to compression test number 4, and from stone cold it immediately made a decent amount of compression? Not zero. I didn't take note of how high it went but it shot up and held it after just the first few turns. OK, so I put it back together and start it up thinking maybe the theory of an intermittently sealing intake valve makes some sense now. It still ran on five, I double checked the injector/coil plugs etc. So I compression tested number 4 again and now it makes zero compression like had been reported at the dyno. The needle barely moves. OK. Interesting. So while this has all been quite disappointing to say the least, I am looking on the bright side, getting angry at it won't fix it. The bottom end is hopefully undamaged (hoping a piece of valve hasn't dropped into the bore, because it was able to make some compression at first). No bad noises. Could it be the spring is bad? The valve spring seat/keepers are loose? Worst case, something melted causing damage to both the head and bore. Middle case, damaged valve. Head comes off and rebuild it. Best case, a replacement valve spring/keepers/seat solves it without taking the head off. It'll be a while before I have time to look at it now but am keeping my fingers crossed. Still looks cool though right?8 points

-

Yeah the lads in Thailand sell forged pistons in whatever CR you request. Up to 15:1 But they're pretty spendy. (Compared to rest of project) heh However my Dad has ordered a 4 axis cnc that will arrive probably in a few months. Pistons and/or rods might be feasible projects eventually. But start with some easier stuff while learning. Could maybe do a cnc port job as well, not as well as a 5 axis but would be cool. But gonna be a learning curve.7 points

-

So by the end of the last east cape ride this had a really horrid vibration, made more horrid by the petrol tank rattling. Last time I took it out for a ride I had a fairly solid look over it all to work out where more issues might be. I found the chain was quite loose, the cush drive sloppy, the petrol tank issue and a loose engine mount. I'm hoping the engine mount might be what was letting the vibrations out. I got a new tank rubber set from Ali, machined up a thing and set about modifying the mount: Much better! Last night I cleaned and tightened the chain, and have whipped the wheel off to inspect the cush drive. Yup that's fucked. So I need to sort that out, clean the air filter, advance the timing and then start thrashing it to work again, hopefully keeping my will to live intact.6 points

-

Nah. I just need to buy Hayabusa pistons, Hayabusa rods, Hayabusa crank, Hayabusa block and head. Then I'll have the world's fastest 1NZ5 points

-

My 200sx 1jz car lost compression on the dyno last week so needed to get the 'parts lancer' off the hoist, so put the 4g15 in and got it rolling again. This combination of transmission jack (500kg rated) to position and lift the engine up in stages plus the hoist to lower the car over it works pretty well. It's in: Wiring is a bit different but have got it turning over at least and confirmed the clutch is all working. Will look at the rest later. Found some amazing twist and tape wiring in a few places: Also here is the fuel filter cut open, this is the one which I suspected might be causing fuel starvation on the mivec/parts car. Doesn't look great but not really as bad as I was expecting. Could still be blocked with tiny particles. Have now moved it out of the garage since the wiring doesn't require it to be on the hoist.5 points

-

4 points

-

When I was a kid, my Mum taught me that it was rude to take basically anything offered to us kids when we went somewhere. So we go to someone's house, and they're expecting us, so they've made some chocolate biscuits especially for us to eat. Which are the best thing ever because I'm like 8 years old. Fucking delicious! However. I'd been conditioned to say "No thank you" because doing otherwise was rude. For the person who baked something especially for us arriving, it's was disappointing that no one wanted their food. "How could kids not want delicious my biscuits?" "Are they especially bad?" "What did I do wrong?" How could my Mum not understand how mutually disappointing this situation was? It didnt make any sense to me then, and I've still no idea who profited from this situation. The people were happy to give me a biscuit, and I was happy to eat it. Surely this is the worlds simplest situation to keep everyone happy. I fucking love biscuits, and it tears me up thinking how many I missed out on, at the stage of my life when they were the most delicious. God damn. For some reason, tonight I have had a revelation that refusing willing help from people here draws parallels to this situation. I have been conditioned to feel shameful about accepting assistance that's willingly offered. Why? So for anyone who's willing to chip in a few bucks, I can promise you this: I'll spend any contributions towards a Prius motor, and maybe exhaust parts. I will not spend any contributed money on psychological counselling for my unresolved childhood trauma about missing out on biscuits. I also promise I will come to your house and eat your biscuits if you invite me over. https://givealittle.co.nz/cause/finding-a-cure-for-the-atkinson-cycle Thanks to anyone that wants to help, and by all means dont anyone feel obligated.4 points

