Leaderboard

Popular Content

Showing content with the highest reputation on 11/30/20 in all areas

-

10 points

-

10 points

-

while im here. Ive built this amazing turd to do some testing on. Its a super janky mixup of parts. but kinda resembles a stock smallport engine. although the head has had port and chamber work done to it, was only spare i have. why? mostly because i need to test some questionable mods, i dont want to try on my good engine. but also good opportunity to kinda start from the bottom an dyno test stuff that works, that doesn't involve building an expensive engine. I have some hand me down parts that can go on it. itb's and cams and the likes9 points

-

While I was fabricating the roller, I visited a bunch of engineers in the region and found that no one had a lathe big enough to machine it. Bugger. After getting some quotes from further abroad that would have blown my entire budget by themselves (15-20k). I decided that I'd just build my own lathe.. I jumped onto Ebay and ordered the cheapest set of linear rails I could find, including the ball screw and bearing blocks. 3-4 weeks later I got set to mocking up the "lathe" using the compound slide from my Stanko mounted to some adapters. Spinning the roll by hand with the compound slide clamped to the linear rail, I took the first test cut. "Fuuck yeah, this'll work" I said.. It would have taken forever to machine the 3mm x 25mm weld bead off, but I remember once when @kpr mounted his angle grinder in the lathe to cut through some hardening on a set of axles from memory? (that image is burnt into my mind, probably thinking it might be a useful trick one day. cheers dude!) The grinder worked really well and made short work of it. Spinning the ball screw with a battery drill.9 points

-

8 points

-

8 points

-

5 points

-

4 points

-

Ripper weekend! cheers lads had a blast. Would post some photos but I'm to retarded to figure out how4 points

-

4 points

-

So, swapped the gas bottle over, brought a cut off saw (with spare disc one for steel one for alloy) and a welding trolley as I am sick of dragging the welder around and want the bench space back. Put 10L of 98 in the tank to check for leaks and seems to be ok so far, will prime the fuel system once I locate the fuel return clamp ive tucked away and after I remove the snapped bolt in the ac condenser (need to weld a nut onto it) Will try get the exhaust done this week/weekend and the intercooler piping may need 2x 90 degree silicon bends to be done but see how I go with the pipe Ive got Need to tighten all the wheel nuts as well once I take it off the stands Pics to come in next update Started on front pipe, cut down the 90degree bend I had, doesnt sit as close to the sump as id like but itll do, cant get it higher without cutting the 2.5-3" adapter which I am not keen to do, even tried piecuts but couldnt get it any higher. Started welding it and had a few blowouts so have ground it back and will reweld it3 points