-

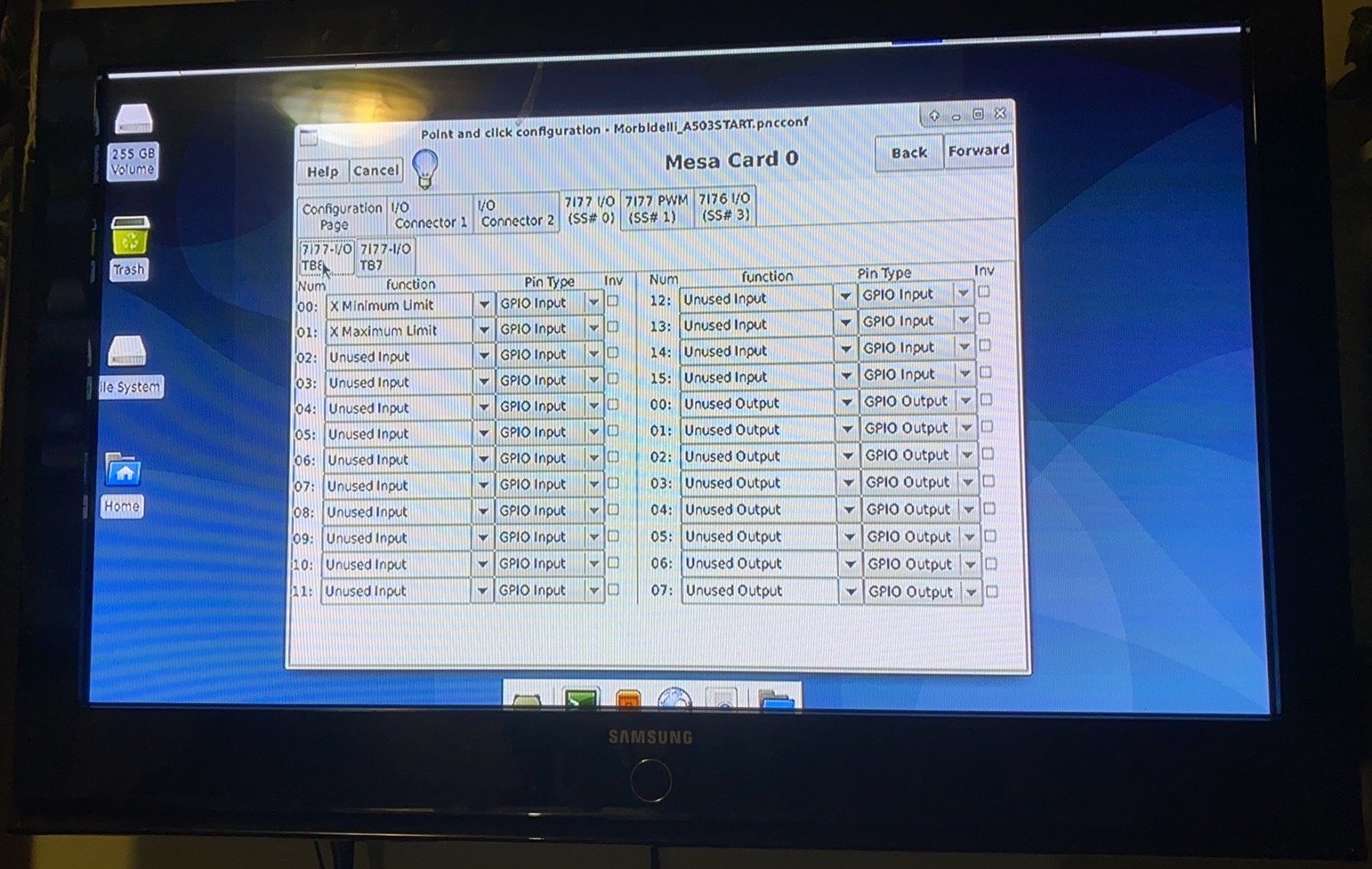

Fun hands on stuff is beginning! Cheers to @- i5oogt - for sorting me a PC, unfortunately my ancient screen didn't have hdmi/dvi so the TV took over. Standby for noob problems, this is my first ever PC, fumbling through BIOS and formatting bootable USB drives somehow happened (Credit youtube/google) and we have linuxcnc loaded up, running latency tests was square in the 'not suitable' window ~1,000,000ns but for now I will ignore it, as my confidence grows i'll work through diagnosis and checking suspects off the list. Its a massive steep learning curve, but happy to have booted linux and loaded up a mock machine, most of it makes sense and the few questions that arose were easily researched and answered if the "help" tab top left couldn't assist. A few weeks back I was informed to buy a certain MPG from our dear friend Ali, in record time it arrived, decent quality and heavy in the hand, hopefully it performs as expected. The MESA boards should be on the way, might be some long nights when they turn up! All for now, stay tuned!3 points

-

It's a bit of a feeble update today. Doesn't look like much but it took me a good while to align the rear quarter window frames with the door window frames. Gaps are almost spot on now. Just need to clean my dirty paw prints off the chrome. With this out of the way I can now install the rear quarter inside panels and then the parcel shelf and back seat.3 points

-

2 points

-

2 points

-

These cars are a ballache There's 2 main problems with coilovers on these 1 is the fact that the steering arms are usually a casting or a forging which in general can't be welded or heated in any way 2nd is a steering arm can't be welded so even if it wasn't cast or forged then welding would be an issue There is an info sheet on lvvta.org.nz about getting a welded casting or forging passed but I've never had anyone do it. Apparently when the info sheet came out, BC had a strut tested as per the sheet, it failed, they modified the welding procedure, failed again so they said nz is a tiny market we won't bother. Brand doesn't matter, I've seen issues with both bilstein and kw, some audis have the same design suspension and kw makes a coilover for those that the steering arm is fabricated from multiple pieces and welded together Years ago before that infosheet came out I got a couple of integras approved to be certed with cusco /tein coilovers but that wouldn't work now. The last one I did the owner found 2x stock honda shocks and had them modified to accept a bilstein insert and an adjustable platform, but it couldn't go very low It's become less of a problem as that shape honda was never really that popular2 points

-

Will be easy to get whatever piston you want made for this if you have $$ (like $1500-2000 at a guess) we will need to up the kitty moneys though lol2 points

-

Whilst the blue panniers were a great addition theyre just too brittle and small parts kept breaking off after every ride. So I bit the bullet and decided to start making some from steel. To start with I made some channel out of 18g with a slight radius, not a breaked edge. Then I had to modify my shrinker stretcher stand as once I got to certain point it would hit the stretcher stand upright. so I moved them apart . Using the shrinker I incrementally started shrinking the sides. Shrinking one side then the other so they'd both be the same. One end is 90 and the other is just under. Next is to make the sides and get them welded in2 points

-

Tried them with another 14" A type wheel and they will work as long as tyre isn't bulging past the rim. Saw these pop up and grabbed them since I haven't seen them before. They are an uncommon 14" work equip mesh Each of the hex head bolts are engraved with 'work' And they have pretty cool black valve stems/caps. These will be widened to a 9/10J stagger as the potenza tr-3 were. I've managed to get a pair of 225/40 toyo t1r to try on and see how they work with the rear flares.2 points

-

I love how the first sniff of a 1nz conversion and DaveScience is in there with the maths. I heartedly approve. #1nztheworld #morerevs2 points

-

It will have been metal fatigue that will have killed the rod. They're a pretty light rod, so the rod bolts wont have been tugged to death. I expect the endless dorting to infinity will have been enough to induce the failure.2 points

-

Some kind of air spring could work. Perhaps using a compressor driven by otherwise wasted exhaust energy? No don't do that....yet.2 points

-

I think you could be right about that. If the piston is trying to fly apart, where the top of the piston is trying to carry on upwards, and the pin is pulling it back down. So the material strength around the pin is the weakness. Then on the exhaust stroke this force is lessened, and when the cylinder is full, on the compression stroke this force is lessened too. The engine didnt fail when it was approaching max rpm, it failed just after a gear shift where throttle got cut to zero. So the worst case scenario would be zero throttle, high vacuum, high rpm on the compression stroke. I'm not sure if these forces are on the same magnitude as each other though. However, I can indeed increase my piston return spring value. I can use e-throttle to set a minimum high rpm throttle value to something like 10% or 20%, and then use a fuel cut and/or pull zillions of ignition timing out to cut power instead. This might bring a host of its own issues, but might be a bodgey solution I guess haha. Flat shifting, interestingly enough, would also help haha. The incredibly clever @Lith made a calculator ages ago that works out forces on pistons/rods. Entering 1NZ stuff. Peak accelleration on the piston at 9000rpm is 4991G! I'm not sure what sort of numbers I was expecting, but thats bloody lots. Then the PEAK piston speed is 41.7 meters per second. Which is 8200 feet per minute. Which is zillions high when 3500fpm is the reccomended mean value.2 points

-

The subframe has a bit of surface rust. And some oily greasy stuff that the water blaster didn't shift. This is a bit of a no-effort experiment. I know the electrolysis will remove the rust and after a few days it may lift some of the paint(from previous experience). But I want to see if it will lift any of the oily stuff. I could do with a deeper container... but where can I get one that's as cheap as a $18 warehouse paddling pool? An IBC tank with the top cut off would be good, but I can't find anything nearby and I also don't want to spend ~$1002 points

-

Having difficulty identifying the original rear brake hose. At the risk of sounding like a grumpy old man (yeah I know……), buying spare parts in our modern world can be a bit of a circus. Recent trip to Reppco with afore mentioned hose in hand for example. After failing miserably to identify the hose the “spare parts salesperson” ( I use that phrase with some hesitation) asks for the cars Rego. When informed it’s BP4*** their millennial face glazed over and he/she/they/it/…..etc. starts looking for a safe space to invent even more PC correct gender fluid pronouns! Rant over……… I made the call to use an HQ front hose (same as on the fronts) and hopefully still available in another 50 years time. How could I not reuse the original, glorious 70 plus year old brass 3-way plumbing fitting? Problem was I needed a male 7/16” NF 20 TPI to female 3/8 NF 24 TPI adaptor. (When it comes to brake plumbing gender diversity is a myth!). Found a piece of scrap ¾” round and fired up the faithful old Emco. Yes I know I could have just gone and bought some hardware but Rigamortice and I had a great evening sampling the new brew with Genesis blasting on the Video/Sound system and the neat and tidy result works for me. Sometimes the journey or process is just as important and rewarding as the end product.2 points

-

2 points

-

Here we go again. The SD1 sickness just gets into your blood and never leaves. I really regret selling Effie, but at the time I had no other choice as I still had Tess and she wasn't ready to sell, and we had just been kicked out of our rental so they could sell it, so had no parking for one SD1, let alone two. I managed to source a spot for Tess to stay until we settled on our house, but Effie had to be moved on. Tess wasn't quite the same, I never quite bonded with her the same and found that between the aftermarket cam and the manual box it didn't quite drive how I wanted an SD1 to drive. I feel the autobox and lazy low down torquey engine suit the style better. So here we are again. That desire for an SD1 didn't leave me, so once the Tomcat was sold, I started my search. I looked at what was available online, of which nothing was suitable (HAD to be a Series 2, and there were none at a reasonable price), and then began reaching out. I started with Nigel, or NP70 as it used to be called. It's been sitting outside, uncovered, untouched and unused since approx 2018. Allegedly it has a starting issue, which is why it was parked up. I contacted the owner and proposed buying the car and saving it, but unfortunately the owner wasn't having a bar of it and more or less said he'd get around to fixing it at some point and that was that. Of course, I checked with Effie's owner if he might sell, but he is dedicated to getting her back on the road and knows full well that selling her would be a regrettable mistake. Next was to try my luck with a comment I had seen on Facebook on an SD1 group. An NZ SD1 owner posted asking if it was worth exporting his Vanden Plas EFI back to the UK as he had tried to sell it in NZ with no luck, and the UK market for these cars is far hotter. This was back in December. I sent the guy a message and just asked if he was still looking to sell the EFI. Sure enough, he was. A few more messages were passed back and forth, a price was discussed, and some photos and a video were sent to indicate the condition. It looked nice enough in the photos and video, and did sound like it ran well. Being the bore that I am, I keep a database of all the injected SD1s I come across in NZ. This is one of the ones on that list (one of 10 VDP EFIs), and I had known about it for a number of years, since it was originally from around my region. I have a few photos of the car from when it was for sale the past couple of times, and had even seen the car in person about 5 years ago, and recall it looked quite tidy. Once we agreed on the deal, I once again booked in my preferred transporter (Brent at Classic Towing) and by some miracle, he managed to fit my collection in this weekend. The next day, today, after a solid effort by Brent, the car was delivered The engine took a few turns to get fired up from cold, but came to life easily enough and without any unusual noises or clouds of smoke. I warmed it up a bit while Brent undid the rest of the tie-downs, and then backed the car off the truck and into the drive. First impressions are a bit of a mixed bag. The paint looks good, but only because it had a blow over at some point, which is really obvious as there are masking lines and overspray everywhere you look. There are a couple of spots of rust that I have found, including some big bubbles in the sunroof panel, and some small blisters at the top corner of the windscreen. Otherwise, without having been under it, it appears to be quite solid. The interior looks in good condition, with no tears in the seats and it all seems to be complete. The obvious elephant in the room is the steering column being in bits, but that is due to a disclosed issue where the indicator stalk has failed, so the previous owner removed it for replacement (and had failed to source the replacement). Everything is really dirty though, so I will need to get the wetvac out and give it a going over. All the doors are really sticky and the catches need a real good slam to catch. The car has only been off the road for about a year, but obviously sitting hasn't been kind to it. The engine looks like a standard, albeit slightly neglected, EFI engine. It starts and runs well enough, and although the temp was low on the gauge, it didn't overheat sitting idle. There is a slight tapping from the engine, which I'm hoping is just an indication it needs an oil change. The obvious modifications/issues I have noticed are that there is an aftermarket electric fan on the radiator, which appears to be running at full speed whenever the key is turned ON. There is also an aftermarket cooler mounted in front of the radiator, for either the transmission or power steering, I haven't looked to see which yet. Someone has also messed with the ignition coil setup, as it has a Bosch GT40 coil and the electronic module for it is mounted to the AFM bracket on the strut top. Speaking of bodges, the breather system can't be working as intended. There should be an inlet filter on the LH valve cover, but instead, someone has blocked it off with a bit of hose and a bolt. I will need to look into refitting a filter to it. It might explain all the weeping oil around the engine. I haven't driven the car yet (as the steering wheel was barely held on and the adjustment clamp for the column was loose - oh, and no indicators), so I'm not sure what the suspension and brakes are up to, so that's some excitement yet to be had. It's a good basis for a car, with some foibles. I'm glad I bought it when I did, as it really needs the Tastes Like Petrol treatment to recover it back to its glorious self. There will be a ton more work to be done, so stay tuned. Also, why Lucas I hear you ask? Well, the obvious link is the Lucas electrics, but the more obscure reason was the little jumping spider the car came with. They're about the only spider I can happily live with. Discussion1 point