-

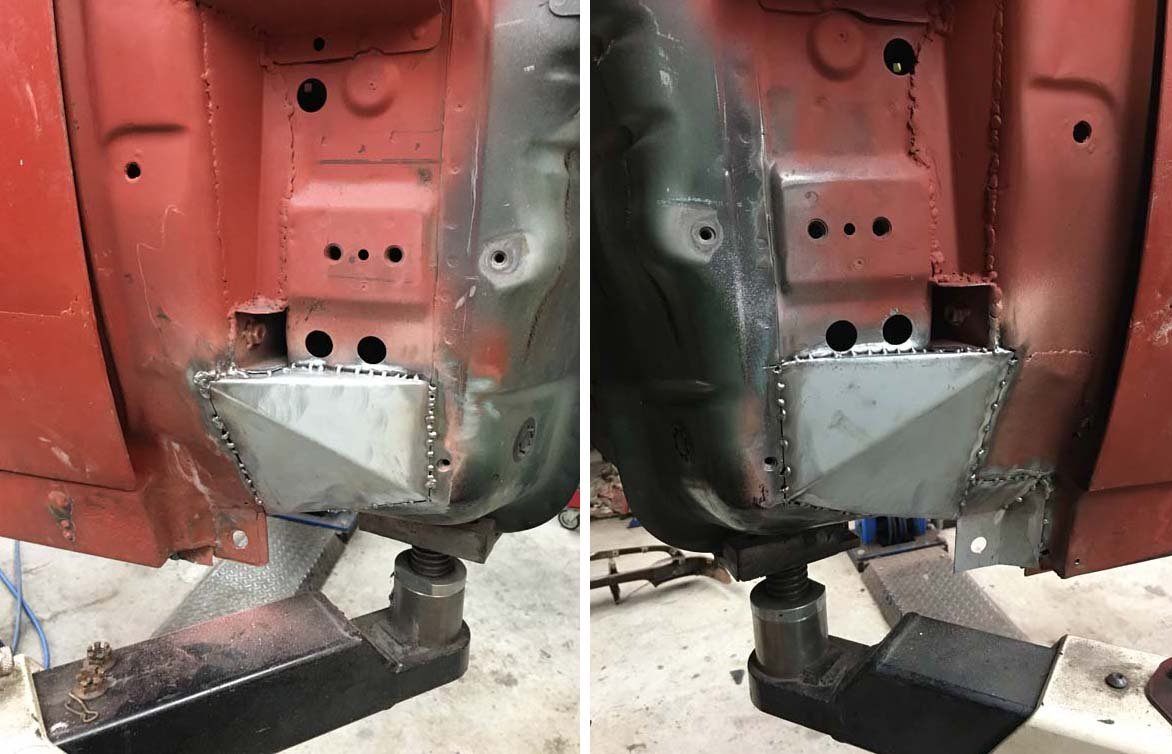

Another Shot of the rear spare wheel well. came together quite nicely. Cut the bottom and inner supports off a spare RH guard I had. And welded them onto my slightly better, but rusty on lower parts, RH guard. To go with the new Dakota Digital Bearclaws. I spun these new pins up on the lathe. (no hex bolt head on them compared to the Dakota Digital ones) And my brother, Matt welded them to some countersunk plates. Which fit like this to the factory adjustable mounting plates/ And work great with the bear claws installed in the doors. Today I managed to partially fill two more holes that still exist between the chevy and lexus. Front of the sills, and a new Guard mounting point on the RH side, as it had also rusted away. From beneath you can still see the hole left to be filled between this new patch and the sills plate.3 points

-

3 points

-

The underside of the Thames feels like the gift that just keeps on giving at the moment. Spent the morning attacking the passenger side wheel well with a small wire brush on my battery drill. It came up pretty good with quite a bit of the original factory paint intact. Managed to make a start on the chassis rail and floor lip too. More of the same tomorrow.3 points

-

Other than not having to find a "closed road" to do testing on. most recent one was the outboard injection. im sure ive told you about 500 times, I based most off my testing off afr change on alpha n tune. with the outboard injection I had a richer afr up top. this would have sent me in the total wrong direction, as would have assumed it lost power. but was actually the same / slightly more power. Kinda the same deal with the runner lengths. the way the afr acted did not directly relate to the power. but did give me the indication i was going in the right direction. enough so that i have barley been able make any improvements on the intake made pre dyno. having the dyno opened my mind/ maybe just confused me more as to what is going on. i can say some of the dyno testing you see is horseshit, especially looking at small changes. its so easy to fire out different numbers changing nothing on the engine. some times it can even be quite tricky just to get a repeatable number, especially on turbo stuff. Ive lead myself into this trap a few times till figured it out.. add ignition advance gain power, sweet add more, more power again and so on. then put timing back to where it was originally was, hmm same power as when i had that big number in there. turns out its just the temps playing games. Ive seen some dyno tunes that seemed to have very aggressive timing numbers, which i assume the tuner has fallen into said trap. so yeah dyno obviously a good tool for ignition tuning but still can have its traps. im sure there are lots of other things i cant think of right now. And them numbers @Roman numbers and graphs2 points

-

Saw your beast on one of the cruise videos on FB nominal. Think it was the one heading into whitianga? Looks so good low n slow2 points

-

2 points

-

You rode on a set all weekend you goose great tyres2 points

-

2 points

-

I spent 4 hours cleaning the front seats today. They went from disgusting crusty greasy messes that I was on the verge of reupholstering to looking really good apart from a few worn patches I didn't take any pictures until I had already cleaned the dirtiest parts but this gives a bit of an indication Cleaned using wet and dry vacuum cleaner, a mix of washing machine powder and an old toothbrush2 points