-

Brian crower has some rods and other bits on clearance on the website for around $250us was looking for buick stuff. Have a gander1 point

-

Ahh wow never considered bike pistons! I will have to get out one of the remaining intact 1nz pistons and measure it up haha 1nz piston has a compression height of 27.5mm (top of piston to centre of pin) Ideally find something with a slightly higher number so I could machine the top to get the compression ratio right. If the compression height number is lower, it will drop CR too much. Might be worth buying one of those pistons to have a look though. I'd need to press out the bronze bush in the rod and refit one for a 17mm pin instead of 18mm. Or hone the pistons to suit 18mm pin. But I'm guessing the bike one will be strong enough and probably lighter.1 point

-

What did that rev to? Being able to rev the piss out of something can make a decent difference haha1 point

-

My best 1/4 with boost wound up on an L67 3.8v6 was 15.1 It's extremely sad that a 1nzfe (in theory) could probably push the same car faster. Fuck......1 point

-

@Romanmaybe you could look into forging your own pistons like Burt Munro? "They were hand-cast using sand from local beaches in a variety of receptacles, including tin cans. They were then painstakingly finished with file and lathe,” Pretty sure you could improve on that with some 3dprints etc for molds Break up some broken pistons to melt down etc1 point

-

Not a huge update but slowly chipping away at dads ST whilst waiting for my engine to arrive from overseas. In the meantime Ive reinstalled the original engine so to stop me from tripping over it everytime I walk past it, and also make it easier to move when I move house end of July. Swingarm is painted satin black to match the guard. The tool holder was stripped and painted too.1 point

-

1 point

-

1 point

-

"In a high performance application 3500 FPM can be used since the burst at that speed will be short in duration" 9000RPM 1NZ is 5000fpm hahaha I know it's probably a different kettle of fish for tiny pistons compared to V8 stuff, but... yeah. It's getting up there.1 point

-

NZ$ 82.35 55%OFF | 30V 10A Laboratory Power Supply Digital Display Adjustable Switching DC Power Supply Voltage Regulator 220 V /110 V New Arrivals https://a.aliexpress.com/_mM5FeCa what about flagging the batteries and running one of these? We run them at work as laptop chargers as way cheaper than multiple laptop chargers. I assume the the 24V is just running a fan?1 point

-

9 years, 2 weeks and 2 days of ownership now. Just passed my 100,000th km in this thing today. Happened to be on the same piece of road that I test drove it too. Trade in value must have just plummeted to near zero.1 point

-

I used a 2 speed electric one from a Volvo 850 I think, on my 13B. It was awesome. I might even have a spare one1 point