-

forgot to mention, a supercharged 1UZ pulling hard at 7200RPM sounds pretty ace.2 points

-

tidying a few things up with the tune. i had no speed signal so the ECU didn't know if we were moving or not. with an E throttle that makes quite the difference. so i put a wheel speed sensor in the back so now it knows we are moving. the other major thing that needed sorting was the rev limit, it was set too low (6500) and it was pretty harsh. so now th rev limit is a more excellent 7500 with a really nice cut that just works. lots of little things were made better in regards to coasting to a stop, the fan coming on, part throttle curse, just more drivability. the other thing that we did was add a bit of timing up top which coupled with the higher rev limit it made 275 killer wasps at the tyres. keen for drag day TBH.2 points

-

Back to the story at hand - with the motor now ported, it left me with quite a dilemma. I bought this car with a specific budget to get it all done and dusted. I procrastinated for a few months while figuring out the next step. I even debated using the stock twins and the existing bolt on stuff, but deep down I knew that the stock turbos would just end up hurting the motor. One of my other good friends is a bit of a encyclopedia for turbo knowledge so I turned to him for advice. I was after something that could flow 400-450hp without giving away too much response. The ideal turbo would have been the Borg Warner EFR8374, but I couldn't afford a $4500 turbo. So the next best option was this guy: A Borg Warner S300SX-E, sorta the poor man's EFR8374. I chose a slighter smaller than usual 1.0 AR twin scroll turbine housing in an attempt to keep the boost threshold at a reasonable point, at the expense of some top end power. Given the most powerful car I've owned before was a 220kw turbo 4age, giving away some horsepower wasn't a real concern! I made another trip up to Auckland to dress the block up and install the motor - the turbo looks fucking huge compared to a bare bones 13B! And pretty snug in an FD engine bay too Because pedantry, I replaced most of the bolts on the motor, and engine bay, with shiny new gold passivated ones. I also splashed out and bought new coolant and washer fluid bottles, as the ones in the engine bay were all fucky. I also made the unusual (apparently) call to retain the stock OMP. Everybody says they fail yada yada yada, but I've not seen any concrete evidence that the electronic ones do. And also modern ECU tech can control them, so why the hell not? Modern ECU tech also means I ditched the Power FC once again, but this time replacing it with a Link G4 plug in It also meant a decent fuel system upgrade in the form of 1050cc primary injectors and 1550cc secondaries fed by one of the other wonders of modern tech, a brushless drop in fuel pump, capable of suppling well over 500hp worth of fuel. Thank god the days of Whinebro pumps are over! With this in the hole, only minor fabrication was needed to get it ready to fire up!2 points

-

2 points

-

2 points

-

does your engine bay not melt with timing that late? Ive just ditched the stock triggers on my 20v which are 24-1 vr in the dizzy. now running 36-1 hall cam speed. runs a whole lot nicer no other changes. i do think the stock setup was getting pretty tired though as it spat the odd trigger error1 point

-

Regarding dyno tuning ignition timing, I found a somewhat similar situation. I tuned each individual load/rpm cell for peak power/torque, was all good on the dyno But on the road it was a bit rough as the power map wasn't even remotely smooth. I ended up just blending the timings in most areas to get a more smooth map, it made a huge difference1 point

-

Lolol just remembering that Tuna bomb mid prize giving and had an actual laugh out loud. So glad I knew what they were or I would have probably shat ma daks mate.1 point

-

1 point

-

Got the transom corner cap home and took to it with a sanding disc, doesn't look too bad. Once I get trailer finished, I'll need to get a plate, register it and get it wofd. I'll tow it to work and TIG it to the transom top. I've been working through replacing all the (few) steel nuts and bolts with stainless items.1 point

-

1 point

-

1 point

-

1 point

-

prius motor swap its been a long strange trip on oldschool.co.nz these last 15 years. But here we are1 point

-

1 point

-

1 point

-

1 point

-

Mechanically mostly plumbed up now: Delivered for wiring today:1 point

-

1 point

-

1 point

-

1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpg.a5b052eadcb502338fa7a85b8de95cda.jpg)

.thumb.jpg.b947e8574e71878b2baeea5b08d17e4f.jpg)