-

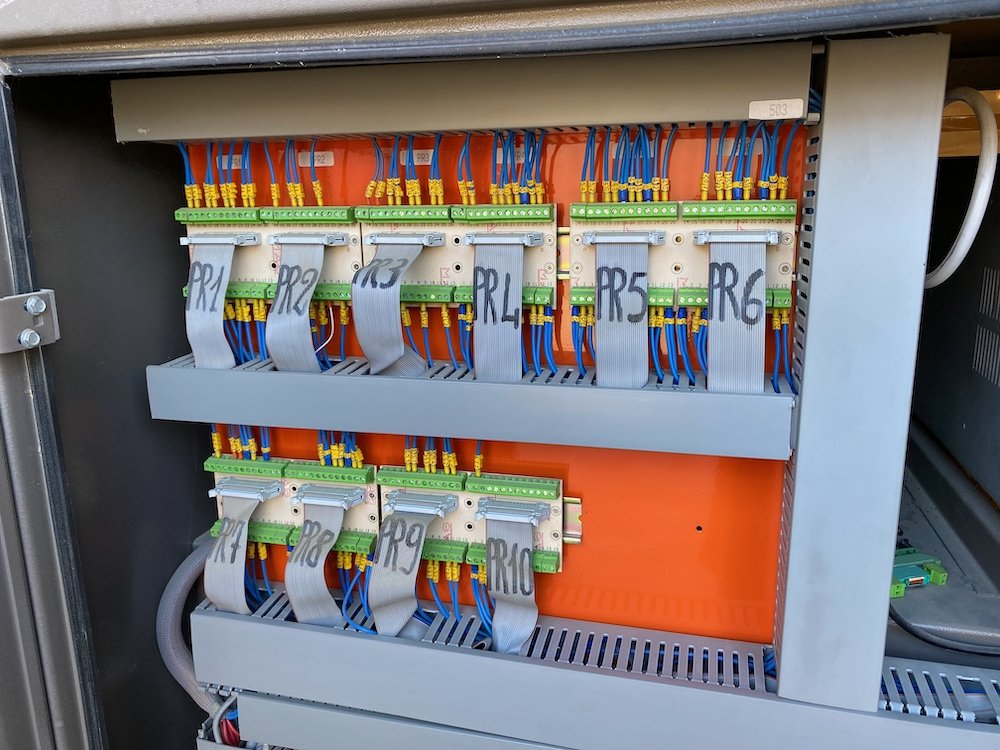

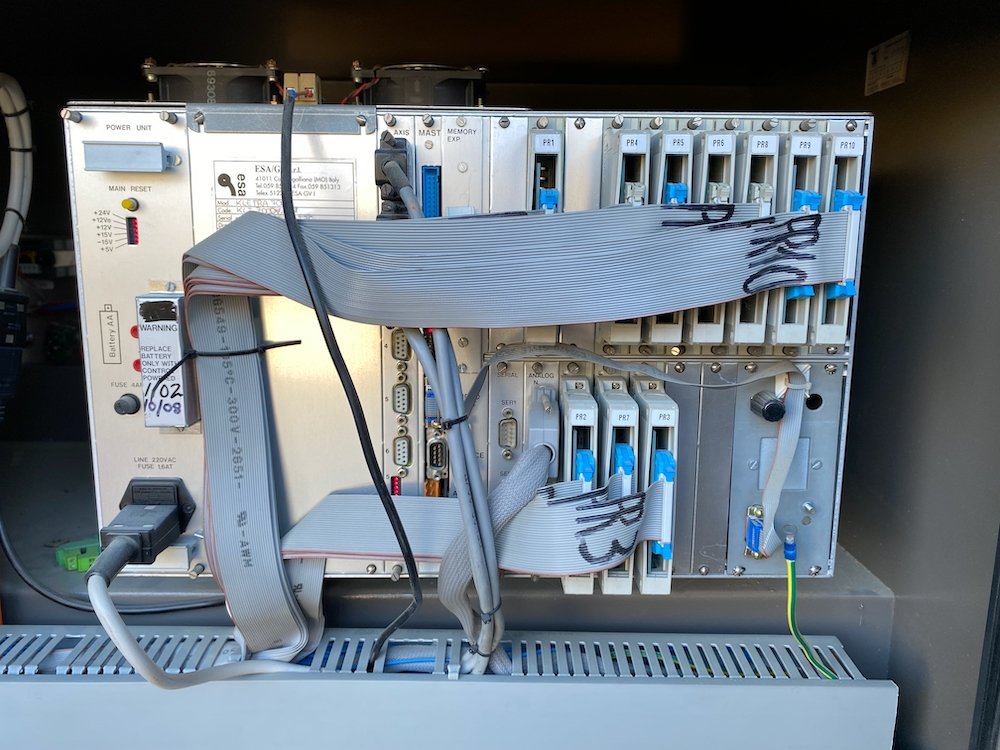

In Short, nah bro... Better chance solving Lucas production faults! I've earlier mentioned the pneumatic issues, the machine is listed as needing 220l/min air, which my compressor is capable of, but when plugged in all you can hear is hissing, from many places along with a rapidly dropping pressure gauge. Air enters the machine at a regulator, here it splits to a clean air feed and an oiled feed, these then head to 3 main banks of valves: On the chassis running parallel to the X-axis, these control the main distribution to the gantry, table controls (end stops and sucker position) and tool library. Second on the gantry, these control the spindle retraction, tool changer, hoods and various other functions The third bank is located on the toolhead, in addition to the two spindles, this machine has 18 drill heads, 6 horizontal drills, saw and surface finder, above each is a solenoid that controls the extension when the tool is called for. Sorry no picture because I still haven't pulled out the guards enough to identify them, but the drawings tell me they are in there, somewhere. As each tool requires an output, I don't plan on enabling them all, but at least one horizontal and the saw could be handy! Back to the air leaks.... I started by gathering up some blanking ports and methodically blocking off banks, starting from the main input and working back, I soon found various solenoids were leaking from their vents, blocking these off allowed working further down the line..... By the time I got to the gantry the list was growing, half the end stop solenoids are done but so far nothing I could live without. This is where it got interesting, during the initial pick up, the machine threw an alarm, the operator just said, 'oh, just give this bit a push' turns out that was the tool changer... With many leaks blocked off the compressor could finally keep up, manually operating the spindles was successful but the dust hoods were all over the show, as was the tool changer which refused to retract. Oh, did I mention the piece of timber blanking off the main spindle? With further digging, the tool changer is manipulated by the messy stack of solenoids that don't match the rest Yeah/nah, not something I feel like working out today! From the drawings, pilot air is used to combine various functions, while it makes sense on paper, the absolute mess needs to be untangled to properly evaluate, test, then reassemble to the drawings (And test again) I would carefully assume the main spindle has not run for some time and likely part of the machines demise, I have managed to enable the vsd and get the spindle to turn, so it is functional, just the state of the tool collet and changer is currently unknown. This was a pretty big sign to me that battling with the existing system was a stack of work with still not much chance of it doing what I want, but strip down, assess then rebuild to something that is useful will yield a pretty cool machine. The existing controller is about the size of a microwave, all the ribbon cables lead over to breakout boards which patch to the rest of the machine, I'm crossing my fingers that I can remove these breakout boards, replace them with the Mesa boards and replace the controller with a smaller desktop and screen.1 point

-

1 point

-

Got the gaskets and rear main seal, they only had upside down ones. Inside looks pretty good: Cleaned up the cover and fitted seals: Even replaced the oil cap seal, old one was hard and brittle: New: New rear main seal installed: Not all that exciting but this'll get the engine ready to go back in the parts car, to then be sold and fund more interesting things.1 point

-

Moving on from the last lot of repairs, I have also been tinkering with a few other small issues, in preparation for a potential WOF check. It may be obvious, but the work on this car is kinda sporadic and not really following much of a plan. That's because there currently isn't really one. I'm feeling a bit lost and well over my head, as I don't want to spend money fixing other issues, only to have to put the car into storage until I can fix the engine if it does go pop. What I have been doing is just ticking some things off the list that don't cost me anything but time. Some of these are also getting fixed with the aim of potentially taking it for a WOF check. Technically a clattering POS engine won't fail a WOF, so it's possible I might be able to get it on the road before doing the engine work. The first work I had to do was kinda forced upon me. The outside temp overnight the other night dropped below zero, and having already checked when I got the car, I knew the anti-freeze mixture in the car was pretty rubbish. I pulled the car into the garage for the night to try and keep it above zero, and the next day worked on draining a few litres out of the system and topping it up with anti-freeze, just so there was some sort of a mixture in there. It's not perfect, but it's better than nothing (and no point flushing the system now). Of course, it wouldn't be one of my Rovers if it didn't leave a green puddle at some point I ran the car up to temp, bleeding the cooling system (it's mostly self bleeding) and then set on the next task. Another easy check is to make sure the throttle pot is set up correctly. Most probably aren't, and will result in the ECU not fuelling correctly. When checked with a multimeter, the throttle pot range should be between 0.32v +/- and 4.7V +/-. Mine wasn't quite there (better than Effie though, which read zero at idle). And this is where I discovered the car cannot reach Wide Open Throttle. It stops opening at about half throttle... I marked the throttle pot and tweaked it slightly. This brought the closed throttle reading into line But I was still stuck at half throttle. If I disconnected the linkage to the throttle I could get the full opening (or near enough, it might need a little more tweaking but it's not an exact science) It turns out the auto trans kickdown cable was so badly adjusted it was stopping the throttle from opening fully. The adjustment was wound completely out (I've actually backed it off slightly in this photo for testing, it was right on the end of the thread initially) I backed it off until I could get full throttle and then locked it off. A test drive shows that the car has significantly more grunt when you give it a boot, no surprise there; nothing like opening the last half of the throttle to wake the engine up, but I had lost kickdown on the transmission. Clearly, I need to wind the adjustment back in a bit further. The kickdown works by the linkages pulling on that cable when at a certain percentage of throttle, which overcomes the spring pressure in the transmission and pulls on a rod that causes the transmission to kick down a gear. If the cable isn't being pulled enough because the throttle hits the stops before the cable overcomes the spring pressure, it won't kick down. I can still manually shift the transmission, but I will tweak it so kickdown works again. Next on my list of things to fix, was the washer system not working, and having a bodge in place. This is a common failure point, and the easy fix is to do what both a previous owner of this car and also Effie did and fit a replacement external pump to suck through a failed pump. The pumps on these have no filter, so if they suck in gunk they are prone to jamming up and no longer working. They are mounted on the bottom of the bottle with grommets. I removed the bottle and found the bottom of it covered in green algae. No guesses for what's jammed the pumps then. The cap is also missing, so that won't help. I cleaned the bottle out with some household cleaner and a good blast from the garden hose. One of the pumps is jammed solid and I cannot free it, but after some gentle persuasion of the percussive kind, the other pump began to spin freely. The good thing is that they are both the same pump, so can be swapped front to rear. I don't need the rear washer to work at this point, so as long as I can get the front working, I'm happy. The replacement pump has been fitted on the front guard, sucking through the failed pump. This pump did make working noises, but with the bottle dry and full of slime I didn't actually try putting any water through it. Thankfully no wiring had been cut or altered, they had made a fly lead that plugged into the standard wiring, so all I had to do was unplug it, cut the zip ties and remove the one screw holding the pump to the car. I then refit the bottle to the car, plugged the pump in, put some water in the bottle and hit the button. Sure enough, a large jet of water fired from the hose. We have a good pump. To replace the external pump and join the two sections of the hose, I fitted a handy one-way valve I happened to have spare. This then allowed the pump to send water to the washer jet, but nothing came out. Darn. The jet is just held in fairly loosely with a couple of clips and pulls free with a bit of wiggling. I found the hose under the jet was kinked completely over, which wouldn't be helping, but the jet was also blocked. I could've cleared this with compressed air, but being too lazy to fire up the compressor I instead used pressurised brake cleaner forced into the outlets of the jet (reverse flushing it). This worked a treat, blasting some black grot out the back of the jet. I did this in both directions until I was getting a nice stream of fluid out of the jet. With the jet fitted directly to the outlet on the pump, I could test that the jet was working. The spray pattern wasn't great; they never are, but there was a good volume of fluid coming out of it. With the jet refitted to the panel, I finally had a front washer jet again. It puts enough fluid on the screen to clear it, so that's a good pass. Probably puts enough fluid onto the car next to me to clear their screen too. Yes, the wipers are mismatched and sit too low. Yet more things to fix. I reluctantly took a look at the rust above the windscreen. There were a couple of small blisters in the paint which had me worried, after having dealt with the Corolla rust. Thankfully it looks like it may have started from a stone chip, as after some careful poking, wire brushing and sanding, it was on the surface, doesn't go too deep and looks worse than it is; a completely different sort of rust to the Corolla. It may go down under the bright trim, but I can't see without removing it. I treated it with some rust converter, and once dry, gave it a coating of epoxy zinc. I'll need to get some colour matched touchup paint at some point, but for now, this should keep it under control. The sunroof panel is still ruined though, but I'm ignoring that and pretending it doesn't exist. Those bubbles on the left will be a hole if I look too hard at them. I did manage to take the car further than around the block, just for a quick shakedown. I took it two blocks away to a local park and grabbed some photos. Despite its flaws, it's a hell of a car to look at and drive. Now, if it would stop clattering, so people were looking at the car for the right reasons, instead of trying to work out if they should move back in case it explodes, that'd be nice.1 point

-

This may not surprise you, but I have been bit by the Rover SD1 bug. I sold NP70/Nigel when petrol hit $2/litre for the first time ever. I was a young’un at the time and that was my only car, which I had to daily to my minimum-wage job. A 3.5L V8 probably wasn't the smartest choice. Look at it though, *swoon* I reluctantly parted with Effie when our landlord faced financial struggles and evicted us at short notice to sell up. We had nowhere to live, let alone somewhere with secure parking for two SD1s. My wife called on a friend to store Tess until we found our feet. On paper, Tess was the holy grail of SD1s. Black, manual, Vitesse. But after investing $3,000 and countless hours in her, she was back on the road (after several years being parked up with a mystery issue) and driving solidly and reliably. I didn’t bond with Tess as I had with Effie and, with no more work to do on her it was time to find her an owner that would drive and enjoy her. For my 65th car, I knew it had to be something special. I wanted another one. Ideally, a Series 2 EFI, of which according to my records, there are ten of in the country. There were none for sale, so I reached out to NP70’s current owner. I know the car has been off the road since 2018 and the owner has a large fleet so hadn’t gotten around to fixing it, but he’s not intending to sell. I tried Effie’s owner too, as we’ve kept in touch, but he’s got plans for her and knows he would regret selling. Then I recalled someone last year had posted something on Facebook about planning to export their SD1 to the UK. It would be a shame to drop another car from NZ’s limited numbers, so I reached out to see if he still had the car and was soon fizzing with the excitement of adding Lucas to the TastesLikePetrol fleet. Alas, some of you may have picked up on social media that very quickly I ascertained that there was something seriously wrong with Lucas. I’ve been conned. At this point - I could skip forward to the moral of the story. But of all 65 cars I have purchased, this is one that’s going down in infamy, so I’m going to lay the facts down. This is Lucas’ story. First impressions After several exchanges with the previous owner, I needed that car. He played hardball - he knew what he ‘had’ and that Series 2 EFI cars were rare. It was now or never. There are so few of these cars and too many of them are rotting into the ground, if I could save a fourth one and get it back on the road after over a year languishing under a ‘best intentions’ owner, I would. In addition to needing a new indicator stalk for a WOF, the one caveat he stressed was that it “wasn’t show quality”. That’s fine, he had already specified no rust, and the body and engine were otherwise solid, just in need of a good service and some "TLC". I’d seen the car under its previous ownership, circa 2016, and recalled it was a tidy example. British Car Day 2016 He sent me some potato quality photos taken from a distance, and a video of the engine starting and running when cold, also potato quality and not quite showing some bits. It seemed solid enough though, and although there was minor lifter clatter on initial start, it sounded fairly normal. We made a deal (or more like, I agreed to his price and sent the money). This is the point where he said he would “hold the money in a separate account” in case I wasn’t satisfied and wanted to return the car. Perhaps that should have been a red flag, but I took it as a positive sign. A few days later Brent’s truck pulled up (cut to ad break for Classic Towing NZ, for all your personal door-to-door automotive delivery needs *no affiliation, he's just a good guy that does a great job*) and first impressions were mixed. He said it wasn’t show quality, but I didn’t realise that he struggled so much with carparks. Both front and rear bumpers were cracked with chunks out of them. From this vantage point, something also seemed off with the fuel tank. Perhaps he had a habit of doing sweet jumps over speed bumps. The paint job is also a bit questionable - overspray everywhere and it’s lifting in places showing little prep may have gone underneath. But I guess that’s covered by not being show quality, and while a niggle, it wouldn’t affect the enjoyability of being behind the wheel again. Speaking of, the steering wheel was at its lowest height, floppy and with the positioning screw MIA. The stalks and surrounds were sitting in a plastic container on the back seat. As I was pulling the car into the garage, I was surprised that the car with “no rust” had clear rust at eye level, including a large area of bubbling on the sunroof and rust around the windscreen that will hopefully hold for a bit, but will eventually require the windscreen to come out. Can of worms You know me, I tend to dive straight into projects and this was no different. I’d only had the car a few hours and already fixed the “one issue” for a WOF - being the replacement indicator stalk (and reassembly of the steering wheel), which I’ve already posted about. In testing the indicator, I discovered I had no headlights and spent a couple of days tracing wiring diagrams and finding that part of the loom had been submerged in water at some point (also covered in the above post). I’m yet to work out where the water was getting in - but the owners manual in the glove box has been destroyed by moisture and overtaken by black mould so there’s a leak on that side somewhere. Snooping around the car and building my shopping list for the inevitable Rimmers order, I found: Three fuel leaks (fire hazard) A dented/weeping fuel tank (fire hazard & WOF issue) Washer jets don’t work (WOF issue) Doors sticking and/or not catching properly (WOF issue - at this point, I’ve been too scared to try the windows other than the drivers once, which is stuffed) Everything was finger-loose. Why does no one like doing up bolts? And this is where it gets really good/bad Following the initial work, I took the car for a gentle lap of the block - just to validate the steering column etc was all good for a Warrant. I had non-existent oil pressure. Rovers are known for low pressure (high flow, low pressure system) and the floppy gauges aren’t decimal-point accurate, but at best it was getting about 1/2 what I should be and you could tell. Less than 15PSI at idle, but hey, the lights not on, so that's something. Then I got the car up to temperature and the knocking started. Turns out it’s made the noise before (of course - cars don’t go from fine to full on metal-spoon in a saucepan by themselves) but “didn’t make the noise when loaded on to the truck”. That doesn’t mean it’s magically better, it just meant the car hadn’t come up to temperature?? But wait, that’s not all I’ve saved the best for last. Last week I noted something not right and I discovered what it was. The tired, worn-out engine was not original to the car. It wasn’t even an EFI engine (31A engine code, 9.75:1CR). It was a lower-spec (11A 9.35:1CR) engine rated at significantly less power. Now, some people legitimately don’t know what’s in their engine bay. These people typically aren’t “enthusiasts” or active club members who explicitly “know what they’ve got” and the value of a Series 2 EFI. But while I knew he knew, I had no way of proving that he knew it was not the original engine. Let's recap Exact quote: Surely it’s reasonable to assume? What he sent me Series 2 EFI A Series 2 EFI with a high compression "Vitesse" EFI engine in the car A Series 2 shell with a lower spec engine, with the EFI gear bolted onto it Just needs an indicator stalk for a WOF Just needs an indicator stalk for a WOF, and maybe a good service Needs an indicator stalk, headlights fixed, the fuel tank repaired, fuel leaks fixed, the doors to function, and maybe some rust work depending how picky the inspector is. “Any rust?” “No rust.” Light surface rust, but no bubbling Visible rust at eye-line - bubbling through the paint on the sunroof and around the windscreen. Have also found rust in the floor pan so far “Got some spares” A box of miscellaneous spares - usually includes an airbox, maybe a spare taillight, radio surround, that set of spark plugs you hadn’t got around to fitting. That sorta thing. A pile of scrap, including the original engine - as yet, not provided. Return to sender After hours of diagnosing and googling and pricing, it was clear that the car was miles away from what was described and sold to me. I don’t have space to do an engine swap at home (noting our steep driveway making manoeuvring limited when a car’s missing running gear, and remembering the Marina has dibs on half the garage). I have no money left to pour into a significant project like this. Effie had an engine rebuild before I got her - receipts for $6,000 NZD. I have a long list of jobs still to get through to get the Marina to British Car Day in February 2023. Earlier in the week, I had signalled to the seller that the car wasn’t happy and I was going to run some further diagnostics just in case it wasn’t serious but it wasn’t looking good and we might need to revisit. Remembering his original offer to hold back the money in case I wasn’t satisfied and needed to return the car. At minimum, I’d need to be compensated at least half of what I paid for the car to keep him but a) I’d still have issues with space and time, and b) let’s face it, the seller was never going to go for that. I drove the Swift up the Coast to clear my head the next day and made a call. A hard call. Lucas had to be returned. I first sent a video of the clattering engine. Then I sent a note outlining the disappointment and that I would have to return the car. I proposed that he covered return costs as the car was so drastically misrepresented - and in the meantime, I’d fixed the indicator stalk he’d spent a year "fixing", and the headlights, given it an oil change, and replaced the AWOL exhaust gaskets for him. He said if I wanted my money back, it was my problem to send it back to the Bay of Plenty. That would put me out $1,400 in transporter fees and I would have nothing to show for it. But better than being out of pocket for the full cost of the car, I suppose. I agreed and provided him with my bank details so I could start arranging return transport. “No no. Send me the car first. I’ll refund after I’ve inspected it.” Well, how about half now - as a sign of good faith, considering everything? “No. Return the car first" Okay, I’ll just get a short agreement written up for us to sign, to cover us both - you get the car, I get a full refund. “No.” You won’t sign? “Send the car first - I'm suspicious you have done something to the car" "Return the car or get lost" So apparently I found one of the dodgiest guys in the Rover community, and his behaviour was getting slipperier by the minute. Even if I returned the car to him at my cost, I had zero confidence I’d see my money back. After the total of the interactions I’ve had with him in the last month, there was no good will there. He declined, on several occasions, to sign a simple agreement to provide a full refund because, I believe, he never had any intention of providing that refund and actively dodged answering the question. I half expected him to come back with things like “Hey, this isn’t the original engine! And it makes noises when up to temperature! Oh well, thanks for the car back. I’ll just have to keep your money as compensation.” So I told him as much. He doesn’t deserve Lucas. He had a plan to export it to the UK (likely as-is. He has no time nor intention to fix it) saying he had a buyer for £12-15,000 GBP. So, you’re welcome unsuspecting British Rover-lover. You would have bought a lemon without an EFI spec engine and who knows how many more to-be-discovered issues. Karma’s a bitch. Final chapter I had no proof that he knew it didn’t have the original engine (except in hindsight I seem to recall it being mentioned in the listing when he bought it in 2018). Or, that is, until two full weeks after money had changed hands. I get this message from the seller: “By the way I still have the spares that came with the car when I bought it. They are the original 31A engine block, cylinder heads power steering pump etc that was replaced with the different engine.” Check and mate. This was the first time he had acknowledged it did not have the original engine - despite commanding such a fixed, high price. Apparently a “nut or screw went through” the original engine, so there is a reason it was taken out, and he knew all about it. For the record - this is grounds for compensation under the Contract and Commercial Law Act 2017 (which does apply to private sales, unlike the CGA). Yes, I’ve had someone look into this. The compensation entitlement would likely be greater than I had asked for. The question is whether having the car in limbo, in order to go through the motions and see him in Court is worth it is another thing. Now, I wasn’t in the market for a project - the Marina is deserving of my time and money first. But had I been told there was an SD1 with a temporary (albeit knocking) engine, so it was rolling, that would come with the original engine needing a full rebuild, maybe I would have reassessed the value and potential of the car. Maybe I wouldn’t have been able to resist. Maybe I still would have taken it on. But that’s not what he sold me, and not at the hefty price I paid for it. And they lived happily ever after When you get sold a lemon, make lemonade. It may Taste Like Petrol, but that’s kinda our signature here. Lucas is staying and he’s going to be back, better than ever. I don’t know how we’re going to get there. I still don’t have time, money, or space. I’m enquiring about offsite storage to keep him dry over winter while I sort a plan and order what I need.1 point

-

Just a small but significant update today. With all the work on the column switches completed, this meant that I could finally take the car for a quick spin around the block to see how it actually drives and if it highlights any further issues. The cold start was really good, only needing a couple of turns to come to life. I wasn't too impressed with the top end rattle though, I will need to get some new oil in there and hope it's not a sign of things to come. The oil in there will be at least a year old, if not two, and I don't know what grade. Before I could back the car out of the drive I had to raise the steering column, as all the wiring work was done with it at its lowest height. Overall the car drove really well. The weird notchy feeling in the steering seemed to clear up, so hopefully that's just from lack of use. It tracked and drove straight, without feeling too rolly polly on the suspensions, so maybe it's not completely poked. The engine pulled well, although I forgot how lazy the autos are; but that's what I like about them. The revs stay low, and it just rides that low end torque and gains speed quickly without fuss. Say what you will about automatic transmissions, especially ones from the 80s, but this old GM 3 speed shifts beautifully. The previous owner claims it was rebuilt, but I have no proof of that. The shifts are smooth and seamless, and kickdown was snappy. I didn't check the trip computer, but everything else seemed to work. The gauges all rose, the speedo and tacho worked, and all the lights worked. The low coolant light worked a little too well though, the bottle and radiator are full, but the light is still on. Will need to do some digging. The Rover SD1 has such a commanding presence on the road. I can't imagine what it's like for the average joe to see one driving around in a sea of boring beige appliances.1 point

-

For some years now both Rigamortice and I have always shared a propensity for saving old tools and painting them blue (don’t ask!). The handle was falling off my favourite planishing hammer (bought in a junk shop years ago when we were buying our first house, ms sr2 had a baby on the way and were broke). This ball-pen was my grandfathers and we think was probably pre WWII. It’s got a name on the head with Sheffield England below it? Found a guy on Trademe selling American Hickory handles and ordered a couple. Spent a pleasant evening with Rigamortice in the “much esteemed & universally applauded” (in NZ) sr2 man cave drinking ½ a bottle of Barossa Valley Pinot Noir while linishing and painting the two hammer heads. Following day I shaped the handle ends and wedged them in tight. These hammers should outlive me and the people reading this thread – It’s easy to discard history but it is just as easy and far more rewarding to keep it alive.1 point

-

Started tacking in pieces I’d cut from the trans (i.e. “gender fluid”) tunnel. Once again a piece of thin copper sheet gives you something to weld against that wont stick. A bit messy but I think we’re heading in the right direction. Cut out a strip to join the two halves. Starting to look like the shape I’m after. It needs to be removable but has to fit well, I’ll fill the big hole where the original gearshift was when it’s out of the car and then see how good (or bad) my hammer and dolly technique is!1 point

-

It lives! There were challenges. I hadn't bent a ring, it was the carbon deposits in the ring grooves that were making the rings tight. That meant the new rings were also tight, so I ordered a whole new piston... Which arrived and was for a different model of TS100... In the end I bent one of the old rings in half and used it as a scraper to clean out the ring grooves. Also on the east cape ride, the muffler fell off at one stage, it had chewed itself to bits to where the spring was loose. So i've fixed that up now. I took it for a ride to town today. Fuck its awful. I need to sort out the petrol tank mounts as all the rubber has worn out and the vibration and noise is horrific. How I've done two east cape rides on this bike, I have no idea. I'll get it to be fun again soon with a bit more tinkering.1 point

-

GRINDING 101 FOR OLD BLIND BASTARDS! Ouch! - While waiting at the local Shorecare A&E (don’t ask!) to have yet another chunk of metal dug out of my eye I came up with a solution for the “reading or safety glasses” dilemma. Spend ten Bucks at the local Warehouse on a pair of plastic reading glasses, cut the arms down and attach them inside a pair of safety glasses. As an added bonus you can comfortably wear ear muffs over them without developing front row forward cauliflower ears! Lastly hang them somewhere handy, in this case the grinding bench in the universally renowned and revered (in NZ) “sr2 man cave”.1 point

-

1 point

-

A bit of heaving with the chain block and over she goes, getting good at this! Have to say that as with the chassis the starboard side is in much better condition, one can only wonder what happened in the last 75 years to cause that? It all cleaned up easily… Found some old repairs that had been done in bronze - makes mental note not to run into it with the mig!1 point

-

Time to start pulling doors and boot lids off the old girl to lighten the shell for flipping her over. Love the way the doors use egg shaped brass balls for hinges. The boot floor made out or tongue and groove, can’t I.D. the timber but I’ll be using it again. Next problem was how to get the old tart over on her side. I didn’t have access to a rotisserie but I did have a pile of scrap that included some old, heavy scaffolding. Had a piece of pipe longer than the body & “guesstimated” the centre of gravity. Managed to hang the rear off the bumper mounts (they were real bumpers in those days). Tacked some tabs to the rear floor. (God I hate trying to weld galv!). Decided I could mount some temporary brackets to the front seat mounts so pulled out my much treasured collection of old imperial taps to clear out the threads. Have to point out how crazy it must have been with the shortage of fasteners after WW2. Look at the random collection of threads that holds the front seat down! Inside mounts finished. For the front of the body I used the bolt holes from where the chassis braces attached to the body and held things together with a scaffolding clamp.1 point

-

1 point

This leaderboard is set to Auckland/GMT+12:00

.jpeg.519da854cdfa902a755021102dc95bfd.jpeg)